Anticorrosive coating layer with good lubricating property and coating process thereof

A technology of anti-corrosion coating and lubricating performance, which is applied in the direction of anti-corrosion coatings, coatings, and devices for coating liquid on the surface, etc. It can solve the problems of aging resistance and thermal stability, poor water resistance, and low mechanical strength. Achieve the effect of excellent wear resistance, excellent comprehensive performance and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of anticorrosion coating with good lubricating property, comprises the raw material of following parts by weight:

[0051] 75-85 parts of water-based two-component polyurethane,

[0052] 18-25 parts of polymers of 2-acrylamide and 1-vinyl-2-pyrrolidone,

[0053] 12-16 parts of water-soluble phenolic resin,

[0054] 4-6 parts of nano metal particles,

[0055] 6-8 parts of mixture of nano-graphite and molybdenum disulfide,

[0056] 2 to 3 parts of nano silicon dioxide,

[0057] 3-5 parts of dispersant, 1-1.5 parts of defoamer, 0.8-1.3 parts of leveling agent;

[0058] The mass ratio of nano-graphite and molybdenum disulfide in the mixture of nano-graphite and molybdenum disulfide is 1:0.2-0.4.

[0059] Preferably, the anti-corrosion coating includes the following raw materials in parts by weight:

[0060] 80 parts of water-based two-component polyurethane,

[0061] 21.5 parts of the polymer of 2-acrylamide and 1-vinyl-2-pyrrolidone,

[0062] 14 parts of wat...

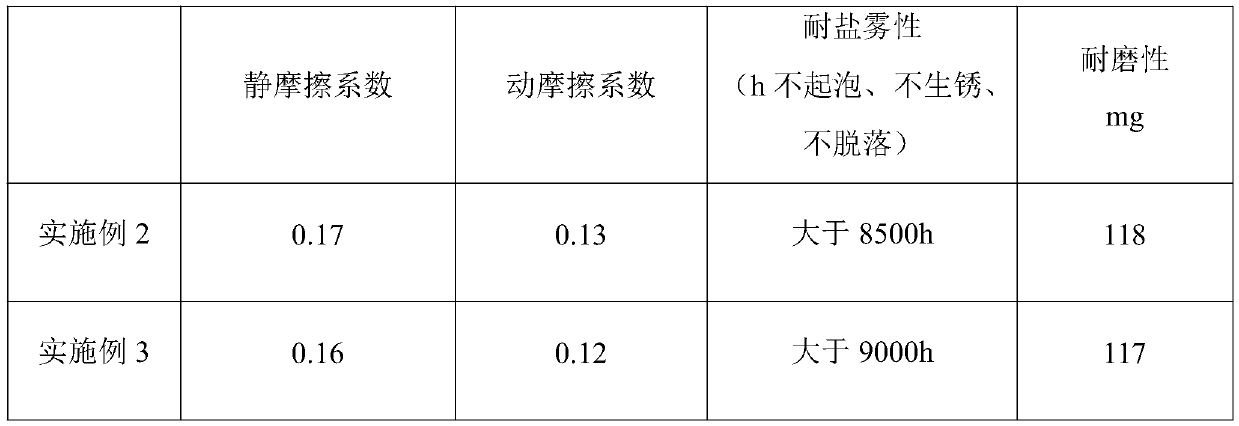

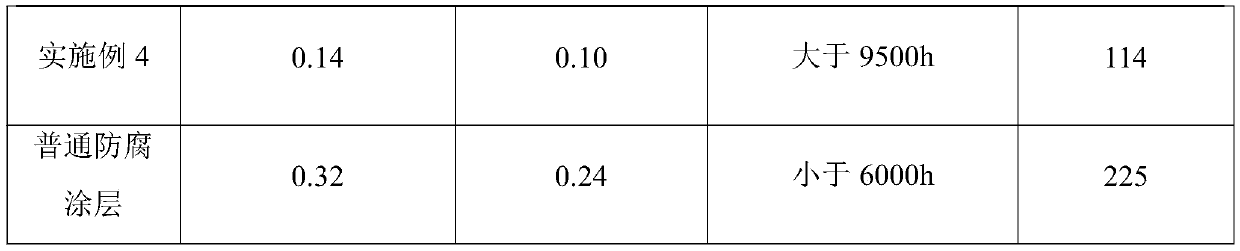

Embodiment 2

[0080] A kind of anticorrosion coating with good lubricating property, comprises the raw material of following parts by weight:

[0081] 75 parts of water-based two-component polyurethane,

[0082] 18 parts of polymers of 2-acrylamide and 1-vinyl-2-pyrrolidone,

[0083] 12 parts of water-soluble phenolic resin,

[0084] Nano metal particles 4 parts,

[0085] 6 parts of the mixture of nano-graphite and molybdenum disulfide,

[0086] Nano silicon dioxide 2 parts,

[0087] 3 parts of dispersant, 1 part of defoamer, 0.8 part of leveling agent;

[0088] The mass ratio of nano-graphite and molybdenum disulfide in the mixture of nano-graphite and molybdenum disulfide is 1:0.2.

[0089] In this embodiment, the water-based two-component polyurethane includes polyether-type water-based polyurethane, polyester-type water-based polyurethane and water-based polyisocyanate, wherein the mass ratio of the three is 50:45:1.

[0090] In this embodiment, the water-based polyisocyanate is B...

Embodiment 3

[0100] A kind of anticorrosion coating with good lubricating property, comprises the raw material of following parts by weight:

[0101] 85 parts of water-based two-component polyurethane,

[0102] 25 parts of polymers of 2-acrylamide and 1-vinyl-2-pyrrolidone,

[0103] 16 parts of water-soluble phenolic resin,

[0104] Nano metal particles 6 parts,

[0105] 8 parts of the mixture of nano-graphite and molybdenum disulfide,

[0106] Nano silicon dioxide 3 parts,

[0107] 5 parts of dispersant, 1.5 parts of defoamer, 1.3 parts of leveling agent;

[0108] The mass ratio of nano-graphite and molybdenum disulfide in the mixture of nano-graphite and molybdenum disulfide is 1:0.4.

[0109] In this embodiment, the water-based two-component polyurethane includes polyether-type water-based polyurethane, polyester-type water-based polyurethane and water-based polyisocyanate, wherein the mass ratio of the three is 50:55:3.

[0110] In this embodiment, the water-based polyisocyanate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com