Self-lubrication composite material used for producing easy-folding outer covers of infusion bottles or bags

A self-lubricating, composite material technology, applied in the direction of transportation and packaging, special packaging items, packaging item types, etc., can solve the problems of poor impact resistance, cold resistance, high brittleness of polypropylene resin, etc., to ensure welding strength, Effect of lower friction coefficient and excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

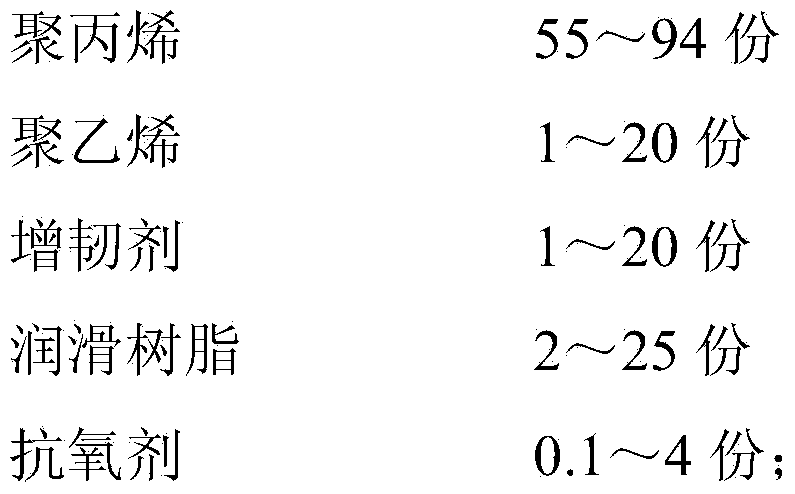

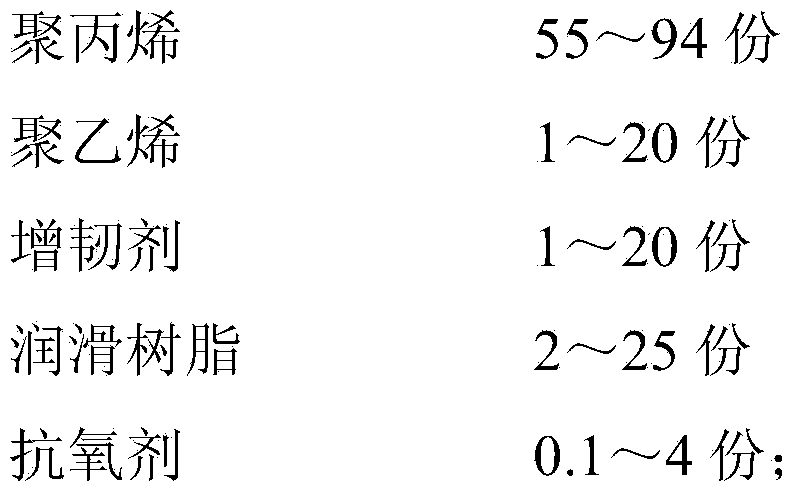

Method used

Image

Examples

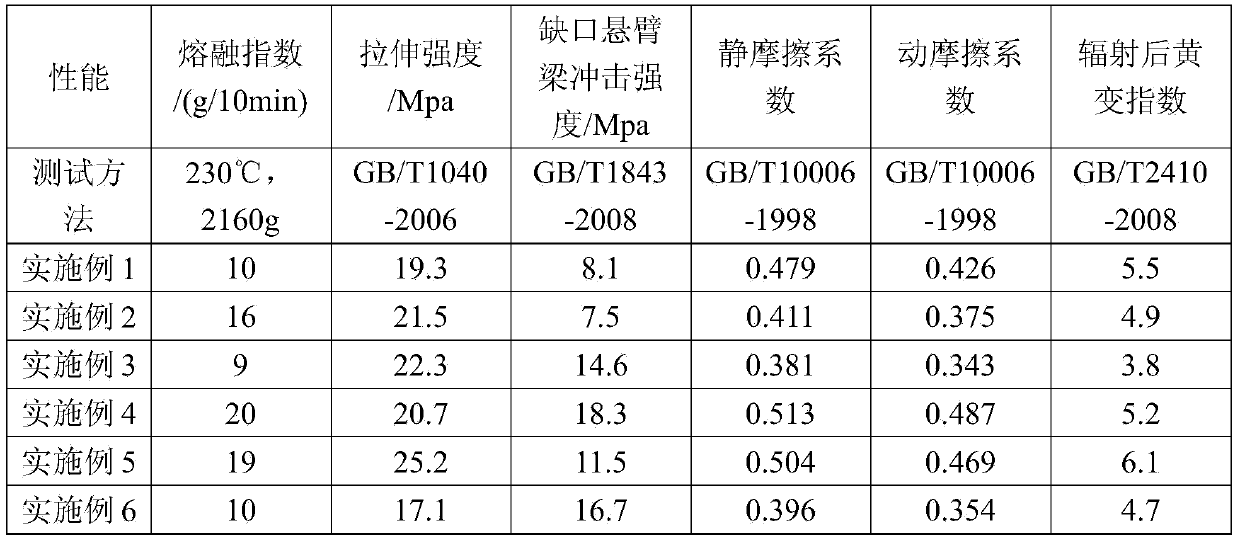

Embodiment 1

[0035] Example 1: Preparation of self-lubricating composite material for making infusion bottle or bag with easy-folding outer cover

[0036] 68 parts by mass of polypropylene (the ethylene content is 7.5% by mass, and the melt index is 8g / 10min under the conditions of 230°C and 2160g), 68 parts by mass of polyethylene (the content of 1-hexene is 4% by mass, at 190 Under the conditions of ℃ and 2160g, the melt index is 5g / 10min) 10 parts by mass, ethylene propylene copolymer (density is 0.90g / cm 3 , under the conditions of 230°C and 2160g, the melt index is 8g / 10min) 8 parts by mass, ethylene and norbornene copolymer (ethylene and norbornene molar percentage 40:60, under the conditions of 260°C and 2160g, the melt index is 14g / 10min) 10 parts by mass, 1,1,2,3,3,3-hexafluoro-1-propene and 1,1-difluoroethylene copolymer masterbatch 2 parts by mass, antioxidant (7-methoxy Rosmanol and 2-methyl-n-pentadecane are mixed at a mass ratio of 1:99) 2 parts by mass are mixed uniformly i...

Embodiment 2

[0037] Example 2: Preparation of self-lubricating composite material for making infusion bottle or bag with easy-fold outer cover

[0038]75 parts by mass of polypropylene (the content of ethylene is 5% by mass, and the melt index is 17g / 10min at 230°C and 2160g), 75 parts by mass of polyethylene (the content of 1-butene is 7% by mass, at 190 Under the conditions of ℃ and 2160g, the melt index is 4g / 10min) 5 parts by mass, ethylene octene copolymer (density is 0.88g / cm 3 , under the conditions of 230°C and 2160g, the melt index is 20g / 10min) 6 parts by mass, ethylene and norbornene copolymer (the molar percentage of ethylene and norbornene is 50:50, the melt index under the conditions of 260°C and 2160g is 4g / 10min) 11 parts by mass, 1,1,2,3,3,3-hexafluoro-1-propene and 1,1-difluoroethylene copolymer masterbatch 2.5 parts by mass, antioxidant (7-methoxy Rosemanol and 2-methyl pentadecane are mixed in a mass ratio of 7:93) 0.5 parts by mass are mixed uniformly in a high-speed ...

Embodiment 3

[0039] Example 3: Preparation of self-lubricating composite material for making infusion bottle or bag with easy-fold outer cover

[0040] 81 parts by mass of polypropylene (the content of ethylene is 6% by mass, and the melt index is 11g / 10min at 230°C and 2160g), 81 parts by mass of polyethylene (the content of 1-octene is 3% by mass, at 190 Under the conditions of ℃ and 2160g, the melt index is 3g / 10min) 7 mass parts, styrene-butadiene-styrene copolymer (density is 0.88g / cm 3 , under the conditions of 230°C and 2160g, the melt index is 6g / 10min) 3 parts by mass, ethylene octene copolymer (density is 0.88g / cm 3 , under the conditions of 230°C and 2160g, the melt index is 20g / 10min) 4 parts by mass, 1,1,2,3,3,3-hexafluoro-1-propene and 1,1-difluoroethylene copolymer masterbatch 4 Parts by mass, 1 part by mass of antioxidant (7-methoxyrosmanol and n-tetracosane mixed in a mass ratio of 5:95) were mixed uniformly in a high-speed mixer, and then under the condition of 210° C. a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com