Sealing arrangement and sealing ring consisting thereof

A technology of sealing components and sealing rings, which is applied in the direction of engine sealing, machine sealing ring testing, engine components, etc., can solve the problems that the sealing ring can no longer be used, cannot detect the gradual change of the sealing ring condition, etc., and achieves the highest risk of assembly errors. , simple manufacturing, the effect of minimizing the risk of assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

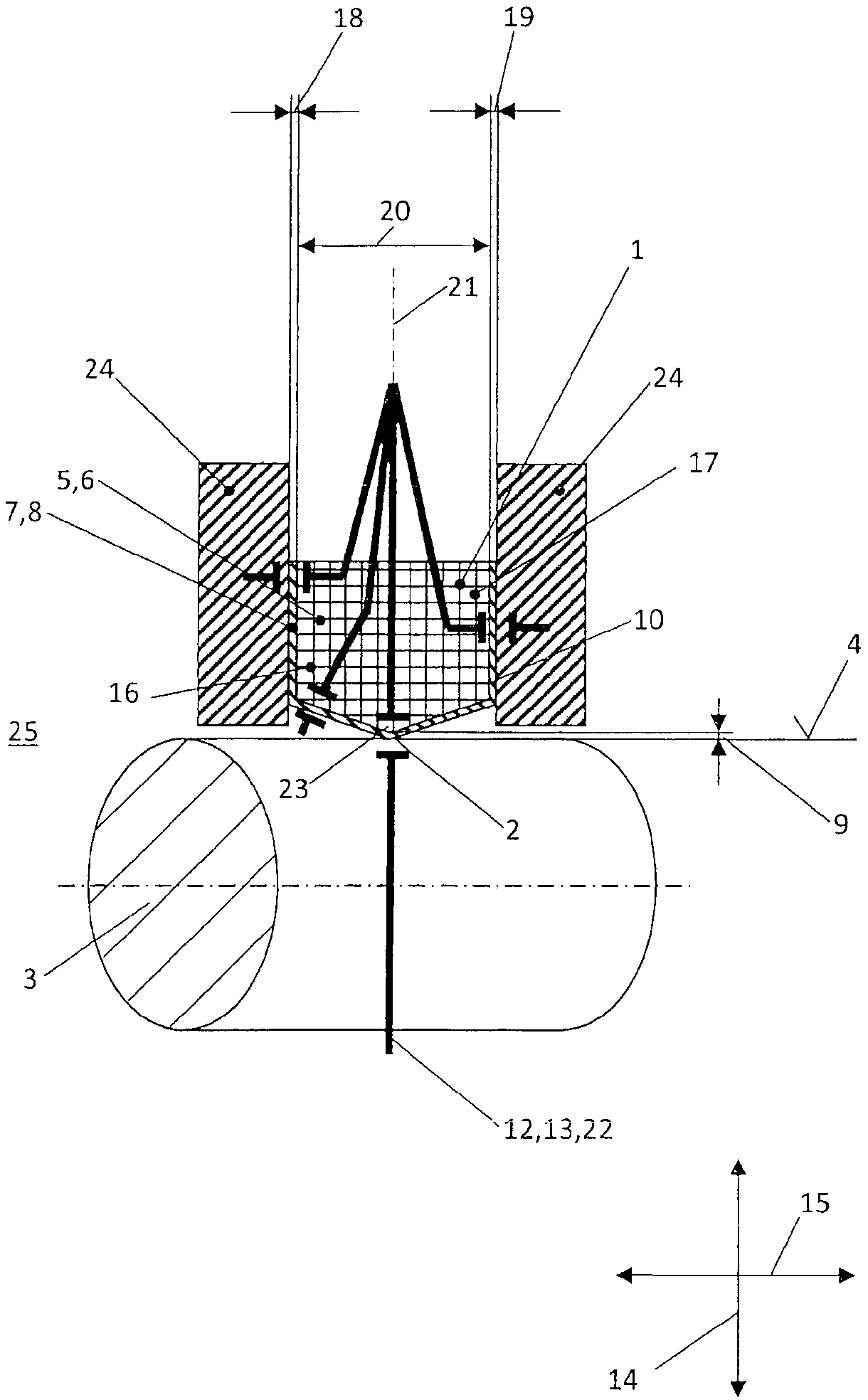

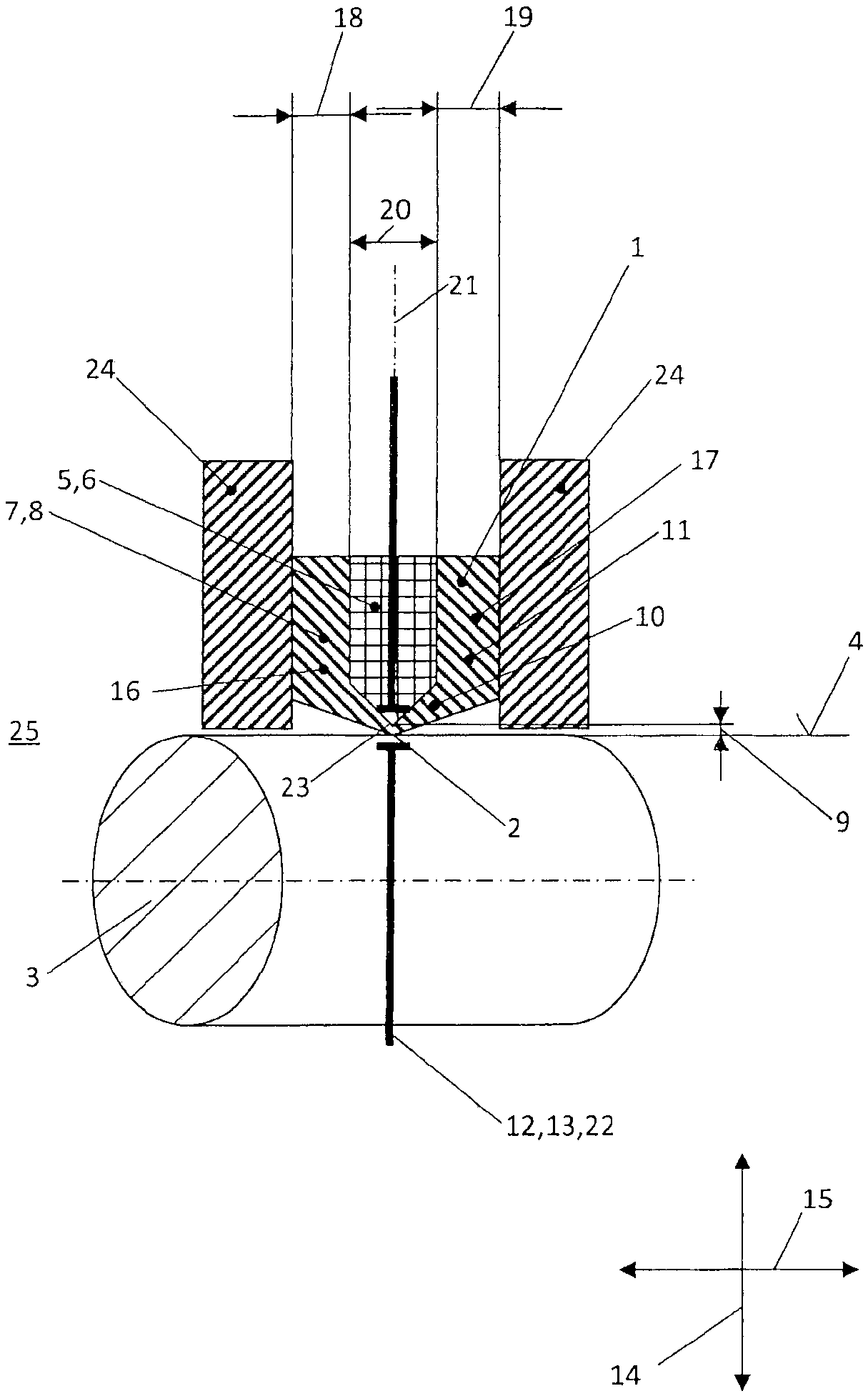

[0039] exist figure 1 An embodiment is shown in , as already disclosed in the earlier application mentioned above.

[0040]The sealing arrangement comprises a sealing ring 1 with a dynamically loaded sealing lip 2 which, with radial prestressing, tightly surrounds a surface 4 to be sealed of a mechanical part 3 to be sealed.

[0041] The surface 4 to be sealed is electrically conductive.

[0042] The sealing ring 1 comprises a core 5 which is surrounded by a cladding 7 in the region of its end faces 16 , 17 and on the side facing the surface 4 to be sealed.

[0043] The core 5 consists of an electrically conductive material 6 , while the cladding 7 consists of an electrically insulating material 8 .

[0044] A wear sensor 12 is shown schematically, which includes an electrical measuring device 13 for detecting the wear state of the sealing ring 1 .

[0045] Seen in the sectional illustration shown here, the cladding 7 has overall a constant material thickness 9 , 10 , 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com