Precision device for detecting ammonia decomposition rate based on physical properties of ammonia

A technology of ammonia physics and precision devices, which is applied in the direction of measuring devices, analyzing gas mixtures, and the structural details of gas analyzers, etc., can solve the problems of affecting measurement results, measurement results, and infeasibility, and achieve the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

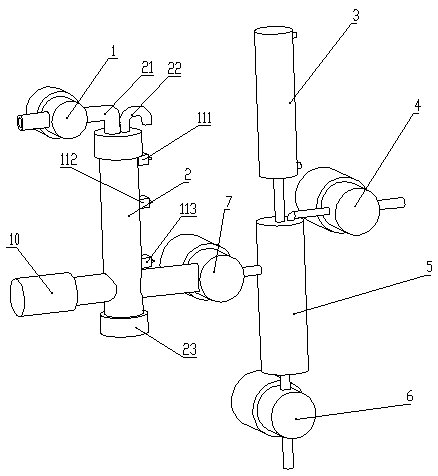

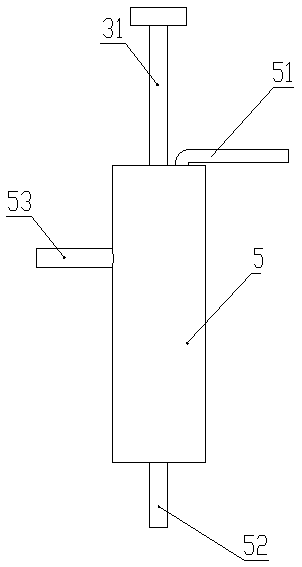

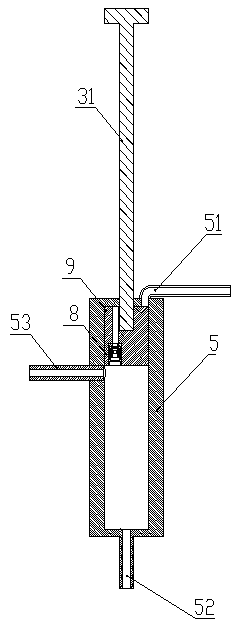

[0019] The present invention is an ammonia decomposition rate detection precision device based on the physical characteristics of ammonia, comprising a water inlet pipe 2 and an ammonia gas dissolving pipe 5, the upper end of the water inlet pipe 2 is installed with a water inlet pipe upper cover 26, and the lower end of the water inlet pipe 2 is installed with a water inlet pipe plug 23. The liquid pressure transmitter 10 is installed on the left side of the water inlet pipe 2. The full water level sensor switch 111 and the initial water level sensor switch 112 are installed on the water inlet pipe 2. The full water level sensor switch 111 is located above the initial water level sensor switch 112. The water inlet pipe 2 Water inlet pipe vent 22 and water inlet pipe replenishment pipe 21 are installed on the water inlet pipe plug 23 at the top, water re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com