Self-lubricating polyurethane paint and enameled wire

A polyurethane paint, self-lubricating technology, applied in the field of enameled wire, can solve the problems of low heat resistance grade, low solid content of nylon paint, unenvironmental use of organic solvents, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

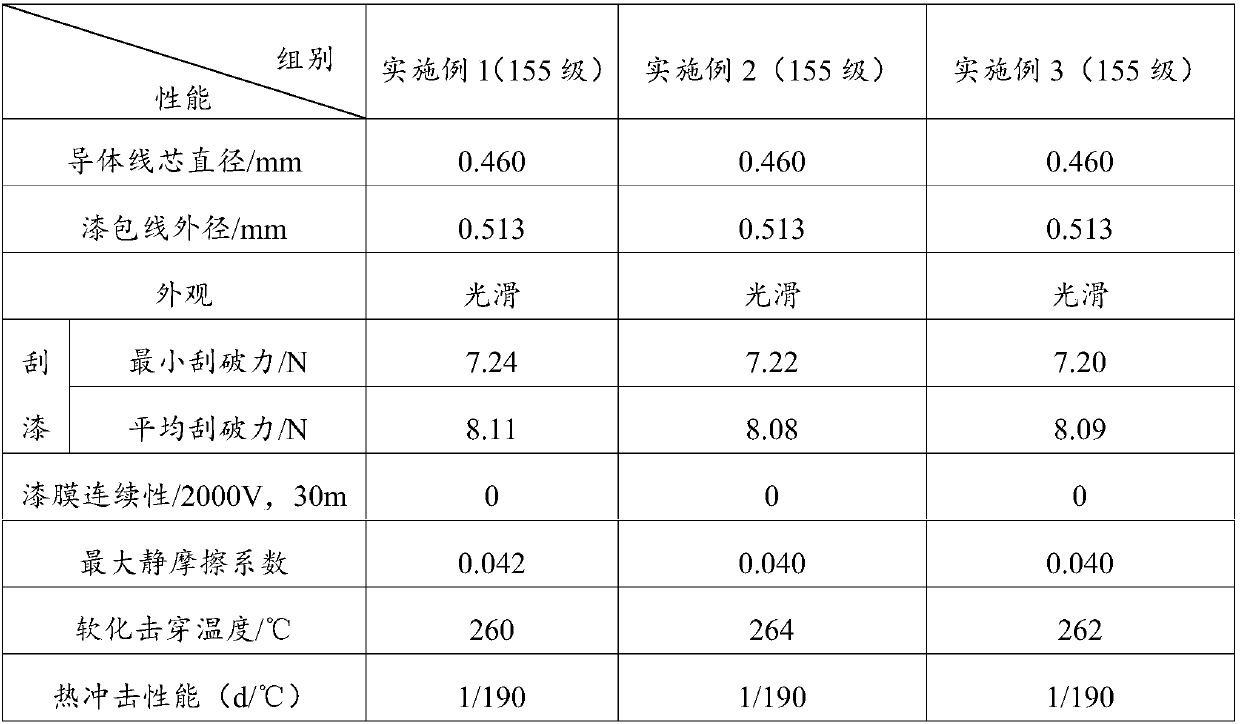

Examples

Embodiment 1

[0024] A self-lubricating polyurethane paint, the polyurethane paint components include, by mass fraction: polyurethane resin 30%, cresol 30%, aromatic solvent naphtha 39.9%, high temperature resistant paraffin 0.1%, wherein the decomposition of the high temperature resistant paraffin Temperature≧200℃.

[0025] A self-lubricating polyurethane enameled wire, the enameled wire sequentially includes a conductor core, an insulating primer layer and a self-lubricating paint layer from the inside to the outside, and the self-lubricating paint layer is prepared from the above-mentioned self-lubricating polyurethane paint; The conductor core is an aluminum core.

[0026] The preparation process of the above-mentioned self-lubricating polyurethane enameled wire comprises the following steps:

[0027] (1) Drawing the conductor wire blank multiple times to obtain a conductor wire core of 0.65mm;

[0028] (2) Carry out annealing treatment to the conductor wire core that step (1) obtains...

Embodiment 2

[0035] A self-lubricating polyurethane paint, the polyurethane paint components include, by mass fraction: polyurethane resin 40%, cresol 14%, aromatic hydrocarbon solvent naphtha 40%, high temperature resistant paraffin 6%, wherein the decomposition of the high temperature resistant paraffin Temperature≧200℃.

[0036] A self-lubricating polyurethane enameled wire, the enameled wire sequentially includes a conductor core, an insulating primer layer and a self-lubricating paint layer from the inside to the outside, and the self-lubricating paint layer is prepared from the above-mentioned self-lubricating polyurethane paint; The conductor core is an aluminum core. The preparation process of the self-lubricating polyurethane enameled wire in Example 2 is the same as that in Example 1.

Embodiment 3

[0038] A self-lubricating polyurethane paint, the polyurethane paint components include, by mass fraction: polyurethane resin 50%, cresol 44%, aromatic hydrocarbon solvent naphtha 5.5%, high temperature resistant paraffin 0.5%, wherein the decomposition of the high temperature resistant paraffin Temperature≧200℃.

[0039] A self-lubricating polyurethane enameled wire, the enameled wire sequentially includes a conductor core, an insulating primer layer and a self-lubricating paint layer from the inside to the outside, and the self-lubricating paint layer is prepared from the above-mentioned self-lubricating polyurethane paint; The conductor core is an aluminum core.

[0040] The preparation process of the self-lubricating polyurethane enameled wire in Example 3 is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com