Vinyl chloride series adhesive sheet and adhesive tape

A technology of adhesive sheets and vinyl chloride, which is applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of reduced adhesive properties, control of plasticizer dosage, uneven gap between semiconductor chips, etc., to achieve easy elongation, The effect of reducing the coefficient of static friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

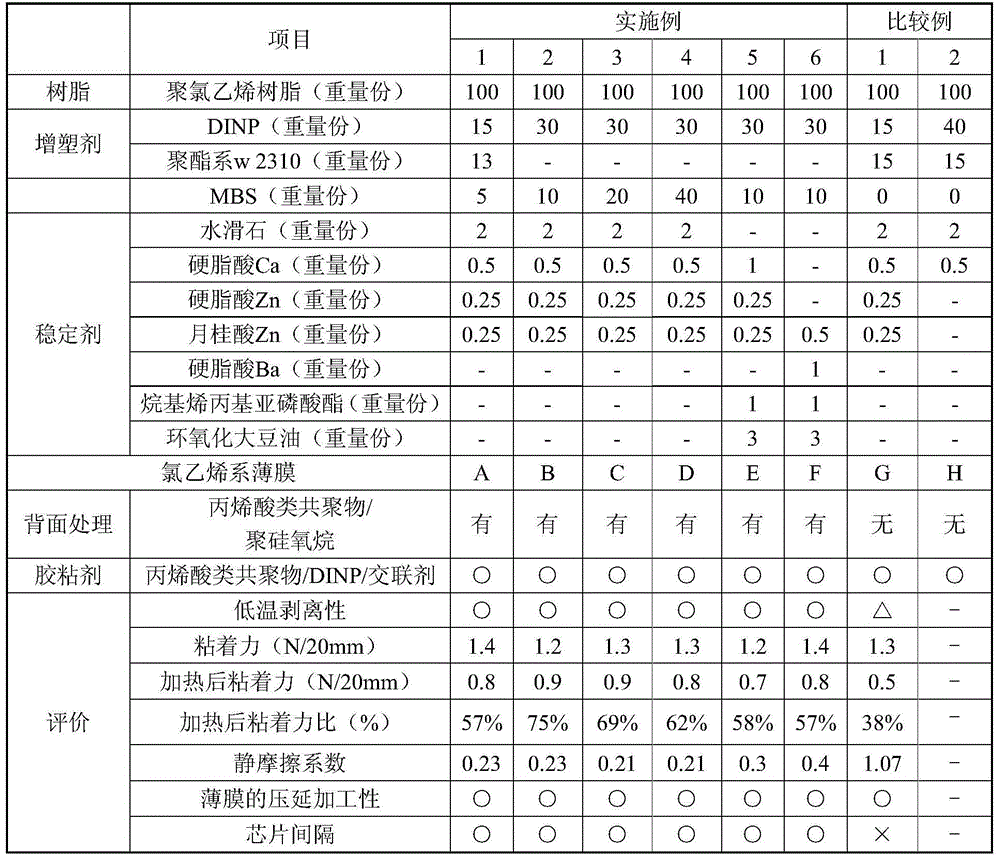

Embodiment 1

[0094] Substrate Manufacturing

[0095] Vinyl chloride film A

[0096] 100 parts by weight of polyvinyl chloride resin (polymerization degree 1100), 15 parts by weight of plasticizer (manufactured by Kao Corporation, trade name "VINYCIZER90" (DINP)), polyester plasticizer (manufactured by DIC Corporation, trade name W2310 ) 13 parts by weight, methyl methacrylate-butadiene-styrene copolymer (MITSUBISHI RAYON Co., Ltd., trade name METABLEN C-223A) 5 parts by weight, zinc laurate (Mitsu and Chemicals Co., Ltd.) 0.25 parts by weight, zinc stearate (KISHIDA CHEMICAL Co., Ltd.) 0.25 parts by weight, calcium stearate (KISHIDA CHEMICAL Co., Ltd.) 0.5 parts by weight as an alkaline earth metal soap, and water 2 parts by weight of talc (Kyowa Chemical Industry Co., Ltd., trade name "ALCAMIZER") were mixed to prepare a vinyl chloride composition. The vinyl chloride-based composition was molded into a film having a thickness of 120 μm at a molding temperature of 150° C. using a calende...

Embodiment 2

[0102] With respect to 100 parts by weight of polyvinyl chloride resin with a degree of polymerization P=1100, a plasticizer (Kao Corporation, trade name "VINYCIZER90" (DINP)) was 30 parts by weight, and no polyester plasticizer, methyl Methyl acrylate / styrene / butadiene copolymer (MITSUBISHI RAYON Co., Ltd., trade name METABLEN C-223A) was 10 parts by weight, and vinyl chloride was produced in the same way as vinyl chloride film A. Department of film B.

[0103] Except having changed the vinyl chloride-type film A of Example 1 into the vinyl chloride-type film B, it carried out similarly to Example 1, and produced the adhesive tape of Example 2 in roll form.

Embodiment 3

[0105] Based on the production method of vinyl chloride film B, a methyl methacrylate-butadiene-styrene copolymer (MITSUBISHI RAYON Co., Ltd., trade name METABLEN C-223A) was changed to 20 parts by weight to produce chlorine Vinyl film C. Except having changed the vinyl chloride-type film A of Example 1 into the vinyl chloride-type film C, it carried out similarly to Example 1, and produced the adhesive tape of Example 3 in roll form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com