Upright type five-shaft processing center Z-direction vertical guide rail unloading devices and manufacturing method

A five-axis machining center and unloading device technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unqualified Z-direction accuracy and wear of the plastic surface of the guide rail, so as to reduce friction, Effect of reducing load and preventing crawling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

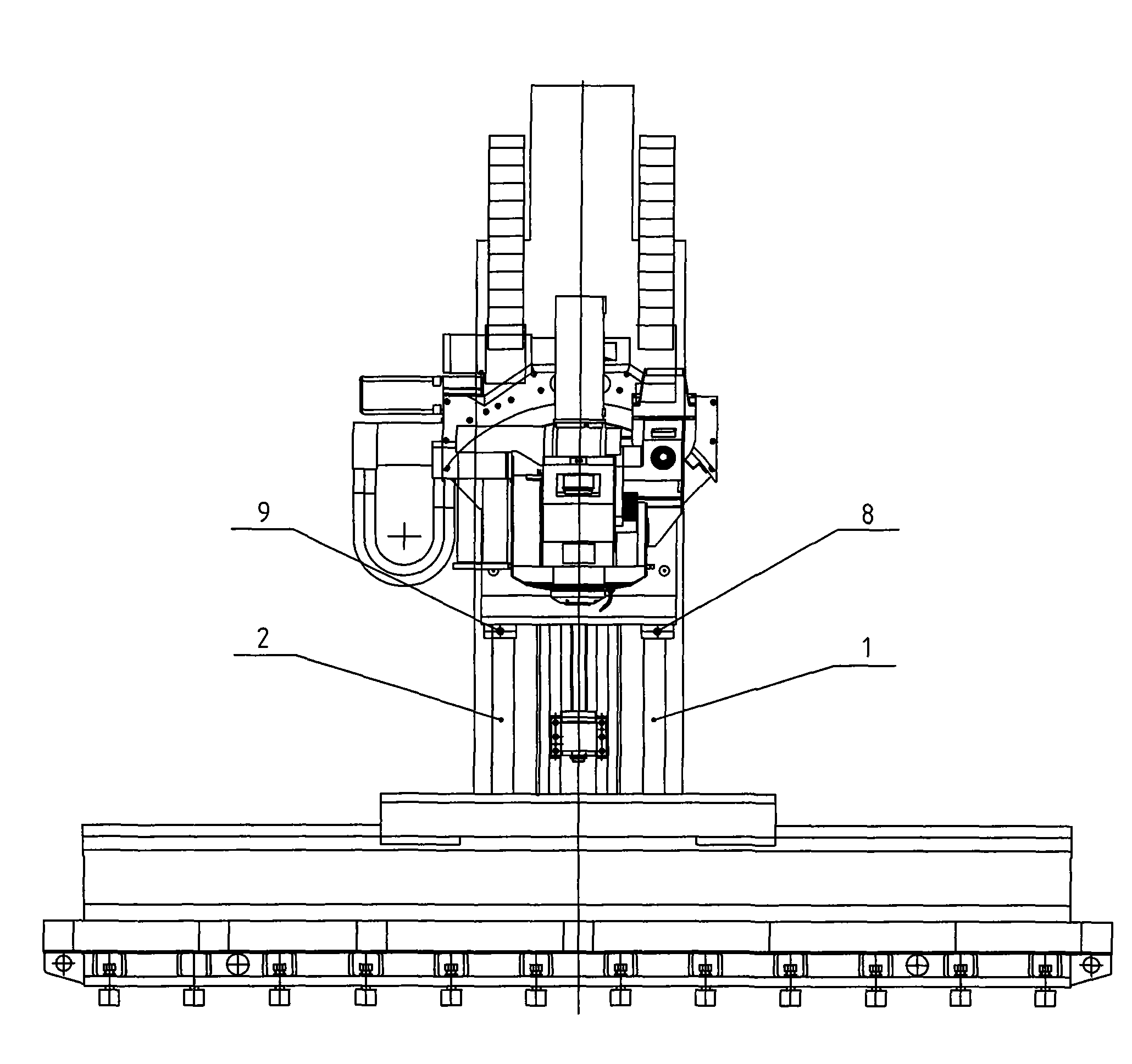

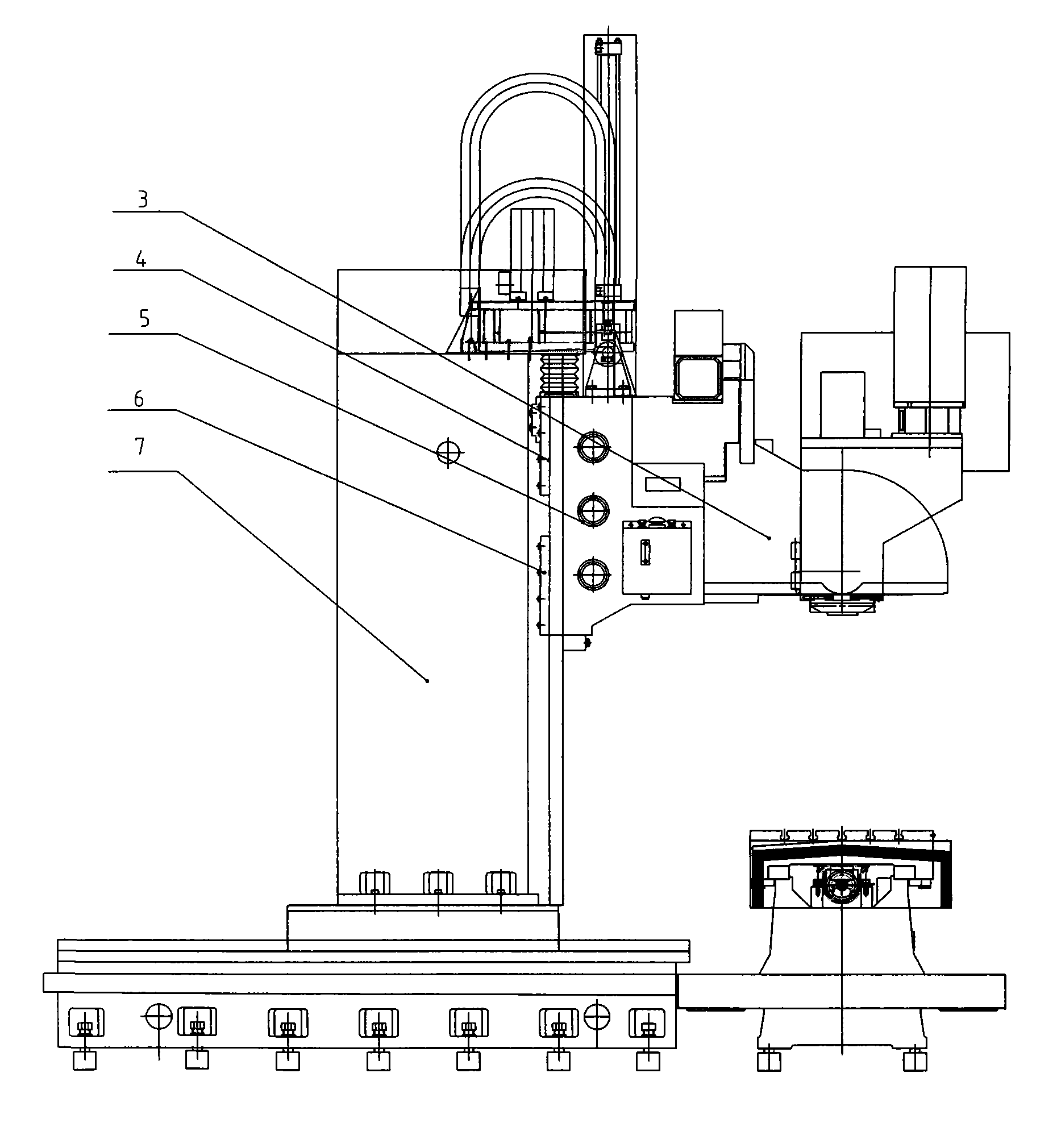

[0023] The connection relationship of this device is illustrated in conjunction with the accompanying drawings:

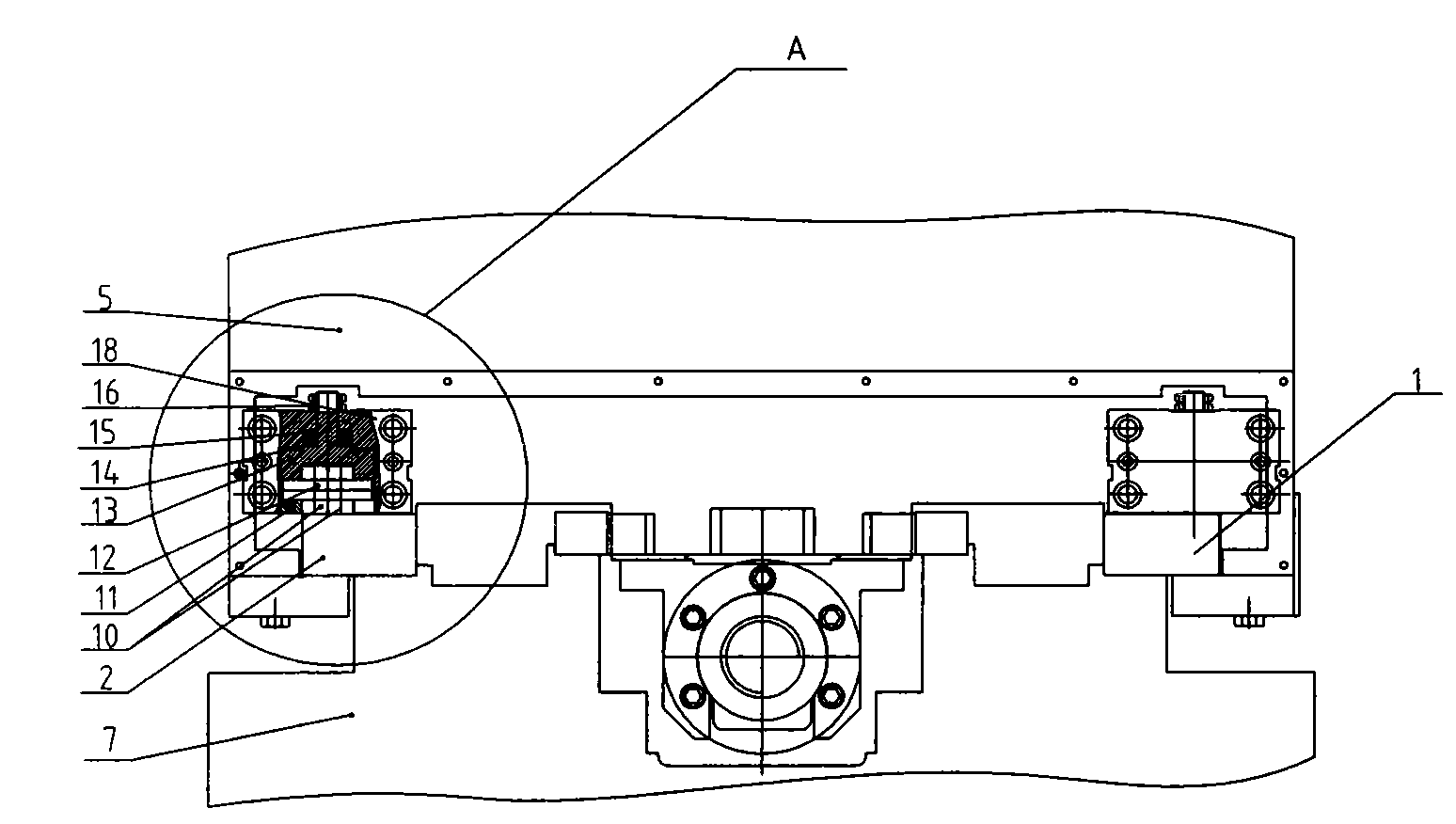

[0024] For a vertical five-axis machining center machine tool with A and B-axis double-swing angle milling heads, two steel guide rails 1 and 2 are arranged side by side on the left and right of the facade on one side of the column 7, such as figure 1 , figure 2 As shown, the moving part moves up and down in the vertical direction of the column 7, and the A and B-axis double swing heads 3 are fixed on the moving part composed of the upper pressing plate 4, the sliding plate 5 and the lower pressing plate 6, which is characterized in that the A unloading device 8, 9 are installed on the left and right guide rails 1,2 fronts respectively, and the rolling bearings 10 in the two sets of A unloading devices are respectively supported on the left and right guide rails 2,1.

[0025] There are two rolling bearings 10 placed side by side in the center of the rolling beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com