Compressed packer sealing cylinder for oil and gas fields

A compression packer, oil and gas field technology, applied in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve problems such as inability to adapt to requirements, limited pressure bearing capacity, high temperature resistance and corrosion resistance , to achieve the effect of small static friction coefficient, corrosion resistance of static friction coefficient, and improved pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

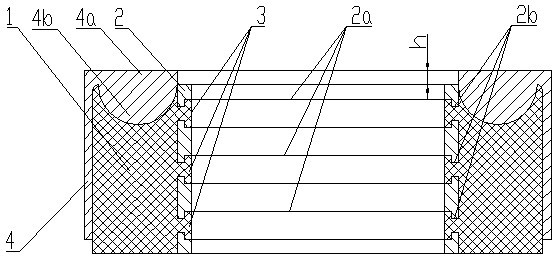

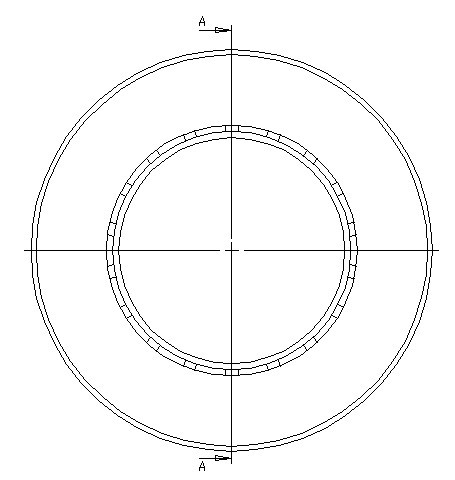

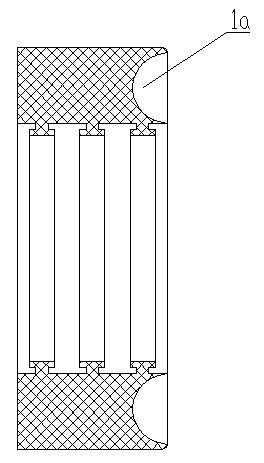

[0032] figure 1 It is a structural schematic diagram of the present invention, figure 2 is a schematic diagram of the structure of the elastomer, image 3 for figure 2 A-A sectional view of, Figure 4 is a schematic diagram of the structure of the support sleeve, Figure 5 is the schematic diagram of the sleeve structure, Figure 6 It is another schematic diagram of the structure of the outer sleeve wall, as shown in the figure: the sealing sleeve of the compression packer for oil and gas fields in this embodiment includes a rubber sleeve 1 for being sleeved on the inner core 5 of the packer, The rubber sleeve 1 is provided with an outer sleeve 4 made of polytetrafluoroethylene, and the rubber sleeve expands and deforms in the radial direction after being pressed. Axial seal, using polytetrafluoroethylene (PTFE) material with high temperature resistance, greater strength than rubber, small static friction coefficient and corrosion resistance, etc., to improve the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com