Non-circular suction wheel and sheet feeder

A non-circular, suction opening technology, applied in the direction of object separation, sending objects, pile separation, etc., can solve problems such as inability to accurately pre-specify time points, suction interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

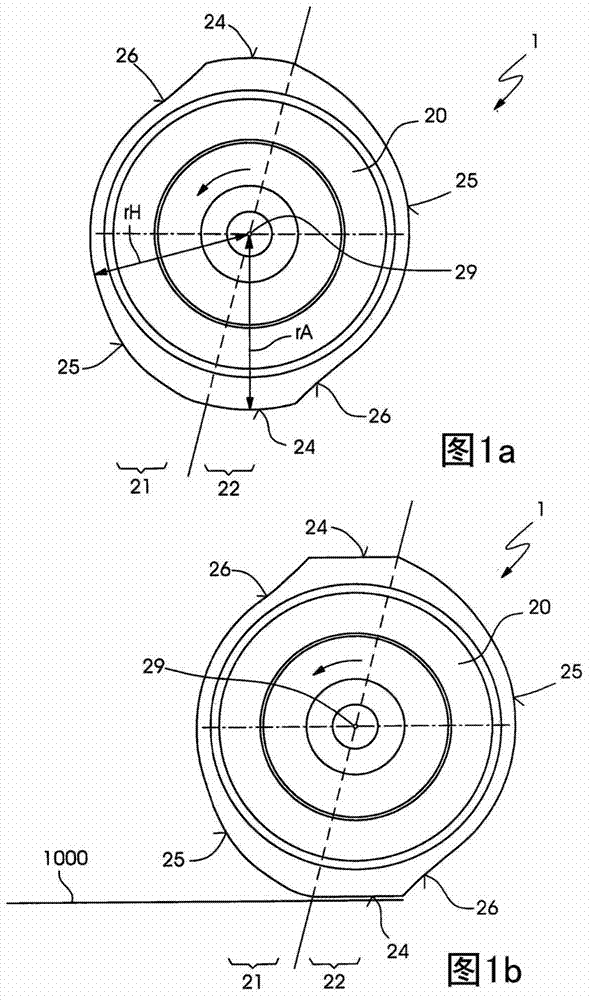

[0026] Figure 1a A first variant of the suction wheel 1 according to the invention is shown: the suction wheel 1 has a suction wheel body 20 and is divided into a first section 21 and a second section 22 . Each segment 21 , 22 has a suction area 24 , a holding area 25 and a release area 26 . The suction area 24 is used for suctioning sheets not shown here. The holding area 25 serves to hold the suctioned sheets and to transport them during the rotation of the suction wheel 1 . The release area 26 serves to release the sucked sheets in order to be able to transfer them, for example, to a subsequent transport device. The suction wheel body 20 of the suction wheel 1 is of non-circular design. This means that the suction wheel body 20 does not have a uniform radius. Conversely, the radius rA of the suction wheel 20 in the suction region 24 is greater than the radius rH in the holding region 25 . The transition between the smaller radius rH and the larger radius rA is designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com