Coating with good lubricating performance and coating process thereof

A lubricating performance and coating technology, which is applied in the coating with good lubricating performance and its coating process, can solve the problems of narrow operating temperature range, poor lubricating performance, and small load capacity, and achieve wide operating temperature range and excellent lubrication The effect of large performance and load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A coating with good lubricating properties comprises the following raw materials in parts by weight:

[0059] 50-60 parts of epoxy acrylate,

[0060] 20-27 parts of fluorine-containing polyacrylic acid ester,

[0061] 12-16 parts of phenolic modified epoxy acrylate,

[0062] Silicone modified epoxy resin 8-11 parts,

[0063] 5-7 parts of the polymer of 2-acrylamide and 1-vinyl-2-pyrrolidone,

[0064] 10-15 parts of polytetrafluoroethylene powder,

[0065] 4-6 parts of mixture of nano-graphite and molybdenum disulfide,

[0066] 3-5 parts of suspension dispersant, 1-1.4 parts of leveling agent, 1.8-2.3 parts of curing agent;

[0067] The mass ratio of nano-graphite to molybdenum disulfide in the mixture of nano-graphite and molybdenum disulfide is 1:0.18-0.28.

[0068] Preferably, the coating with good lubricity includes the following raw materials in parts by weight:

[0069] 55 parts of epoxy acrylate,

[0070] 24 parts of fluorine-containing polyacrylic acid es...

Embodiment 2

[0089] A coating with good lubricating properties comprises the following raw materials in parts by weight:

[0090] 50 parts of epoxy acrylate,

[0091] 20 parts of fluorine-containing polyacrylic acid ester,

[0092] 12 parts of phenolic modified epoxy acrylate,

[0093] Silicone modified epoxy resin 8 parts,

[0094] 5 parts of polymers of 2-acrylamide and 1-vinyl-2-pyrrolidone,

[0095] 10 parts of polytetrafluoroethylene powder,

[0096] 4 parts of the mixture of nano-graphite and molybdenum disulfide,

[0097] 3 parts of suspension dispersant, 1 part of leveling agent, 1.8 parts of curing agent;

[0098] The mass ratio of nano-graphite and molybdenum disulfide in the mixture of nano-graphite and molybdenum disulfide is 1:0.18.

[0099] In this embodiment, the suspending and dispersing agent is a copolymer of vinylpyrrolidone and vinylimidazole.

[0100] In this embodiment, the leveling agent is AC-3777.

[0101] In this embodiment, the curing agent is a mixture o...

Embodiment 3

[0110] A coating with good lubricating properties comprises the following raw materials in parts by weight:

[0111] 60 parts of epoxy acrylate,

[0112] 27 parts of fluorine-containing polyacrylic acid ester,

[0113] 16 parts of phenolic modified epoxy acrylate,

[0114] 11 parts of silicone modified epoxy resin,

[0115] 7 parts of polymers of 2-acrylamide and 1-vinyl-2-pyrrolidone,

[0116] 15 parts of polytetrafluoroethylene powder,

[0117] 6 parts of the mixture of nano-graphite and molybdenum disulfide,

[0118]5 parts of suspension dispersant, 1.4 parts of leveling agent, 2.3 parts of curing agent;

[0119] The mass ratio of nano-graphite and molybdenum disulfide in the mixture of nano-graphite and molybdenum disulfide is 1:0.28.

[0120] In this embodiment, the suspending and dispersing agent is a copolymer of vinylpyrrolidone and vinylimidazole.

[0121] In this embodiment, the leveling agent is AC-3777.

[0122] In this embodiment, the curing agent is a mix...

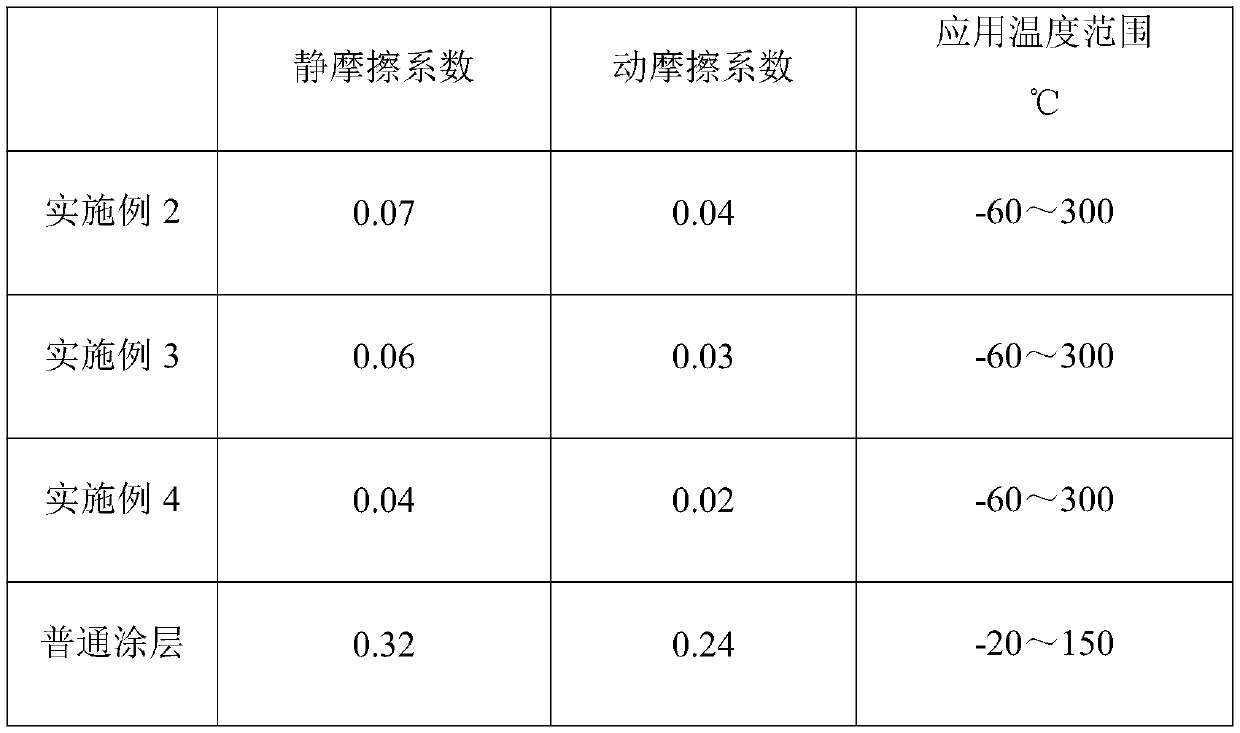

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com