Demulsifying and flocculating treatment method of machining cutting fluid sewage water

A treatment method and technology of cutting fluid, which is applied in the field of demulsification and flocculation treatment of machining cutting fluid sewage, and can solve problems such as difficult demulsification and flocculation, incomplete pollution control, and poor treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

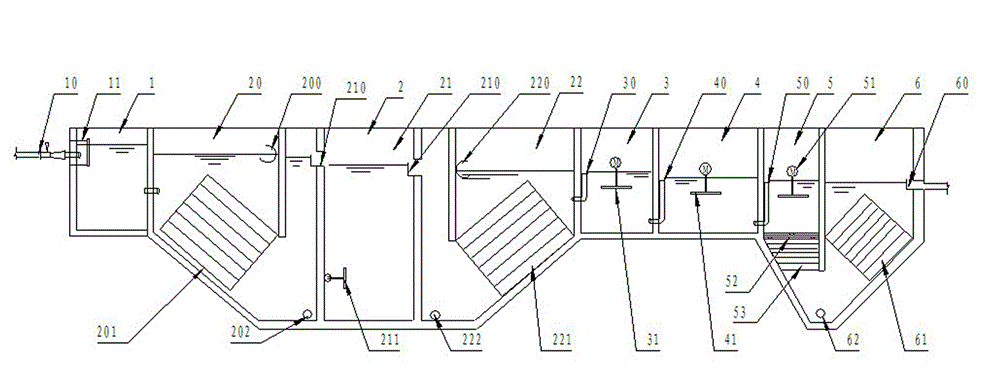

[0013] Below in conjunction with accompanying drawing, the demulsification flocculation treatment method of a kind of machining cutting fluid sewage of the present invention is further described;

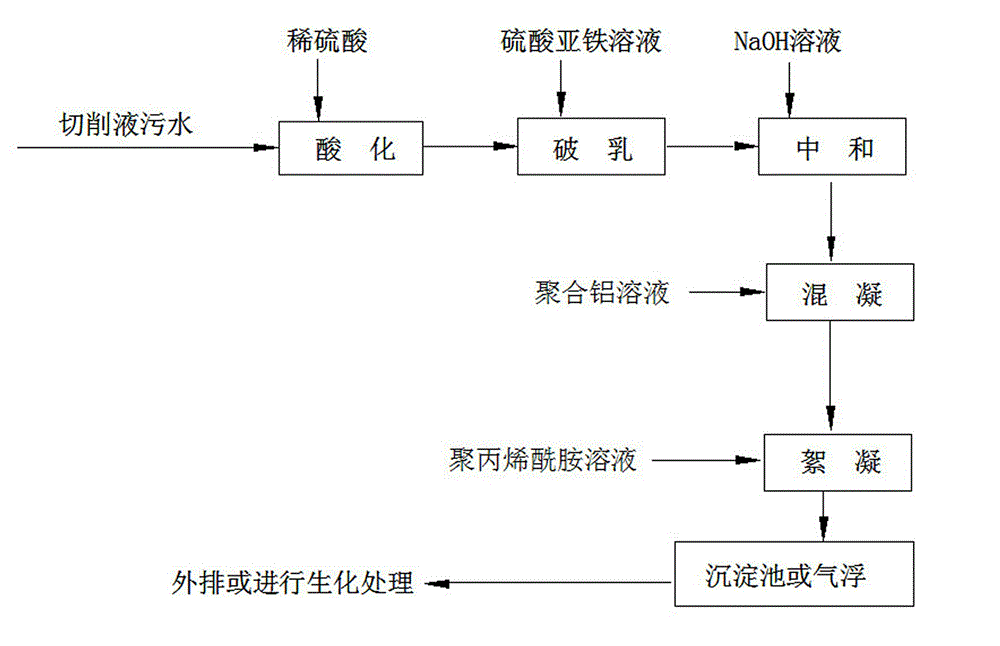

[0014] Depend on figure 1 , figure 2 Visible, the demulsification flocculation processing method of a kind of machining cutting fluid sewage of the present invention comprises the following steps:

[0015] a. Input the cutting fluid sewage through the pipeline mixer 10 into the acidification tank 1 equipped with the hydraulic rectification plate 11. The flow rate is controlled to 0.5t / h, the COD concentration is 15000mg / L, and 15% concentration is continuously added to the acidification tank 1. The dilute sulfuric acid is used to adjust the pH of the sewage to the range of 4-5, the mixing method is mechanical stirring, and the residence time of the sewage is controlled at about 20 minutes.

[0016] b. The acid cutting fluid sewage in step a is input into the grease trap 20 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com