A manufacturing method of a stator bar for increasing the corona inception voltage of a winding

A technology of stator bar and corona inception voltage, which is applied in the shape/style/structure of winding insulation, winding insulation material, manufacturing of motor generators, etc. It is difficult to increase the gap between the oblique edges and other problems, so as to achieve the effect of simple repair method and implementation process, stable resistance value range and small resistance value range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

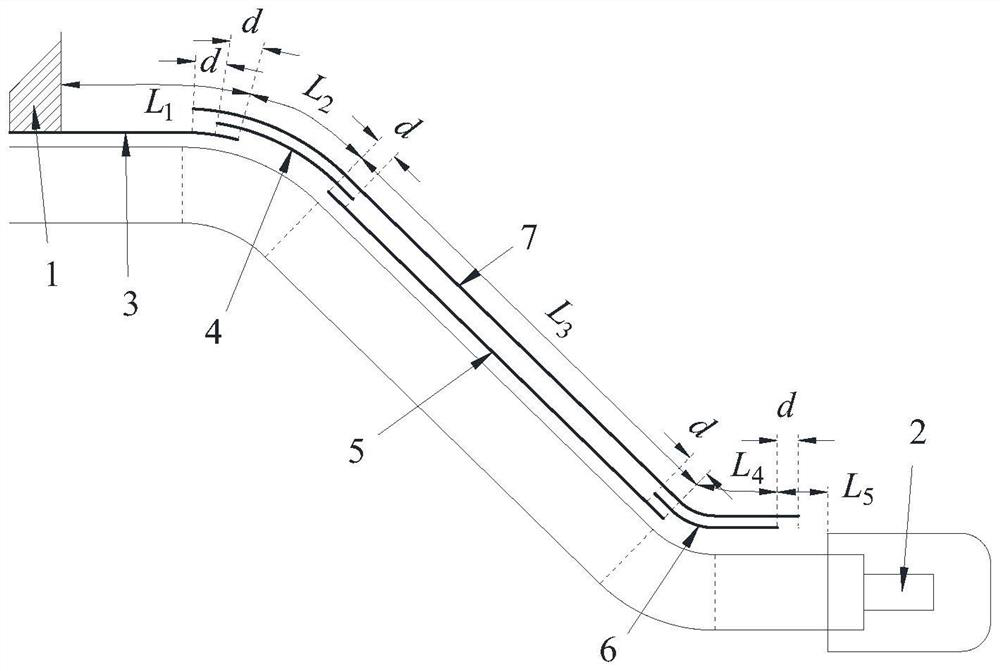

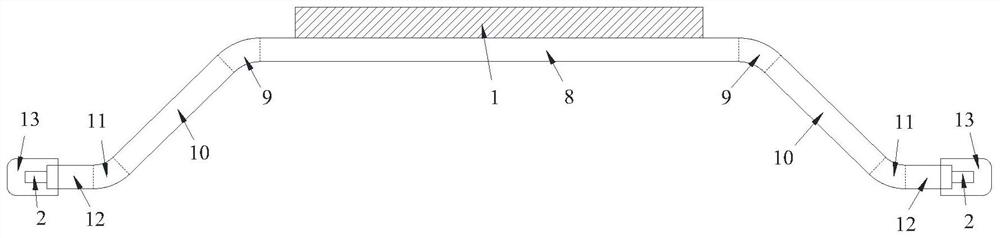

[0021] 1) if figure 1 As shown, the anti-corona structure at the end of the stator bar, from the stator core 1 to the lead wire 2, is as follows: the first low-resistance anti-corona structure 3, the second medium-resistance anti-corona structure 4, the third low-resistance anti-corona Corona structure 5 and the fourth section of high-resistance anti-corona structure 6; the outermost layer of the end of the wire rod is covered with an additional insulating structure 7;

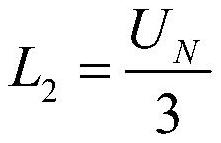

[0022] 2) if figure 1 As shown, the anti-corona materials of each anti-corona structure are: the low-resistance anti-corona tape material used in the first low-resistance anti-corona structure 3 and the third low-resistance anti-corona structure 5, with a width of 25mm and a thickness of 0.08mm 、The surface resistivity under 500V DC voltage is 10 2 Ω~10 3 Ω; the medium-resistance anti-halation belt material used in the second-stage medium-resistance anti-halation structure 4 has a width of 25mm, a thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com