Preparation method of magnesium-hydroxide-coated calcium carbonate inorganic composite flame retardant filler

A technology of magnesium hydroxide and flame-retardant fillers, which is applied in the direction of inorganic pigment treatment, chemical instruments and methods, and fibrous fillers. Problems such as high cost, achieve good application prospects, increase functions, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

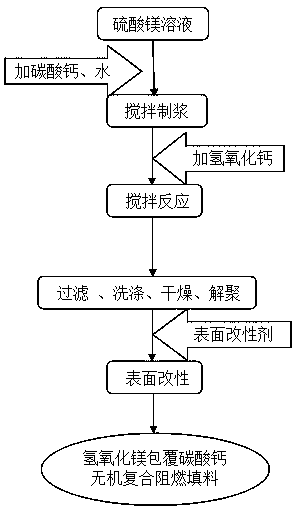

Method used

Image

Examples

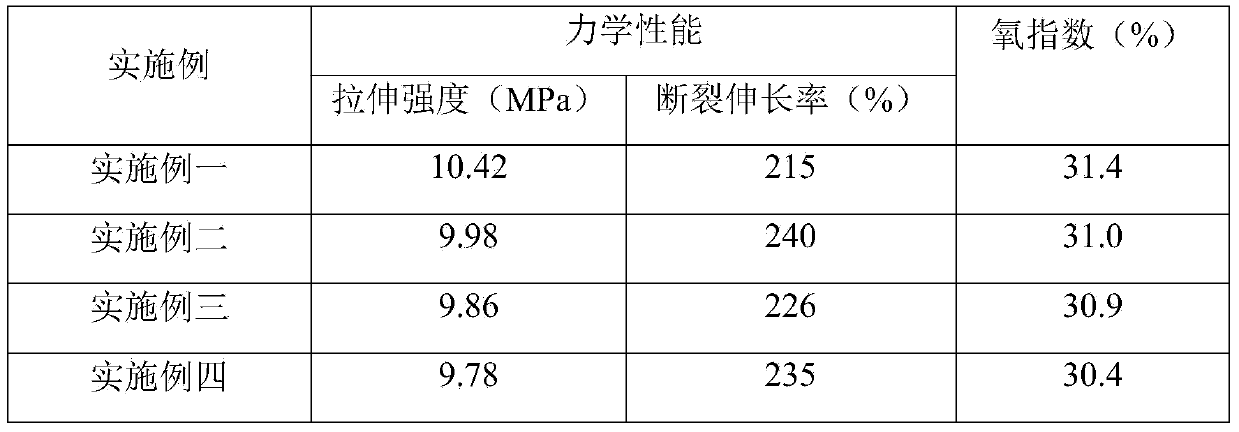

Embodiment 1

[0020] Get 200g magnesium sulfate and put into stirring reactor, add 1000ml water wherein, configure magnesium sulfate solution; Add ground calcium carbonate (D 97 =5μm) 400g, after stirring evenly, make a mixed slurry; slowly add 130g of calcium hydroxide to the mixed slurry at a constant temperature of 90°C while stirring; after stirring for 150min, the reaction product is filtered, washed, dried, and depolymerized. Then it is modified by dry method with 10g of silane and 5g of stearic acid to obtain magnesium hydroxide-coated calcium carbonate inorganic composite flame-retardant filler.

Embodiment 2

[0022] Get 200g magnesium sulfate and put into stirring reactor, add 1300ml water wherein, configure magnesium sulfate solution, add heavy calcium carbonate (D 97 =10μm) 600g, after stirring evenly, to make a mixed slurry; slowly add 140g of calcium hydroxide to the mixed slurry at a constant temperature of 75°C while stirring, and after stirring for 120min, the reaction product is filtered, washed, dried, and depolymerized. Then, 11 g of silane and 6 g of stearic acid are used for dry modification to obtain magnesium hydroxide-coated calcium carbonate inorganic composite flame-retardant filler.

Embodiment 3

[0024] Get 200g magnesium sulfate and put into stirring reactor, add 1200ml water wherein, configure magnesium sulfate solution, add light calcium carbonate (D 97 =15μm) 500g, after stirring evenly, to make a mixed slurry; slowly add 130g of calcium hydroxide to the mixed slurry at a constant temperature of 70°C while stirring, and after stirring for 90min, the reaction product is filtered, washed, dried, and depolymerized. Then it is modified by dry method with 10g of silane and 5g of stearic acid to obtain magnesium hydroxide-coated calcium carbonate inorganic composite flame-retardant filler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com