High-hardness wood-plastic building template and preparation method thereof

A building formwork, high hardness technology, applied in the field of high hardness wood-plastic building formwork and its preparation, can solve problems such as poor hardness and affecting use, and achieve the effect of smooth and delicate surface, high hardness and strong wood feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

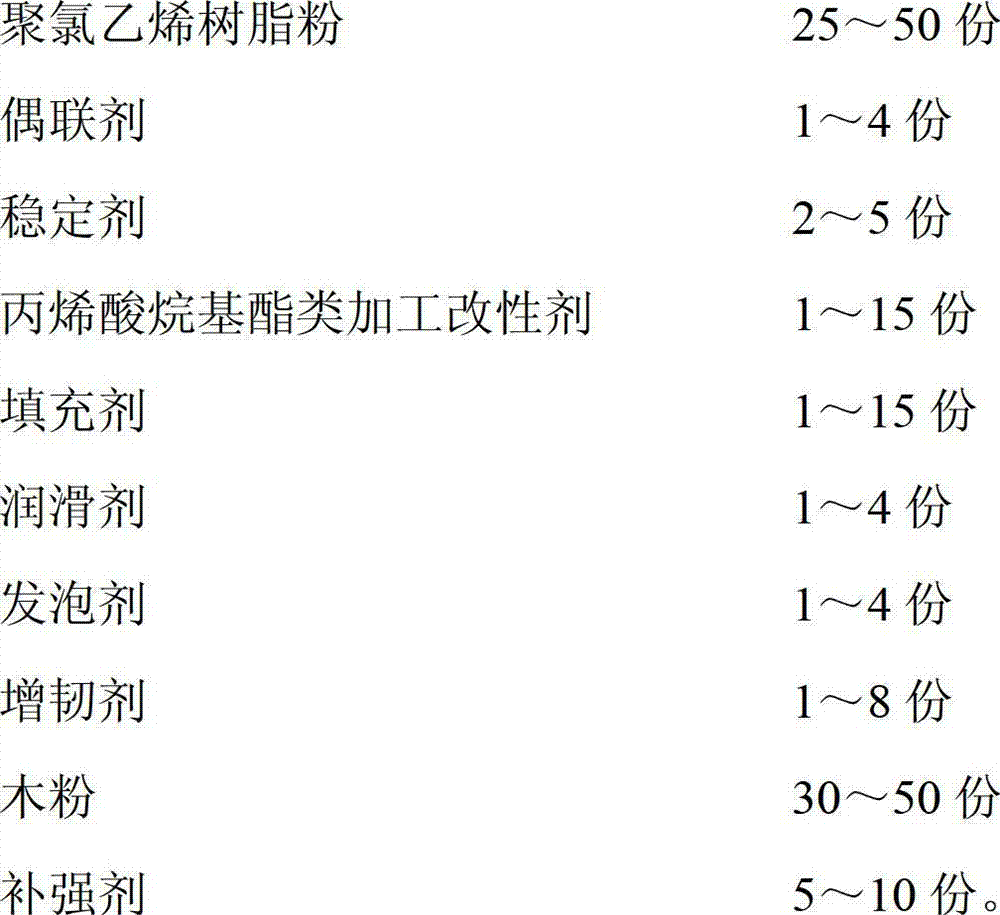

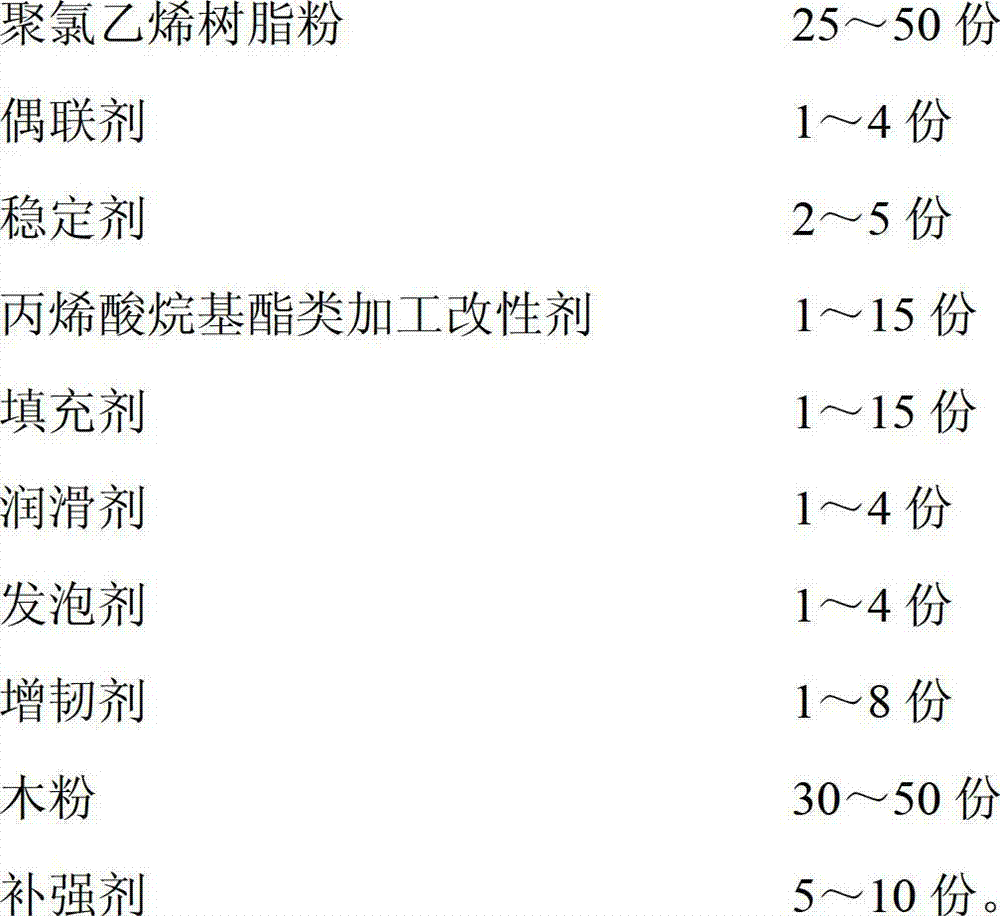

Method used

Image

Examples

Embodiment 1

[0020] The formula of the high-hardness wood-plastic building formwork is as follows: 50 parts by weight of polyvinyl chloride resin powder with a polymerization degree of 1000, 1 part by weight of silane coupling agent, 2 parts by weight of composite lead stabilizer, 5 parts by weight of ACR Processing modifier, the activation of ground calcium carbonate of 2 parts by weight, the polyethylene wax of 1 part by weight, the azodicarbonamide of 0.4 parts by weight, the sodium bicarbonate of 0.6 parts by weight, the chlorinated polyethylene of 1 part by weight, 30 parts by weight of 40 mesh wood flour, 7 parts by weight of nano-calcium carbonate, the total weight part is 100 parts.

[0021] The preparation method of the polyvinyl chloride wood-plastic board: first, add the above-mentioned raw materials in the formula amount into the high-speed mixer, heat through the oil jacket and self-friction to 110°C, put them into the cold mixing, and when the materials are cooled to 50 Put i...

Embodiment 2

[0024] The formula of the high-hardness wood-plastic building formwork is as follows: 30 parts by weight of polyvinyl chloride resin powder with a polymerization degree of 700, 1 part by weight of silane coupling agent, 3 parts by weight of composite lead stabilizer, and 6 parts by weight of ACR Processing modifier, the activated ground calcium carbonate of 4 parts by weight, the polyethylene wax of 2 parts by weight, the azodicarbonamide of 0.4 parts by weight, the sodium bicarbonate of 0.6 parts by weight, the chlorinated polyethylene of 5 parts by weight, 42 parts by weight of 40 mesh wood flour, 6 parts by weight of nanometer calcium carbonate, the total weight part is 100 parts.

[0025] The preparation method of the high-hardness wood-plastic building formwork is as in Example 1.

[0026] The product prepared in this embodiment is a 15mm plate with a density of 500kg / m 3 , Plate hardness (Shore hardness) D=69.

Embodiment 3

[0028] The formula of the polyvinyl chloride wood-plastic board is as follows: 33 parts by weight of polyvinyl chloride resin powder with a polymerization degree of 700, 2 parts by weight of silane coupling agent, 5 parts by weight of composite lead stabilizer, and 8 parts by weight of ACR Processing modifier, the activated ground calcium carbonate of 6 parts by weight, the polyethylene wax of 1 part by weight, the azodicarbonamide of 0.4 parts by weight, the sodium bicarbonate of 0.6 parts by weight, the chlorinated polyethylene of 6 parts by weight, 30 parts by weight of 40 mesh wood flour, 8 parts by weight of modified ultrafine silicon dioxide, the total weight part is 100 parts.

[0029] The preparation method of the high-hardness wood-plastic building formwork is as in Example 1.

[0030] The product prepared in this embodiment is a 15mm plate with a density of 510kg / m 3 , Plate hardness (Shore hardness) D=70.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com