Flame-retardant resin composition and molded body using same

A resin composition and flame retardant technology, used in the field of cables, flexible wires or optical fiber core wires, can solve the problems of flame retardancy, reduced flexibility, dioxin, etc., and generate a large amount of corrosive gas, and achieve excellent resistance. Excellent flammability, high mechanical properties, and excellent recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

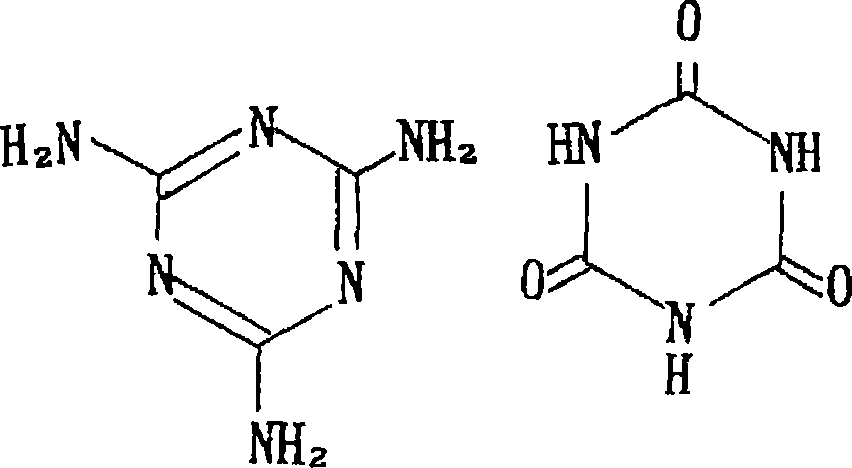

Method used

Image

Examples

Embodiment 1~12、 comparative example 1~10

[0104] Table 1 shows the content of each component of the resin composition of Examples 1 to 12, and Table 2 shows the content of each component of the resin composition of Comparative Examples 1 to 10 (unless otherwise specified, the numbers in the table represent parts by mass. ). Each component shown in the table|surface was dry-blended at room temperature, and melt-kneaded using the Banbury mixer, and each resin composition was manufactured.

[0105] The respective component materials shown in the table are as follows.

[0106] (a-1) Ethylene-vinyl acetate copolymer

[0107] Product name: Ebaflex EV180, manufacturer: Mitsui DuPont Poly Chemical Co., Ltd.

[0108] Vinyl acetate content: 33% by mass

[0109]Product name: VPKA8784 Manufacturing unit: Bayer Corporation

[0110] Vinyl acetate content: 70% by mass

[0111] Product name: レバプレン 800HV Manufactured by: Biel Corporation

[0112] Vinyl acetate content: 80% by mass

[0113] Product name: レバプレン 900HV Manufactured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com