Flame retardation control cable with excellent mechanical performances

A technology to control the performance of cables, applied in the direction of insulated cables, twisted/quad-stranded cables, cables, etc., can solve the damage of insulation and sheath materials, threats to equipment and personal safety, and cables without resistance Combustibility and other issues, to achieve excellent toughness and thermal stability, good thermal stability and mechanical properties, and enhanced flame retardancy and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

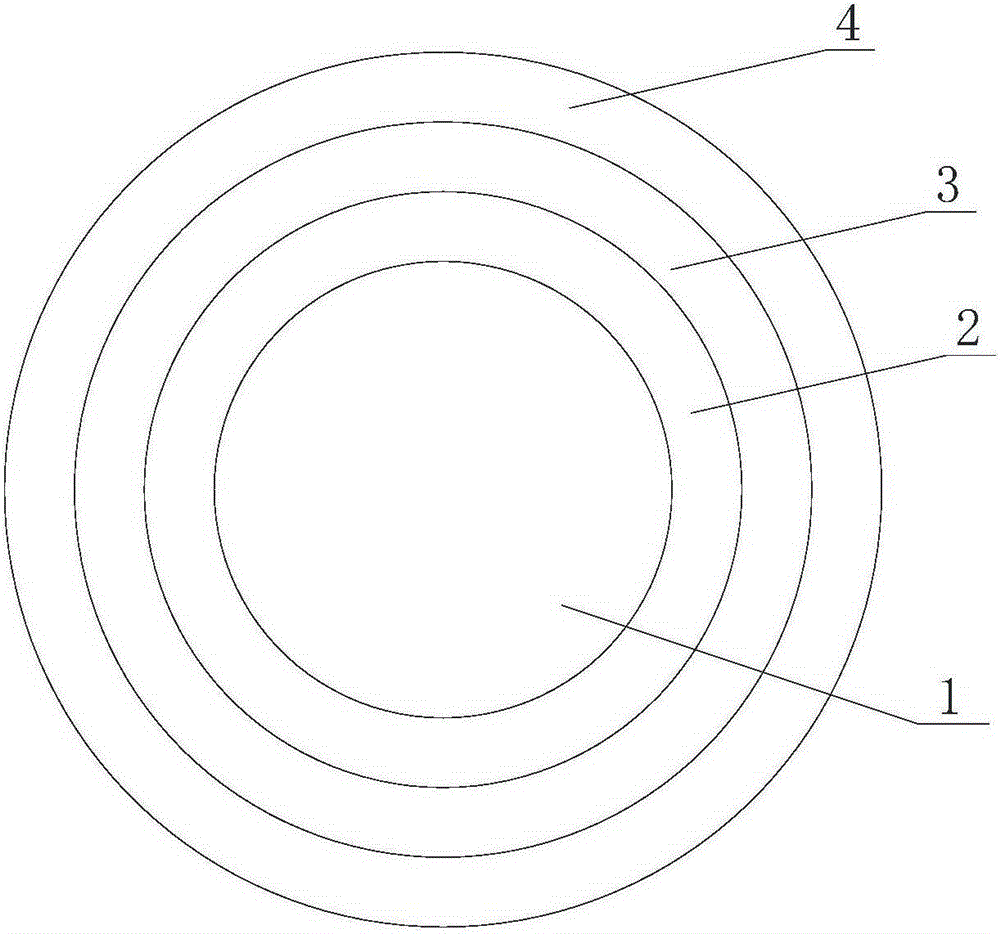

[0017] refer to figure 1 , a flame-retardant control cable with excellent mechanical properties, including a core 1, an insulating layer 2, a shielding layer 3 and a sheath layer 4, the insulating layer 2 covers the core 1, and the shielding layer 3 covers the insulating layer 2 , The sheath layer 4 is wrapped outside the shielding layer 3; wherein the insulating layer 2 is made of modified polypropylene.

[0018] The raw materials of the modified polypropylene include by weight: 40 parts of polyethylene, 15 parts of polypropylene, 25 parts of neoprene, 1.7 parts of vinyl triethoxysilane, tert-amyl peroxide 2-ethylhexyl carbonate 2.5 parts, 2 parts of diethylenetriamine, 0.5 parts of dibutyltin dilaurate, 1.5 parts of styrylated-N-phenylaniline, 0.7 parts of 3,5-di-tert-butyl-4-hydroxycinnamic acid, 1.5 parts of dioctyl phthalate, 2.5 parts of sodium carboxymethyl cellulose, 2 parts of paraffin, 0.7 parts of magnesium stearate, 5 parts of diatomaceous earth, 40 parts of talc,...

Embodiment 2

[0020] refer to figure 1 , a flame-retardant control cable with excellent mechanical properties, including a core 1, an insulating layer 2, a shielding layer 3 and a sheath layer 4, the insulating layer 2 covers the core 1, and the shielding layer 3 covers the insulating layer 2 , The sheath layer 4 is wrapped outside the shielding layer 3; wherein the insulating layer 2 is made of modified polypropylene.

[0021] The raw materials of the modified polypropylene include by weight: 20 parts of polyethylene, 30 parts of polypropylene, 15 parts of neoprene, 2.5 parts of vinyl triethoxysilane, tert-amyl peroxide 2-ethylhexyl carbonate 0.5 parts, 3 parts of diethylenetriamine, 0.1 parts of dibutyltin dilaurate, 2.5 parts of styrylated-N-phenylaniline, 0.2 parts of 3,5-di-tert-butyl-4-hydroxycinnamic acid, 2.8 parts of dioctyl phthalate, 1 part of sodium carboxymethyl cellulose, 4 parts of paraffin, 0.2 parts of magnesium stearate, 15 parts of diatomaceous earth, 20 parts of talc, a...

Embodiment 3

[0023] refer to figure 1 , a flame-retardant control cable with excellent mechanical properties, including a core 1, an insulating layer 2, a shielding layer 3 and a sheath layer 4, the insulating layer 2 covers the core 1, and the shielding layer 3 covers the insulating layer 2 , The sheath layer 4 is wrapped outside the shielding layer 3; wherein the insulating layer 2 is made of modified polypropylene.

[0024] The raw materials of the modified polypropylene include by weight: 30 parts of polyethylene, 26 parts of polypropylene, 18 parts of neoprene, 2.4 parts of vinyl triethoxysilane, tert-amyl peroxide 2-ethylhexyl carbonate 0.8 parts, 2.8 parts of diethylenetriamine, 0.2 parts of dibutyltin dilaurate, 2.1 parts of styrylated-N-phenylaniline, 0.3 parts of 3,5-di-tert-butyl-4-hydroxycinnamic acid, 2.1 parts of dioctyl phthalate, 1.6 parts of sodium carboxymethyl cellulose, 3 parts of paraffin, 0.3 parts of magnesium stearate, 14 parts of diatomaceous earth, 30 parts of ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com