Rubber sheath rubber matrix

A technology of rubber sheath and rubber compound, applied in the field of rubber sheath compound, can solve the problems of easy aging, deformation and damage of the rubber sheath, and achieve the advantages of low production cost, long service life, good elasticity and aging resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

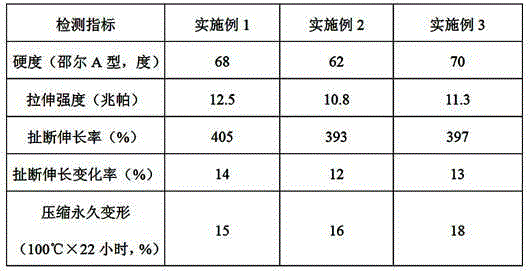

Examples

Embodiment 1

[0015] The rubber sheath compound of this embodiment is prepared from the following raw materials in parts by weight: 30 parts of silicone rubber, 25 parts of chlorohydrin rubber, 5 parts of stearic acid, 15 parts of paraffin oil, 3 parts of nano-titanium dioxide, and 3 parts of anti-aging agent , 1 part of accelerator, 5 parts of dioctyl phthalate, 5 parts of carbon black; among them, the anti-aging agent is a mixture of N-phenyl-β-naphthylamine and p-phenylenediamine, N-phenyl-β -The mass ratio of naphthylamine and p-phenylenediamine is 1:2.

[0016] The preparation method is as follows: Weigh each raw material according to the above parts by weight, mix silicone rubber, chlorohydrin rubber, stearic acid, paraffin oil, nano-titanium dioxide, anti-aging agent, dioctyl phthalate, and carbon black evenly, and control The temperature is at 80°C, the first mixing is carried out for 13 minutes, and then transferred to the open mill, triethanolamine is added, the temperature is con...

Embodiment 2

[0018] The rubber sheath compound of this embodiment is prepared from the following raw materials in parts by weight: 40 parts of silicone rubber, 32 parts of chlorohydrin rubber, 9 parts of stearic acid, 13 parts of paraffin oil, 1 part of nano-titanium dioxide, and 7 parts of anti-aging agent , 6 parts of accelerator, 9 parts of dioctyl phthalate, 7 parts of carbon black; Among them, the anti-aging agent is a mixture of N-phenyl-β-naphthylamine and p-phenylenediamine, N-phenyl-β -The mass ratio of naphthylamine and p-phenylenediamine is 1:2.

[0019] The preparation method is as follows: Weigh each raw material according to the above parts by weight, mix silicone rubber, chlorohydrin rubber, stearic acid, paraffin oil, nano-titanium dioxide, anti-aging agent, dioctyl phthalate, and carbon black evenly, and control The temperature is 75°C, and the first mixing is carried out for 15 minutes, and then transferred to the open mill, and triethanolamine is added, the temperature i...

Embodiment 3

[0021] The rubber sheath compound of this embodiment is prepared from the following raw materials in parts by weight: 35 parts of silicone rubber, 40 parts of chlorohydrin rubber, 13 parts of stearic acid, 15 parts of paraffin oil, 6 parts of nano-titanium dioxide, and 12 parts of anti-aging agent , 10 parts of accelerator, 2 parts of di-n-octyl phthalate, 10 parts of carbon black; Among them, the anti-aging agent is a mixture of N-phenyl-β-naphthylamine and p-phenylenediamine, N-phenyl-β -The mass ratio of naphthylamine and p-phenylenediamine is 1:2.

[0022] The preparation method is as follows: Weigh each raw material according to the above parts by weight, mix silicone rubber, chlorohydrin rubber, stearic acid, paraffin oil, nano-titanium dioxide, anti-aging agent, dioctyl phthalate, and carbon black evenly, and control The temperature is at 80°C, the first mixing is carried out for 15 minutes, and then transferred to the open mill, triethanolamine is added, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com