Preparation method of plasticized, copolymerized and modified organic glass

A technology of plexiglass and copolymerization modification, which is applied in the field of super-tough and high-transmittance plexiglass, and can solve problems such as easy silver cracks and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Step 1: Wash and dry two pieces of 120x120x3mm silicon glass, wrap a square rubber strip with tin foil, the size of the internal cavity is 8x8x3mm, stick one side of the rubber strip to a piece of silicon glass with glass glue, and then cover Put another piece of glass on it, clamp it with clips, and set it aside.

[0023] Step 2: Stir and mix 10g of methyl methacrylate (MMA) distilled under reduced pressure and 0.01g of initiator azobisisobutyronitrile (AIBN) with a glass rod, then pour into a clean 100ml round bottom flask , Stir and heat up to 85 ° C, stop heating when the solution becomes viscous, cool to room temperature, that is, prepolymer.

[0024] Step 3: Pour the prepolymer into the mold made in step 1, clamp and seal it, put it in a 50°C oven for slow polymerization for 24 hours, and when the polymer becomes a solid gel, raise the temperature to 100°C and then polymerize for 1~2 hours, so that It is fully polymerized, then gradually cooled to room temperatur...

example 2

[0026] The operation is the same as in Example 1, except that when the monomer methyl methacrylate (MMA) is added in step 2, the comonomer n-butyl acrylate (BA) is added, and the amount of the initiator and other reagents remains unchanged.

example 3

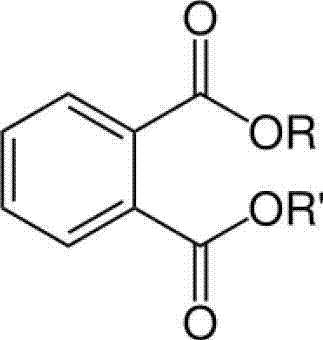

[0028] The operation is the same as in Example 2, except that the plasticizer dioctyl phthalate is added when the monomer methyl methacrylate (MMA) and the comonomer n-butyl acrylate (BA) are added in step 2 (DOP), the amount of initiator and other reagents was unchanged.

[0029] Example 4~8:

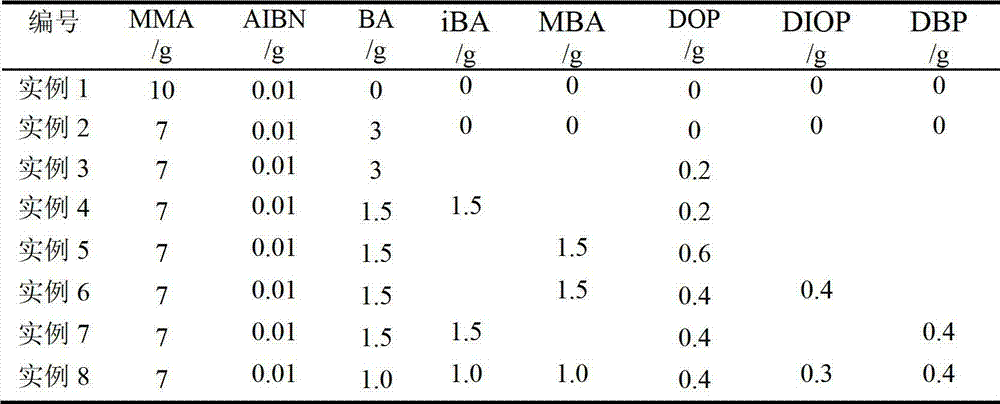

[0030] The operation is the same as in Example 3, except that the mass ratios of MMA, BA, iBA, DOP, DIOP and DBP added in step 2 are different, as shown in Table 1.

[0031] The material proportion of table 1 example 1~7

[0032]

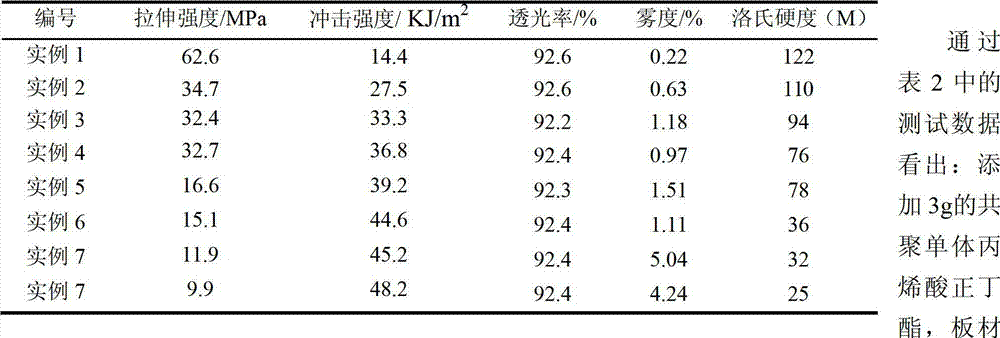

[0033] Table 2 Sheet properties

[0034]

[0035] Impact strength from 14.4KJ / m 2 Increased to 27.5KJ / m 2 , increased by 91%, and then added 0.2gDOP, the impact strength increased by 21%; the tensile strength decreased significantly, and the impact strength was less than 30MPa after the DOP was greater than 0.2g; the light transmittance remained at 92%, and the haze increased; Rockwell hardness also decreases with increasing DOP. In short, the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com