Strong and tough self-healing dual-response shape memory polylactic acid-based composite material and its preparation method

A dual-response, composite material technology, applied in the field of strong and tough self-healing dual-response shape memory polylactic acid-based composite materials and its preparation, can solve the problems of low resilience, poor shape memory performance, and increased PLA brittleness, etc., to achieve Effects of repairing damage, good balance of rigidity and toughness, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

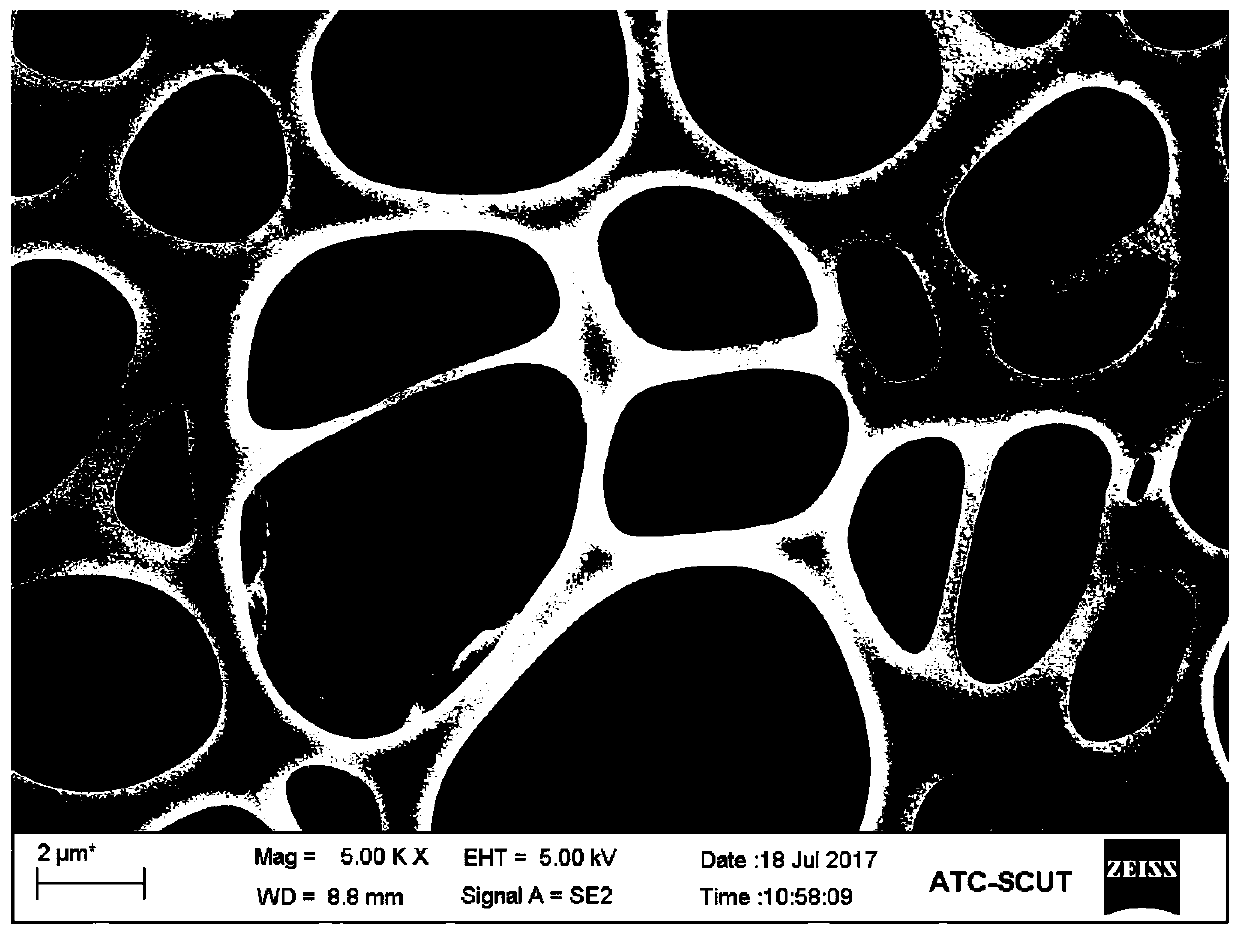

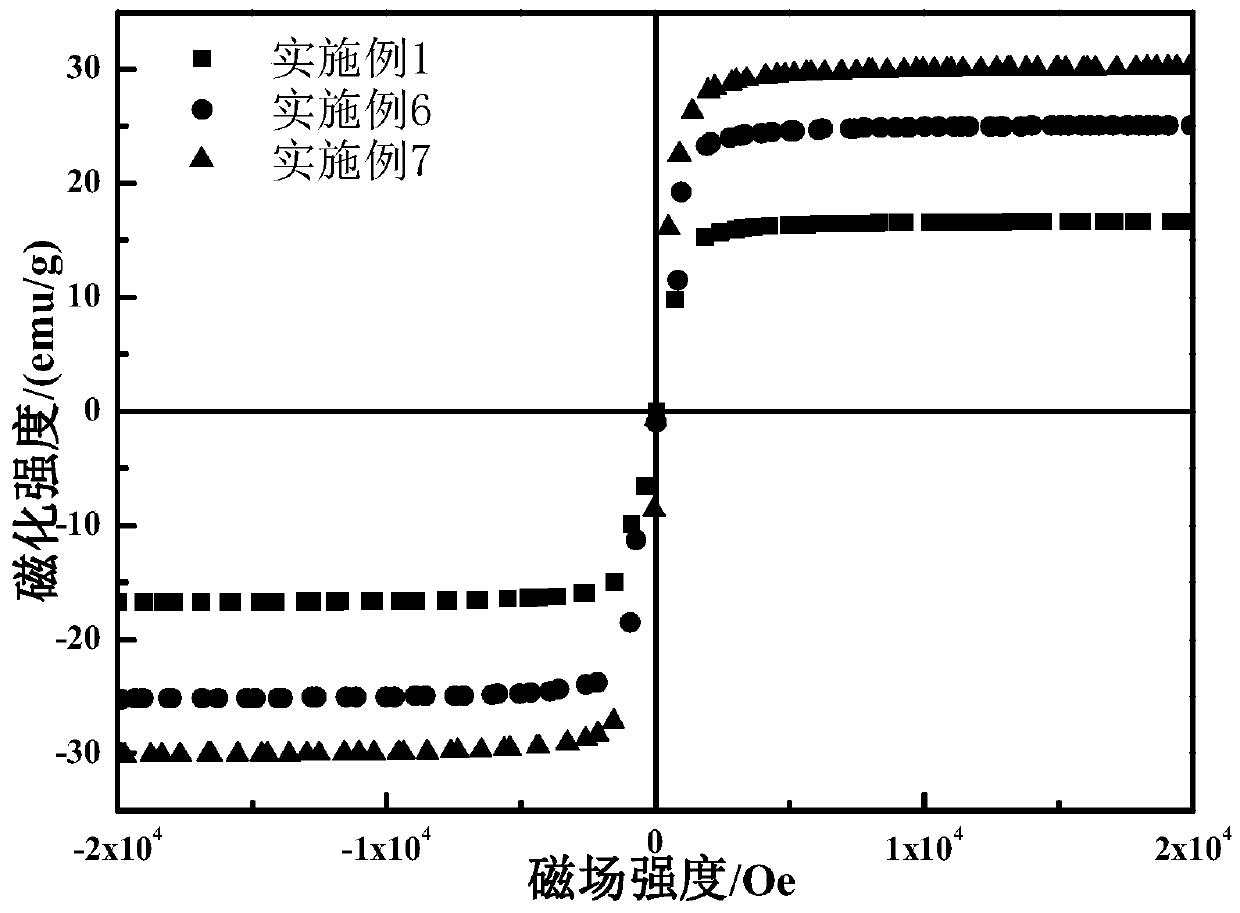

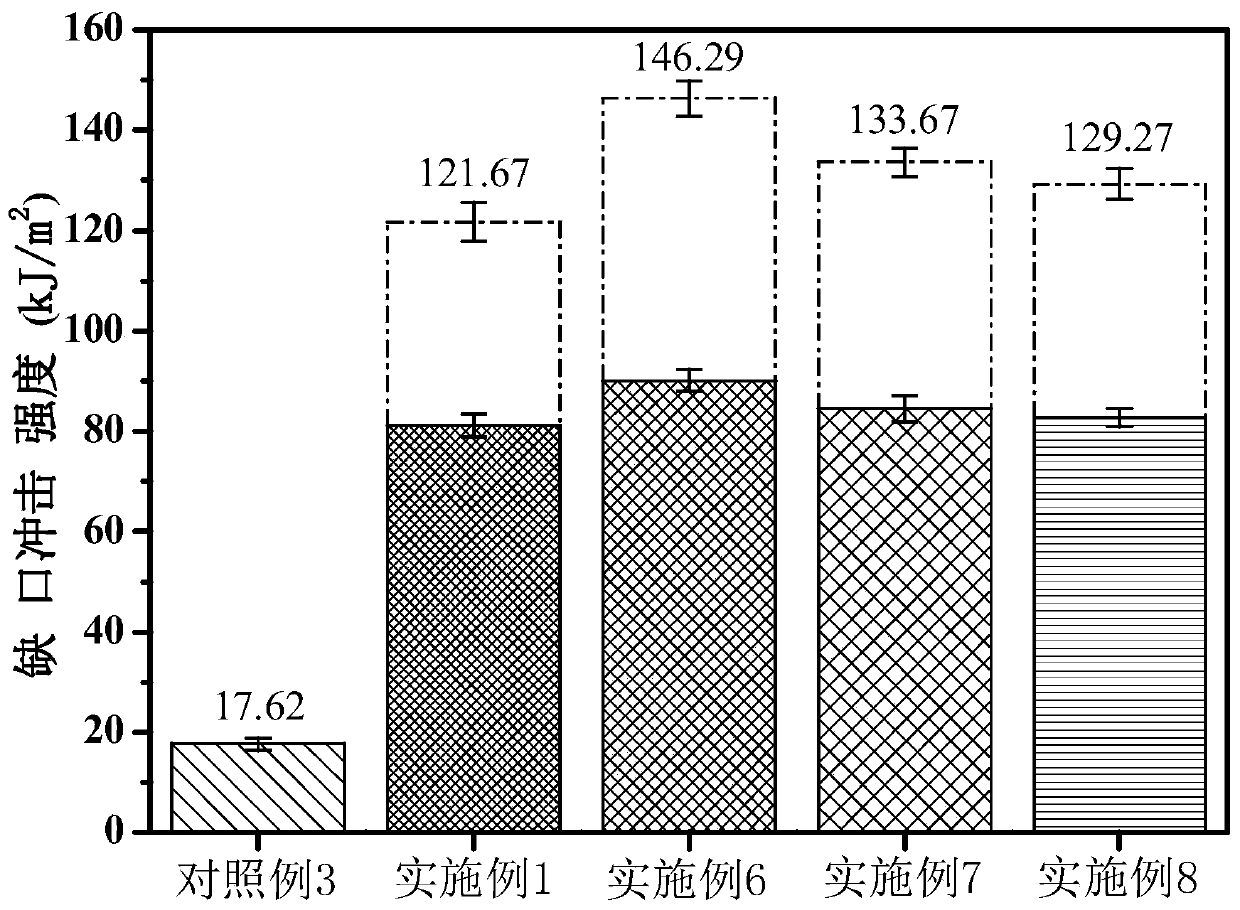

Embodiment 1

[0042] Polylactic acid was selected as the matrix resin (Zhejiang Hisun Biomaterials Co., Ltd., racemic polylactic acid (PDLLA)), and ENR‐50 was used as the matrix rubber. In order to reduce rubber elasticity, increase plasticity, and facilitate processing, the epoxidized natural rubber is masticated on an open mill, and the mass fraction of epoxidized natural rubber is 100%, and the average particle size is 50nm. The refined rubber is mixed evenly. In this embodiment, the mass ratio of polylactic acid and epoxidized natural rubber is 70 / 30. First, polylactic acid and 0.2% antioxidant 1010 of the total mass of rubber and plastic were added to a torque rheometer with a temperature and a rotational speed of 170°C and 60r / min, respectively, and melt blended for 3 minutes, and then epoxidized natural For rubber / iron tetroxide blended rubber, after mixing for 3 minutes, add 1.5% dicumyl peroxide to the rubber for dynamic vulcanization, and discharge after 4 minutes. The injection...

Embodiment 2

[0044] Polylactic acid was selected as the matrix resin (Zhejiang Hisun Biomaterials Co., Ltd., racemic polylactic acid (PDLLA)), and ENR‐30 was used as the matrix rubber. In order to reduce rubber elasticity, increase plasticity, and facilitate processing, the epoxidized natural rubber is masticated on an open mill, and the mass fraction of epoxidized natural rubber is 100%, and the average particle size is 50nm. The refined rubber is mixed evenly. In this embodiment, the mass ratio of polylactic acid and epoxidized natural rubber is (60 / 40). First, polylactic acid and 0.2% antioxidant 1010 of the total mass of rubber and plastic were added to a torque rheometer with a temperature and a rotational speed of 170°C and 60r / min, respectively, and melt blended for 3 minutes, and then epoxidized natural For rubber / iron tetroxide blended rubber, after mixing for 3 minutes, add 1.5% dicumyl peroxide to the rubber for dynamic vulcanization, and discharge after 4 minutes. The injecti...

Embodiment 3

[0046] Polylactic acid was selected as the matrix resin (Zhejiang Hisun Biomaterials Co., Ltd., racemic polylactic acid (PDLLA)), and ENR‐50 was used as the matrix rubber. In order to reduce rubber elasticity, increase plasticity, and facilitate processing, natural rubber is masticated on an open mill, and the mass fraction is 75% of epoxidized natural rubber, and the average particle size is 50nm. The rubber is mixed evenly. In this example, the mass ratio of polylactic acid and epoxidized natural rubber is (70 / 30). First, polylactic acid and 0.2% antioxidant 1010 of the total mass of rubber and plastic were added to a torque rheometer with a temperature and a rotational speed of 170°C and 60r / min, respectively, and melt blended for 3 minutes, and then epoxidized natural For rubber / sodium ferric oxide blended rubber, after mixing for 3 minutes, add 1.5% dicumyl peroxide to the rubber for dynamic vulcanization, and discharge after 4 minutes. The injection temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com