Open-spandrel arch bridge system adopting UHPC wet joint connection and construction method

A wet joint and fasting technology, applied in the fasting arch bridge system and construction field, can solve the problems of complex arch bridge construction technology, long construction period, and reduce on-site construction time, so as to ensure the interface connection strength and cross-section permeability resistance, The effect of shortening the construction period and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing.

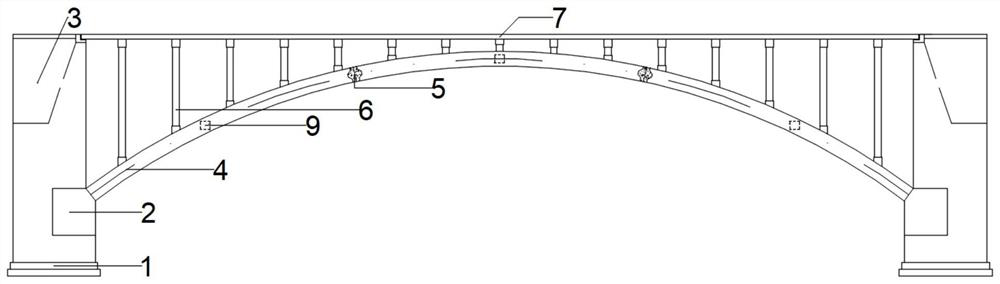

[0035] Such as figure 1 As shown, a hollow arch bridge system connected by UHPC wet joints, including a concrete foundation 1 set on the foundation soil layer, an abutment 2 and an abutment 3 set on the foundation 1, and a prefabricated reinforced concrete arch ring 4 It is arranged on two abutments 2, and the abutments 2 are provided with ventral piers 6 and bridge slabs 7.

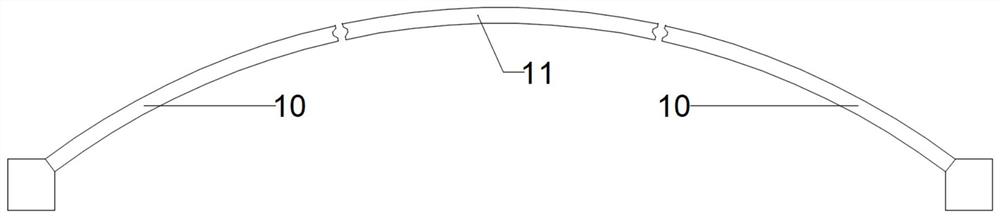

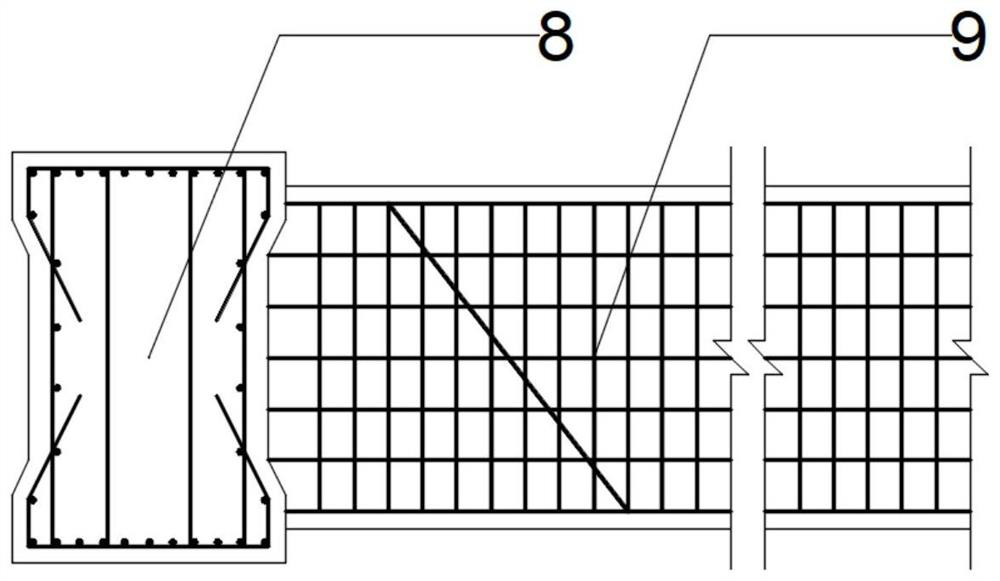

[0036] Such as figure 2 , image 3 As shown, the arch ring 4 is divided into three sections, which are formed by splicing the side sections 10 and the middle section 11 on both sides through the UHPC wet joint 5, and the side sections 10 and the middle section 11 are composed of two arch ribs 8 and A transverse tie beam 9 is formed, wherein the section of the arch rib 8 is rectangular.

[0037] Such as Figure 4 As shown, the UHPC wet joint 5 is formed by pouring ultra-high performance concrete. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com