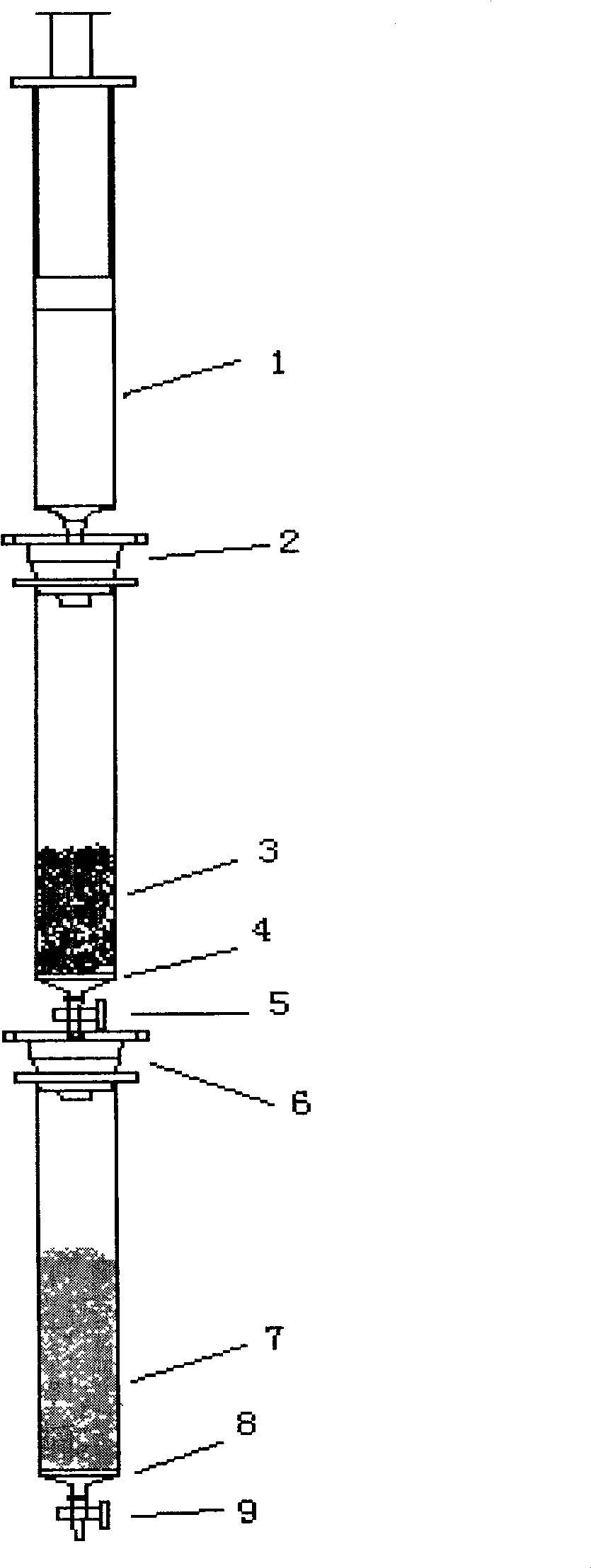

Two-step separation-purification column and use thereof

A purification column and packing column technology, applied in the chemical field, can solve the problems of low PAEs, large difficulty, complex matrix, etc., and achieve high application value and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Polyvinyl chloride (PVC) film was cut into 0.5 cm x 0.5 cm pieces. Weigh 0.500g of film, add 1.96mg / kg DNOP standard solution and 2.094mg / kg DBP standard solution. Add 30ml of n-hexane, sonicate for 30min, wash the residue with 20ml of n-hexane for 3 times, combine the washings, concentrate to 3-5ml by rotary evaporation, and carry out subsequent operations.

[0030] ①No column: Blow dry directly with nitrogen blower, dilute to 1ml with methanol, measure the concentration of DNOP and DBP, and calculate the recovery rate;

[0031] ② Activated carbon column: Add about 0.500g of activated carbon particles, first pre-wash the column with 2ml of dichloromethane, then pre-wash the column with 2ml of n-hexane, then load the sample, elute with 5ml of dichloromethane, collect the eluate, Blow dry with a nitrogen blower, dilute to 1ml with methanol, measure the concentration of DNOP and DBP, and calculate the recovery rate;

[0032] ③Through Florisil column: Add 1.500g of Flori...

Embodiment 2

[0039] After the apples were washed and crushed in a high-speed tissue grinder, 15.00 g was weighed, and 0.327 mg / kg of DNOP standard solution and 0.2327 mg / kg of DBP standard solution were added. Add 50 mL of extract solution (V (acetone): V (n-hexane) = 1:3), ultrasonically extract for 1 h, and suction filter to discard the residue. Wash the suction filter flask and funnel with 10 mL of extract, transfer the filtrate to a separatory funnel, collect the organic phase, extract the aqueous phase twice with 50 mL of n-hexane, and combine the organic phases. After concentrating to 3-5ml by rotary evaporation, follow-up operations were performed.

[0040] ①No column: Blow dry directly with nitrogen blower, dilute to 1ml with methanol, measure the concentration of DNOP and DBP, and calculate the recovery rate;

[0041] ② Activated carbon column: Add about 0.500g of activated carbon particles, first pre-wash the column with 2ml of dichloromethane, then pre-wash the column with 2ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com