Lead ion selective electrode film using poly-1-aminoanthraquinone as carrier, its preparation method and uses thereof

A technology of aminoanthraquinone and selective electrodes, which is applied in the direction of material analysis, measuring devices, instruments, etc. by electromagnetic means, can solve problems such as difficult to realize online monitoring of heavy metal ions, expensive instruments, cumbersome operation, etc., and achieve great competitive advantages, equipment Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Preparation of carrier poly-1-aminoanthraquinone

[0040]Poly-1-aminoanthraquinone (PAAQ) was prepared by chemical oxidation synthesis. Weigh 2mmol (446mg) 1-aminoanthraquinone monomer, put it into a 100ml beaker, add 40ml of acetonitrile, and pipette perchloric acid into the beaker, so that the concentration of perchloric acid in the acetonitrile solution is 0.05mol / L. In addition, accurately weigh 2 mmol (456 mg) of ammonium persulfate as an oxidizing agent with an analytical balance, dissolve it in 0.75 mL of deionized water, and place the two beakers containing the monomer solution and the oxidizing agent in a constant temperature water bath at 20°C. Then drop the oxidant solution into the monomer solution at a rate of 1 drop / 3 seconds, and at the same time, the monomer should be stirred on a magnetic stirrer. After the oxidant is dripped, react at a constant temperature under the magnetic stirrer for 24 hours. After the reaction, the system was centrifuged, and t...

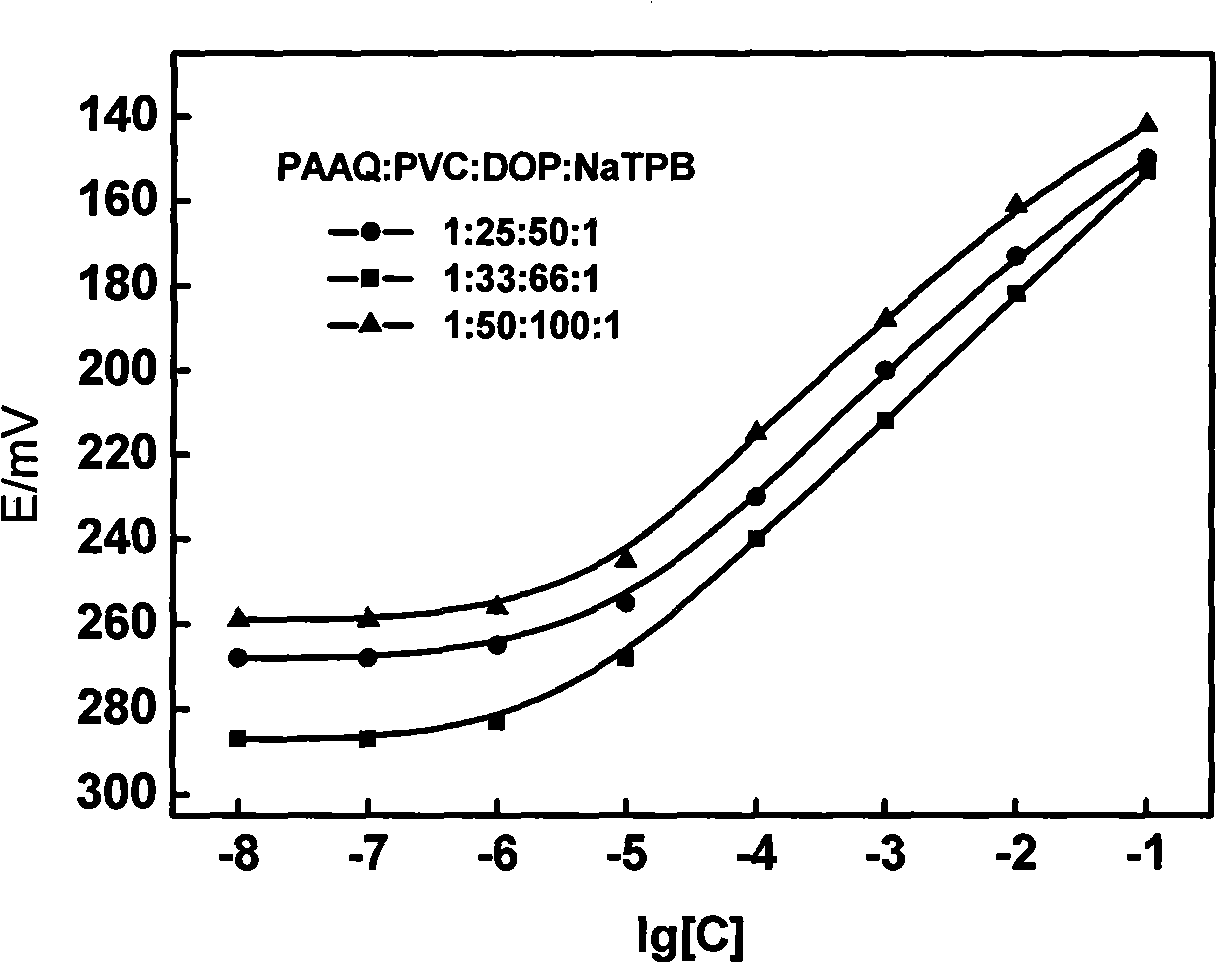

Embodiment 1

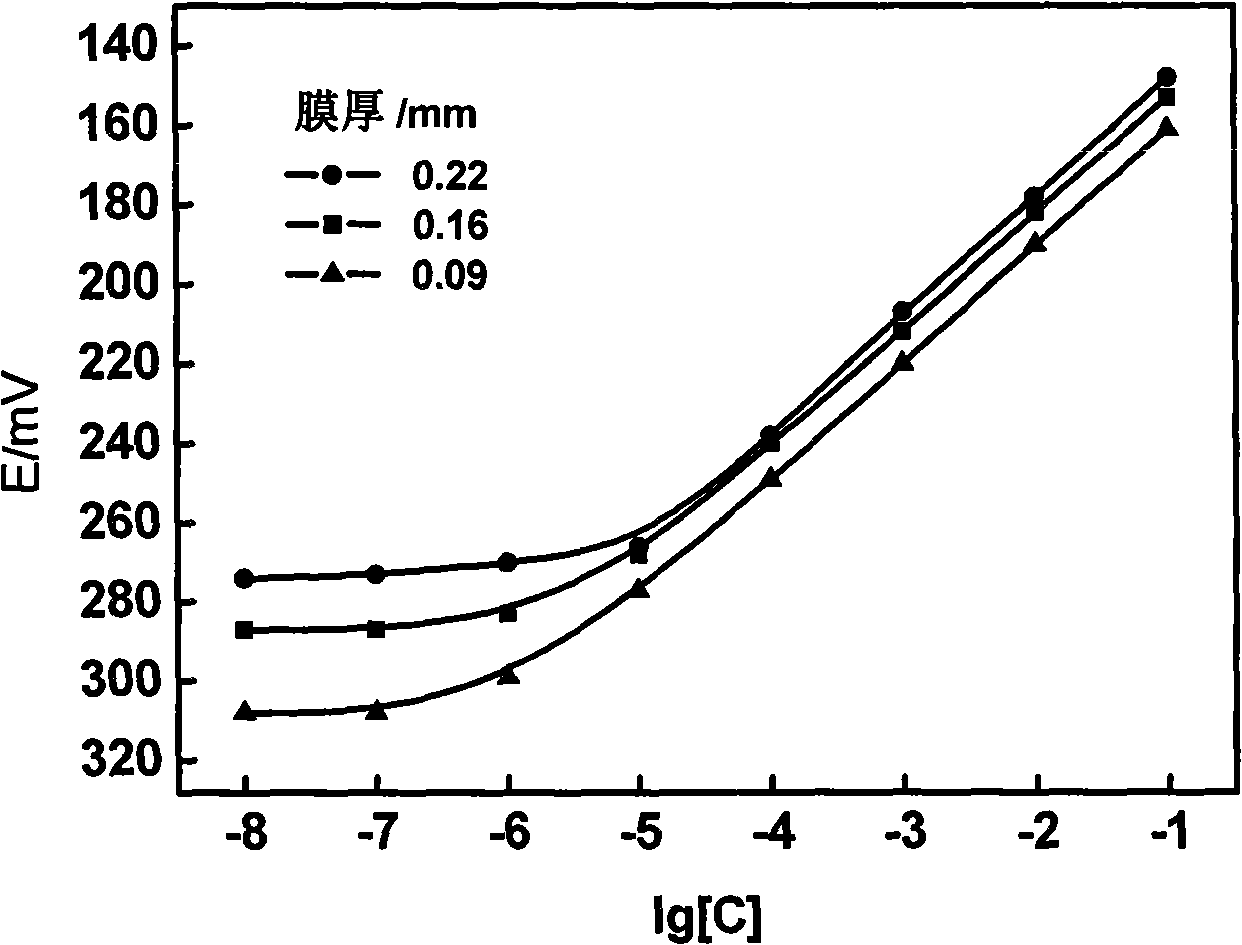

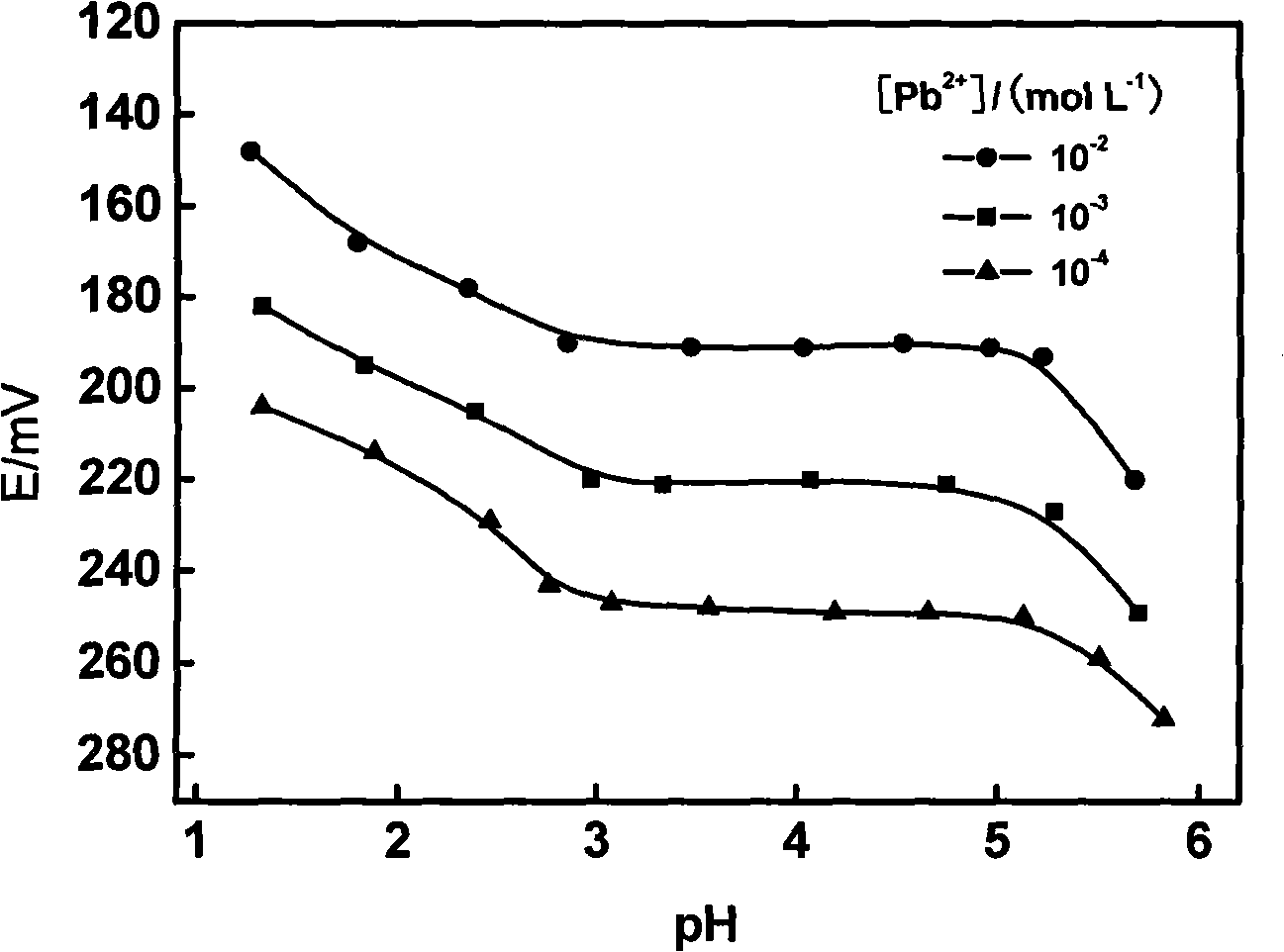

[0042] Weigh respectively 8 mg of poly-1-aminoanthraquinone (PAAQ), 200 mg of polyvinyl chloride (PVC), 400 mg of di-n-octyl phthalate (DOP), and 8 mg of sodium tetraphenylborate (NaTPB), and add these four reagents beaker, and added 5mL of tetrahydrofuran, intermittent ultrasonic dissolution for 1 hour. Then the mixed solution is poured on the flat bottom glass and left for 24 hours. After the THF is completely volatilized, a tough and elastic film is obtained. The composition of the film is PAAQ: PVC: DOP: NaTPB=1: 25: 50: 1, The thickness of the film was 0.16 mm. A disc with a diameter of about 16 mm is cut from the obtained film, and is glued to a PVC pipe end with an inner diameter of 13 mm and an outer diameter of 15 mm with epoxy resin. Fill the tube with 0.1mol·L -1 of Pb(NO 3 ) 2 Reference solution, and insert the Ag / AgCl electrode as the internal reference electrode. Before using the electrodes, use 10 -3 mol L -1 The lead nitrate solution was activated for 12...

Embodiment 2

[0044] Weigh respectively poly-1-aminoanthraquinone (PAAQ) 6.06mg, polyvinyl chloride (PVC) 200mg, dioctyl phthalate (DOP) 400mg, sodium tetraphenylborate (NaTPB) 6.06mg, these four kinds The reagent was added to the beaker, and 5 mL of tetrahydrofuran was added, and dissolved by intermittent ultrasonication for 1 hour. Then the mixed solution is poured on the flat bottom glass and left for 24 hours. After the THF is completely volatilized, a tough and elastic film is obtained. The composition of the film is PAAQ: PVC: DOP: NaTPB=1: 33: 66: 1, The thickness of the film was 0.16 mm. A disc with a diameter of about 16 mm is cut from the obtained film, and is glued to a PVC pipe end with an inner diameter of 13 mm and an outer diameter of 15 mm with epoxy resin. Fill the tube with 0.1mol·L -1 of Pb(NO 3 ) 2 Reference solution, and insert the Ag / AgCl electrode as the internal reference electrode. Before using the electrodes, use 10 -3 mol L -1 The lead nitrate solution was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com