Preparation method of breathable polytetrafluoroethylene film for fabric

A technology of polytetrafluoroethylene and breathable membrane, which is applied in applications, clothing, protective clothing, etc., can solve the problems of overweight fabrics and uncomfortable wearing, and achieve the effects of preventing bacterial growth, comfortable wearing experience, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0019] Embodiment 1~4: a kind of preparation method of polytetrafluoroethylene gas-permeable film for fabric, comprises the following steps:

[0020] S1. Add N,N-dimethylformamide, ethyl acetate, diacetone alcohol, dioctyl phthalate and silane coupling agent into the reaction kettle, and stir evenly;

[0021] S2. Put sodium carboxymethyl cellulose and nano-graphene into the reactor, and disperse at high speed for 30-60 minutes;

[0022] S3. Add polytetrafluoroethylene resin, fluorine-containing polyacrylate, polyether ether ketone, hydroquinone and chitosan into the reaction kettle, and heat and melt;

[0023] S4. Blow molding by a film blowing machine to obtain the polytetrafluoroethylene film with high water vapor transmission rate.

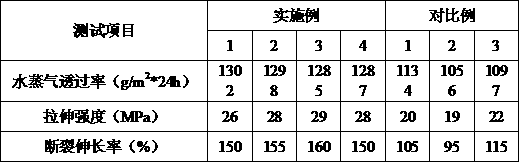

[0024] The specific component ratio of the high water vapor transmission rate polytetrafluoroethylene film of each embodiment is as follows, all are parts by weight:

[0025] Table 1

[0026] components Example 1 Example 2 Exa...

Embodiment 1

[0028] The silane coupling agent in embodiment 1 is 3-chloropropyltriethoxysilane, the silane coupling agent in embodiment 2 is 3-aminopropyltriethoxysilane, and the silane coupling agent in embodiment 3 The agent is 3-(methacryloyloxy)propyltrimethoxysilane, and the silane coupling agent in Example 4 is 3-aminopropyltriethoxysilane and 3-(methacryloyloxy)propyl A mixture of trimethoxysilanes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com