A waterproof and breathable cast film composite material and its preparation method

A composite material and airflow technology, which is applied in the field of waterproof and breathable cast film composite materials and its preparation, can solve the problems of complex production process, high cost, harsh material selection, etc., and achieve the effect of simple production process, low cost and light texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

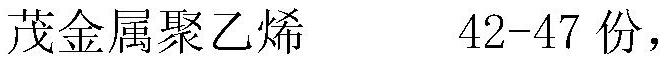

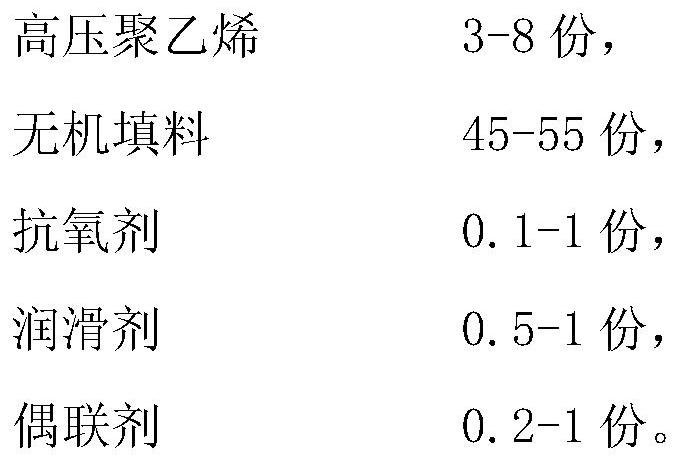

[0023] Take the raw materials by weighing the components and proportioning ratio (parts by weight) in Table 1

[0024] Mix in a high mixer for 5 minutes, mix the above raw materials evenly, and extrude the mixed blend through a twin-screw extruder to granulate. The temperature of each zone of the extruder is 150°C from the feeding section to the head. . The prepared mixture was subjected to a performance test, and the test results are shown in Table 2.

Embodiment 2

[0026] Take the raw materials by weighing the components and proportioning ratio (parts by weight) in Table 1

[0027] Mix in a high mixer for 10 minutes, mix the above raw materials evenly, and extrude the mixed blend through a twin-screw extruder to granulate. The temperature of each zone of the extruder is 170°C from the feeding section to the head. . The prepared mixture was subjected to a performance test, and the test results are shown in Table 2.

Embodiment 3

[0029] Take the raw materials by weighing the components and proportioning ratio (parts by weight) in Table 1

[0030] Mix in a high mixer for 15 minutes, mix the above raw materials evenly, and extrude the mixed blend through a twin-screw extruder to granulate. The temperature of each zone of the extruder is 150°C from the feeding section to the die head. . The prepared mixture was subjected to a performance test, and the test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com