Super whether resistant high antipollution composite elastic construction paint

An architectural coating and ultra-weather-resistant technology, used in antifouling/underwater coatings, coatings, and biocide-containing paints, etc., which can solve the problems of poor stain resistance, increased molecular weight, and increased Tg value of the coating film , to achieve the effect of low surface tension, strong achromatic power and large electronegativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

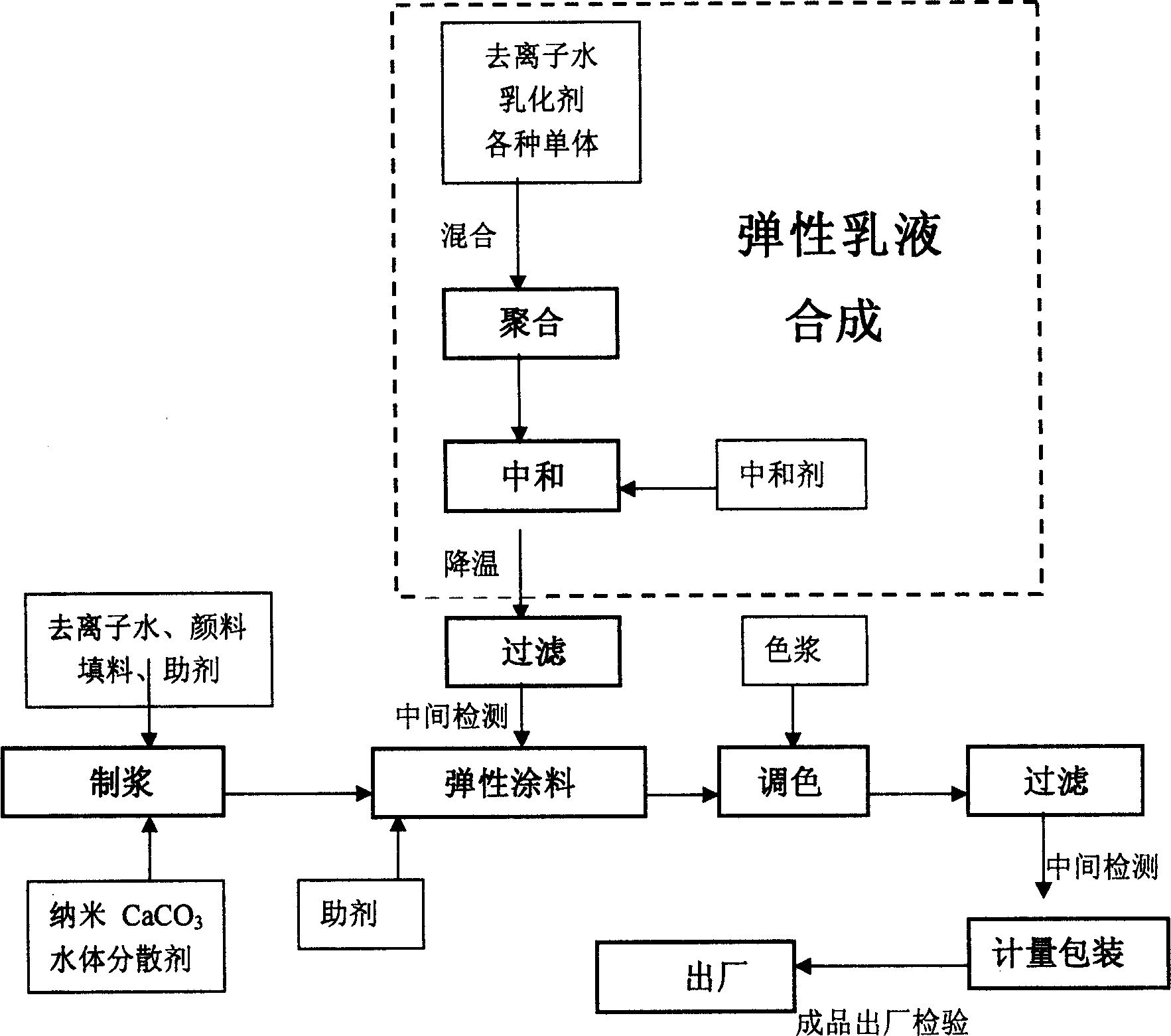

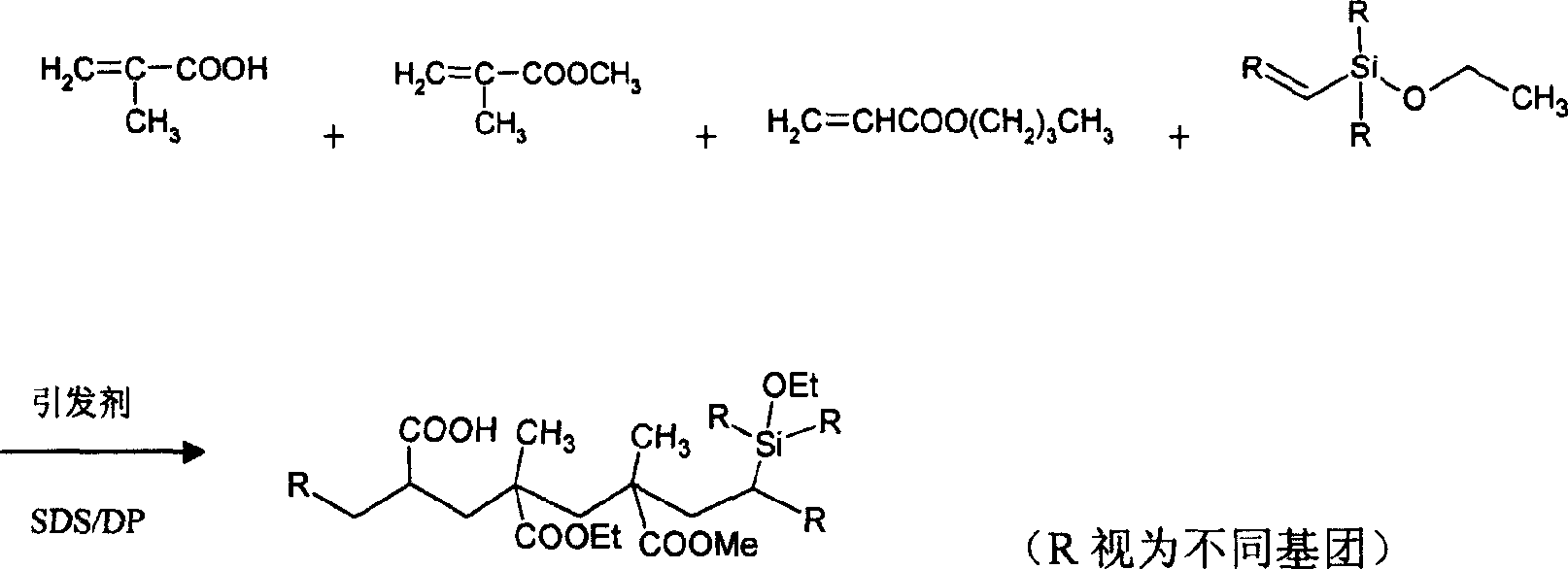

[0029] Embodiment 1: This super-weather-resistant high anti-contamination composite elastic architectural coating mainly includes silicone acrylic elastic emulsion, rutile type TiO 2 , Nano CaCO 3 And water, its weight ratio is: silicone acrylic elastic emulsion 45%, rutile TiO 2 15%, nano CaCO 3 2% and the rest of water, wherein the silicone acrylic elastic emulsion mainly includes methyl methacrylate, butyl acrylate, acrylate, silicone monomer, emulsifier, initiator, PH regulator and water, and its weight ratio is: 11% of methyl acrylate, 32% of butyl acrylate, 1.5% of acrylate, 6% of silicone monomer, 1.5% of emulsifier, 0.2% of initiator, 0.1% of pH regulator and the rest of water.

Embodiment 2

[0030] Embodiment 2: This super-weather-resistant high anti-contamination composite elastic architectural coating mainly includes silicone acrylic elastic emulsion, rutile type TiO 2 , Nano CaCO 3 And water, its weight ratio is: silicone acrylic elastic emulsion 55%, rutile TiO 2 20%, nano CaCO 3 3% and the rest of water, wherein the silicone acrylic elastic emulsion mainly includes methyl methacrylate, butyl acrylate, acrylate, silicone monomer, emulsifier, initiator, PH regulator and water, and its weight ratio is: 13% of methyl acrylate, 37% of butyl acrylate, 3% of acrylate, 8% of silicone monomer, 3% of emulsifier, 0.7% of initiator, 0.15% of pH regulator and the rest of water.

Embodiment 3

[0031] Embodiment 3: The difference from Example 1 is: the silicone acrylic elastic emulsion, rutile TiO 2 , Nano CaCO 3 Add pigments and fillers, dispersants, thickeners, defoamers and pH regulators to water, and the weight ratio is: 45% silicone acrylic elastic emulsion, rutile TiO 2 15%, nano CaCO 3 2%, 10% of pigment and filler, 2% of dispersant, 2% of thickener, 0.5% of defoamer, 0.2% of pH regulator and the rest of water.

[0032] The emulsifier is potassium laurate, the initiator is potassium persulfate, the pH regulator is sodium bicarbonate, the pigment and filler is sericite or silica fume powder; the dispersant is polyphosphate, polyacrylic acid Sodium salt, ammonium polyacrylate, potassium polyacrylate or sodium hexametaphosphate. The thickener is a hydrophobic polyurethane thickener RM8W or TT935 thickener. Described defoamer is latex paint defoamer DEFOAMER334. The pH regulator is the pH regulator of AMP95.

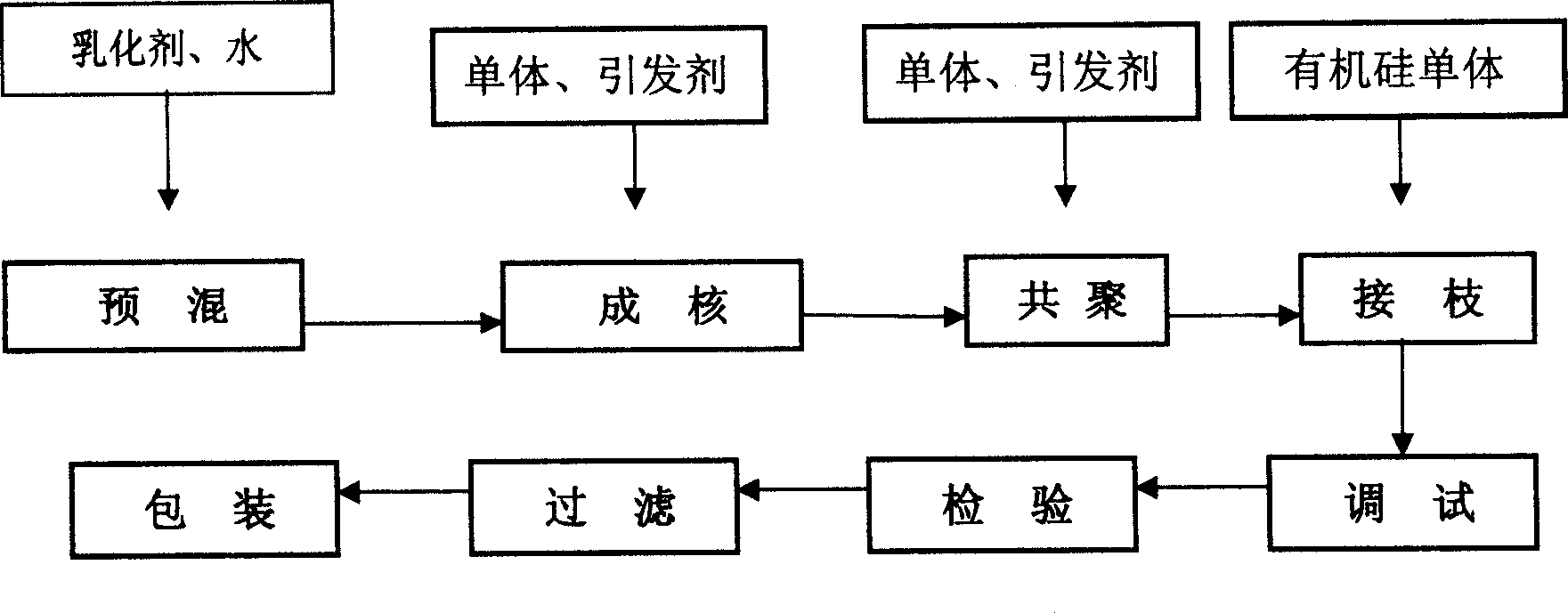

[0033] The production process of silicone acryli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com