Touch screen heat curing peelable blue gel and preparing method thereof

A thermal curing, touch screen technology, applied in applications, coatings, inks, etc., can solve the problems of poor acid and alkali resistance, not easy to peel off, and poor flexibility of protective adhesives, and achieve excellent gloss, easy peeling, and good film-forming properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

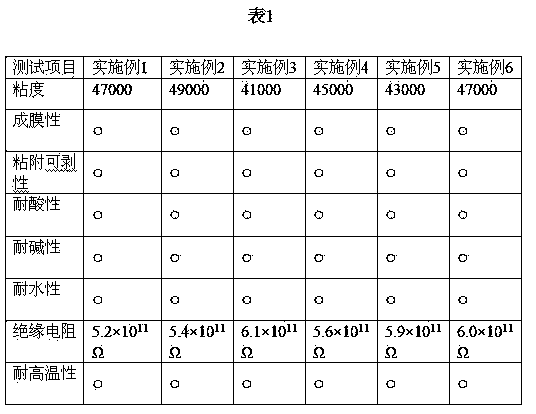

Examples

Embodiment 1

[0044] A heat-cured peelable blue glue for touch screen, which is composed of the following raw materials in weight percentage: 30% PU modified epoxy vinyl ester resin, 10% acrylic modified alkyd resin, 35% melamine formaldehyde resin, hard plasticizer Barium fatty acid 5% and dioctyl azelate 15%, filler nano TiO 2 2%, organic pigment phthalocyanine blue 3%.

[0045] The preparation method of the above-mentioned heat-cured peelable blue glue for the touch screen comprises the following preparation steps:

[0046] Step A, adding plasticizers, fillers and organic pigments in a formula amount into the acrylic modified alkyd resin and stirring evenly to obtain the first mixture;

[0047] Step B, adding the formulated amount of PU modified epoxy vinyl ester resin and melamine formaldehyde resin into the first mixture, stirring evenly and then discharging to obtain a heat-cured peelable blue glue for touch screen.

Embodiment 2

[0049] A kind of touch screen thermosetting peelable blue glue, it is made up of the raw material of following percentage by weight: PU modified epoxy vinyl ester resin 33%, acrylic acid modified alkyd resin 5%, melamine formaldehyde resin 30%, plasticizer hard Barium fatty acid 14% and dioctyl sebacate 14%, filler nano TiO 2 3%, organic pigment iron blue 1%.

[0050] The preparation method of the above-mentioned heat-cured peelable blue glue for the touch screen comprises the following preparation steps:

[0051] Step A, adding plasticizers, fillers and organic pigments in a formula amount into the acrylic modified alkyd resin and stirring evenly to obtain the first mixture;

[0052] Step B, adding the formulated amount of PU modified epoxy vinyl ester resin and melamine formaldehyde resin into the first mixture, stirring evenly and then discharging to obtain a heat-cured peelable blue glue for touch screen.

Embodiment 3

[0054] A kind of touch screen thermosetting peelable blue glue, it is made up of the raw material of following percentage by weight: PU modified epoxy vinyl ester resin 30%, acrylic acid modified alkyd resin 5%, melamine formaldehyde resin 35%, plasticizer hard Barium fatty acid 13% and dioctyl sebacate 13%, filler nano TiO 2 2.5%, organic pigment ultramarine blue 1.5%.

[0055] The preparation method of the above-mentioned heat-cured peelable blue glue for the touch screen comprises the following preparation steps:

[0056] Step A, adding plasticizers, fillers and organic pigments in a formula amount into the acrylic modified alkyd resin and stirring evenly to obtain the first mixture;

[0057] Step B, adding the formulated amount of PU modified epoxy vinyl ester resin and melamine formaldehyde resin into the first mixture, stirring evenly and then discharging to obtain a heat-cured peelable blue glue for touch screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com