Chemical nickel-plating liquor

A technology of electroless nickel plating solution and nickel salt, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of difficulty in obtaining phosphorus, inability to process workpieces, low plating speed, etc., and achieve the best coating appearance Good, low cost, strong throwing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

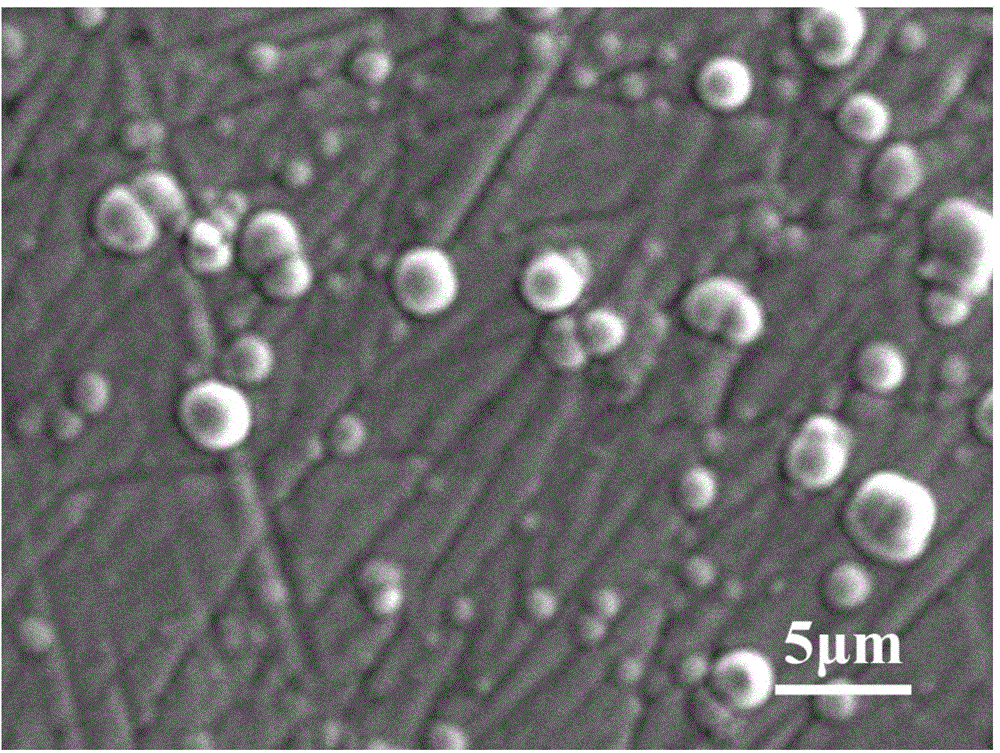

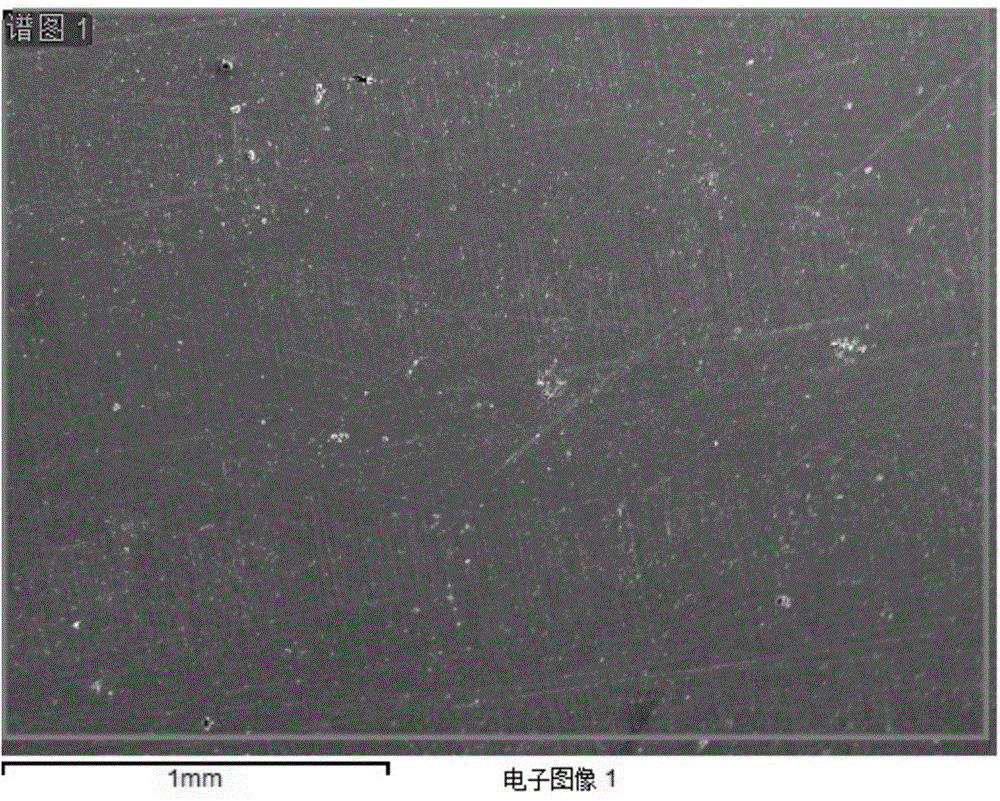

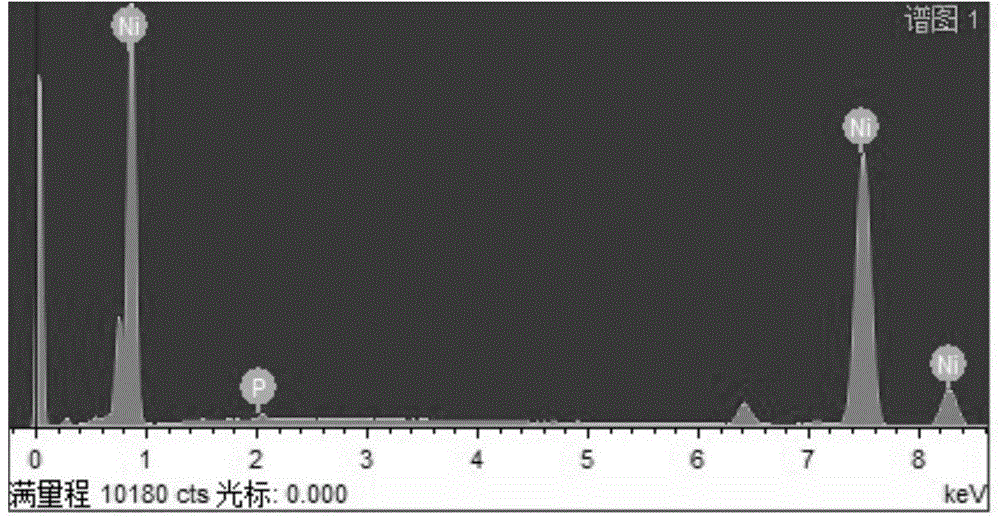

Image

Examples

Embodiment 1

[0027] Present embodiment uses electroless nickel plating liquid of the present invention to carry out electroless nickel plating to low carbon steel, and its operation process is as follows:

[0028] 1. Put 0.5g thiourea and 2g potassium iodate in a beaker, add deionized water, stir with a magnetic stirrer until clarified, add deionized water to a 1L volumetric flask to obtain 1L of stabilizer solution;

[0029] 2. Put 2g sodium polydithiodipropane sulfonate and 0.5g sodium N,N-dimethyldithioformamide propane sulfonate into a beaker, add deionized water, stir with a magnetic stirrer until clear, Add deionized water to a 1L volumetric flask to obtain 1L of phosphorus content inhibitor solution;

[0030] 3. Put 50g of ammonium acetate, 50g of lactic acid, and 140g of succinic acid into a beaker, add deionized water, stir with a magnetic stirrer until clarification, and obtain 1L of complexing agent after constant volume in a 1L volumetric flask;

[0031] Wherein, the sequence ...

Embodiment 2

[0035] Present embodiment uses electroless nickel plating liquid of the present invention to carry out electroless nickel plating to stainless steel, and its operation process is as follows:

[0036] 1. Put 0.8g of thiourea, 1g of potassium iodide, and 0.5g of cerium sulfate into a beaker, add deionized water, stir with a magnetic stirrer until clear, add deionized water to a 1L volumetric flask to obtain 1L of stabilizer solution ;

[0037] 2. Put 0.5g of methylthiourea and 4g of isothiourea propanesulfonic acid inner salt into a beaker, add deionized water, stir with a magnetic stirrer until clarified, add deionized water to a 1L volumetric flask to obtain Phosphorus content inhibitor solution 1L;

[0038] 3. Put 40g of sodium acetate, 70g of lactic acid, and 100g of succinic acid into a beaker, add deionized water, stir with a magnetic stirrer until clarification, and obtain 1L of complex complexing agent after constant volume in a 1L volumetric flask;

[0039] Wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com