Copper plating solution for PCB (printed circuit board) through holes, and preparation method and plating method thereof

A through-hole electroplating and copper solution technology, which is applied in the direction of electrical connection formation of printed components, can solve the problems of poor plating ability of copper plating layer, uneven copper plating layer, poor ductility, gloss and toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A copper electroplating solution for PCB through holes, each component of the copper electroplating solution and its content are:

[0083] Copper sulfate pentahydrate: 70g / L

[0084] Sulfuric acid: 105g / L

[0086] Brightener: 5g / L

[0087] Carrier: 3g / L

[0088] Leveling agent: 2g / L

[0089] Deionized water balance;

[0090] And the concentration ratio of copper sulfate pentahydrate to sulfuric acid is 1:1.5.

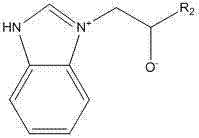

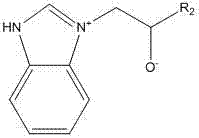

[0091] The brightener is a mixture of 2-mercaptobenzimidazole and ethylenethiourea with a weight ratio of 1.5:1; the carrier is polyethylene glycol with a molecular weight of 2000.

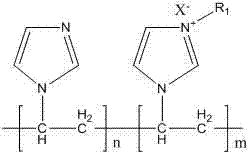

[0092] The leveling agent is a mixture of leveling agent A and leveling agent B with a weight ratio of 1.2:1; wherein, the leveling agent A is a polyvinylimidazolium quaternary ammonium compound, and the leveling agent B is N- Polymer of vinylimidazole and epoxy compound.

[0093] The structural formula of the leveling agent A is:

[0094]

[...

Embodiment 2

[0108] A copper electroplating solution for PCB through holes, each component of the copper electroplating solution and its content are:

[0109] Copper sulfate pentahydrate: 90g / L

[0110] Sulfuric acid: 150g / L

[0112] Brightener: 15g / L

[0113] Carrier: 10g / L

[0114] Leveling agent: 5g / L

[0115] Deionized water balance;

[0116] And the concentration ratio of copper sulfate pentahydrate to sulfuric acid is 1:1.67.

[0117] The brightener is a mixture of 2-mercaptobenzimidazole and ethylenethiourea in a weight ratio of 2:1; the carrier is polyethylene glycol with a molecular weight of 3500.

[0118] The leveling agent is a mixture of leveling agent A and leveling agent B with a weight ratio of 1.5:1; wherein, the leveling agent A is a polyvinylimidazolium quaternary ammonium compound, and the leveling agent B is N- Polymer of vinylimidazole and epoxy compound.

[0119] The structural formula of the leveling agent A is:

[0120]

[0...

Embodiment 3

[0134] A copper electroplating solution for PCB through holes, each component of the copper electroplating solution and its content are:

[0135] Copper sulfate pentahydrate: 110g / L

[0136] Sulfuric acid: 200g / L

[0138] Brightener: 25g / L

[0139] Carrier: 15g / L

[0140] Leveling agent: 10g / L

[0141] Deionized water balance;

[0142] And the concentration ratio of copper sulfate pentahydrate to sulfuric acid is 1:1.82.

[0143] The brightener is a mixture of 2-mercaptobenzimidazole and ethylenethiourea with a weight ratio of 2.5:1; the carrier is polyethylene glycol with a molecular weight of 5000.

[0144] The leveling agent is a mixture of leveling agent A and leveling agent B with a weight ratio of 1.8:1; wherein, the leveling agent A is a polyvinylimidazolium quaternary ammonium compound, and the leveling agent B is N- Polymer of vinylimidazole and epoxy compound.

[0145] The structural formula of the leveling agent A is:

[0146] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com