Preparation method of copper-zinc-iron ternary alloy chemical plating layer on surface of aramid fiber

A ternary alloy and chemical plating technology, which is applied in liquid chemical plating, metal material coating technology, coating, etc., can solve the problem that it is difficult to achieve the desired effect on the surface of aramid fibers, it is difficult to guarantee the bonding force of the surface of aramid fibers, and the consumption of ethanol Large quantity and other problems, to achieve the effect of satisfying electrical conductivity, atmospheric corrosion resistance, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

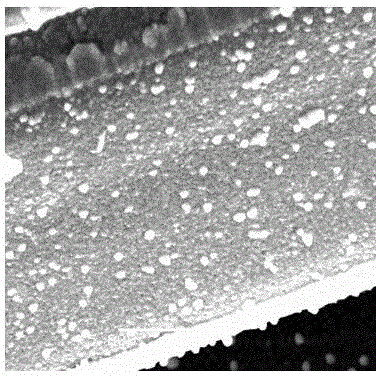

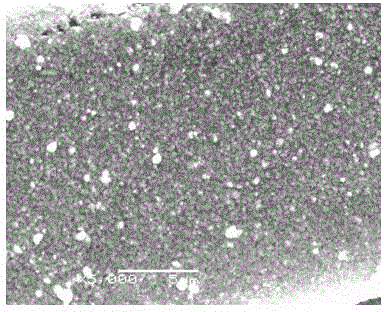

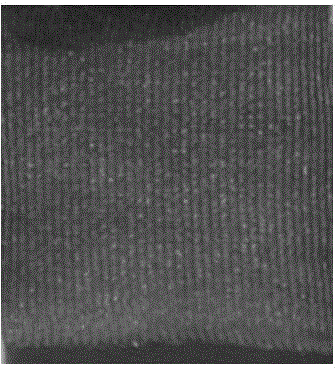

Image

Examples

preparation example Construction

[0032] In order to prepare metallized aramid fibers with conductive, electromagnetic shielding functions and stable properties, the invention provides a method for preparing an electroless copper-zinc-iron-iron ternary alloy coating on the surface of aramid fibers, comprising the following steps:

[0033] (1) Aramid fiber surface modification: including two continuous processes of aramid fiber surface modification by ultraviolet light irradiation and surface nano-film modification;

[0034] (2) Low-concentration colloidal palladium treatment: including low-concentration colloidal palladium activation solution activation, water washing, degumming, and water washing processes;

[0035] (3) Electroless copper-zinc-iron ternary alloy plating process: the aramid fiber treated with surface modification and low-concentration colloidal palladium is immersed in the copper-zinc-iron ternary alloy chemical plating solution, and copper, zinc, and iron ions are treated with B Aldehydic aci...

Embodiment 1

[0044] The surface of the aramid fiber is irradiated continuously with ultraviolet light with a wavelength of 200nm for 60s at a distance of 50mm from the surface of the aramid fiber, and the surface of the aramid fiber is irradiated and modified; then, the surface of the aramid fiber is modified with a nano-sized film, and an environmentally friendly water-based nano-sized treatment solution is used. Containing 0.2% by mass fraction of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 0.03% bis-[γ-(triethoxysilyl)propyl]tetrasulfide, 0.005% The aqueous solution of sodium dodecyl sulfonate was left to stand at room temperature for 72 hours to prepare a hydrosol, and the aramid fiber was immersed in the hydrosol for 3.0 minutes and dried at 60°C for 15 minutes; then soaked in a low-concentration colloidal palladium activation solution at room temperature In 5 minutes, the activation solution was composed of 0.03g / L PdCl 2 , 1g / L VC, 5g / L SnCl 2 , 5mL / L hydrochloric acid, the bal...

Embodiment 2

[0047] The surface of the aramid fiber is irradiated continuously with ultraviolet light with a wavelength of 100nm for 90s at a distance of 100mm from the surface of the aramid fiber, and the surface of the aramid fiber is irradiated and modified; then the surface of the aramid fiber is modified with a nano-sized film, and an environmentally friendly water-based nano-sized treatment solution is used. Containing 0.1% N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 0.05% bis-[γ-(triethoxysilyl)propyl]tetrasulfide, 0.001% The aqueous solution of sodium dodecyl sulfonate was left to stand at room temperature for 60 hours to prepare a hydrosol, and the aramid fiber was soaked in the hydrosol for 2.0 minutes, and dried at 70°C for 5 minutes; then soaked in a low-concentration colloidal palladium activation solution at room temperature 3 minutes, the activation solution was made of 0.1g / L PdCl 2 , 3g / L VC, 6g / L SnCl 2 , 10mL / L hydrochloric acid, the balance is composed of deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com