Patents

Literature

135results about How to "Pollution-free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

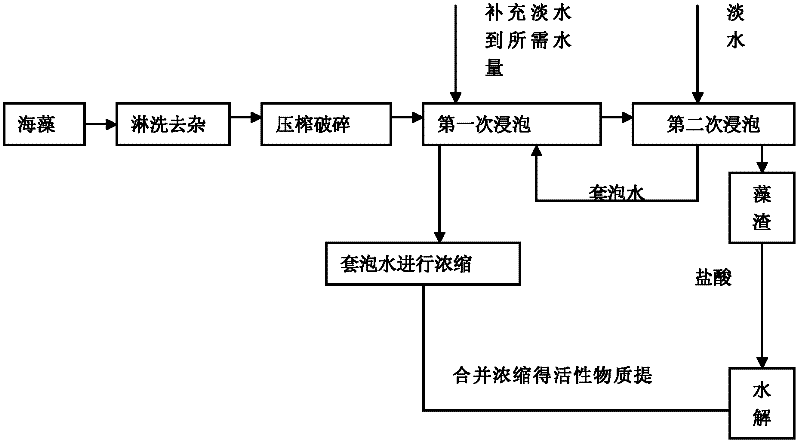

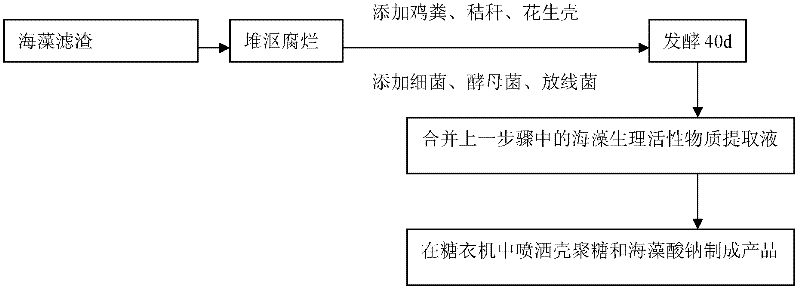

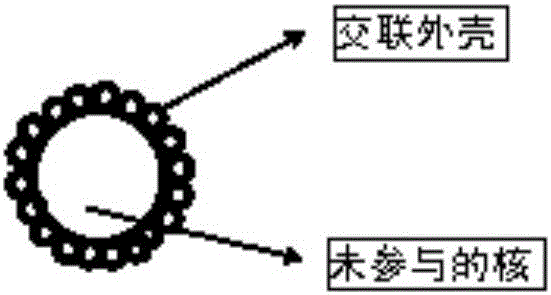

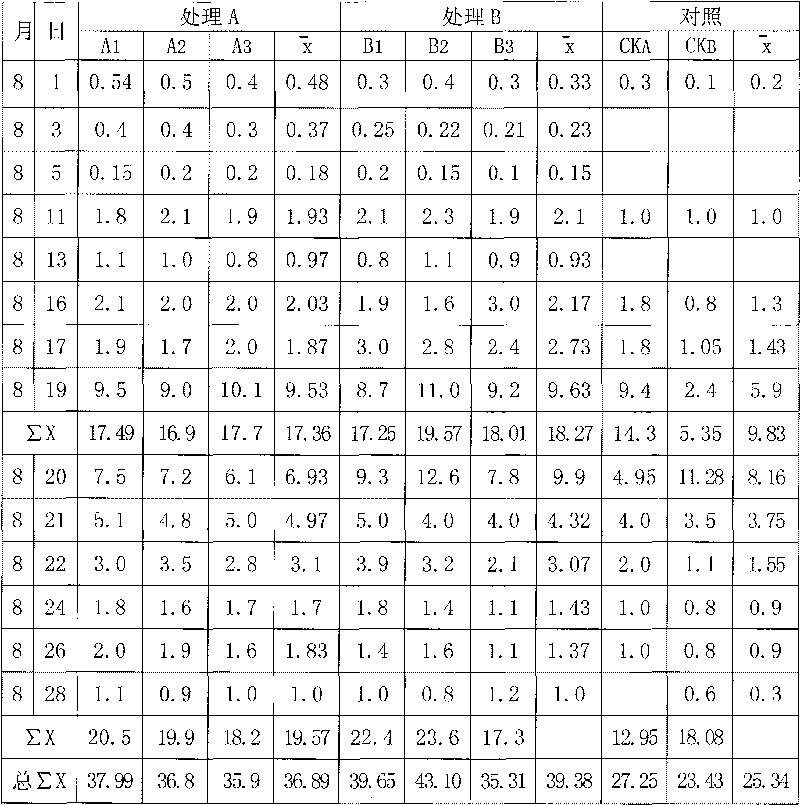

Chitosan coated alga bioorganic fertilizer and preparation method thereof

ActiveCN102515952ADisease resistance and yield increaseWith living soilFertilizer mixturesChemical treatmentFreeze-drying

The invention provides a chitosan coated alga bioorganic fertilizer and a preparation method thereof. The chitosan coated alga bioorganic fertilizer is obtained by adopting a process combining high efficiency physical fragmentation with a chemical processing technology to extract physiological active substances and nutrients of algae, adding zymocytes with the synergism to alga residues, preparing an alga organic fertilizer in an aerobic fermentation mode, adding proper amounts of nitrogen phosphorous potassium, trance elements and functional bacteria, mixing alga extracts with the alga organic fertilizer, freeze-drying, and spraying the obtained alga bioorganic fertilizer with chitosans and a sodium alginate solution. The organic fertilizer which contains various biological growth promoters can improve utilization rates of the nutrients by crops and increase endurances and validities of effective components, and also can increase ventilation and coalescence capabilities of soil, obviously promote the formation of granule structures of the soil, slowly release the nutrients, satisfy demands of plants of different growth stages, and generate obvious positive effects on the crop maturation, output and quality improvements, disease and insect pest resisting and the like.

Owner:SHANDONG BAOYUAN BIOTECH CO LTD

Single-component, high-solid-content and low-volatility organic compound and environment-friendly type varnish composition and preparation method and application of varnish composition

The invention discloses a single-component, high-solid-content and low-volatility organic compound (VOC) and environment-friendly type varnish composition. The varnish composition comprises at least one polymer with a hyper-branched or tree-shaped structure, at least one hydroxyl acrylic resin or hydroxyl methacrylic resin, at least one cross-linking curing agent, at least one acid catalyst, at least one rheology control agent and at least one auxiliary agent. With the adoption of the varnish composition and application of the varnish composition, disclosed by the invention, the viscosity of a varnish coating system can be effectively reduced, and the solid content of the construction can be easily improved to be 58 percent or above; construction VOC emission is reduced to be smaller than or equal to 420g / L; varnish film shrinkage caused in a curing process can also be effectively reduced and a cured multi-coating varnish film has better appearance effect; particularly, the effect in a wet-on-wet process, a three-coating and one-drying process of curing three coatings together or an IPP system of primers, paints and varnishes is obvious.

Owner:LANGFANG NIPPON PAINT

Carcass innocent treatment method

InactiveCN104690075AAchieve recyclingThorough treatmentSolid waste disposalElectronic waste recyclingDecompositionDead body

The invention discloses a carcass innocent treatment method. The method comprises the following steps: low-temperature freezing, crushing, high-temperature decomposition, solid-liquid separation, sterilization and drying. The carcass innocent treatment method disclosed by the invention has the advantages that the treatment is thorough and environment-friendly, and the recycling of resources is achieved, so that the defect of conventional treatment without utilization is overcome by decentralized collection, centralized treatment, cleaning treatment and recycling, and the advantages of being ecological, environment-friendly, pollution-free and recycling are achieved.

Owner:江西绿环生物科技有限公司

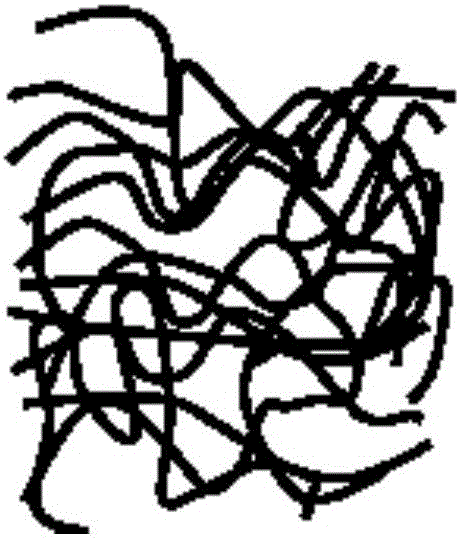

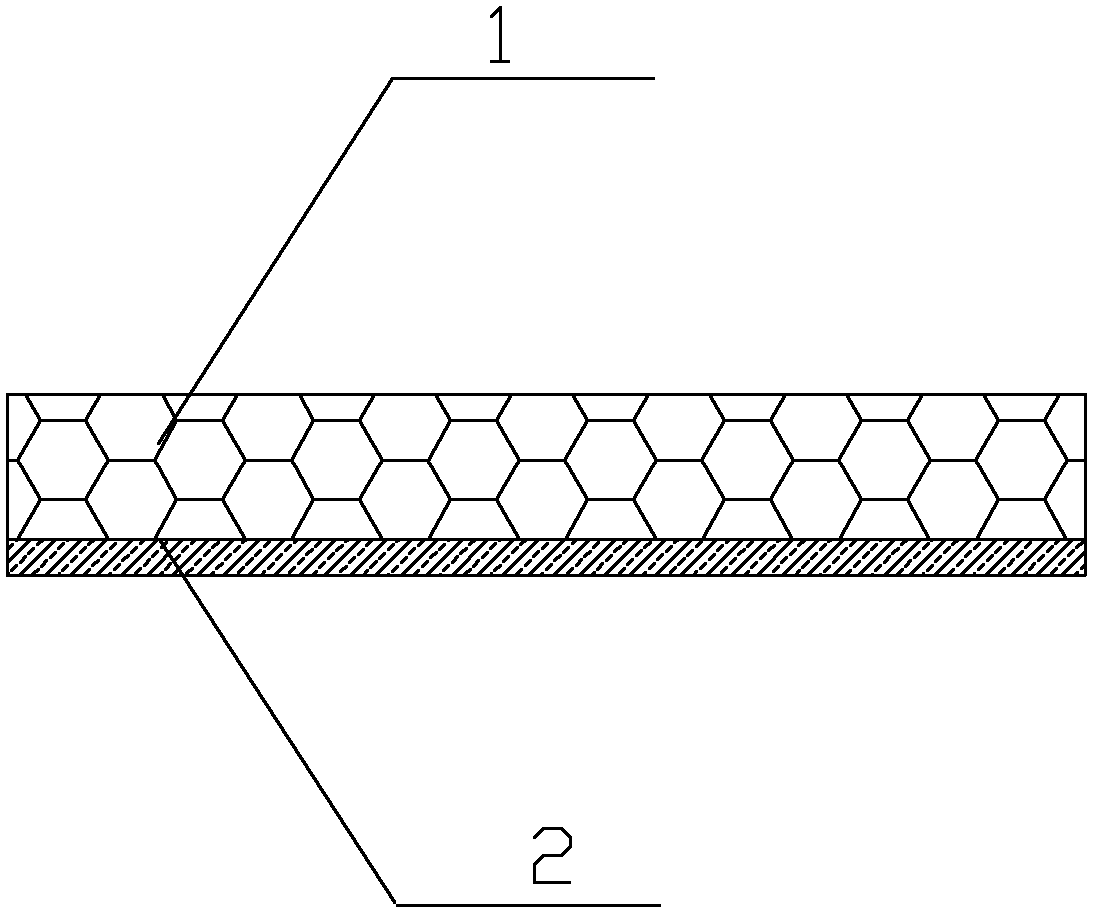

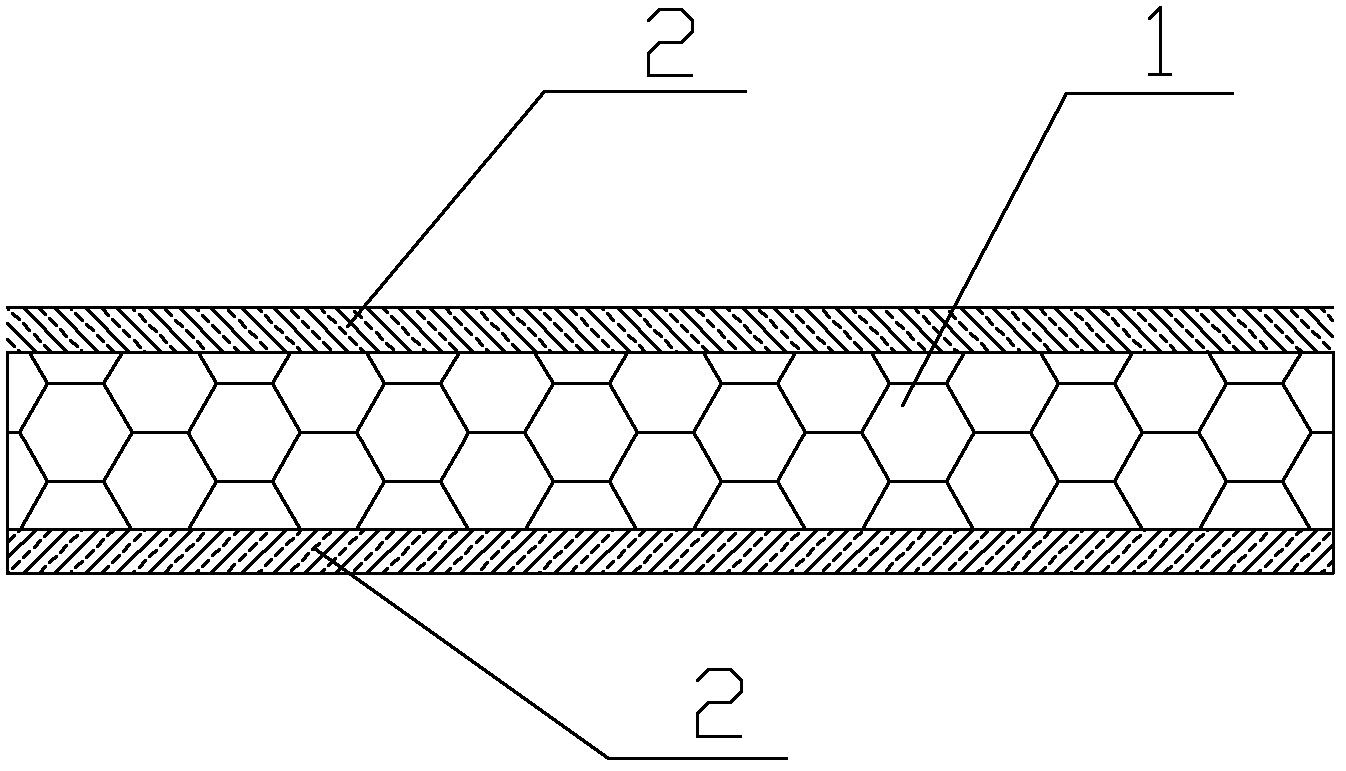

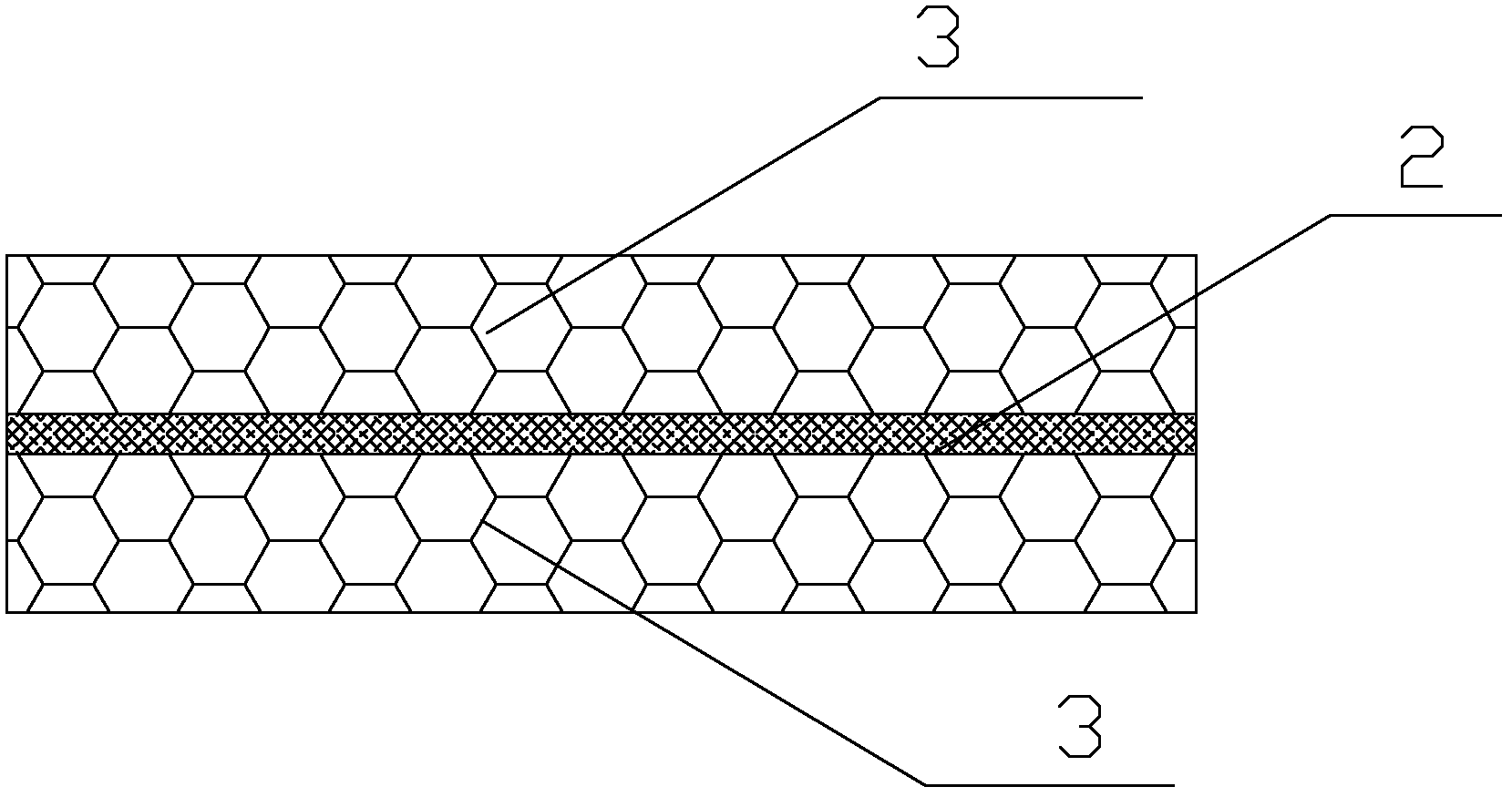

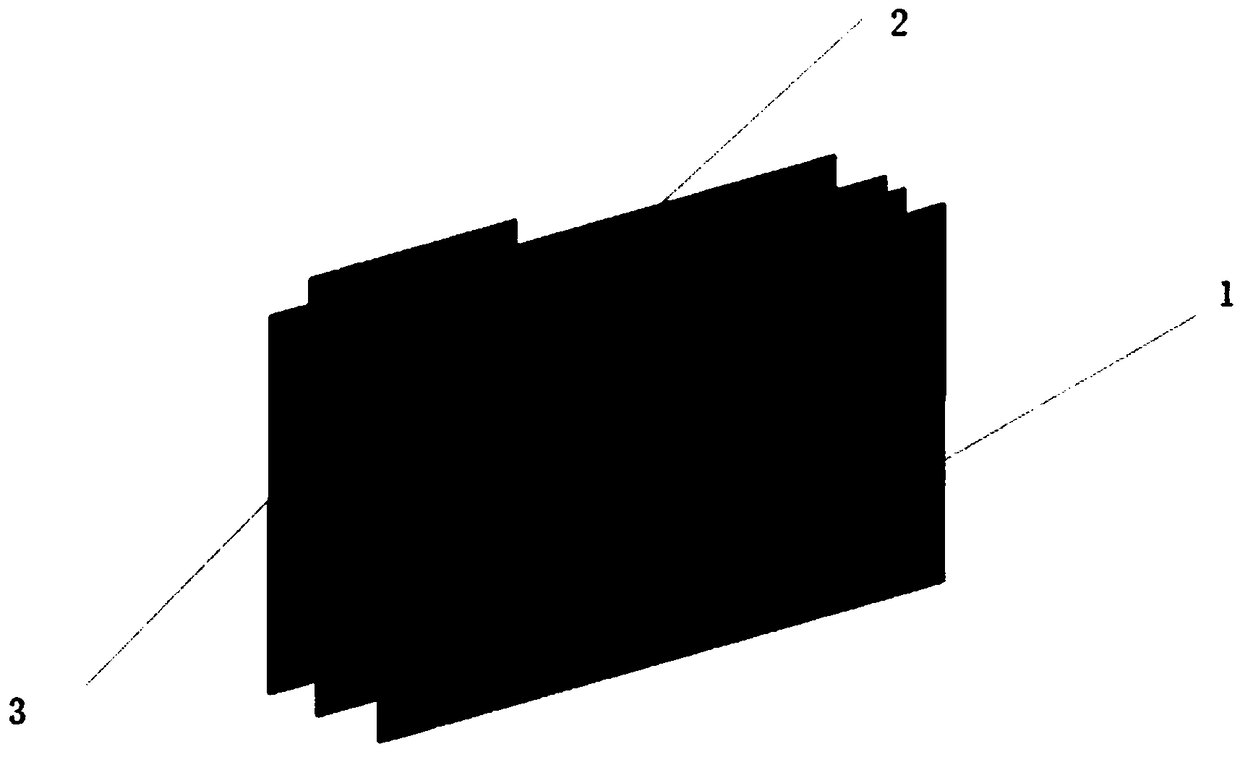

Full-frequency sound absorbing cotton

ActiveCN103177719AReduce stressExtended service lifeLayered productsSound producing devicesFiberEngineering

The invention relates to full-frequency sound absorbing cotton which is provided with a double-layer structure or three-layer structure. The full-frequency sound absorbing cotton of the double-layer structure is composed of a melt-blow high polymer fiber layer and a varicosity polytetrafluoroethylene layer. The full-frequency sound absorbing cotton of the three-layer structure is composed of a melt-blow high polymer fiber layer with double faces compounded with the varicosity polytetrafluoroethylene layer or the varicosity polytetrafluoroethylene layer with double faces compounded with the melt-blow high polymer fiber layer. A high-performance composite micropore thin layer new material has better full-frequency sound absorbing capacity; is environment-friendly, non-toxic and free of peculiar smell, volatile gas, pollution or carcinogenic substances; and is free of stimulation caused by operating similar glass fiber on the skin, can be machined in punching mode, and does not generate dust or scraps and the like. The sound absorbing cotton made of the two materials of the melt-blow high polymer fiber layer and the varicosity polytetrafluoroethylene layer has good thermal resistance, and a sound absorbing effect cannot be affected by high-humidity climate and water.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

Separation and purification process of lentinan

The separation and purification process of lentinan uses the lentinan crude product as raw material and adopts the following steps: using hot water to make extraction, using micrometer-grade filter to make prefiltration, ultrafiltration membrane separation whose molecular weight trapping value is 5-100000 dalton, ultrafiltration membrane concentration whose molecular weight trapping value is 0.6-50000 dalton, using conventional filter to make end filtration, ethyl alcohol precipilation and drying so as to obtain the invented purified lentinan powder.

Owner:武汉东保科技开发有限责任公司

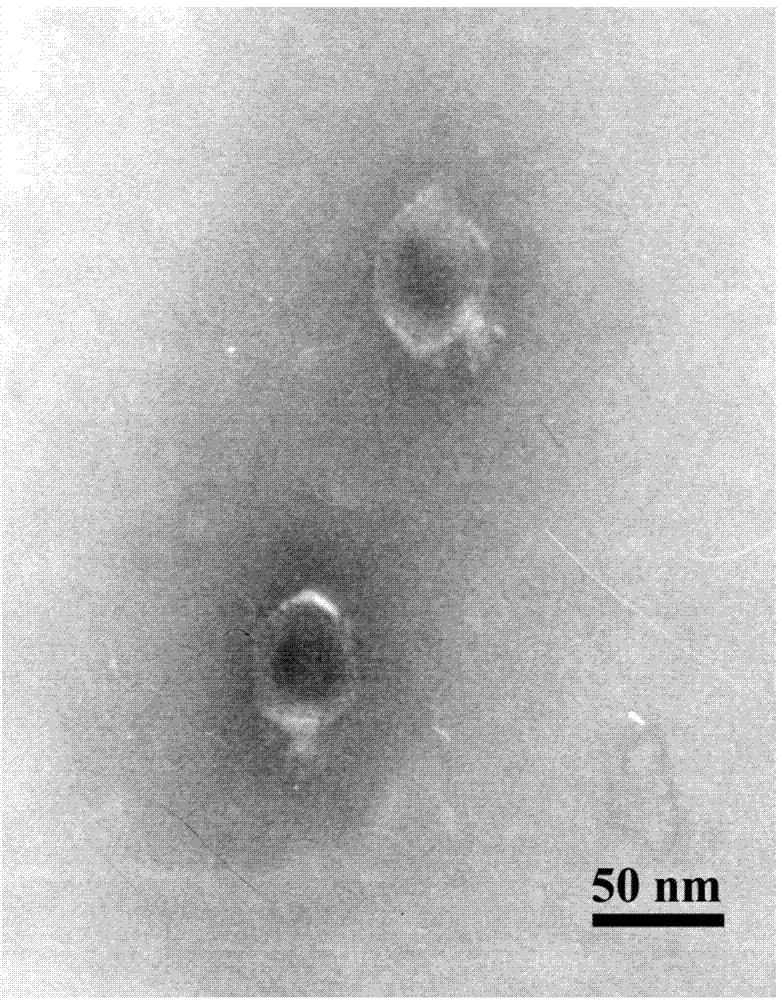

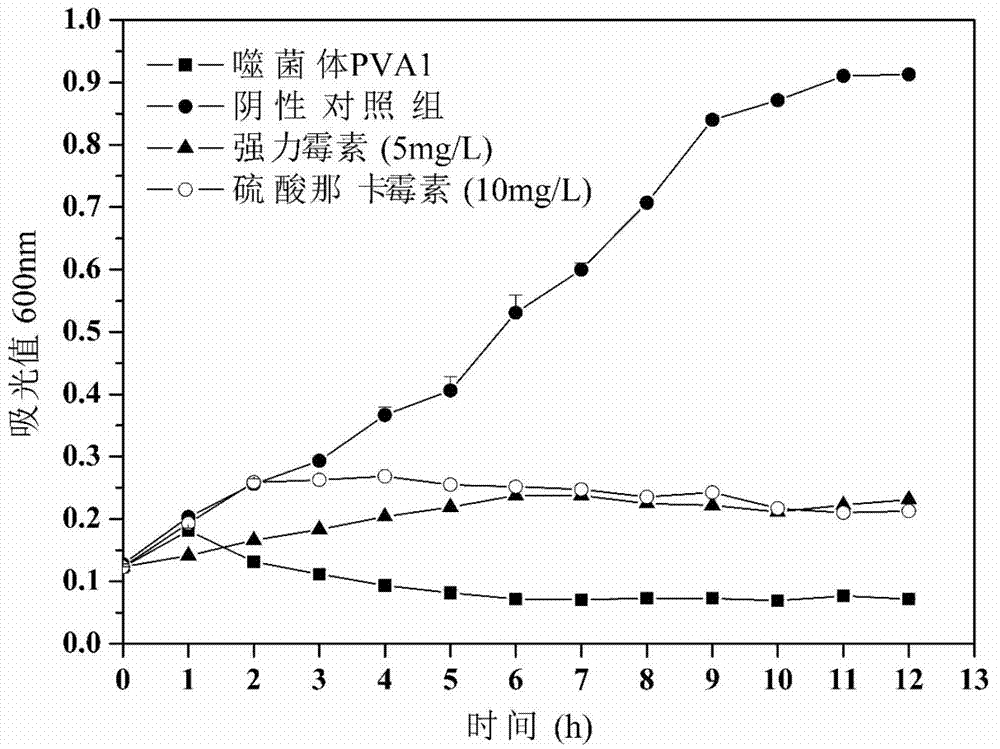

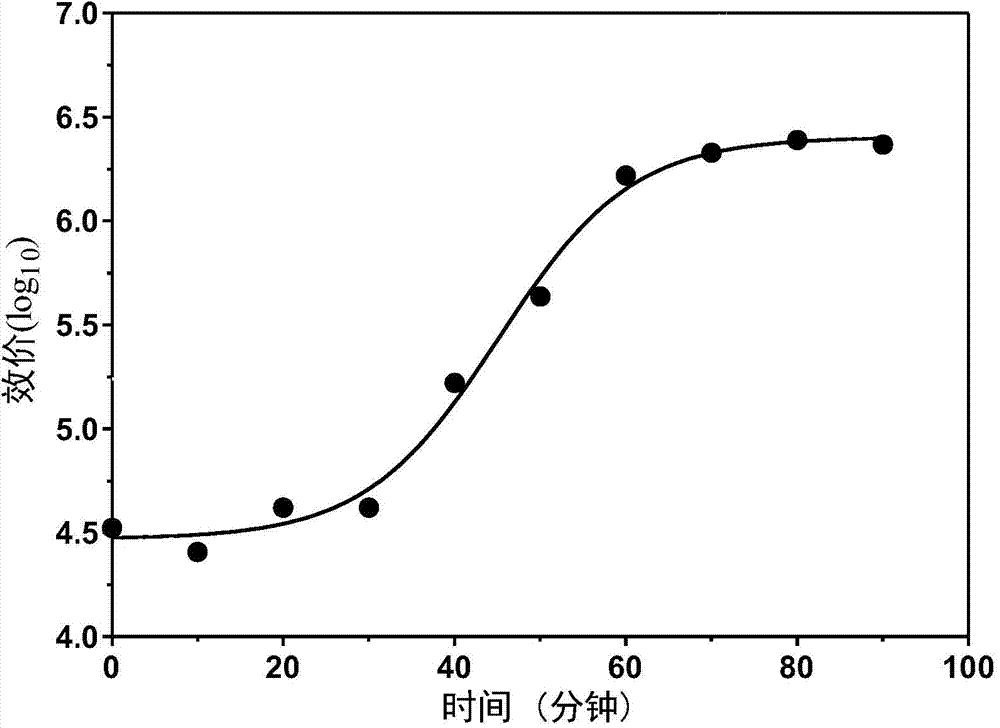

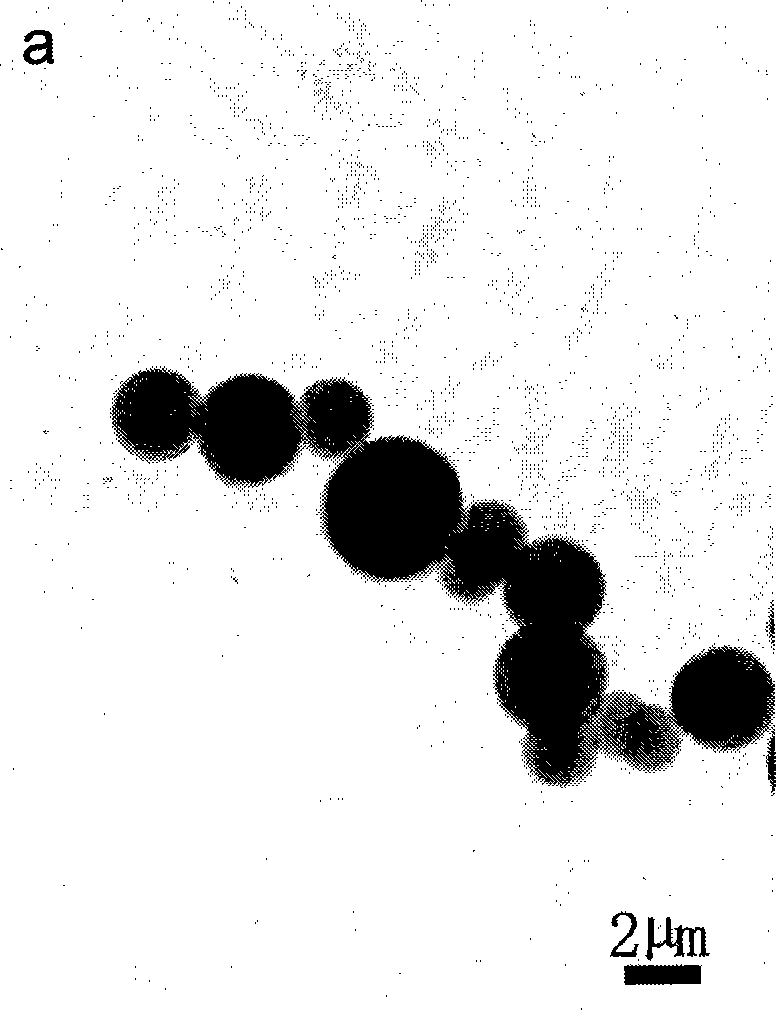

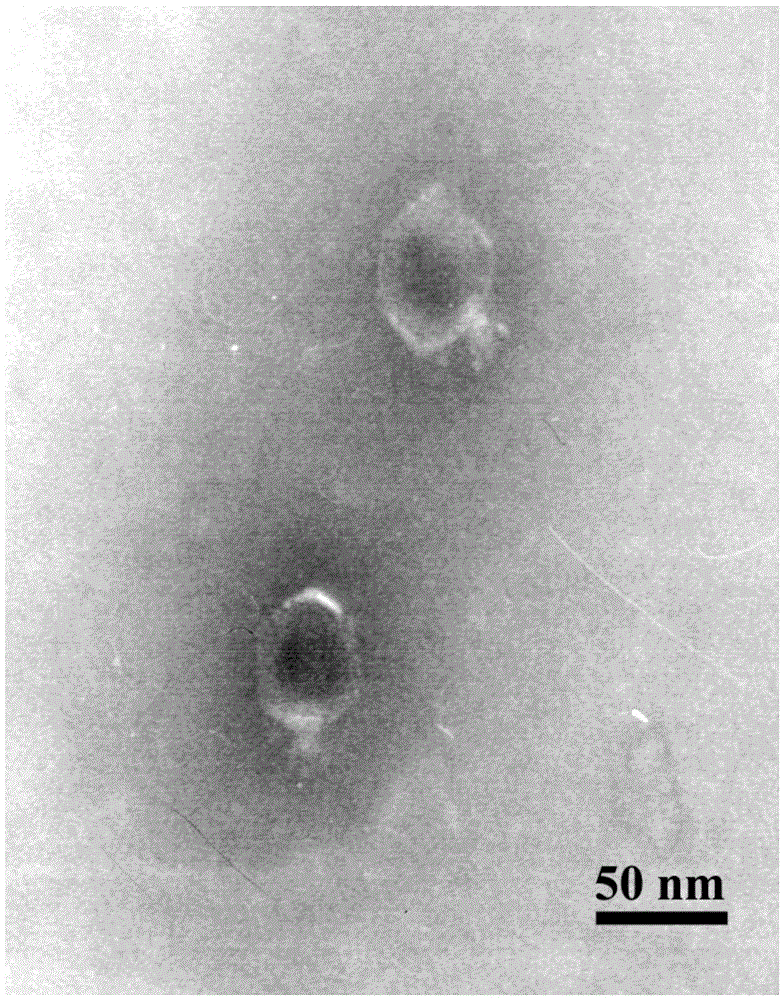

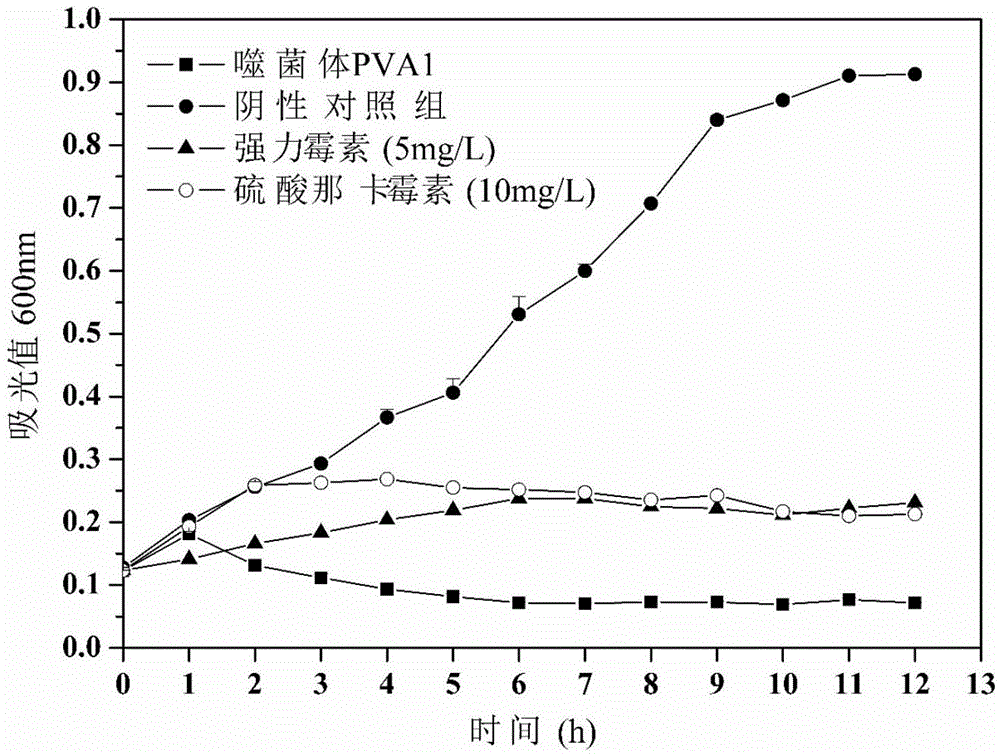

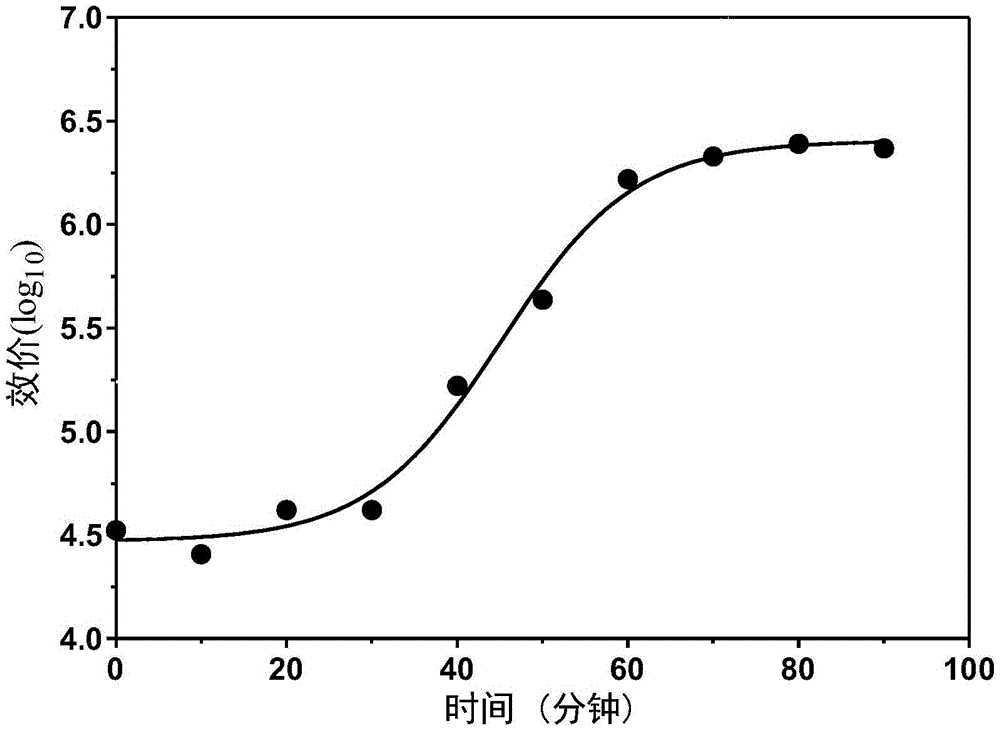

Vibrio alginolyticus bacteriophage and application thereof to prevention of sea cucumber disease

ActiveCN103898015AGood environmental toleranceBroad application prospectsAntibacterial agentsBacteriaLaboratory cultureSeawater

The invention discloses a vibrio alginolyticus bacteriophage and application thereof to prevention of sea cucumber disease, belonging to the technical field of biology. The bacteriophage is collected in the China General Microbiological Culture Collection Center on March 11, 2014 and has a collection number of CGMCC No.8792 and a classification name of Vibrio alginolyticus bacteriophage; the vibrio alginolyticus bacteriophage is a short-tailed phage, has a head diameter being 50 nanometers and tail length being 15 nanometers, and has no shrinkage tail sheath and six short tail fibers. The bacteriophage is used for preventing infection and pollution caused by corresponding vibrio alginolyticus in the culturing process of sea cucumbers, and the potency is more than or equal to 10<5>PFU / mL. The bacteriophage has an inhibiting function on vibrio alginolyticus, and no vibrio alginolyticus-resistant strain is produced within 12 hours; the incubation period lasts for 28 minutes, the burse size is 79, and two orders of magnitude are lowered within 14 days in a seawater culturing environment.

Owner:DALIAN UNIV OF TECH

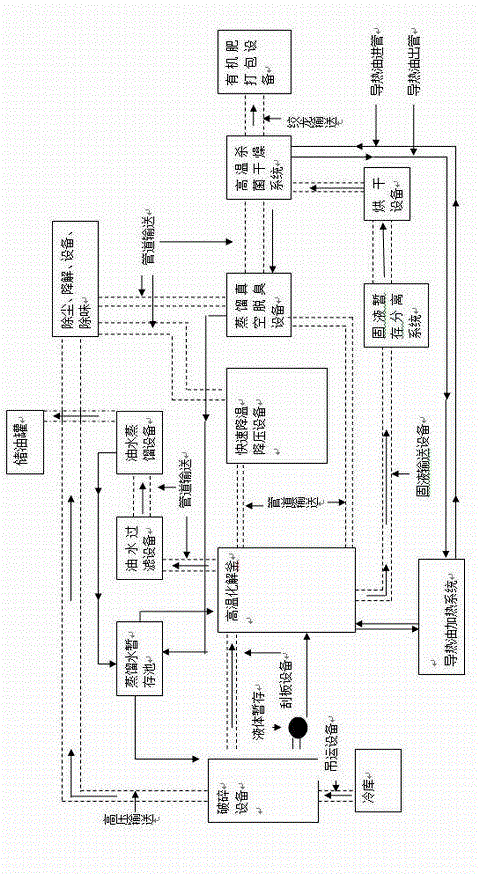

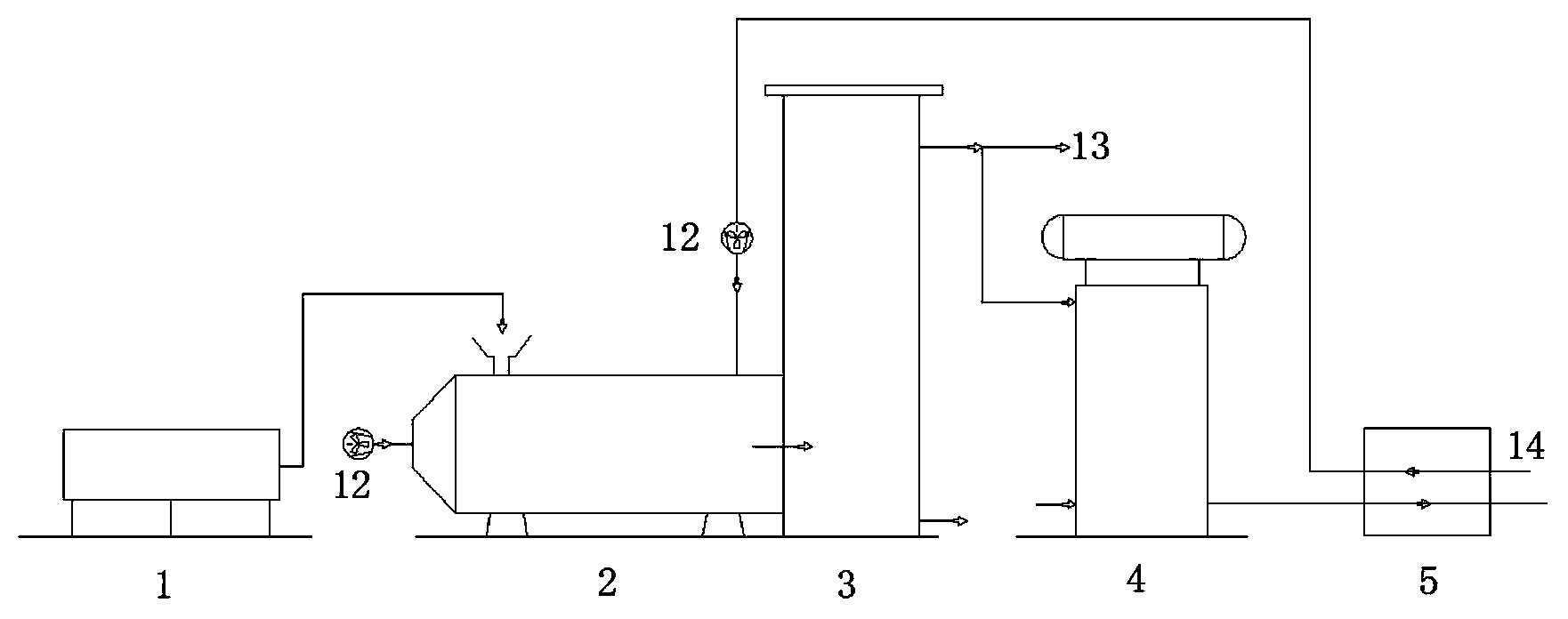

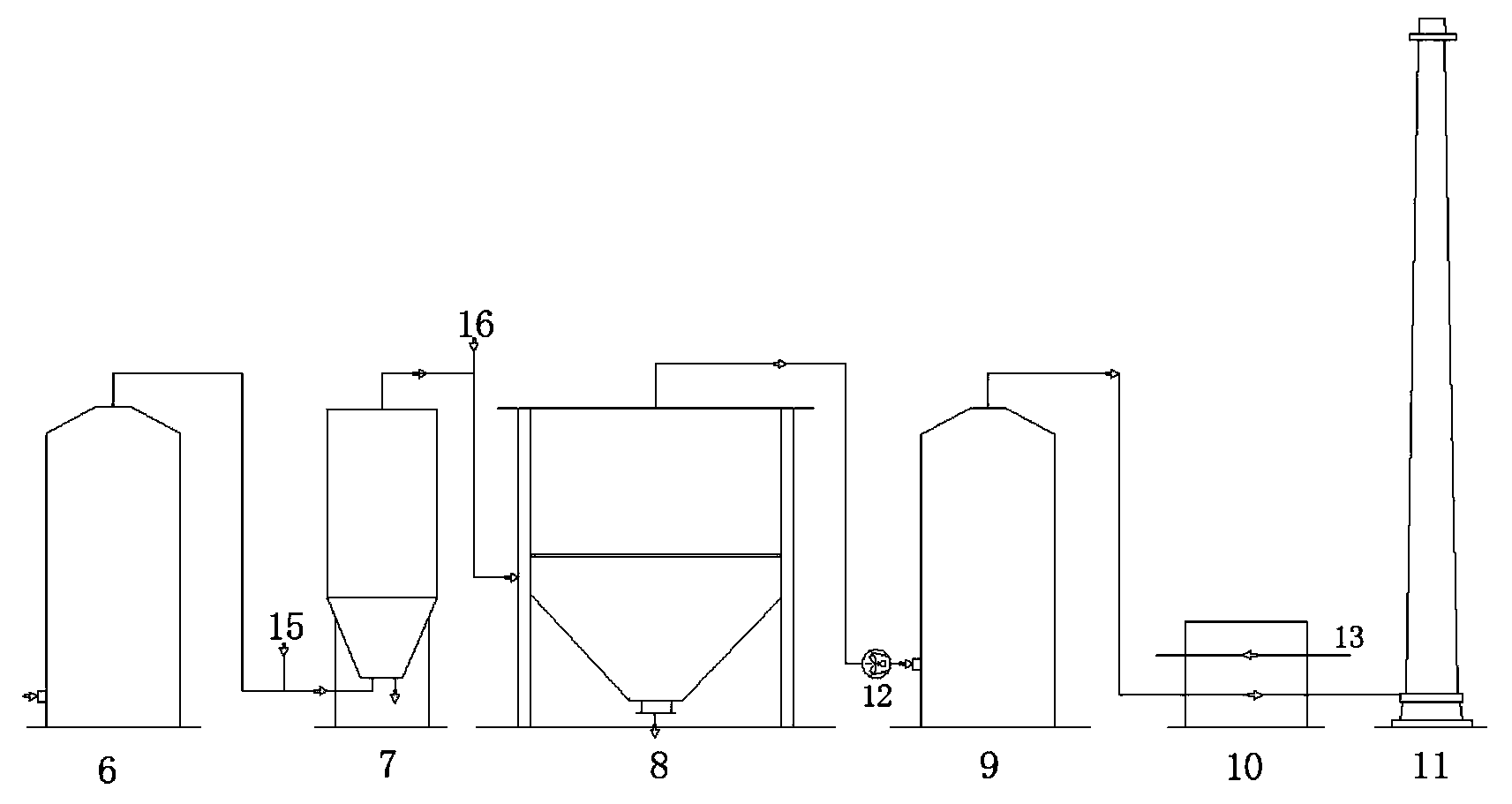

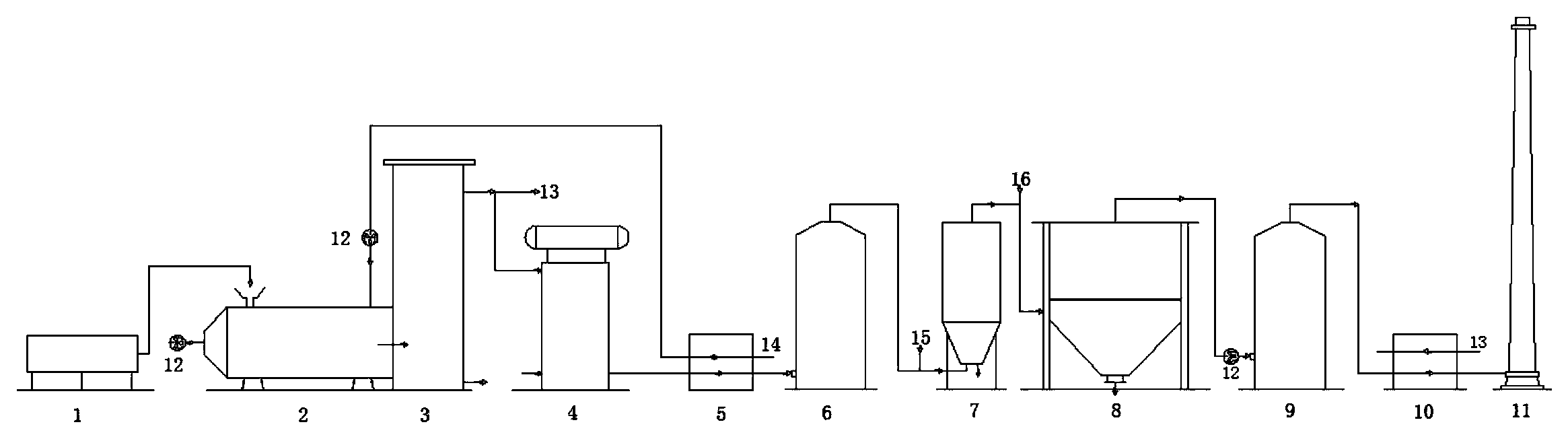

Gas, solid and liquid integrated combustion system

The invention relates to a gas, solid and liquid integrated combustion system, and belongs to the technical field of the environment. The system is composed of a waste gas collection system, a granulation system, a feeding system, a rotating furnace, a combustion furnace, a waste heat boiler, a heat exchanger, a rapid quenching tower, a smoke dry type washing system, a cloth bag dust removal device, a spray tower, a reheater and a chimney. Coal, solid waste and liquid waste are evenly mixed according to the mass ratio (1-12):(2-30):(1-16) in the granulation system for granulation; after collected waste gas is preheated, part of the waste gas enters the rotating furnace, and the other part of the waste gas enters the combustion furnace to be processed through high temperature combustion; high temperature tail gas of the combustion furnace enters the rapid quenching tower, the dry type washing system, the cloth bag dust removal device and the spray tower after heat energy recovery, and is sent to the chimney by a draught fan after the tail gas is cooled and fly ash, dioxin and acid gas are removed, so that emission reaching the standard is completed. Liquid waste produced in the running process of the system is recycled in the granulation system, solid waste such as activated carbon is fed into the rotating furnace to be combusted, and therefore harmless treatment is achieved while running cost of the system is reduced.

Owner:JIANGSU ANQIER WASTE GAS PURIFICATION

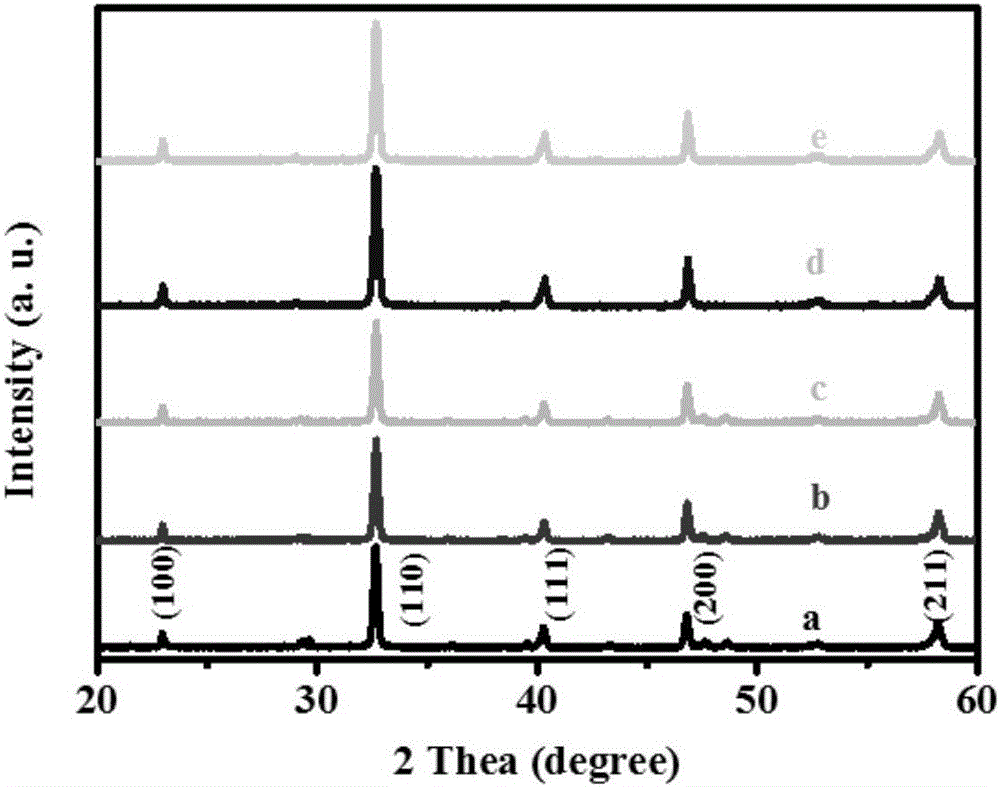

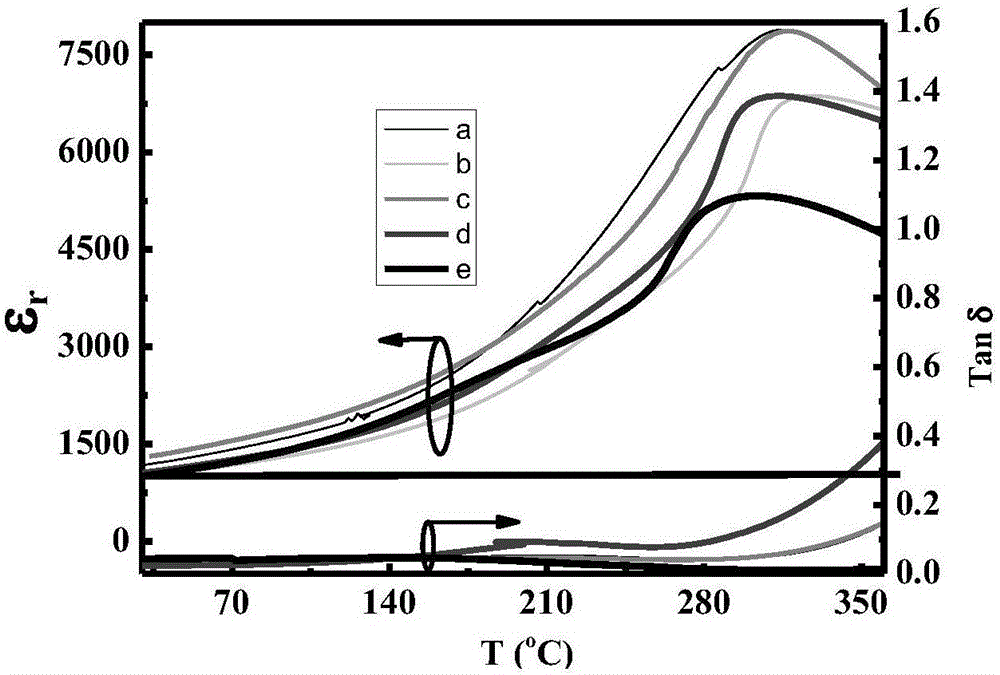

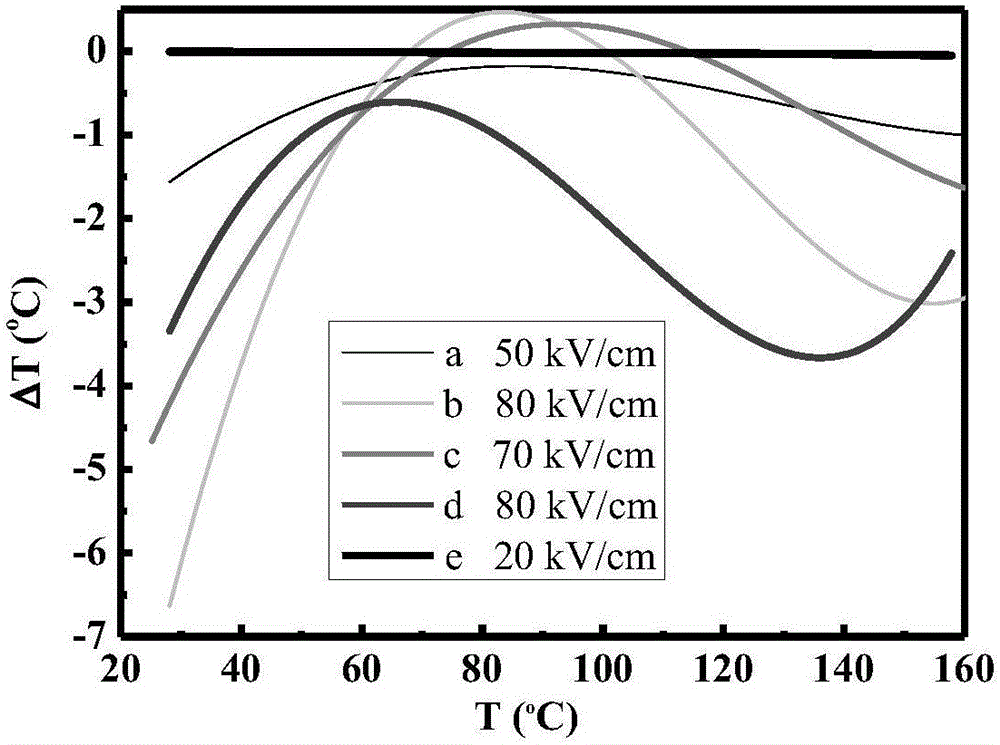

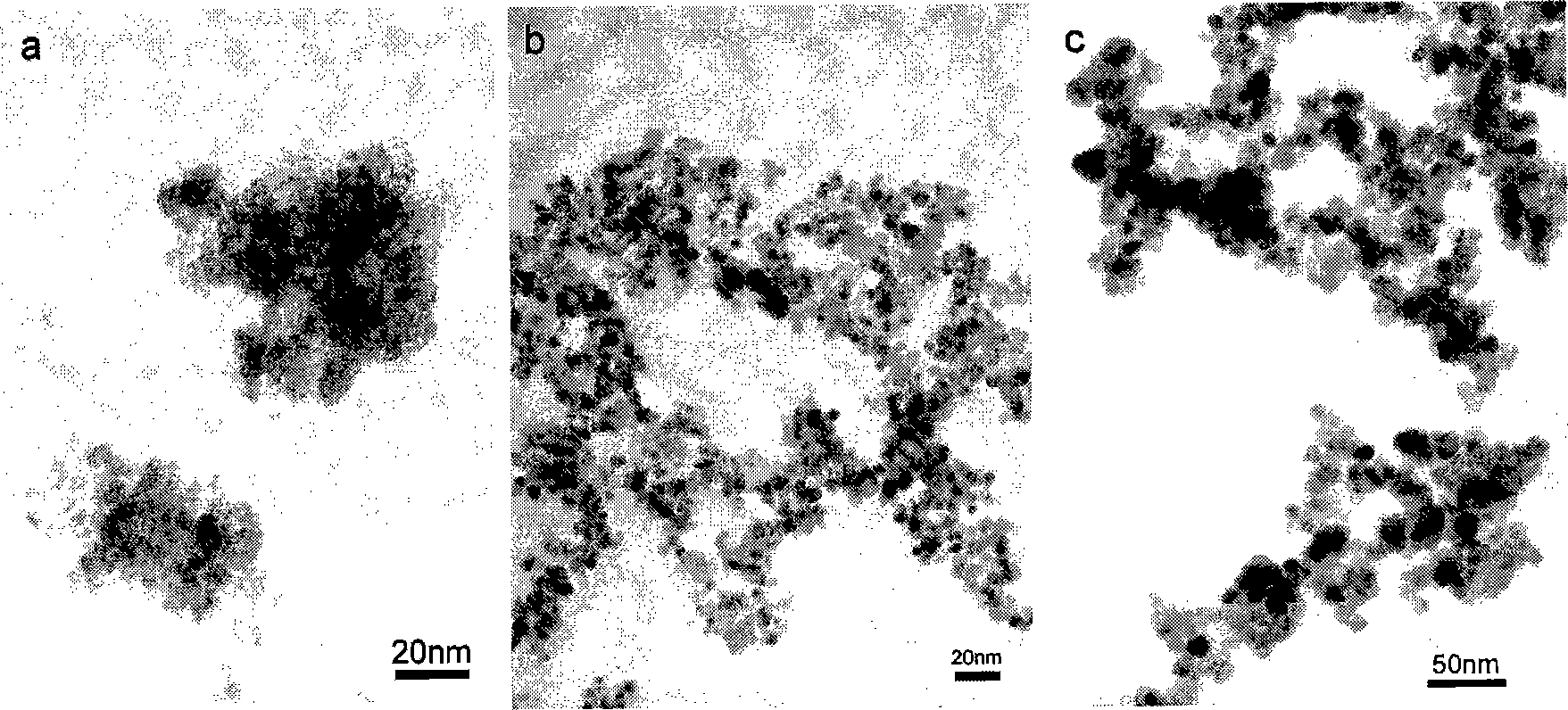

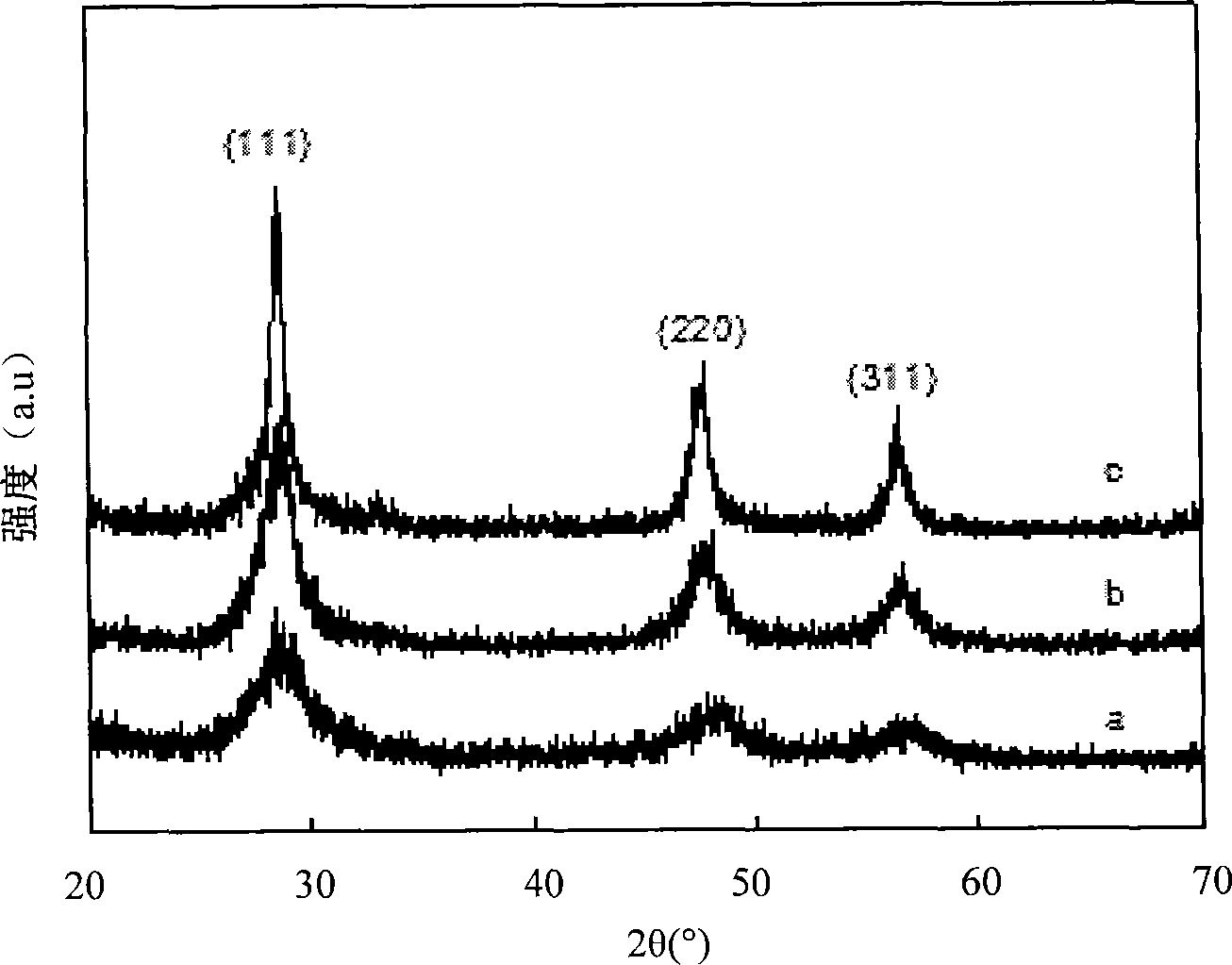

Sodium-bismuth-titanate-based unleaded ceramic with negative electrocaloric effect and preparing method of sodium-bismuth-titanate-based unleaded ceramic

The invention relates to a sodium-bismuth-titanate-based unleaded ceramic with the negative electrocaloric effect and a preparing method of the sodium-bismuth-titanate-based unleaded ceramic. The chemical composition of the ceramic is (1-x)(Na0.5Bi0.5)TiO3-xSrTiO3, wherein x is larger than or equal to 0 but smaller than or equal to 0.10. The ceramic is prepared through combination of a sol-gel method and a microwave sintering method, lead is not contained in the ceramic material, the ceramic has the advantages of being environmentally friendly and nuisanceless, meanwhile, the ceramic material has the high negative refrigerating performance and also has the low dielectric loss energy, the negative electrocaloric effect near the room temperature can reach up to 0-minus 7 DEG C, and the ceramic can be widely applied to development of environment-friendly micro-refrigerators high in refrigerating efficiency and energy conversion efficiency.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for preparing zinc blende nano particle and zinc blende nano particle prepared thereby

InactiveCN101249982ALow reaction temperaturePollution-freeNanostructure manufactureZinc sulfidesHydrothermal synthesisZinc sulfide

Disclosed is a preparing process for zinc sulfide nanometer particles, which comprises steps that a hydrothermal synthesis process is employed, Zn (NO3) 2, 6H2O and Na2S, 9H2O are selected as reaction materials and H2O is used as hydrothermal reaction medium. The process selects microemulsion systems of CTAB / n-butanol / cyclohexane / water to be a zinc sulfide precursor, thereby obtaining the zinc sulfide nanometer particles in hydrothermal reaction in 8-16 hours under the temperature of 120 DGE C-200 DGE C. The preparing process is capable of obtaining the zinc sulfide nanometer particles with sizes of 5-20 nm in adequate distribution and can be used for substrates of light emitting materials.

Owner:CHINA BUILDING MATERIALS ACAD

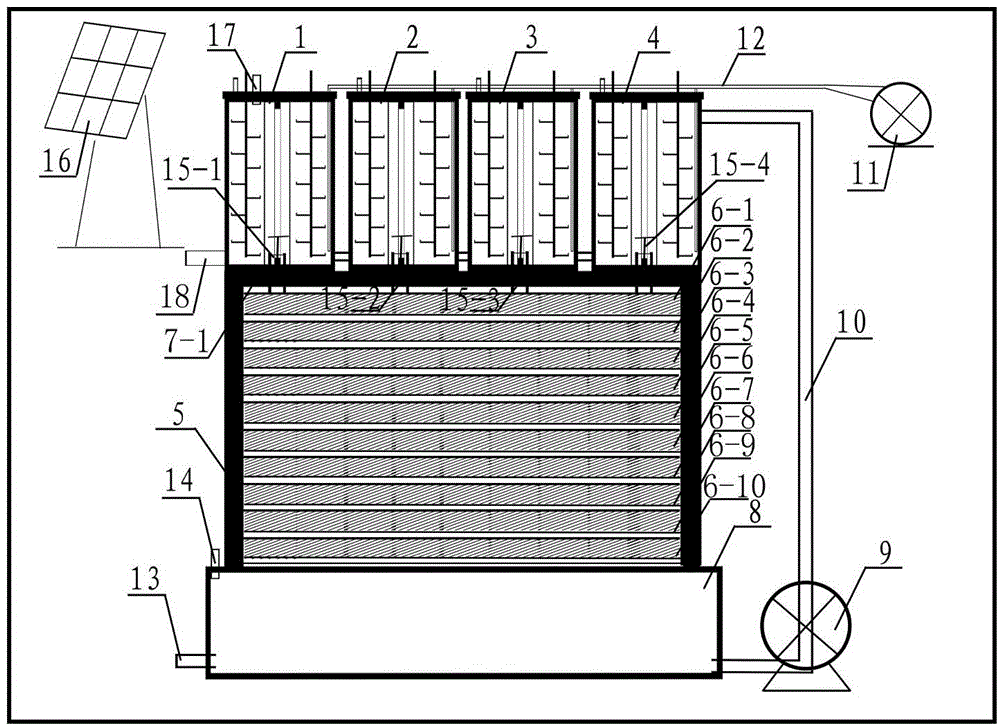

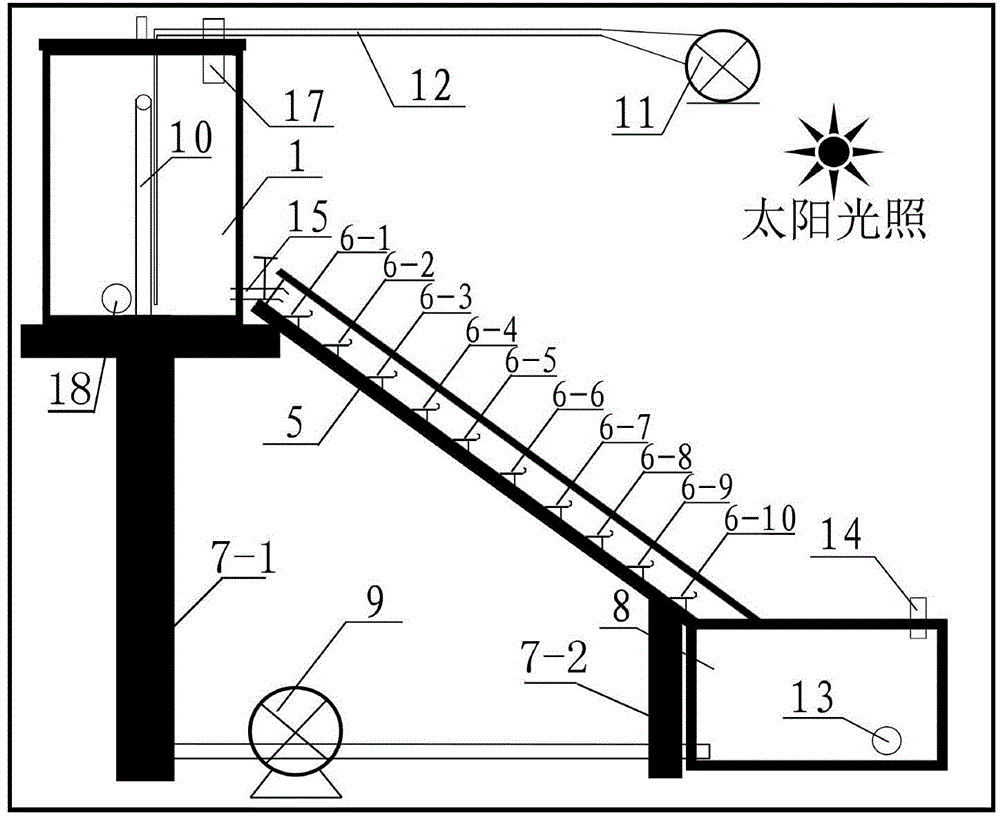

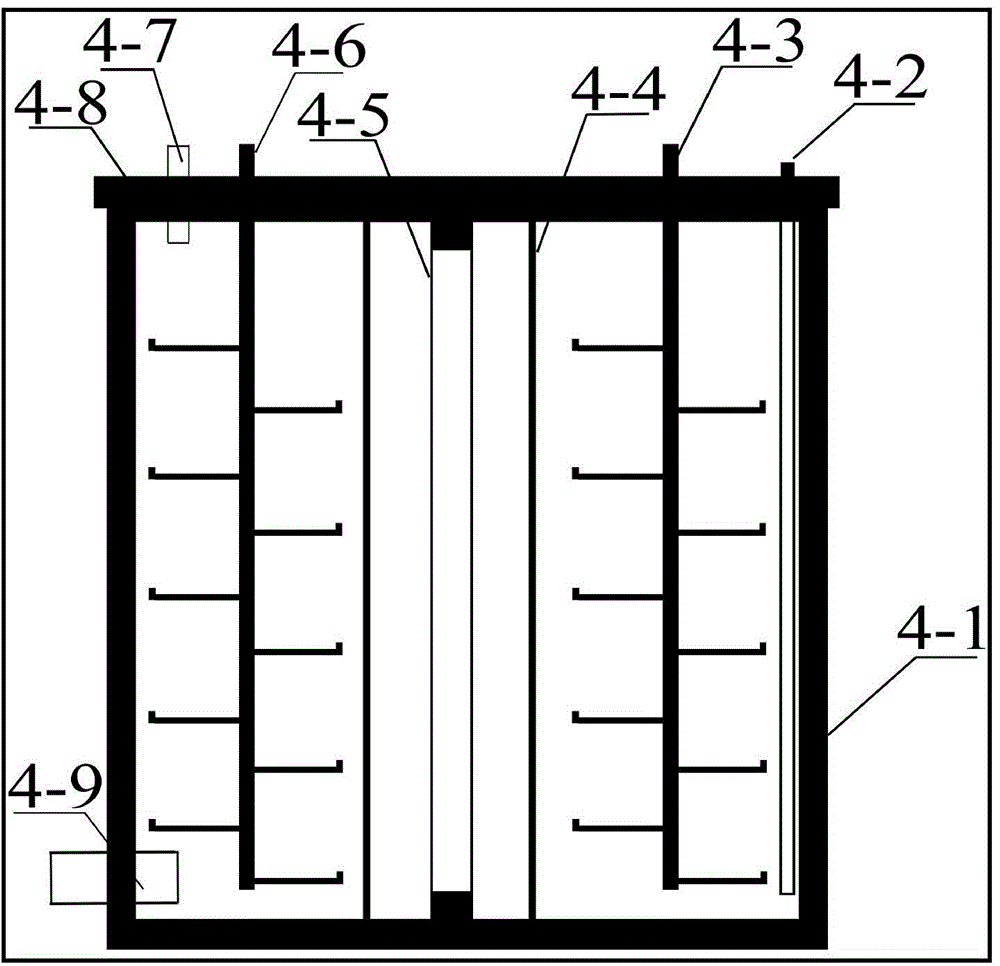

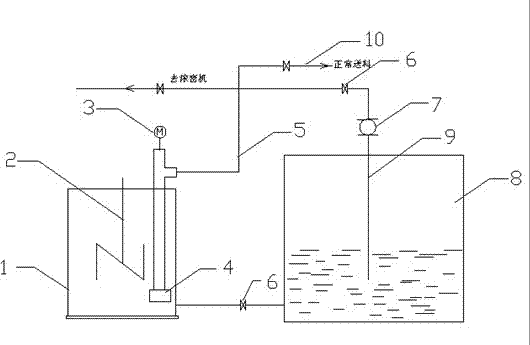

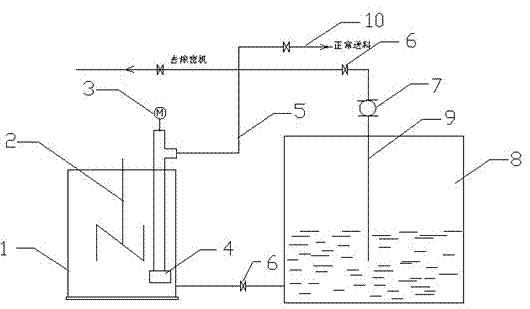

Solar photocatalytic degradation device

InactiveCN104528871AIncrease exposure timeImprove purification efficiencyWater/sewage treatment by irradiationGeneral water supply conservationPhotocatalytic reactionEngineering

The invention discloses a solar photocatalytic degradation device, belongs to the technical field of sewage treatment and particularly relates to a device which solves the problems that a sewage treatment device is high in energy consumption, high in price and prone to secondary pollution by using a modified photocatalyst responsive to ultraviolet visible light and taking sunlight as a light source to drive reactions to degrade pollutants. The device mainly comprises reaction tanks, hollow pipes, air ejecting pipes, an air pump, a transparent stair-shaped photocatalytic reaction chute, circular arc baffles, a water conveying pipe, a water pump, a water collecting pool and a solar cell panel. The reaction tanks are used for providing sites for homogenizing and processing sewage, the hollow pipes are used for carrying ultraviolet visible light modulator tubes, the air ejecting pipes and the air pump are used for aerating the reaction tanks, the transparent stair-shaped photocatalytic reaction chute is used for providing a photocatalytic degradation site, the circular arc baffles are used for homogenizing and slowing down a sewage solution, the water conveying pipe and the water pump are used for conveying the sewage in the water collecting pool into the reaction tanks, the water collecting pool is used for collecting degraded sewage, and the solar cell panel is used for storing electric energy. The sunlight is mainly used, and the device has the advantages of being clean, efficient, free of secondary pollution, controllable in reaction atmosphere, high in light source utilization rate and the like.

Owner:ANHUI UNIV OF SCI & TECH

Medicament for killing cockroach

The invention discloses a medicament for killing cockroach, and belongs to the technical field of hygiene and disease control. The medicament is prepared from the following raw materials in part by weight: 10 parts of wrinkled gianthyssop herb, 8 parts of light-yellow sophora root, 15 parts of sessile stemona root, 8 parts of stiff silkworm, 15 parts of cockroach, 10 parts of flies, 30 parts of soybean, 20 parts of brown sugar, and 23 to 35 parts of onion juice. Non-chemical medicaments such as Chinese medicament and the like are used as raw materials, so the medicament for killing the cockroach is safe to use, has no toxin to people and livestock, and has no pollution to environment; and the death rate of the cockroach is as high as 100 percent.

Owner:济南市疾病预防控制中心

Production technology of boron trifluoride complex

ActiveCN102276638ALow costPollution-freeGroup 3/13 element organic compoundsAqueous solutionBoron trifluoride

The invention relates to a process for producing a boron trifluoride complex. The process comprises the following steps of: a, making gas, namely slowly dripping an organic solvent into a caustic soda flake kettle and absorbing water to generate an organic solvent with vapor, leading the organic solvent with the vapor into a complexing device, leading boron trifluoride gas and performing a complexing reaction, and controlling the temperature to 30 to 50 DEG C and the reaction time to 2 to 5 hours; b, crystallizing, namely after the reaction is finished, stirring for 1 to 2 hours, reducing the temperature to 15 to 20 DEG C, centrifuging, collecting centrifugate and applying; and c, drying under reduced pressure, namely allowing crystals obtained after centrifugation to enter a double cone dryer, controlling the temperature to 35 to 45 DEG C, and drying for 3 to 5 hours to obtain the boron trifluoride complex. The process has the characteristics that: aqueous solution is adopted, the cost is low, liquid caustic soda generated after water is absorbed by using caustic soda flakes can be used for other working sections, and the pollution is avoided; and the reaction temperature is normal temperature or a little higher than the normal temperature and is easy to control, the vacuum drying is adopted, the cost for the application of the centrifugate is low and the like.

Owner:RUNTAI CHEM CO LTD

Process for deplating gold plated layer and recovering gold with cyanide-free gold stripping powder

ActiveCN103668204ALow pricePollution-freeProcess efficiency improvementSodium carbonatePotassium cyanide

The invention belongs to the technical field of gold recovery of gold plated parts, and discloses a process for deplating a gold plated layer and recovering gold with cyanide-free gold stripping powder. A solid gold ore separation agent, solid sodium carbonate and sold sodium citrate are made into the gold stripping powder at the ratio of 5:3:2, water and the gold stripping powder are prepared into gold stripping liquid with the concentration of 2.9%-3.8% according to the ratio of 100:(3-4), a gold plating part or gold layer plating metal is put into the gold stripping liquid for soaking to strip gold, and the processes of zinc paper replacement, zinc removal and crucible smelting are carried out to obtain gold the purify of 99.9%. The process is improved through research, the mixture of the nontoxic and cheap ore separation agent, solid sodium carbonate and sold sodium citrate is used to replace a sodium cyanide or editpotassium cyanide solution to carry out deplate the gold plated layer, and the invention provides the process which has no pollution, is simple to operate and easy to understand, and is environment-friendly.

Owner:王金良

Polymer lithium ion battery and production method thereof

PendingCN109378412APollution freeNot subject to performance degradationFinal product manufactureJackets/cases materialsIonLithium electrode

The invention relates to a polymer lithium ion battery and a production method thereof. The polymer lithium ion battery provided by the invention comprises a battery cell and at least one layer of inner-layer packaging film and at least one layer of outer-layer packaging film coating the battery cell, wherein the inner-layer packaging film is a plastic film or a plastic composite film, and the outer-layer packaging film is an aluminum plastic composite film. The polymer lithium ion battery provided by the invention has better airtightness and appearance effect, and performances of the batteryare better guaranteed. By using the production method provided by the invention, it can be ensured that the edge sealing airtightness of an outer layer of a battery package is qualified and appearancepollution or poor appearance does not exist, and it is ensured that the battery has no performance deterioration caused by poor packaging.

Owner:北京环宇东方聚能科技有限公司

Method for removing mud out of titanium-tetrachloride storage tank in production process of titanium tetrachloride

InactiveCN102441549AImprove working environmentPollution-freeHollow article cleaningTitanium tetrachlorideWorking environment

The invention relates to a method for removing mud out of a titanium-tetrachloride storage tank in the production process of titanium tetrachloride, and the method is used for removing mud deposited in a crude titanium-tetrachloride storage tank in the production process of titanium tetrachloride and belongs to the technical field of titanium tetrachloride production. According to the technical scheme disclosed by the invention, the method comprises the following steps of (1) in a closed state, repeatedly and circularly impacting deposited mud in a storage tank by using the conventional feeding pump for titanium tetrachloride production, so that the deposited mud is suspended; (2) feeding the suspended mud into a thickener so as to deposit the suspended mud into mud; and (3) feeding the mud into a dust arrester by a mud recycling device so as to separate and recycle the mud. In the invention, because a closed method is adopted to transfer mud to a recycling system which can carry out mud treatment, the working environment is improved, and no pollution is caused; since no new equipment is added and the conventional feeding pump is utilized, the investment is reduced; and titanium tetrachloride is recycled, the metal recovery efficiency is improved, and waste and pollution caused by mud washing can be avoided.

Owner:中航天赫(唐山)钛业有限公司

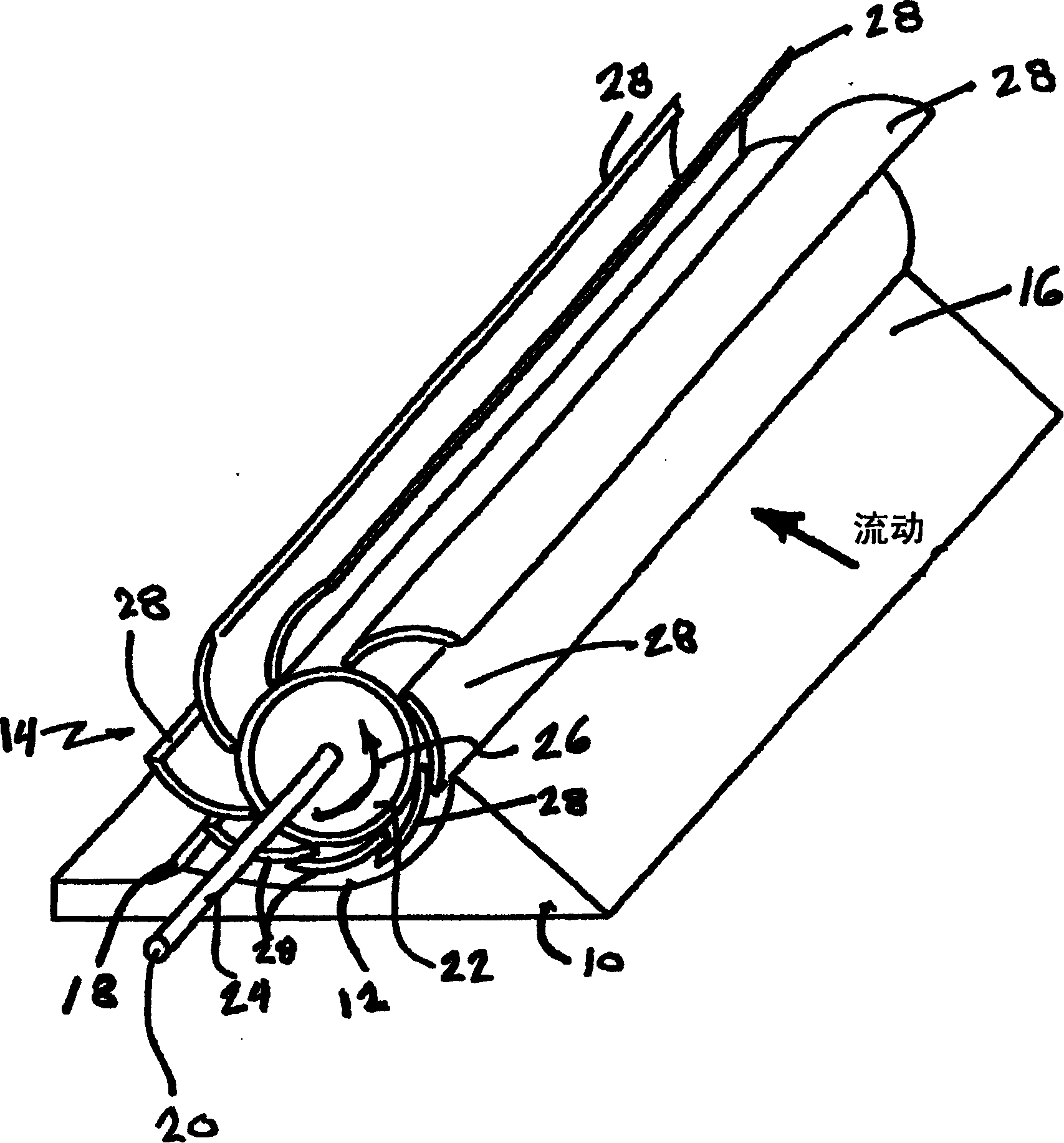

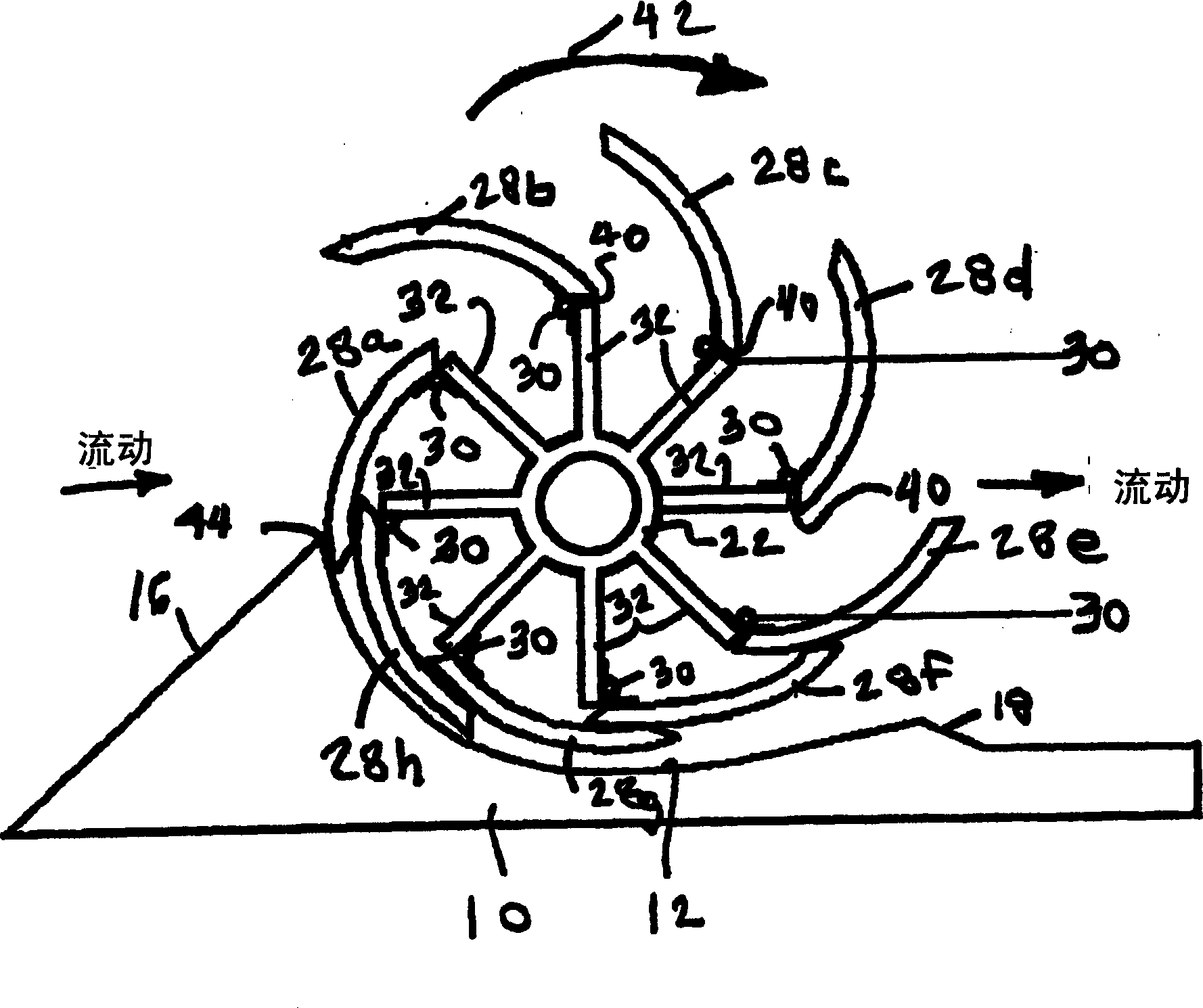

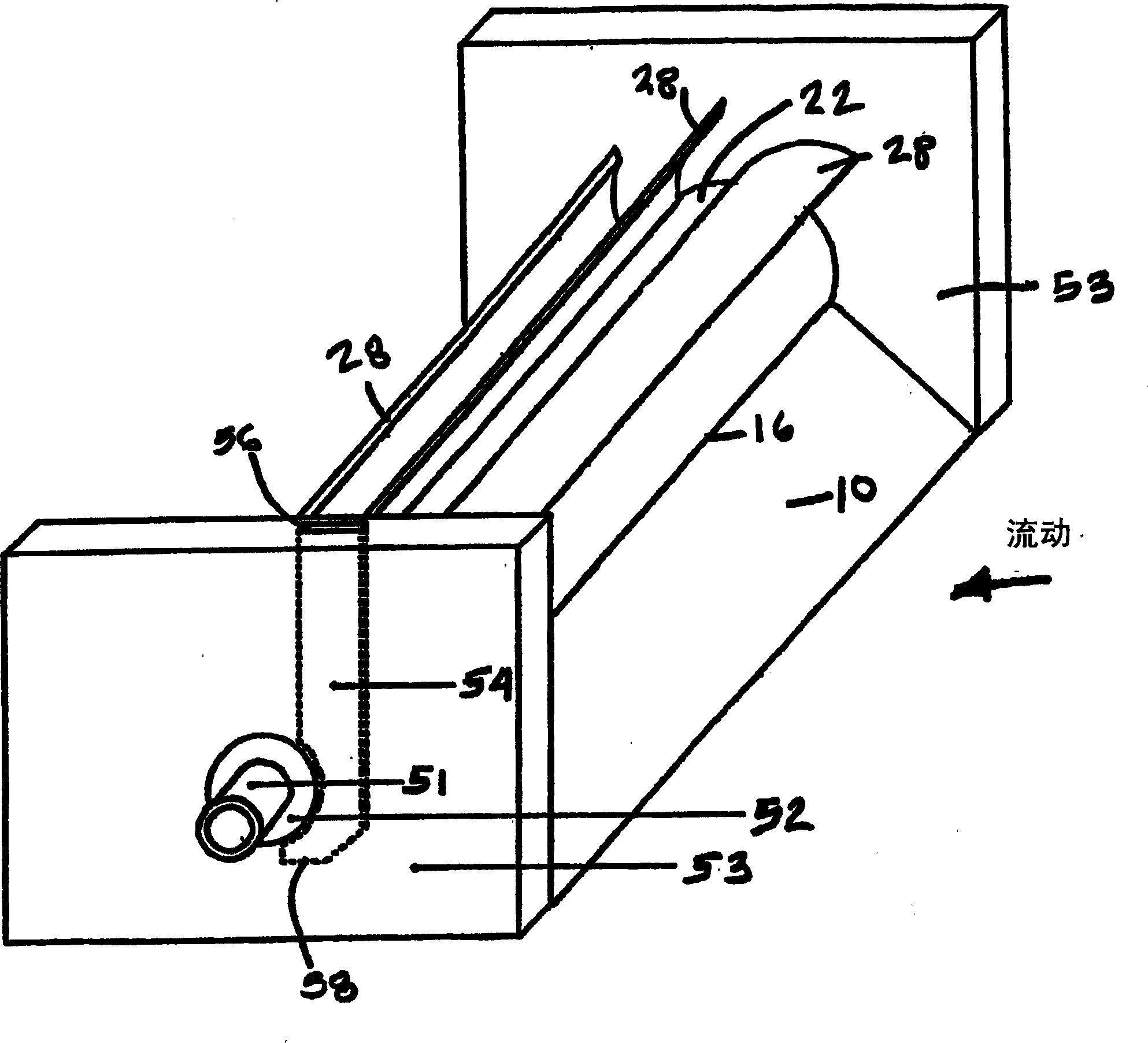

Low head, dynamic variable pitch, submersible hydro generator

InactiveCN1795330AIncrease power generationPollution-freeMachines/enginesEngine componentsElectric generatorEngineering

The hydroelectric generator system includes a rotor that rotates about an axis on its base, and a plurality of blades hinged to the rotor and extending radially outward from the rotor. These blades are designed to expand on the upstream side to a fully extended position during a partial revolution of the rotor, where water flow from the upstream side to the downstream side hits the blades and opens them to the fully extended position to drive the rotor. The rotor or rotor and blades can be completely submerged in water.

Owner:尤金・G・利格曼

Preparation method of special flexible ceramic composite infiltration layer

ActiveCN103243323ANo bond strength issuesImprove physical propertiesMetallic material coating processesCeramic compositeLow temperature curing

The invention relates to a preparation method of a special flexible ceramic composite infiltration layer, which belongs to the technical field of a ceramic composite infiltration layer preparation method, and aims at solving the technical problem that a common hardening technology and a common anticorrosion technology can be only used for improving the abrasion resistance or the corrosion resistance of a metal surface. The preparation method provided by the invention is capable of simultaneously and greatly improving the abrasion resistance and the corrosion resistance of the metal surface. According to the technical scheme, the preparation method comprises the following steps of: a, washing a workpiece; b, preheating the workpiece; c, infiltrating the workpiece with ceramics; d, curing the workpiece at a low temperature; and e, drying the cured workpiece cleaned by clean water. After being processed by the method disclosed the invention, the workpiece has extremely high abrasion resistance, excellent corrosion resistance and good fatigue resistance, and only slightly deforms. The preparation method is suitable for processing the workpiece with high requirements on the abrasion resistance and the corrosion resistance and has a good effect.

Owner:SHANXI YITONG ENVIRONMENTAL ENERGY TECH GROUP

Dyeing machine with energy-saving function

InactiveCN107354650AReduce wasteWell mixedTextile treatment containersLiquid/gas/vapor removalElectric machineryEngineering

The invention discloses a dyeing machine with an energy-saving function. The machine includes a dyeing box, one side of the dyeing box is provided with a working door, and the rear side plate of the dyeing box is fixedly provided with a servo motor, wherein the rotating shaft of the servo motor is in transmission connection with a main shaft through a coupler, one end of the main shaft stretches into the dyeing box and is fixedly connected with a first cloth guiding roller, and one side of the first cloth guiding roller is provided with a second cloth guiding roller. The top of a supporting plate positioned on the other side of the dyeing box is welded to the dyeing box, a cover plate is hinged to one side of the top of the dyeing box through a hinge, and a connecting component is hinged to the rear side plate of the dyeing box through a hinge. The dyeing machine with the energy-saving function, by arranging a torque spring to generate pretightening force, the connecting component and an L-shaped plate cover the dyeing box and the cover plate much tighter, so that the situation is prevented from occurring that the cover plate is opened to spill out the dyestuff inside the dyeing box by the vibration generated by a control motor and a stirring rod during stirring, and therefore waste of the dyestuff is reduced.

Owner:梁留伟

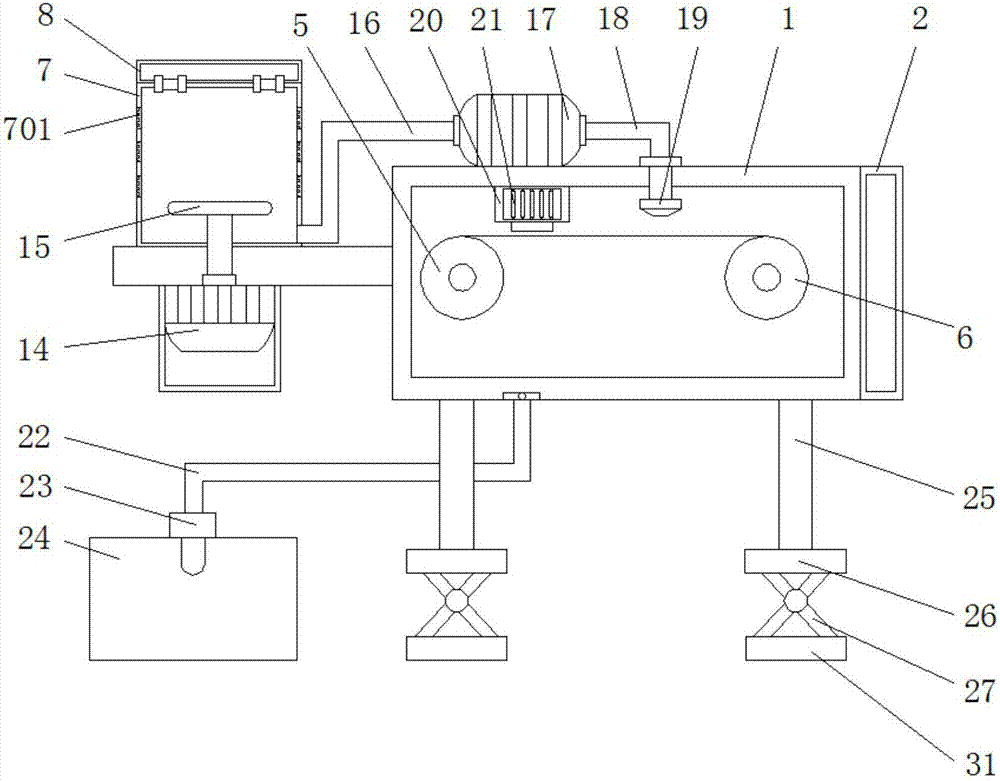

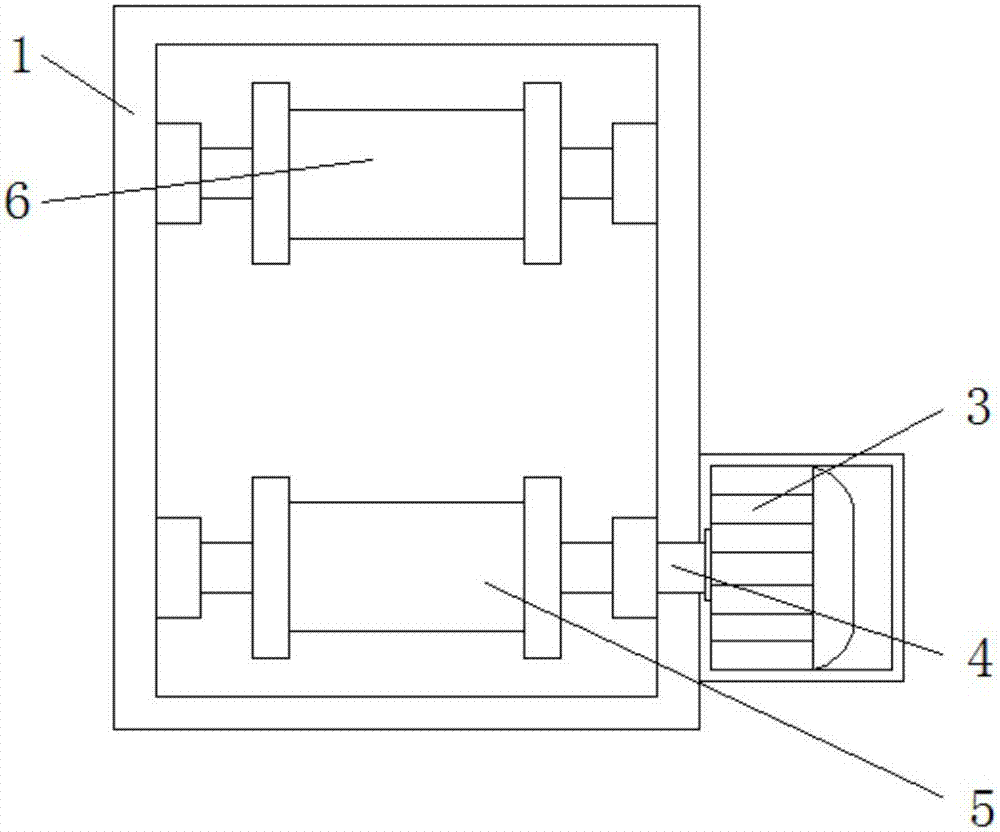

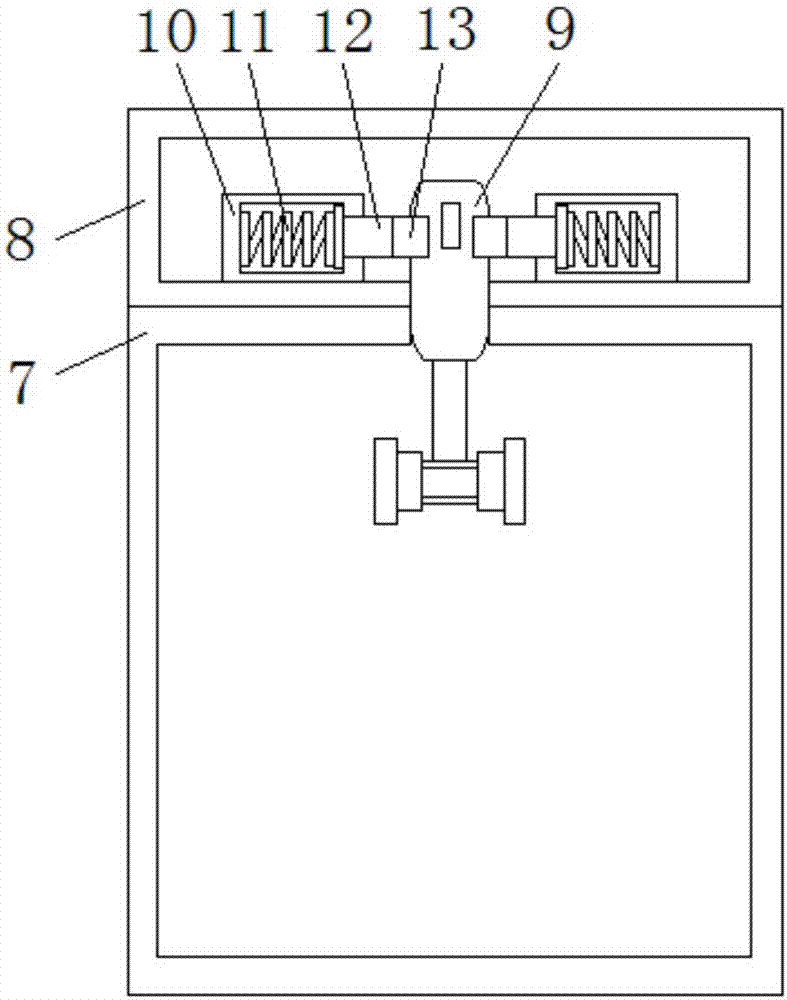

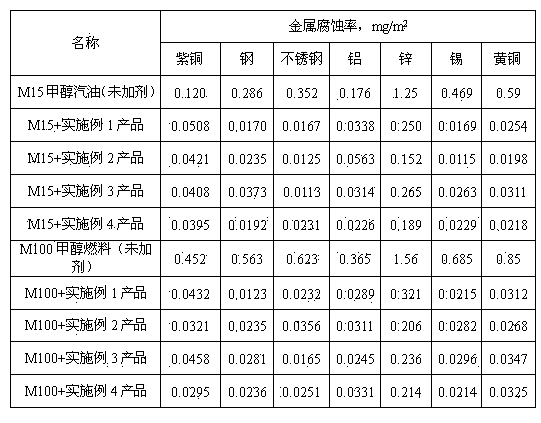

Vehicle methanol fuel corrosion-inhibitor for various metals

The invention belongs to the field of substituting an automobile alcohol ether for a fuel additive, and in particular relates to a vehicle methanol fuel corrosion-inhibitor for various metals. The methanol fuel corrosion-inhibitor for various metals is composed of 30-40wt% of imidazoline derivatives, 5-10wt% of dimer acids, 3-7wt% of polyaspartic acid, 3-10wt% of benzoxazole, 1-5wt% of organic amine, 2-6wt% of nitrogen heterocyclic ring-containing compounds, 0.05-0.1wt% of metal ion passivator and the balance of dispersant. The vehicle methanol fuel corrosion-inhibitor is suitable for anti-corrosion and corrosion inhibition of various metals, such as red copper, brass, 45# steel disc, stainless steel, alumium, zinc and tin. Besides, the vehicle methanol fuel corrosion-inhibitor for various metals is low in the addition amount of additives, nontoxic and pollution-free, and belongs to an environment-friendly corrosion inhibitor.

Owner:中油延长石油销售股份有限公司

Kit for determining ornithine decarboxylase by using marker immunological technique and its determination method

The kit for determining ornithine decarboxylase by using labelling immune technology contains the following various reagents: precoated plate coated by antibody for resisting ornithine decarboxylase;biotin labelled antibody for resisting ornithine decarboxylase; horseradish peroxidase labelled avidin; ornithine decarboxylase standard product; sample diluent; washing liquor; development reagent Aand B; and stop buffer. Said invention utilizes the labelling immune assey technology to determine ornithine decarboxlase dantigen content to indirectly reflect the activity of ornithine decarboxylase.

Owner:SHANDONG MEDICAL BIO TECH RES CENT

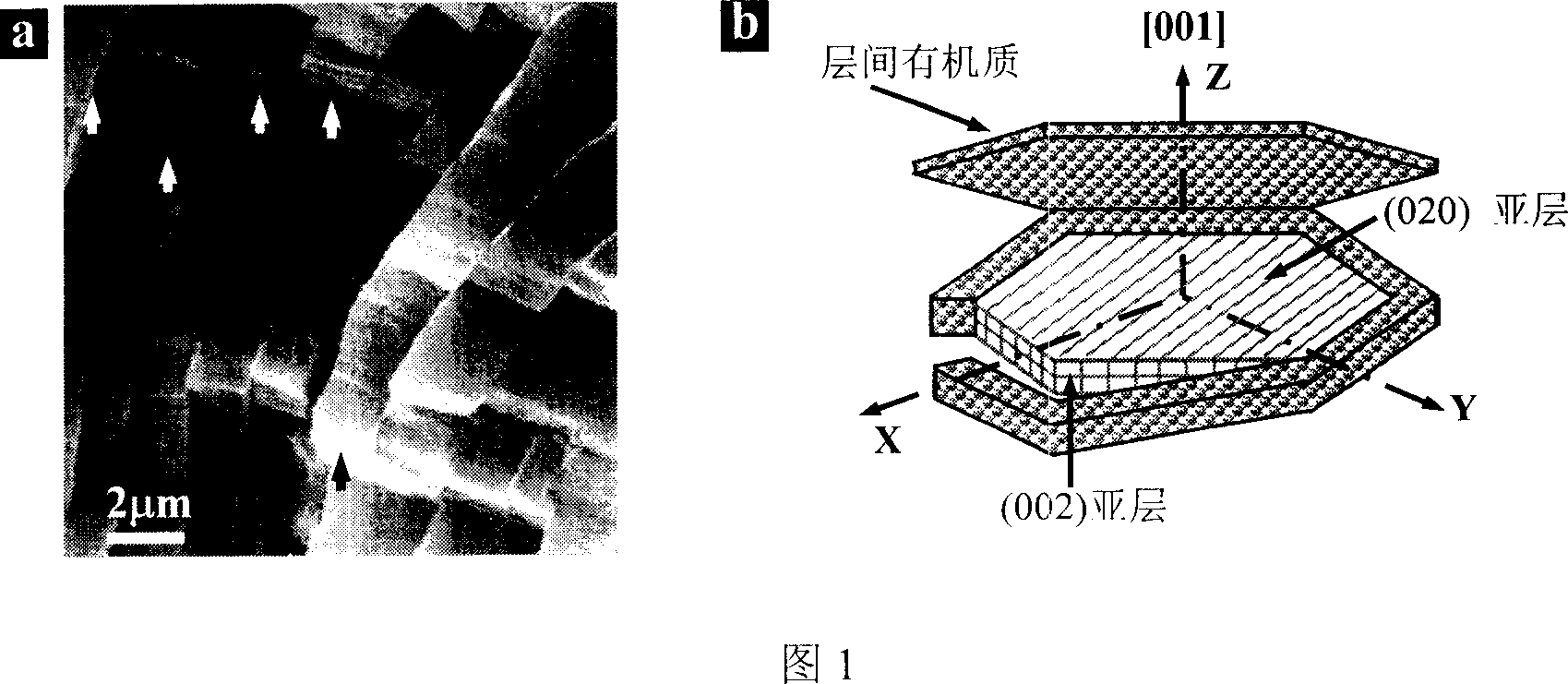

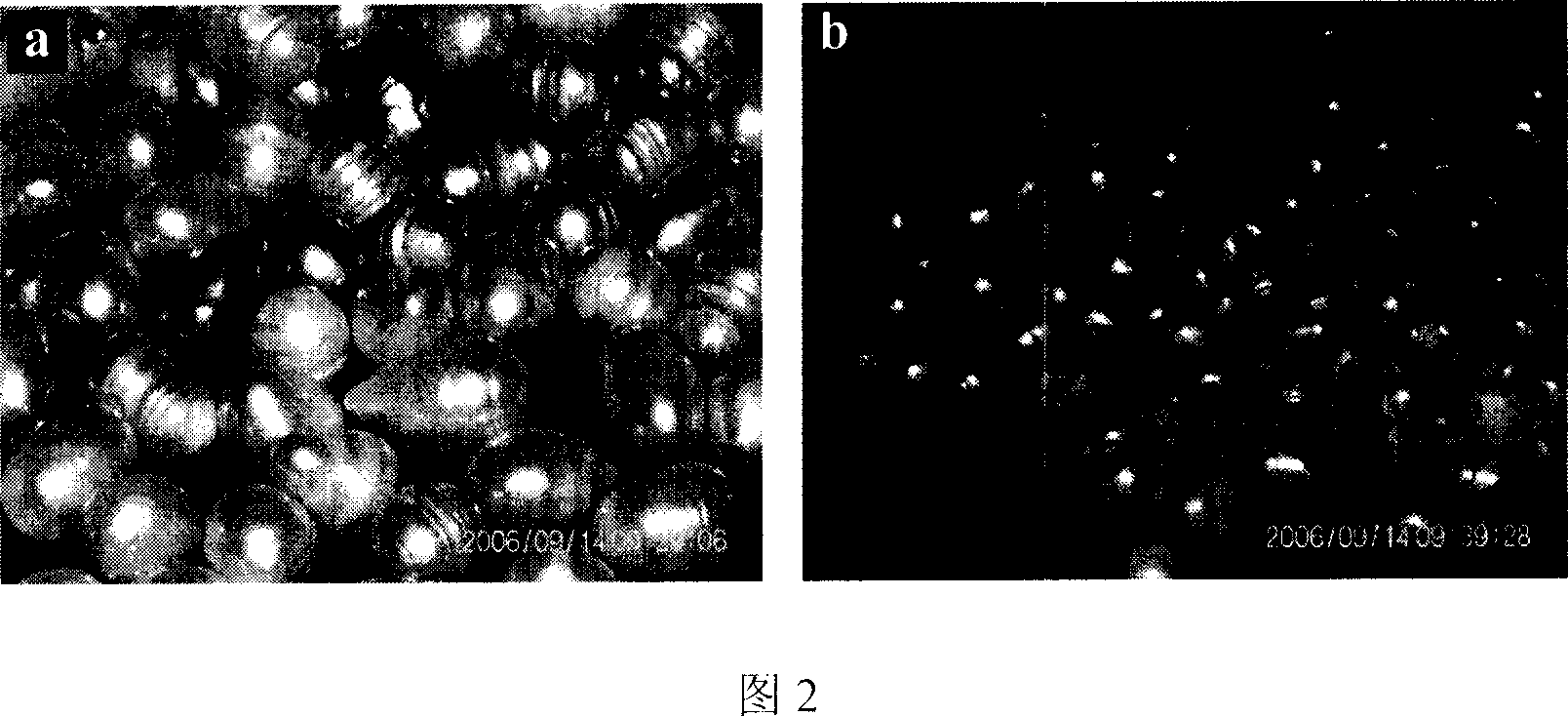

Internal stress self explosion auxiliary crushing method

InactiveCN1943865ARetain biological activityNano crushing is easy to handlePowder deliveryGrain treatmentsWater immersionThermal expansion

The present invention relates to crushing technology for mineralized biomass and is internal stress explosion aided crushing method. Based on the differences between the organic matter and inorganic matter inside the mineralized biomass in thermal expansion coefficient and water immersion capacity, the mineralized biomass is applied with thermal shock and water soaking, so as produce great internal stress and thus spontaneous explosion and cracking. The present invention may be used in the pre-treatment of superfine crushing mineralized biomass, such as pearl, and has the advantages of simple operation, no pollution, low cost and other advantages.

Owner:TSINGHUA UNIV

Building material and preparation method thereof

Owner:河北天基新材料有限公司

Method for producing kraft using American waste paper

InactiveCN1876958AReasonable workmanshipPollution-freePaper recyclingWaste paper working-upHeating timeAccelerant

The invention provides a method of producing exquisite brown paper by American waste paper, firstly picking American waste paper, encasing the American waste paper which is up to the mustard in case, by furnace run after adding water, controlling temperature between 90-130DEG C, the heating time is between 90-130min, adding boiling accelerant after high-temperature processing, controlling dosage less than ton dosage 0.5-0.9Kg, adding boiling accelerant at twice, adding 50% of gross before the high-temperature processing for the first time, adding 50% of gross when the high-temperature processing temperature reaching 80DEG C; The heated materials need to be dispersedly disposed by thermal dispersion equipment, and then after beating, poaching and pulping returning to perch vat, by netting, expression, drying, calendaring and crimp would get product. The invention has reasonable technique, convenient operation, no pollution and high economic value.

Owner:李明全

A phage of Vibrio alginolyticus and its application in disease prevention of sea cucumbers

ActiveCN103898015BImprove disinfection effectGood environmental toleranceAntibacterial agentsBacteriaFiberDisease

The invention discloses a vibrio alginolyticus bacteriophage and application thereof to prevention of sea cucumber disease, belonging to the technical field of biology. The bacteriophage is collected in the China General Microbiological Culture Collection Center on March 11, 2014 and has a collection number of CGMCC No.8792 and a classification name of Vibrio alginolyticus bacteriophage; the vibrio alginolyticus bacteriophage is a short-tailed phage, has a head diameter being 50 nanometers and tail length being 15 nanometers, and has no shrinkage tail sheath and six short tail fibers. The bacteriophage is used for preventing infection and pollution caused by corresponding vibrio alginolyticus in the culturing process of sea cucumbers, and the potency is more than or equal to 10<5>PFU / mL. The bacteriophage has an inhibiting function on vibrio alginolyticus, and no vibrio alginolyticus-resistant strain is produced within 12 hours; the incubation period lasts for 28 minutes, the burse size is 79, and two orders of magnitude are lowered within 14 days in a seawater culturing environment.

Owner:DALIAN UNIV OF TECH

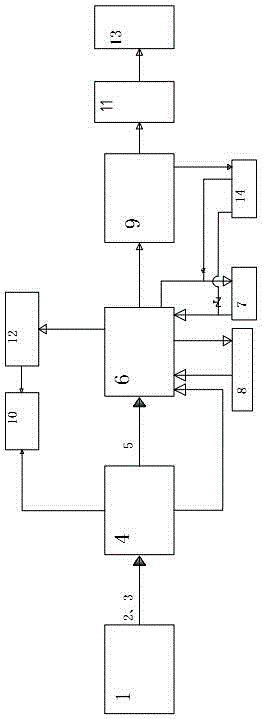

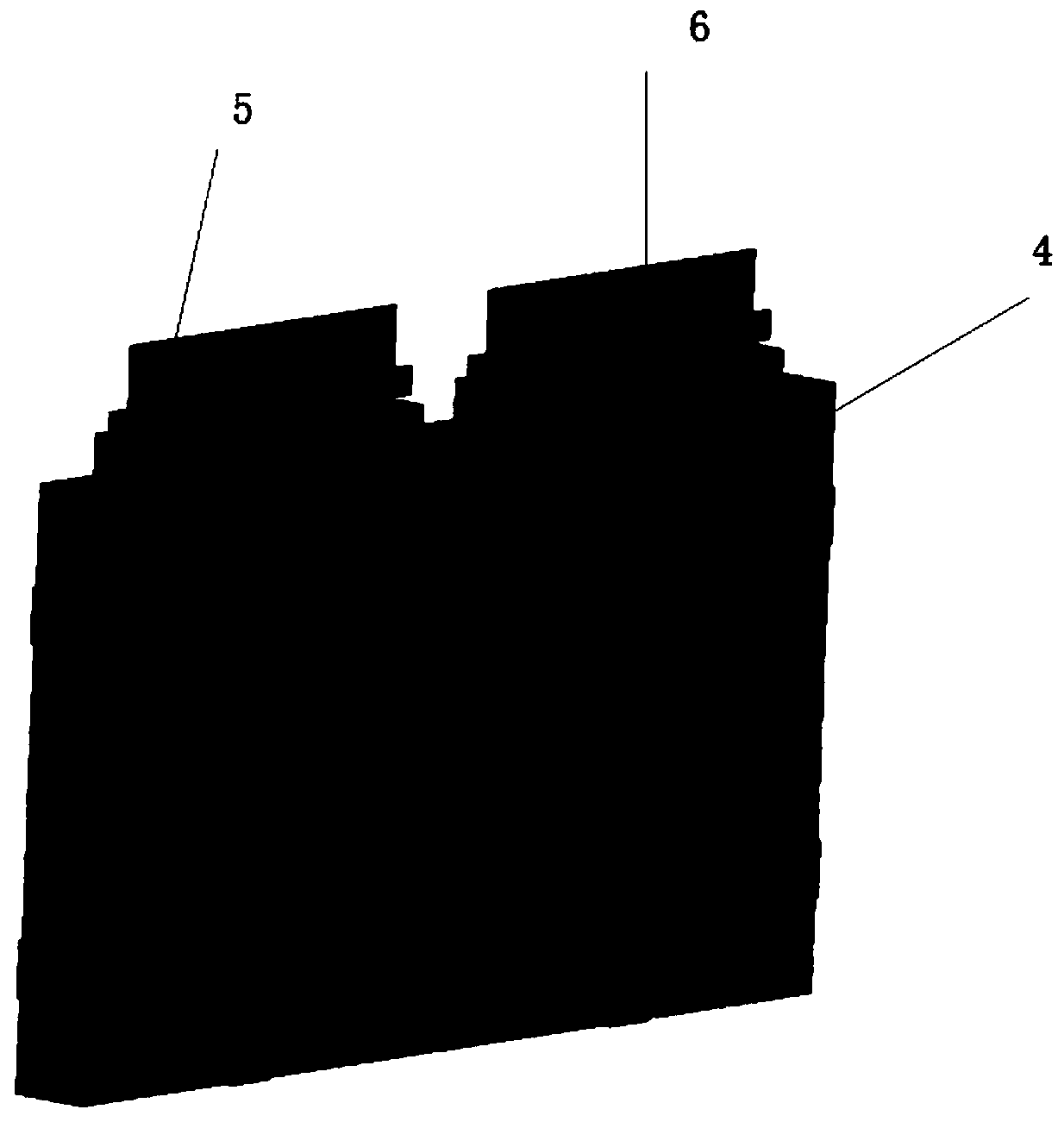

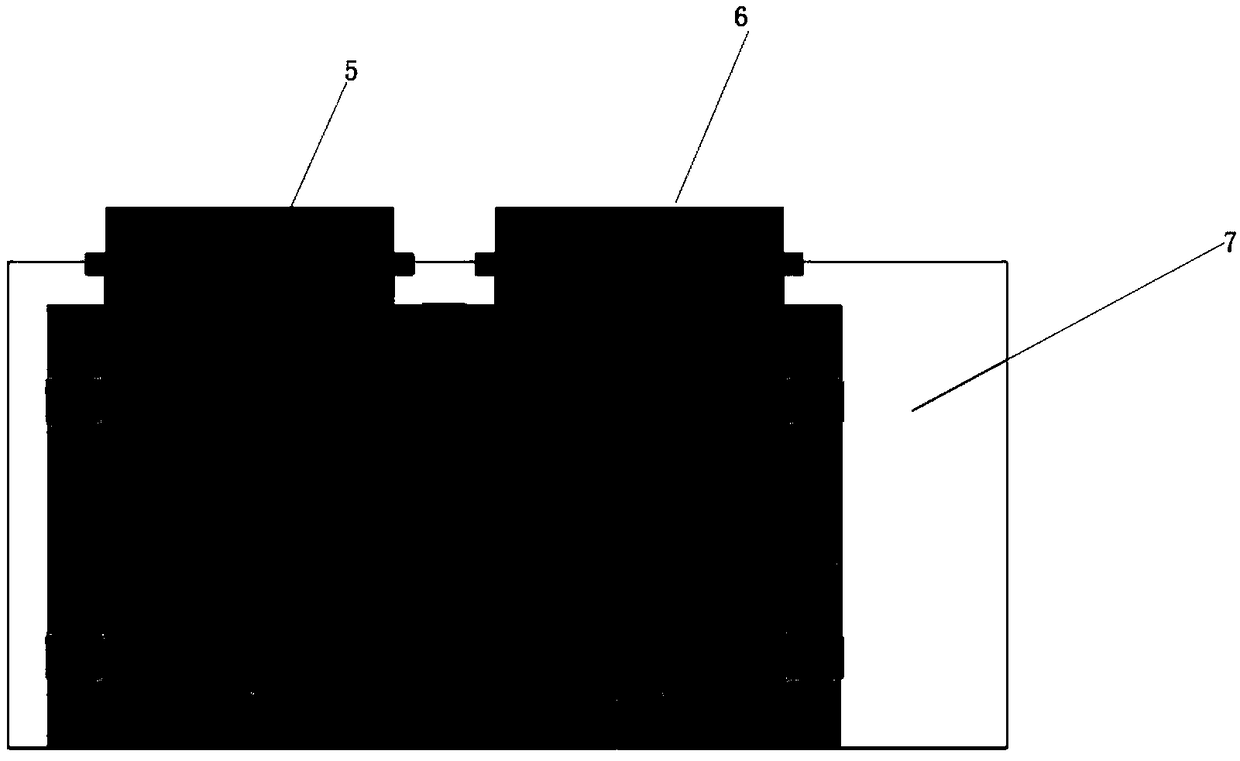

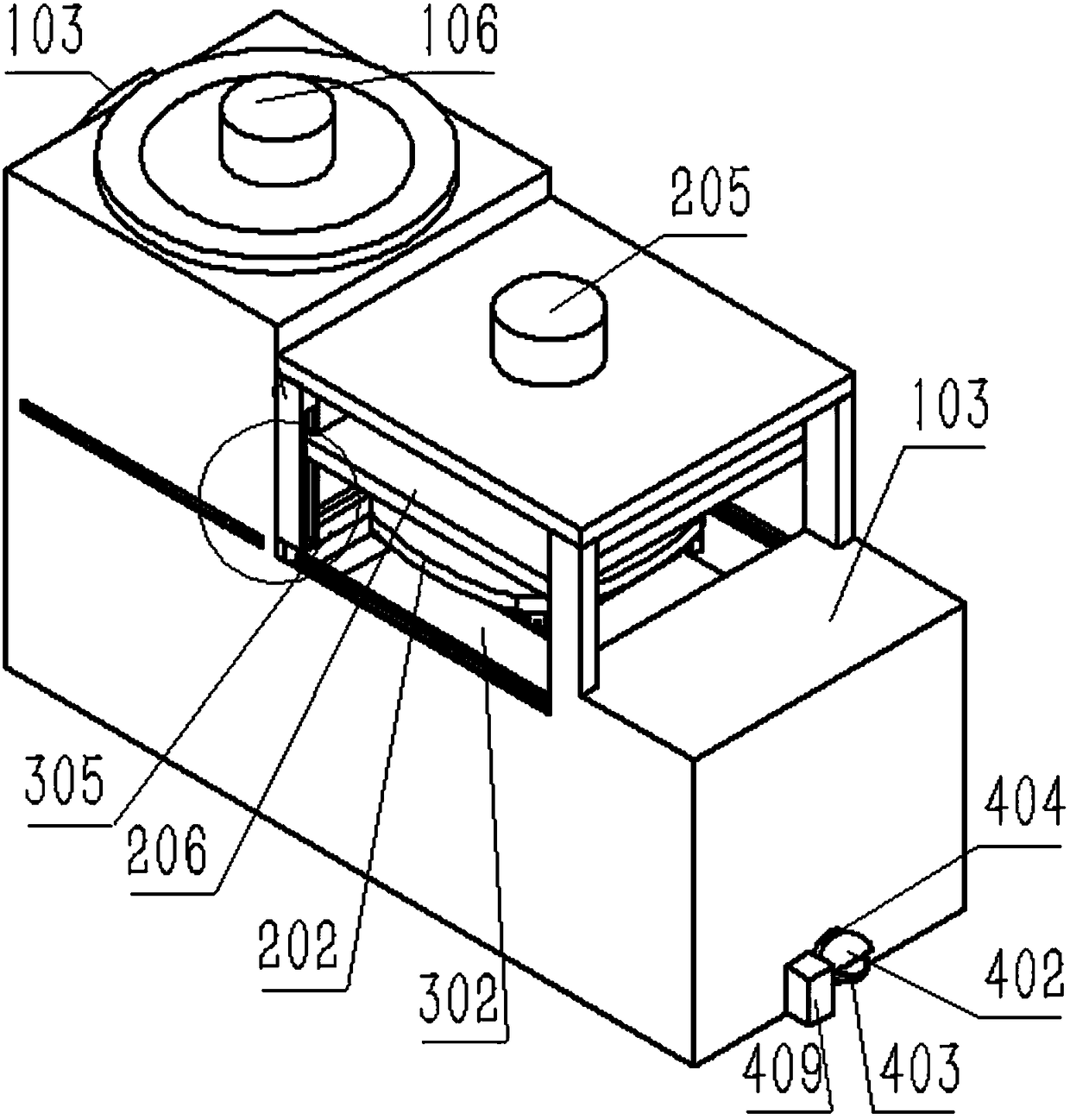

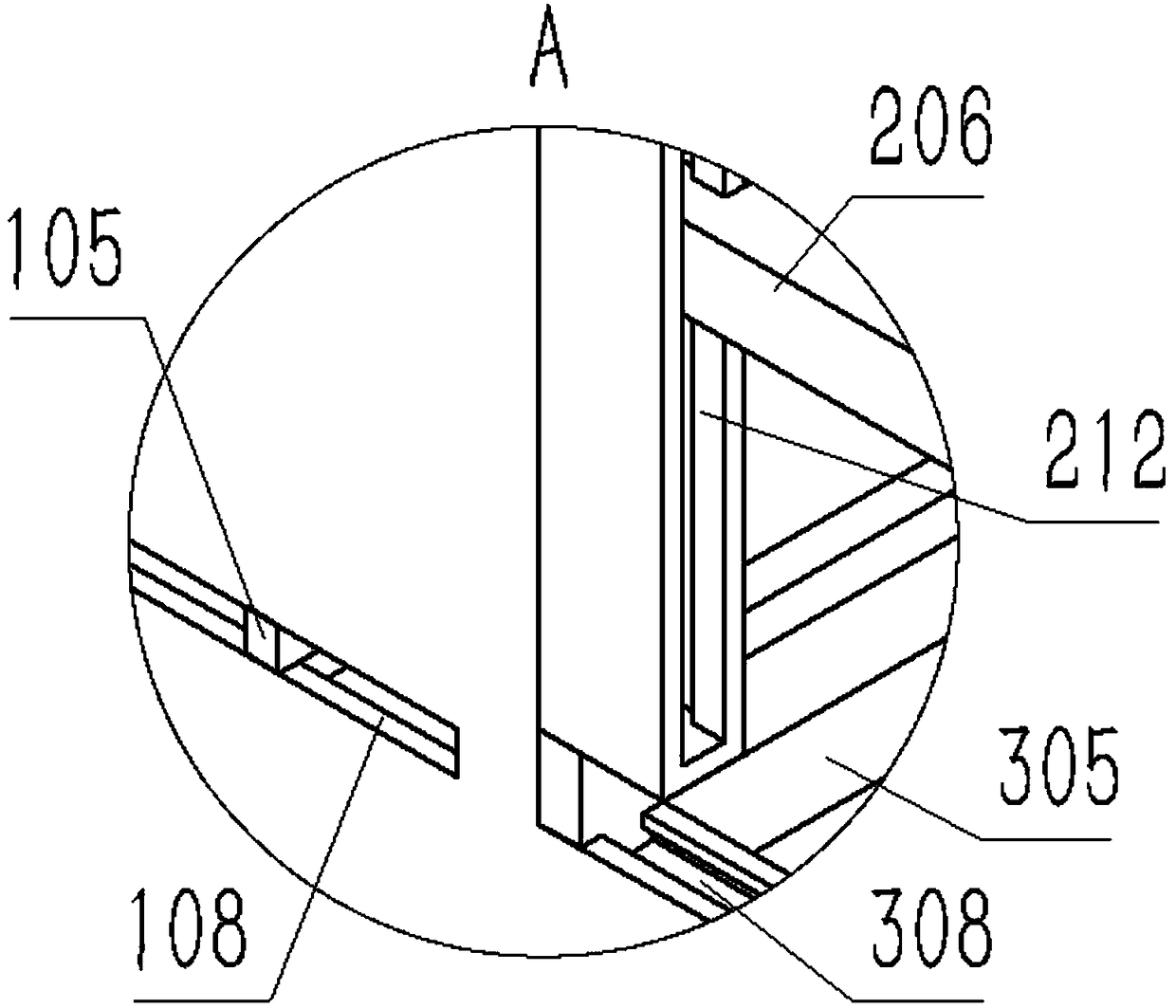

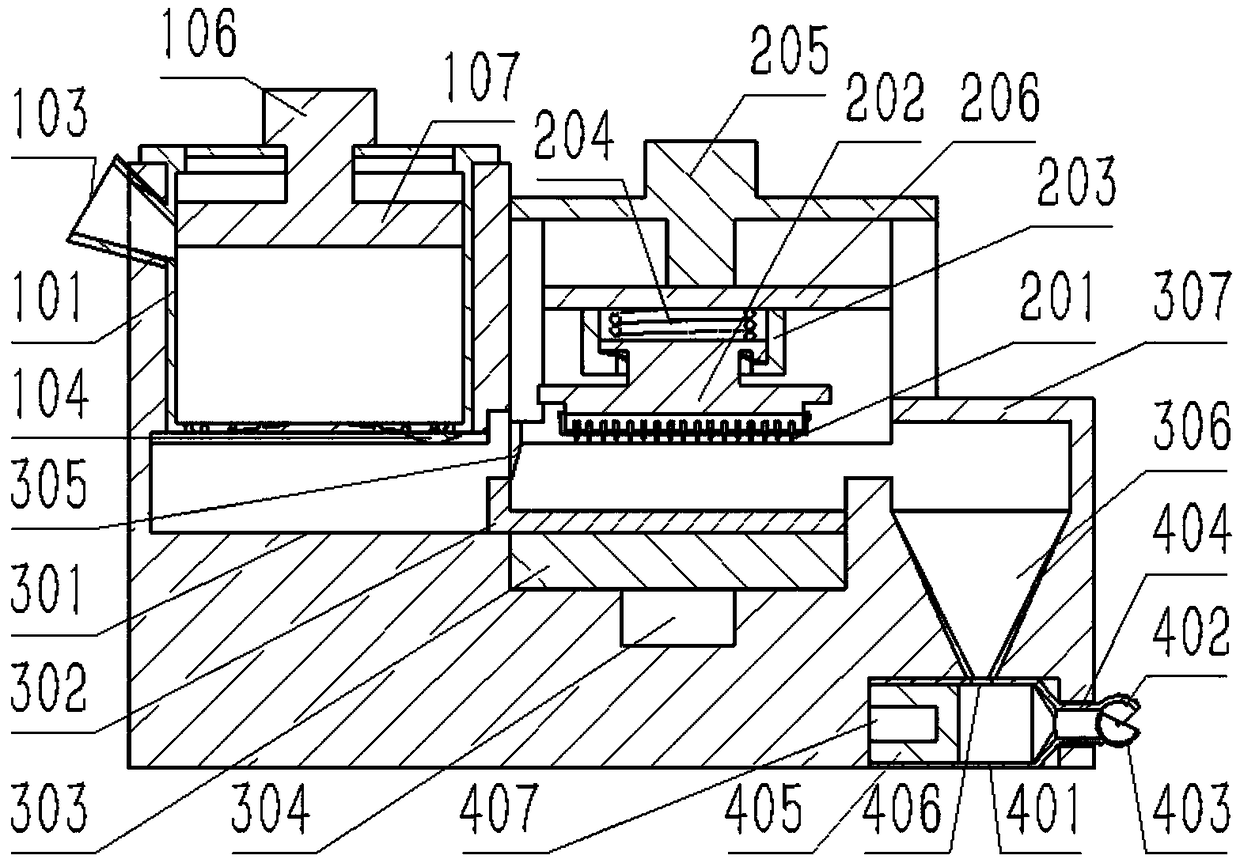

Puree processing and molding apparatus for meat ball production

ActiveCN108402156AEasy to operatePollution-freeMeat pressingMeat processing devicesPeripheralEngineering

The invention discloses a puree processing and molding apparatus for meat ball production. The puree processing and molding apparatus for meat ball production comprises a meat cutting device, a meat chopping device, a meat receiving device, and a meat ball molding device; peripherals of the devices are coated with boxes; the meat cutting device and the meat chopping device are adjacent to each other; the meat receiving device is arranged under the meat chopping device; and the meat ball molding device is laterally arranged under the meat receiving device under the meat chopping device. The invention has the following beneficial effects: the puree processing and molding apparatus for meat ball production provided by the invention is capable of imitating artificial meat chopping and realizing high-efficiency round meat balls, and is simple in operations, economical of time and labor, free of pollution and safety hazards; moreover, the produced meat balls are compact and elastic in taste,and thus, requirements of people for taste and efficiency are simultaneously met.

Owner:SHANDONG NEW HOPE LIUHE GROUP +2

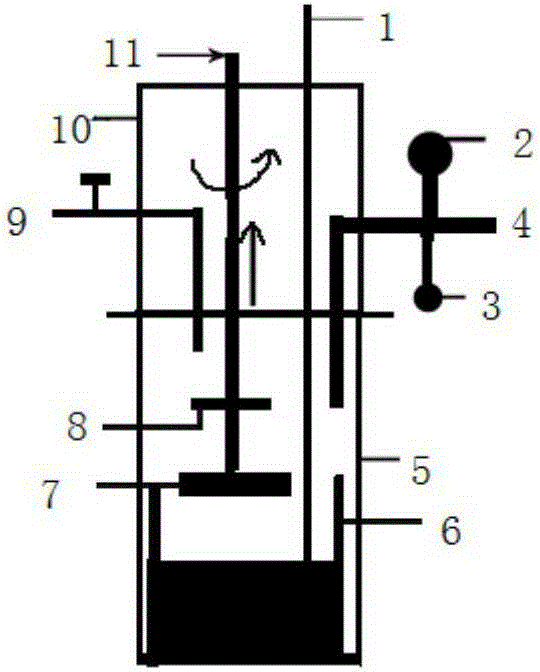

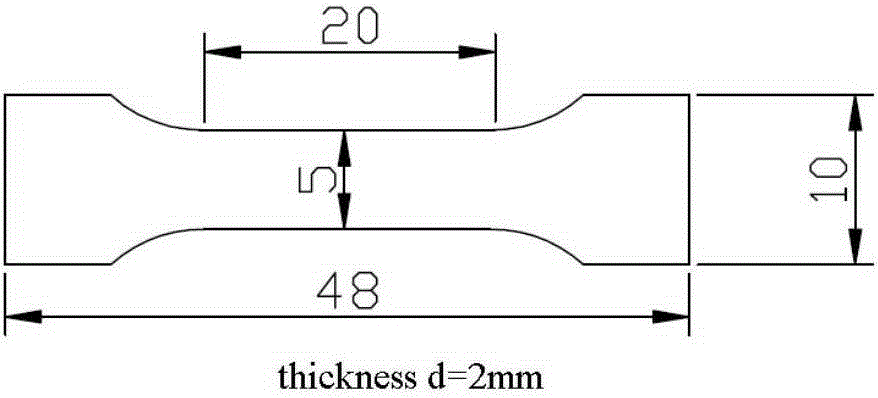

In-situ reinforcement preparation method and device for high-strength and high-ductility casting magnesium-based composite material

The invention relates to an in-situ reinforcement preparation method and device for a high-strength and high-ductility casting magnesium-based composite material. Mg-9%Al alloy is adopted as matrix alloy, N2 gas is introduced in an alloy melt in a vacuum smelting resistance furnace, so that the N2 gas and the alloy melt are in gas / gas and gas / liquid reaction, AlN particles evenly distributed are formed in the alloy melt in situ, and therefore the AlN / Mg composite material with the highest extension strength of 193 Mpa and elongation with 14% is prepared. The process and preparation device have the characteristics of being easy to operate, environmentally friendly, low in cost, small in energy consumption and short in preparation period. The strength and ductility of the prepared magnesium-based composite material are superior to those of corresponding Mg-Al alloy (AZ91D), and density is smaller.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

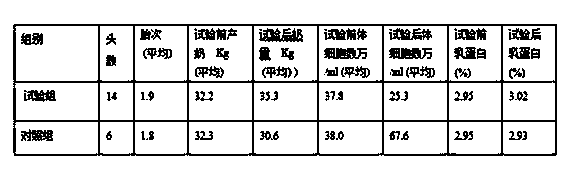

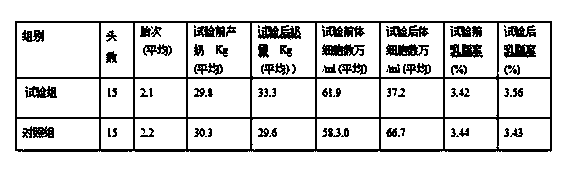

Chinese and western medicine compound for preventing and treating recessive mastitis of dairy cows

InactiveCN104258031ACompatibility is reasonableHeat-clearing and detoxifyingPowder deliveryUnknown materialsBiotechnologyMyrrh

The invention belongs to the field of biotechnologies of dairy cow veterinary drugs, and particularly relates to a Chinese and western medicine compound for preventing and treating recessive mastitis of dairy cows. The compound is prepared from the following Chinese and western medicinal materials by weight: 10-15g of levamisole hydrochloride, 25-30g of taurine, 55-60g of honeysuckle, 45-50g of angelica sinensis, 25-30g of orange peel, 15-20g of radix saposhnikoviae, 15-20g of radix angelicae, 20-25g of fritillaria thun-bergli, 20-25g of frankincense, 20-25g of myrrh, 25-30g of radix paeoniae rubra, 15-20g of manis pentadactyla and 10-15g of liquorice. The Chinese and western medicine compound for preventing and treating recessive mastitis of dairy cows is prepared on the basis of years of clinical experience, has the effects of clearing away heat and toxic materials, promoting blood circulation to remove blood stasis and eliminating swelling to promote lactation, and has the advantages of being residue-free, pollution-free, environment-friendly, safe, simple in production process and convenient to use.

Owner:河南亚卫动物药业有限公司

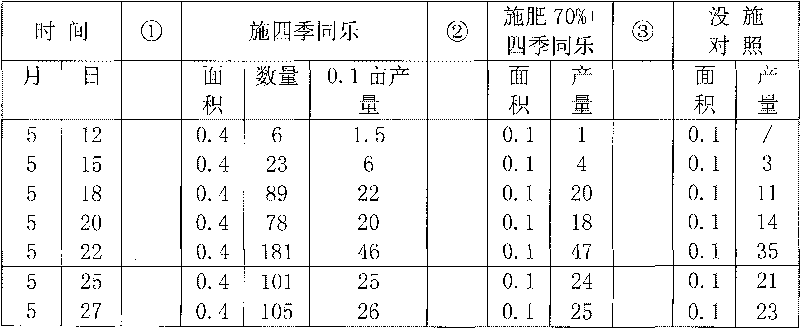

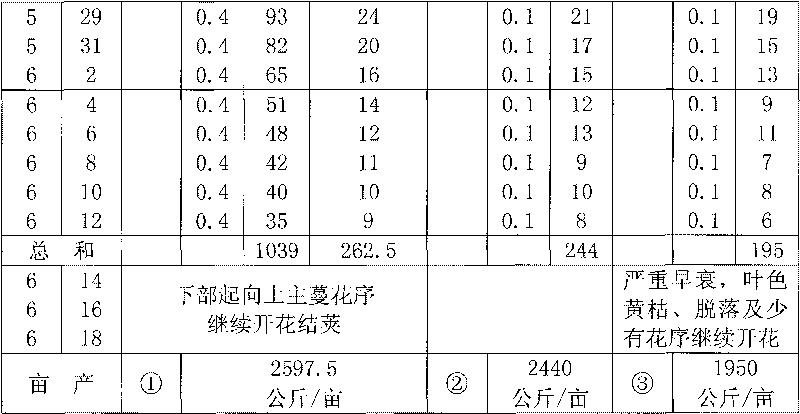

Method for planting cucumbers by fermented organic fertilizer

The invention provides a method for planting cucumbers by fermented organic fertilizer. The cucumbers cultivated by the method are good in growth vigour, organic biological fermentation fertilizer is used for being mixed with soil to obtain planting soil, the nutrition of the soil is improved, comprehensive nutrition can be provided for the cucumbers in the growing process, environmental protection is achieved, and pollution is avoided.

Owner:芜湖诚德农业科技有限公司

Natural, mild and green cleaning agent

ActiveCN101165151BPollution-freeZero pollutionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium metasilicateCleansing Agents

The natural mild green detergent consists of composite surfactant 1 (in weight portions, the same below), sodium carbonate 15-21.428, mirabilite 17-24.28, sodium percarbonate 6-8.58, sodium metasilicate 15-21.428, citric acid 10-14.28, sodium carboxymethyl ellulose 2-2.86, EDTA 2-2.86, stuffing 10-14.28 and water 3-4.28. It has the advantages of environment friendship, no pollution to undergroundwater, high detergency, no harm to skin, natural sterilizing capacity and no toxicity.

Owner:SHANGHAI TEDIWANG AGRI TECH

Side slope grouting slurry for silty-fine sand embankment widening and method for preparing same

The invention discloses side slope grouting slurry for silty-fine sand embankment widening, prepared from the following raw material in parts by weight: 3-15 parts of water glass, 2-10 parts of acetic acid, 1-5 parts of calcium chloride, 0.2-3 parts of disodium hydrogen phosphate, 0.1-5 parts of ferric trichloride, 0.1-5 parts of aluminum chloride, and 0.1-3 parts of phosphoric acid or sulfuric acid. The side slope grouting slurry for silty-fine sand embankment widening has the advantages as follows: (1) the slurry provided by the invention is good in permeability, large in dispersion radius after grouting, high in grouting reinforcement strength and good in homogeneity, and the gelation time of the slurry in the air and the sand layer is long; (2) the rest materials of the raw materials apart from the acetic acid which is an organic matter are all inorganic matters, and all of the raw materials do not belong to the range of hazardous article control, and may not cause pollution on the surrounding environment in the use process; the by-products of the slurry after solidification reaction also has no pollution on the environment, and is environment-friendly and harmless; and (3) the raw materials are low in price and wide in source.

Owner:SHIJIAZHUANG TIEDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com