Polymer lithium ion battery and production method thereof

A lithium-ion battery and a manufacturing method technology, applied in the field of lithium-ion batteries, can solve the problems of tearing, battery electrochemical performance deterioration, battery appearance dirty and scrapped, etc. Edge sealing, air tightness, no pollution, bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

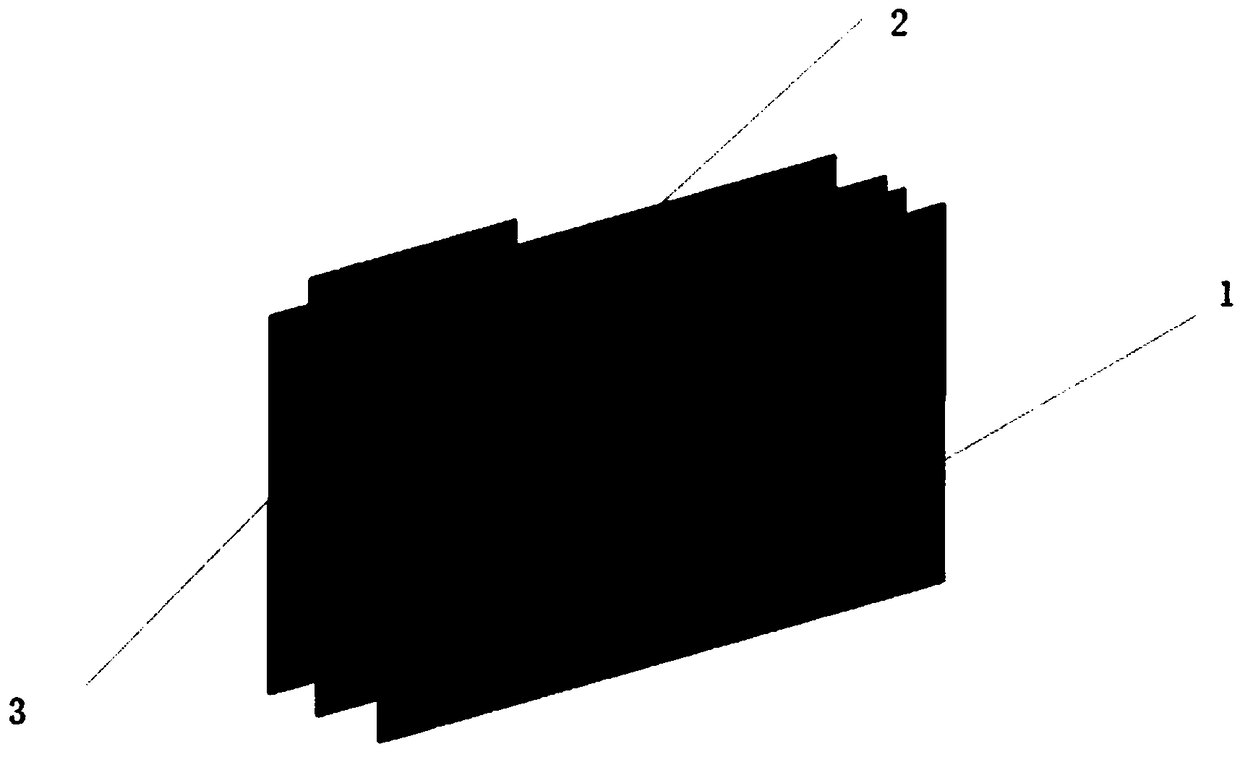

[0053] Preparation of positive electrode sheet: layered transition metal oxide lithium salt LiMO 2 (M=Co, Ni, Mn, etc. or their multiple combination complexes) such as LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 or LiFePO 4 It is the positive electrode active material, its ratio is 95% of the powder content, polyvinylidene fluoride is used as the binder, the content is 2.5%, the conductive agent is carbon nanotube and carbon black content is 2.5%, the above materials are added to N - Stir evenly in methylpyrrolidone (NMP) to make a slurry, evenly coat the positive electrode slurry on the positive electrode current collector aluminum foil with carbon powder, dry and compact it, and cut it into the size specified by the process, Obtain the positive pole piece.

[0054] The preparation of negative plate: take artificial graphite as negative active material, its ratio is 95% of powder content, with styrene-butadiene rubber (SBR) as binding agent, its content is 2%, sodium carboxymethyl cellul...

Embodiment 2

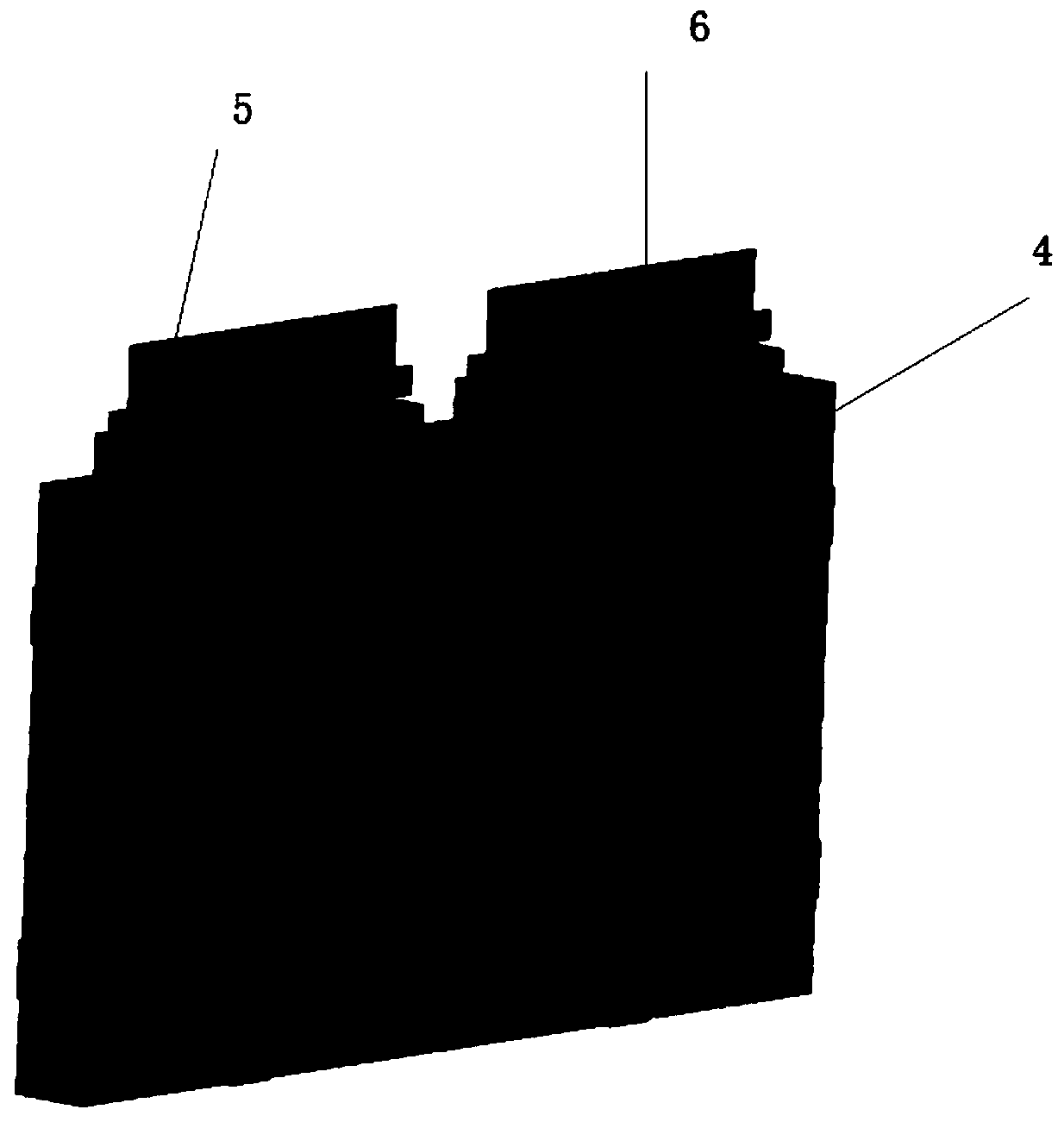

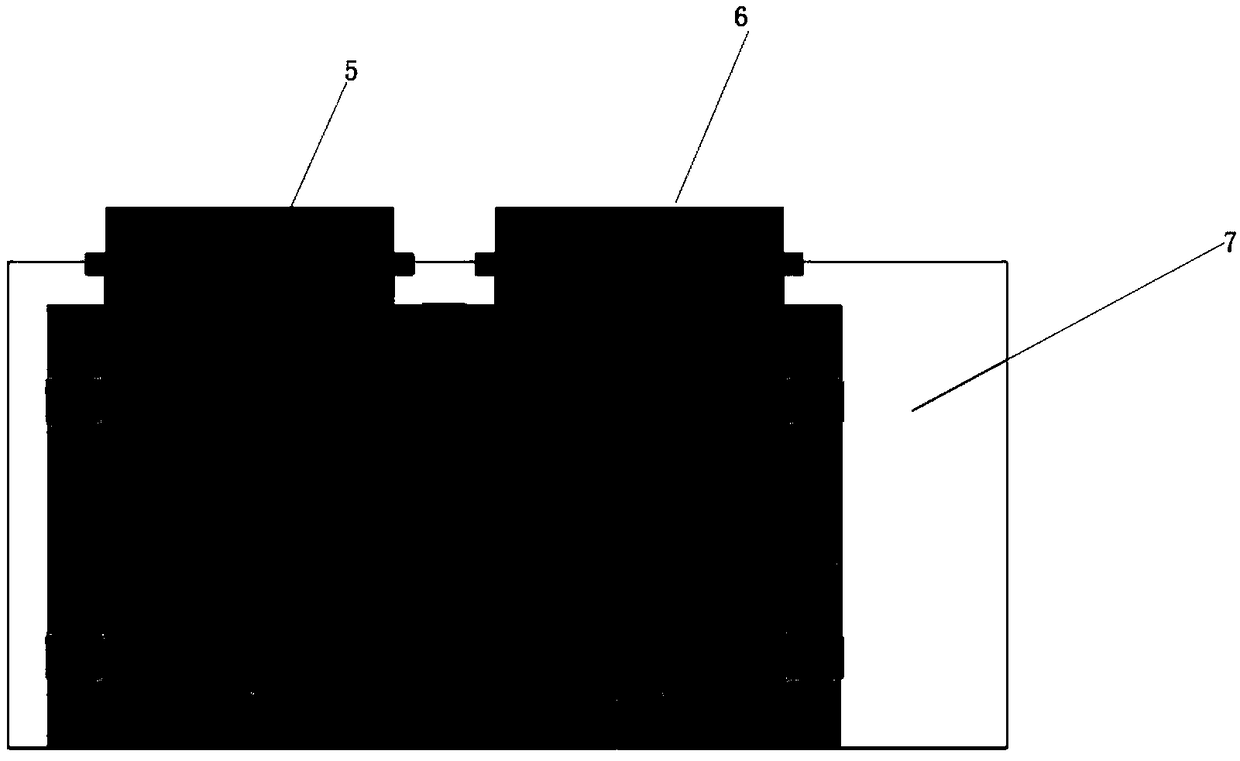

[0060] The difference from Example 1 is; the preparation of large-capacity polymer lithium-ion batteries: the positive electrode of the battery cell is ultrasonically or laser welded with a positive ear with ear glue, and the negative electrode is ultrasonically or laser welded with an ear. For the negative electrode tab of the glue, the battery core is packaged with a material of 0.1mm polyethylene (PE) in the inner layer for the first packaging. The packaging temperature is 140°C, the pressure is 0.3MPa, and the time is 1 second. The relative humidity is ≤1%, and the dew point is -60°C; the once-packaged cell is baked to remove moisture and then injected with electrolyte, and after chemical formation, secondary sealing and other processes and shaping, the finished cell is top-sealed Fold the tabs together to form a square shape, and extend the positive and negative tabs, weld the positive tabs and negative tabs with tab glue with ultrasonic or laser, and put them into the alu...

Embodiment 3

[0063] The difference from Example 1 is; the preparation of large-capacity polymer lithium ion battery: the positive electrode ear with ear glue on the positive electrode of the obtained battery cell is ultrasonically or laser welded, and the negative electrode is welded with ear glue on the negative electrode The negative electrode tab of the battery packs the battery core with a material of 0.1mm cast polypropylene film (CPP) on the inner layer for the first packaging. The packaging temperature is 175°C, the pressure is 0.3MPa, and the time is 2 seconds. , the relative humidity is ≤1%, and the dew point is -60°C; the once-packaged cell is baked to remove moisture and then injected with electrolyte, and after chemical formation, secondary sealing and other processes and shaping, the finished cell is topped The seal is folded up into a square shape together with the tabs, and the positive tab and the negative tab are extended, and the positive tab and the negative tab with tab ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com