Sodium-bismuth-titanate-based unleaded ceramic with negative electrocaloric effect and preparing method of sodium-bismuth-titanate-based unleaded ceramic

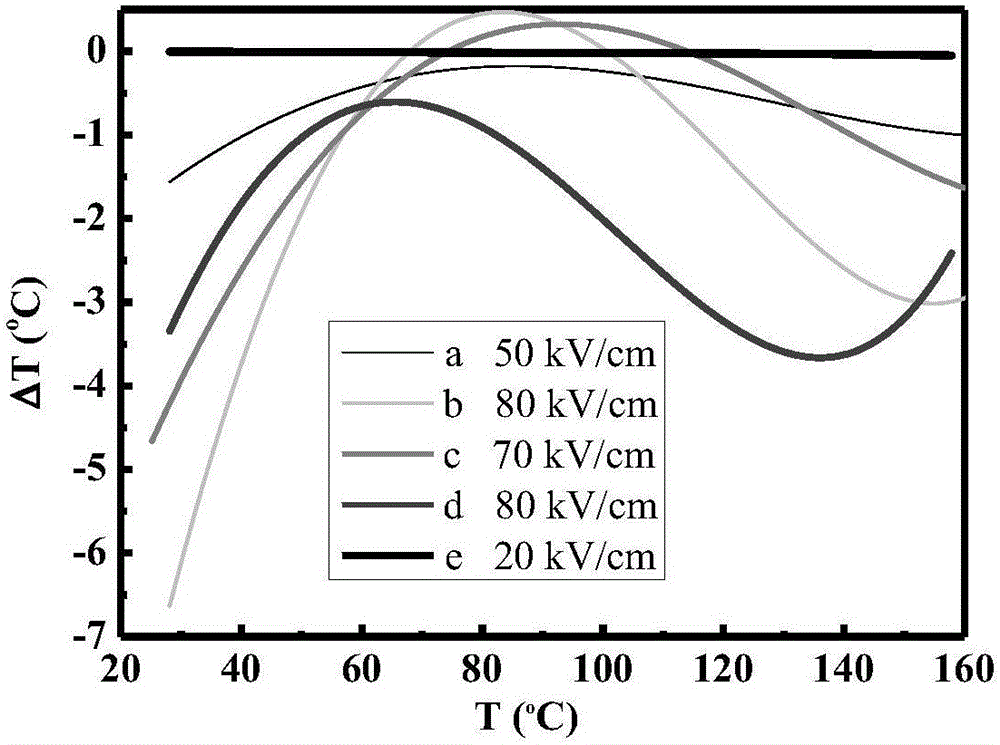

A technology based on lead-free ceramics and sodium bismuth titanate, applied in the field of ceramic materials, can solve the problems of ecological environment and human health hazards, high requirements for the surrounding environment, etc., to improve energy collection, improve solid-state refrigeration efficiency and high Curie temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

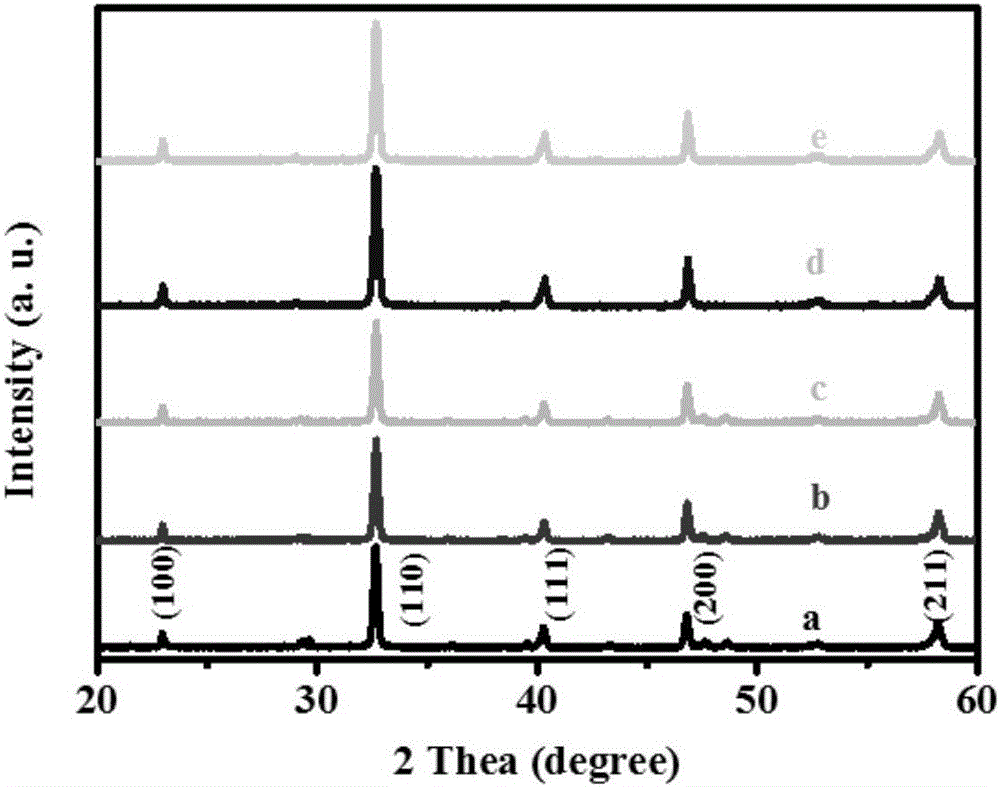

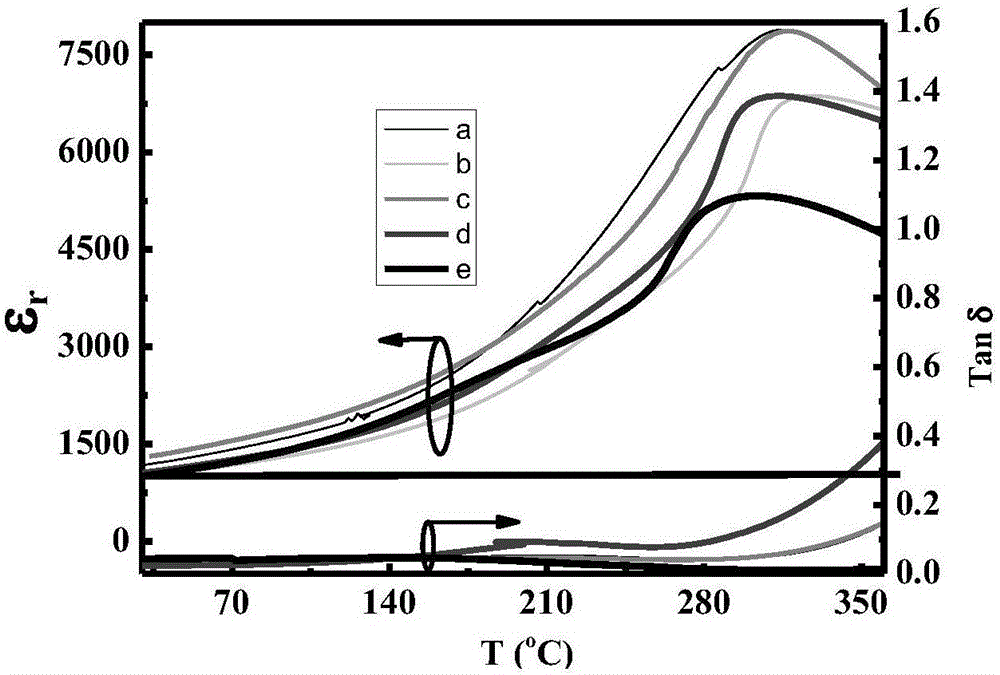

[0026] The chemical composition of the bismuth sodium titanate base lead-free ceramics of the negative electric card effect of the present invention is: (1-x) (Na 0.5 Bi 0.5 )TiO 3 -xSrTiO 3 , wherein: 0≤x≤0.10, prepared by sol-gel powder microwave sintering method, the preparation method includes the following steps: (1) using sodium acetate, bismuth nitrate, strontium acetate and tetra-n-butyl titanate as raw materials, Ethylene glycol methyl ether or acetic acid is used as a solvent, acetylacetone or formamide is used as a chelating agent, and a precursor solution is prepared. The molar concentration of the precursor solution is controlled at 0.3-0.7mol / L; (2) dehydration to form xerogel: the precursor Put the body solution in an oven, control the temperature at 30-70°C, and dehydrate for 10-24 hours; then put it into a vacuum drying oven, keep the pressure at 60-90kPa and 30-70°C for 10-24 hours, and form a dry Gel; (3) Sintering Grind the dry gel, put it into a crucibl...

Embodiment 1

[0030] Ceramic a, the chemical composition is: (Na 0.5 Bi 0.5 )TiO 3 , ie x=0

[0031] Its preparation method is:

[0032] (1) Configure the precursor solution

[0033] Sodium acetate, bismuth nitrate, strontium acetate and tetra-n-butyl titanate are used as raw materials, ethylene glycol methyl ether is used as a solvent, and acetylacetone is used as a chelating agent. The molar ratio is: sodium acetate: bismuth nitrate: strontium acetate: tetratitanate n-butyl ester 1:1:0:1, ethylene glycol methyl ether: acetylacetone = 9:2, control the excess of sodium acetate and bismuth nitrate by 5% and 2% respectively, and control the molar concentration of the precursor solution at 0.5mol / L ;

[0034] (2) Dehydration to form xerogel

[0035] Place the precursor solution in an oven, control the temperature at 50°C, and dehydrate for 24 hours; then put it into a vacuum drying oven, keep the pressure at 80kPa and 50°C for 24 hours, and form a xerogel;

[0036] (3) Sintering conditi...

Embodiment 2

[0041] Ceramic b: 0.98 (Na 0.5 Bi 0.5 )TiO 3 -0.02SrTiO 3, , ie x=0.02

[0042] Its preparation method is:

[0043] (1) Configure the precursor solution

[0044] Sodium acetate, bismuth nitrate, strontium acetate and tetra-n-butyl titanate are used as raw materials, ethylene glycol methyl ether is used as a solvent, and acetylacetone is used as a chelating agent. The molar ratio is: sodium acetate: bismuth nitrate: strontium acetate: tetratitanate n-butyl ester 0.49:0.49:0.02:1, ethylene glycol methyl ether: acetylacetone = 9:2, control the excess of sodium acetate and bismuth nitrate by 5% and 2% respectively, and control the molar concentration of the precursor solution at 0.5mol / L ;

[0045] (2) Dehydration to form xerogel

[0046] Place the precursor solution in an oven, control the temperature at 50°C, and dehydrate for 24 hours; then put it into a vacuum drying oven, keep the pressure at 80kPa and 50°C for 24 hours, and form a xerogel;

[0047] (3) Sintering cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com