Method for removing mud out of titanium-tetrachloride storage tank in production process of titanium tetrachloride

A titanium tetrachloride and storage tank technology, which is applied in the field of clearing the deposit mud of crude titanium tetrachloride storage tanks in the production of titanium tetrachloride, can solve the problems of waste, pollution, and large manpower consumption, so as to avoid waste and pollution, Improving the working environment and increasing the actual income rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

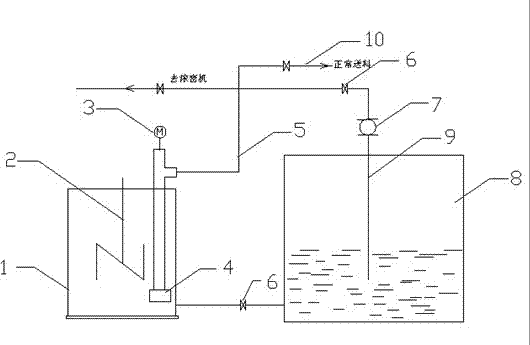

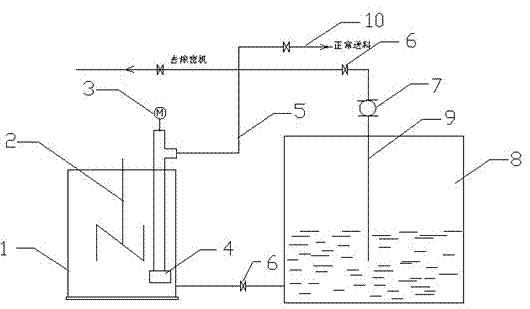

[0010] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0011] A method for removing mud from a titanium tetrachloride storage tank in titanium tetrachloride production, comprising the following steps: 1. In a closed state, using titanium tetrachloride to produce the existing feeding pump to repeatedly circulate the impact of the sedimentation in the storage tank Slurry to make it suspend; ②Then put it into the thickener to settle into mud; ③The mud is put into the dust collection through the mud recovery device for separation and recovery.

[0012] The injection pipe connected to the feeding pump is installed in the storage tank to repeatedly circulate the impact on the settled mud in the storage tank. In order to expand the impact range of the feeding pump, an angle adjustment device for the injection pipe is installed on the top of the storage tank. The feeding pump adjusts the angle of the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com