Puree processing and molding apparatus for meat ball production

A molding device and a technology for tribute balls, which are applied in meat processing equipment, processed meat, applications, etc., can solve problems such as reducing meatiness and meat quality, loosening meatballs, and destroying meat texture, etc., so as to meet the requirements of taste and efficiency. Firm and elastic, no safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

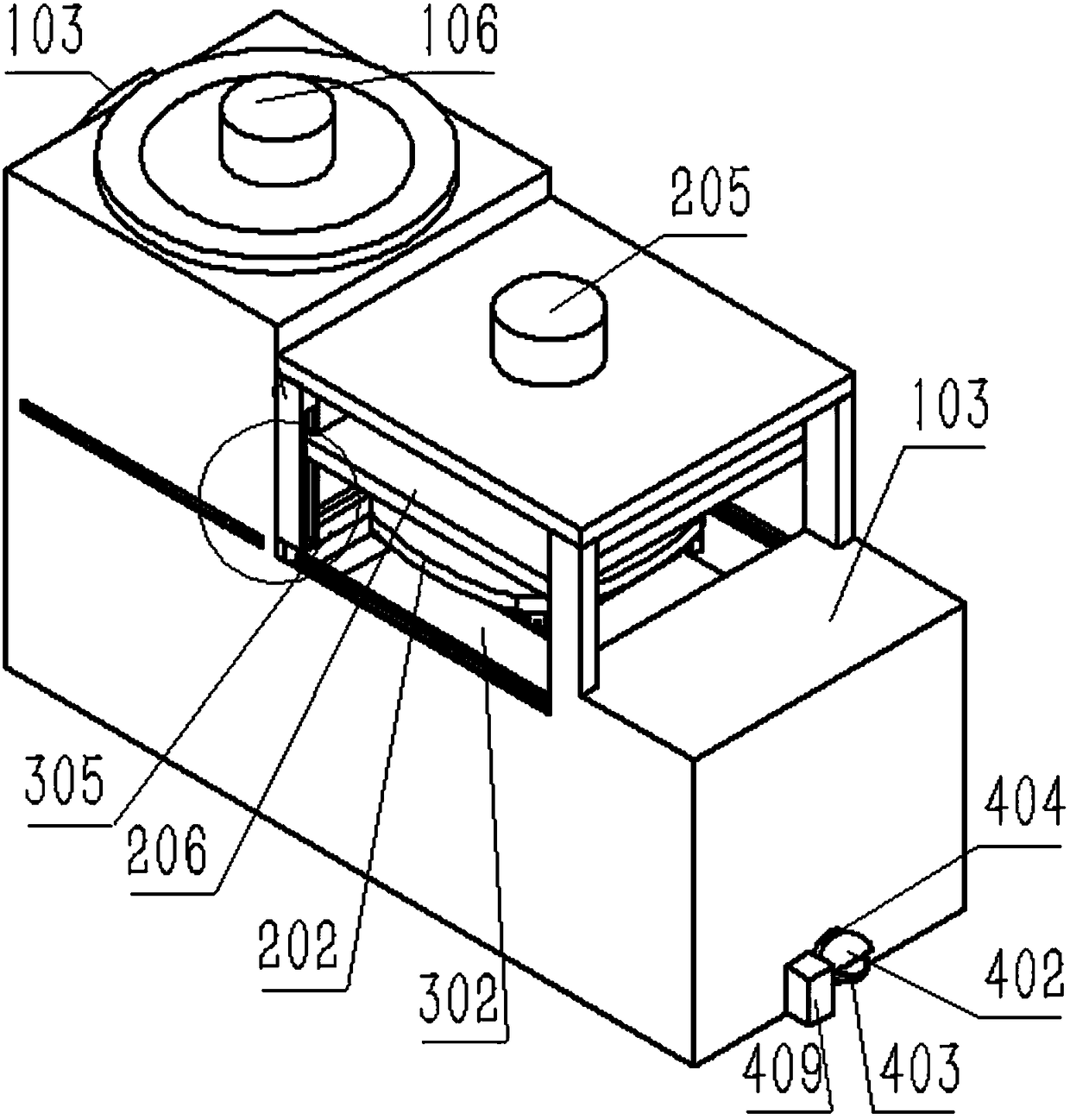

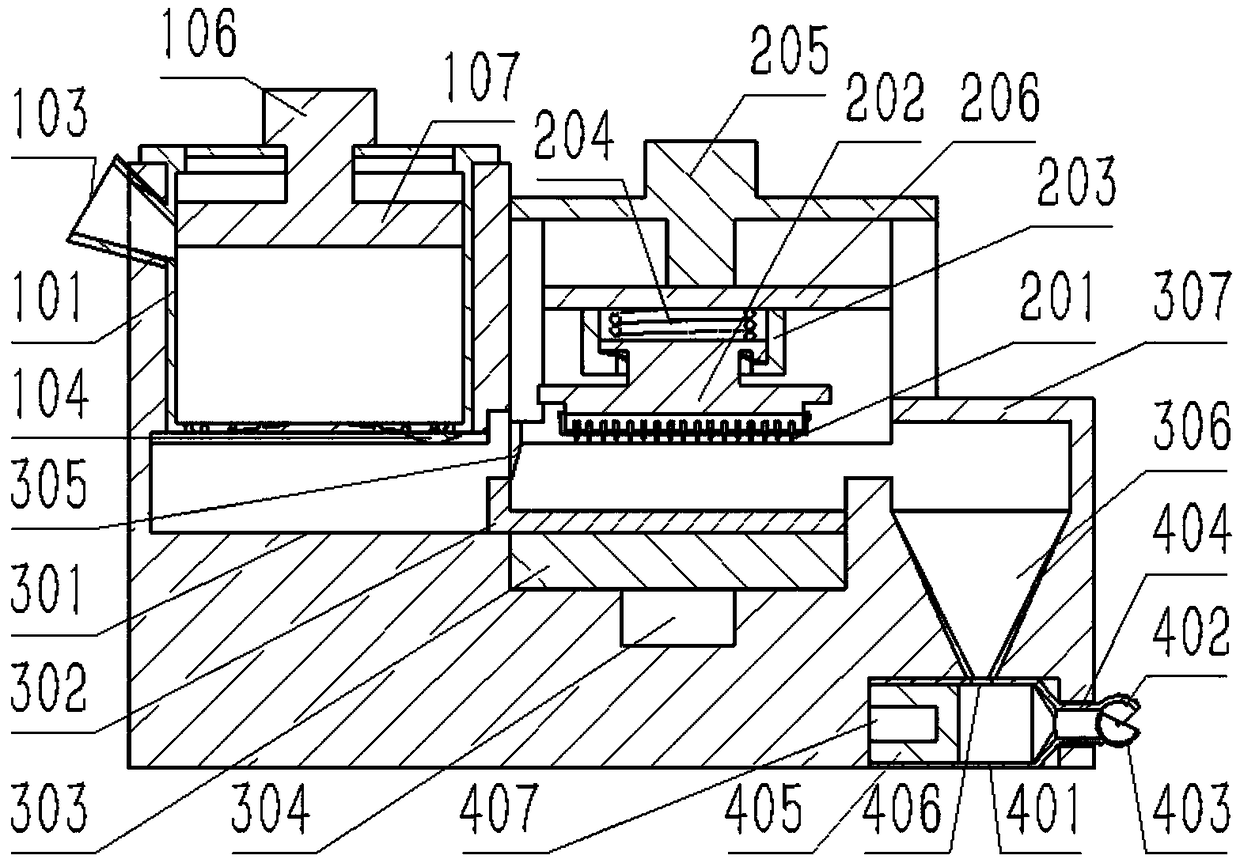

[0022] The embodiment of the present invention provides a meat paste processing and forming device for the production of tribute balls, including a meat cutting device, a meat chopping device, a meat receiving device and a tribute ball forming device. The meat device is adjacent to the meat chopping device, the meat receiving device is below the meat cutting device and the meat chopping device, and the tribute ball forming device is at the bottom of the meat receiving device below the meat chopping device side down.

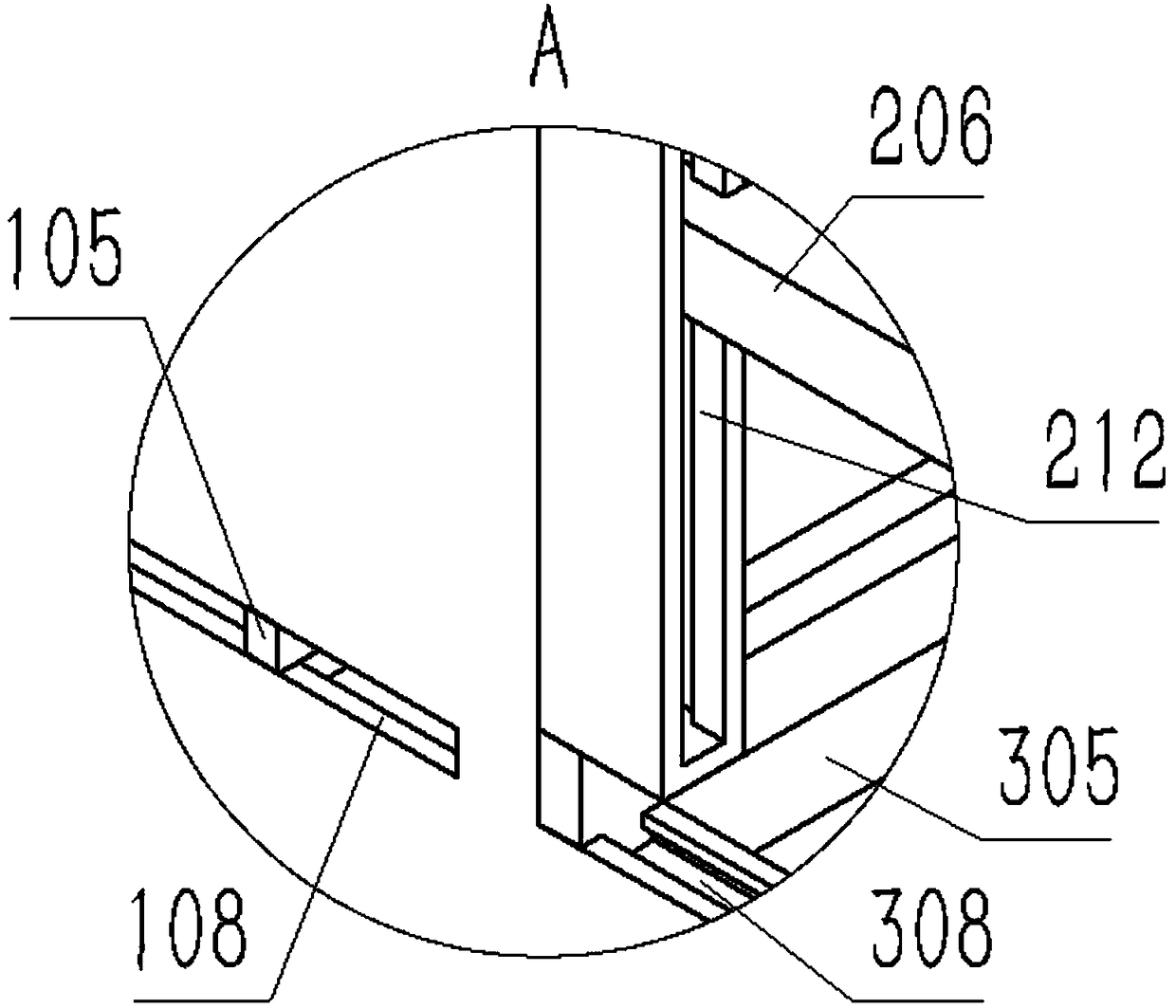

[0023] The meat cutting device is provided with a feeding tube 101, a feeding port 103 is arranged on the upper side of the feeding tube 101, a mesh knife 102 is fixedly arranged at the discharge end of the feeding barrel 101, and a double-edged knife 104 is arranged below the mesh knife 102. 104 two ends are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com