Chemical prepn process of composite hydroxyapatite/collagon layer on the surface of Ni-Ti alloy

A hydroxyapatite and nickel-titanium alloy technology, applied in medical science, prosthesis, etc., can solve problems such as the inability to approximate the growth process of human bone, the inability to fully exert biocompatibility, and the inability to fully simulate human bone, etc. The effect of low processing temperature, high bonding strength and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

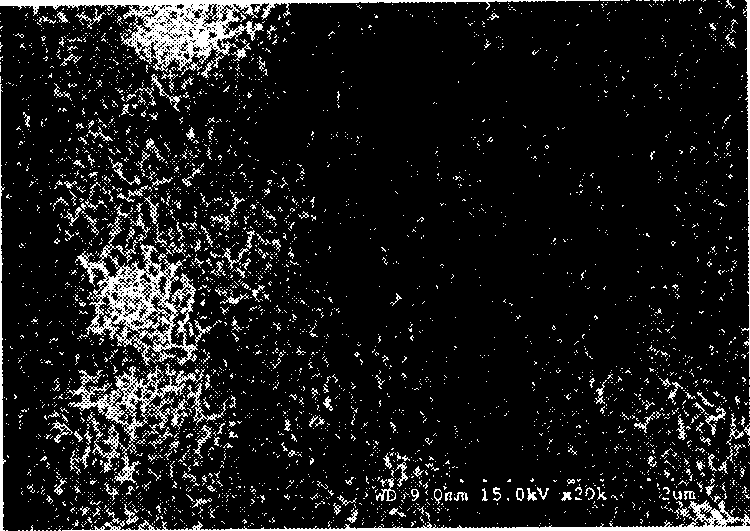

[0011] Take a NiTi alloy matrix bulk sample (10×10×3mm 3 ), polished to 800# step by step with water sandpaper, then ultrasonically cleaned in deionized water, and then sealed and dried at room temperature. The dried sample was put into 30% nitric acid and treated at 50°C for 30min. After ultrasonic cleaning with deionized water and airtight drying at room temperature, place it in a sodium hydroxide solution with a concentration of 1.2M and soak for 2 hours at 100°C. After that, the sample needs to be ultrasonically cleaned with deionized water and airtightly dried at room temperature deal with. The obtained sample was placed in Na 2 HPO 4 Soak in a supersaturated aqueous solution at 40°C for 8 hours, and then in Ca(OH) 2 Soak in supersaturated aqueous solution at 25°C for 8h. After that, the pre-calcified sample was ultrasonically cleaned with deionized water and airtightly dried at room temperature, and then soaked in the composition: Na + 213.0mmol / L, Cl - 187.5mmo...

example 2

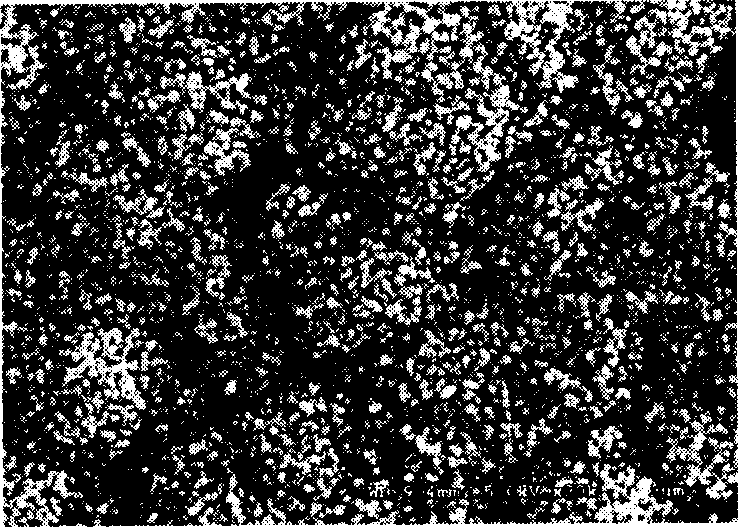

[0013] Take a NiTi alloy matrix bulk sample (10×10×3mm 3 ), polished to 800# step by step with water sandpaper, then ultrasonically cleaned in deionized water, and then sealed and dried at room temperature. The dried sample was put into 50% nitric acid and treated at 60°C for 10 minutes. After ultrasonic cleaning with deionized water and airtight drying at room temperature, place in 2M sodium hydroxide solution and soak for 5 hours at 100°C. After that, the sample needs to be ultrasonically cleaned with deionized water and airtightly dried at room temperature. . The obtained sample was placed in Na 2 HPO 4 Soak in a supersaturated aqueous solution at 40°C for 4 hours, and then in Ca(OH) 2 Soak in supersaturated aqueous solution at 40°C for 12h. After that, the pre-calcified sample was ultrasonically cleaned with deionized water and airtightly dried at room temperature, and then soaked in the composition: Na + 213.0mmol / L, Cl - 187.5mmol / L, HCO 3 - 40.5mmol / L, K + ...

example 3

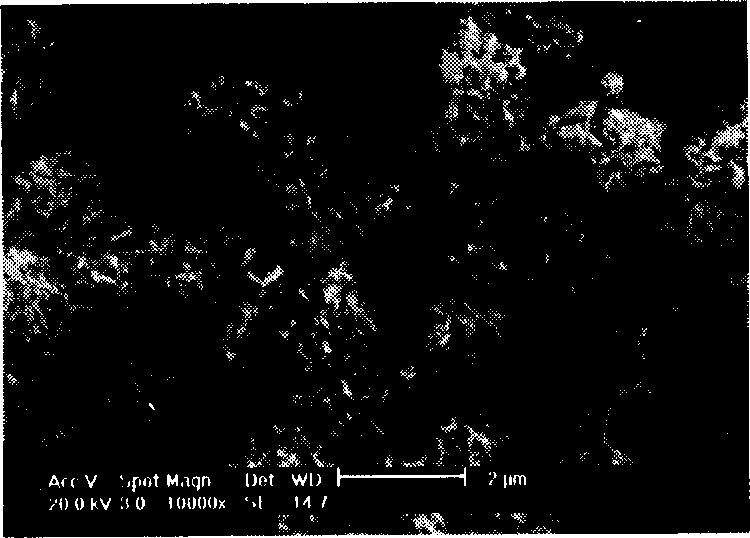

[0015] Take a NiTi alloy matrix bulk sample (10×10×3mm 3 ), polished to 800# step by step with water sandpaper, then ultrasonically cleaned in deionized water, and then sealed and dried at room temperature. The dried sample was put into 30% nitric acid and treated at 60°C for 30min. After ultrasonic cleaning with deionized water and airtight drying at room temperature, place it in a sodium hydroxide solution with a concentration of 1.2M and soak for 6 hours at 100°C. After that, the sample needs to be ultrasonically cleaned with deionized water and airtightly dried at room temperature deal with. The obtained sample was placed in Na 2 HPO 4 Soak in a supersaturated aqueous solution at 40°C for 15 hours, and then in Ca(OH) 2 Soak in supersaturated aqueous solution at 25°C for 8h. After that, the pre-calcified sample was ultrasonically cleaned with deionized water and airtightly dried at room temperature, and then soaked in the composition: Na + 213.0mmol / L, Cl - 187.5mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com