Target holder applied to pulsed laser co-deposition and mounting method

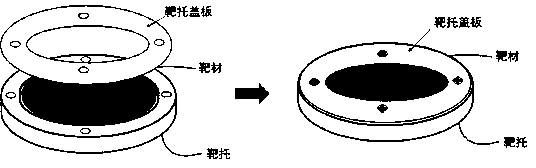

A technology of pulsed laser and installation method, which is applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of target loss, center of bombardment circles not coincident, and pits, etc., so as to improve the utilization rate , Slow down the speed of scrapping, avoid the effect of pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

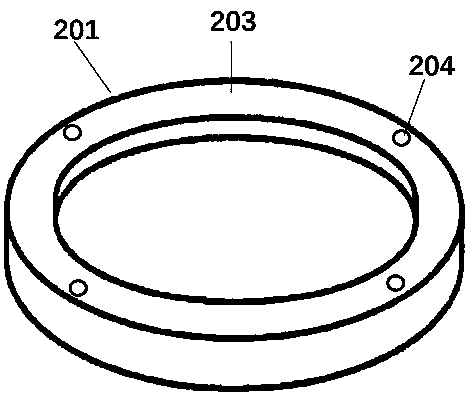

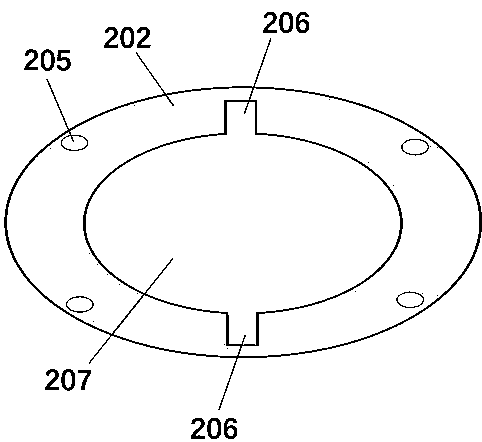

[0028] A target support applied to pulsed laser co-deposition, comprising a target support base 201 ( figure 2 ) and target cover plate 202 ( image 3 ), the target support base 201 is provided with a raised surrounding wall 203 and a circular groove, and a plurality of screw holes 204 are provided on the surrounding wall 203. The target support is set in cooperation with the target material, and the target material includes Disassembled circular target module 101 and circular target module 102 ( Figure 4 ), the side walls of the circular target module 101 and the annular target module 102 are provided with a through hole, and a through column 104 is arranged in the through hole; the target cover plate 202 also has two oppositely arranged adjustment In the zone 206 , both ends of the through column 104 are placed in the adjustment zone 206 .

[0029] The target cover plate 202 is ring-shaped, the outer diameter of the ring is equal to the outer diameter of the target suppo...

Embodiment 2

[0033] A target material matched with the target holder in Embodiment 1, which is set in the process chamber of multi-pulse laser deposition (PLD). The target includes a circular target module 101 and a plurality of circular target modules 102 that can be independently disassembled, wherein the side walls of the circular target module 101 and the multiple circular target modules 102 have Through-hole, the through-pillar 104 passes through the through-hole of the circular target module 101 and the circular target module 102, and fixes a circular target module 101 and multiple circular target modules 102 into a circular target , both ends of the through column 104 are exposed, and the through column 104 is provided with a scale mark. The length of the through post 104 is equal to the inner diameter of the target holder groove. In order to facilitate target installation, the diameter of the combined circular target is smaller than the inner diameter of the target holder. There ...

Embodiment 3

[0035] The installation method of embodiment 1 target support and embodiment 2 target material, the steps are as follows:

[0036] Step 1, a circular target module 101, one or more circular target modules 102 and circular isolation modules 105 that can be independently disassembled are combined into a circular target, wherein the circular target module 101 and one Or a plurality of annular target modules 102 are aligned with the through holes of the side walls of the annular isolation module;

[0037] Step 2, the through-pillar 104 passes through the through-holes of the circular target module 101 and the annular target module 102, so that the combined targets are integrated, and the scale marks are exposed at both ends of the through-pillar 104;

[0038] Step 3, put the combined target inserted into the through column 104 into the circular groove of the target support bottom 201, and cover the target cover plate 202;

[0039] Step 4, after aligning the screw holes of the targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com