Alloy nanotube and manufacturing method thereof

A technology of alloy nano and metal, which is applied in the field of nano materials, can solve the problems of alloy nanotubes that have not been reported in the literature, and achieve the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

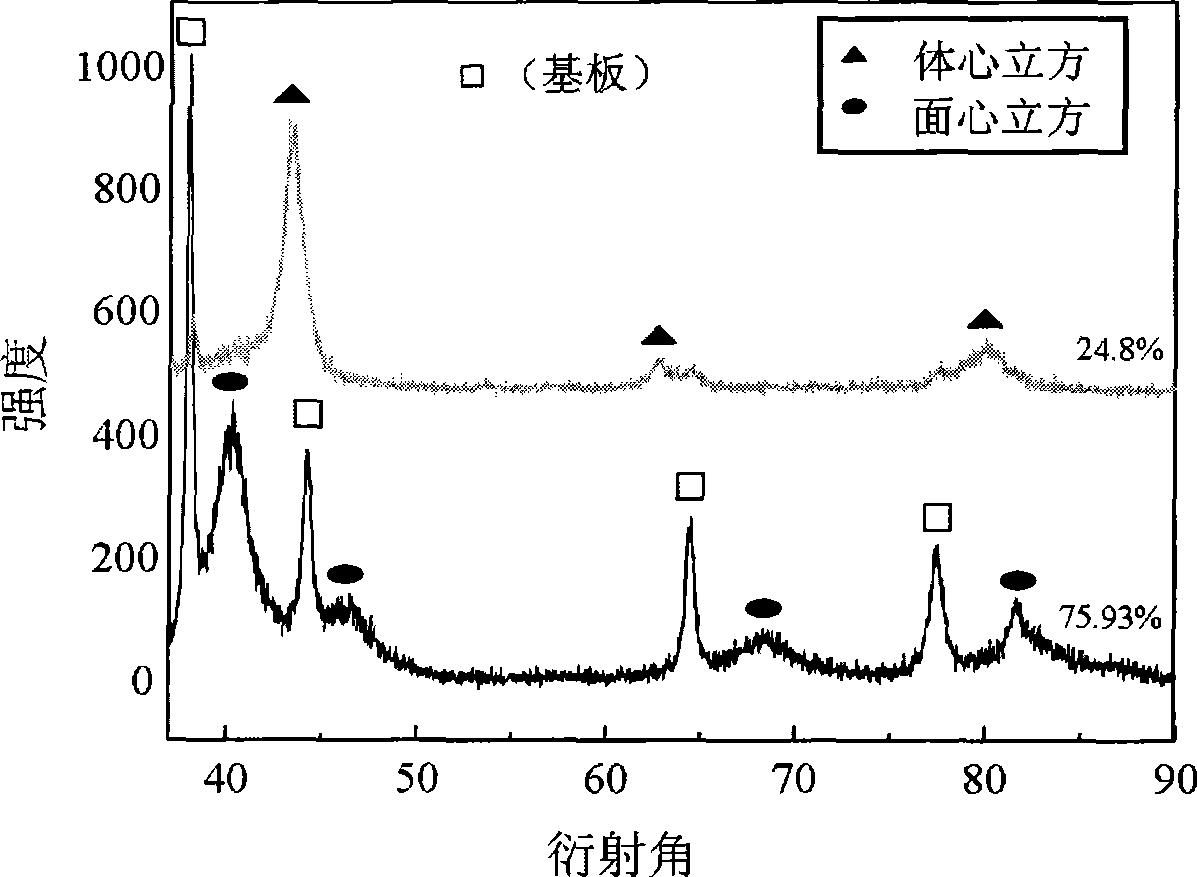

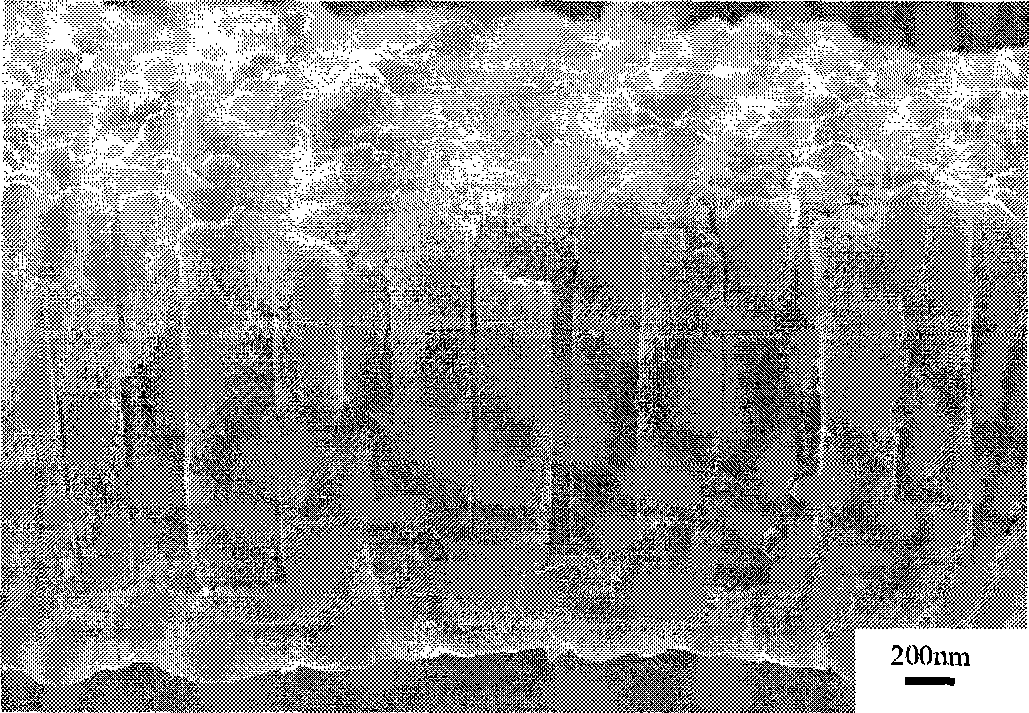

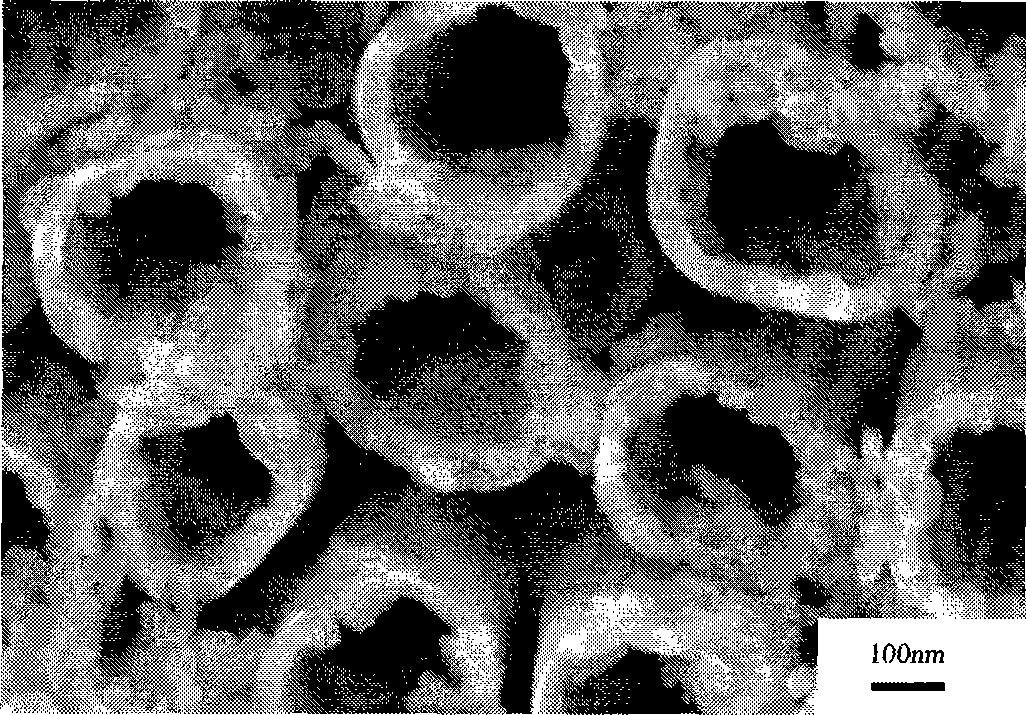

Examples

Embodiment 1

[0029] 1) prepare the electrolyte solution of two kinds of metal ions:

[0030] ①Add 30ml of 0.1mol / l ammonium tartrate solution into a 50ml beaker, then pour 10ml of 0.2mol / l ferrous sulfate solution into the ammonium tartrate solution, stir to obtain a light yellow colloid, drop in concentrated ammonia water to make It dissolves and adjusts the pH of the solution to 8.5;

[0031] ②Add 30ml of 0.05mol / l citric acid solution into a 50ml beaker, then add 10ml of 0.01mol / l palladium chloride, heat and stir until the precipitate dissolves, and obtain a yellow-brown solution. Adjust the pH value of the solution to 8.5 with concentrated ammonia water ;

[0032] ③ Mix the solutions prepared in steps ① and ②, then add 10ml of 0.5mol / l ammonium chloride solution, and adjust the pH value of the solution to 8.5 with concentrated ammonia water;

[0033] 2) The aluminum oxide template was ultrasonically treated for 15 minutes with solvents of different polarities (water, ethanol and ace...

Embodiment 2

[0038] 1) prepare the electrolyte solution of two kinds of metal ions:

[0039] ①Add 30ml of 0.3mol / l ammonium tartrate solution into a 50ml beaker, then pour 10ml of 0.1mol / l cobalt chloride hexahydrate into the ammonium tartrate solution to obtain a purple-red solution, and drop concentrated ammonia water to adjust the solution The pH value is 9.5;

[0040] ② Add 30ml of 0.1mol / l citric acid solution into a 50ml beaker, then add 10ml of 0.03mol / l chloroplatinic acid, heat and stir until the precipitate dissolves, and obtain a light yellow solution. Adjust the pH value of the solution to 9.5 with concentrated ammonia water ;

[0041] ③ Mix the solutions prepared in steps ① and ②, then add 10ml of 1mol / l ammonium chloride solution, and adjust the pH value of the solution to 9.5 with concentrated ammonia water;

[0042] 2) Before using the etched polycarbonate template, use solvents of different polarities (water, ethanol and acetone) to perform ultrasonic treatment for 30 minu...

Embodiment 3

[0047] 1) prepare the electrolyte solution of two kinds of metal ions:

[0048] ①Add 30ml of 0.3mol / l ammonium tartrate solution into a 50ml beaker, then pour 10ml of 0.25mol / l ferrous sulfate heptahydrate solution into the ammonium tartrate solution, stir to obtain light yellow colloid, drop into concentrated Ammonia makes it dissolve, and the pH value of adjusting solution is 6;

[0049] ②Add 30ml of 0.075mol / l citric acid solution into a 50ml beaker, then add 10ml of 0.02mol / l chloroplatinic acid, heat and stir until the precipitate dissolves, and obtain a light yellow solution. Adjust the pH of the solution to 6 with concentrated ammonia water ;

[0050] ③ Mix the solutions prepared in steps ① and ②, then add 10ml of 0.8mol / l ammonium chloride solution, and adjust the pH value of the solution to 6 with concentrated ammonia water;

[0051] 2) Before using the Al2O3 template, ultrasonically treat it with solvents of different polarities (water, ethanol and acetone) for 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com