Composite solid polymer electrolyte film and preparation method and application thereof

A solid polymer and electrolyte membrane technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of difficult and uniform dispersion of nano-ceramic particles and not put into actual production, so as to reduce impedance, increase ionic conductivity, The effect of accelerating the migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention proposes a method for preparing a composite solid electrolyte membrane, which specifically includes the following steps:

[0047] S1. Dissolving the polymer in an organic solvent, ultrasonically dispersing, and stirring evenly to obtain a mixed solution. The concentration of the polymer in the solution is 10-30 wt%. The selection of the organic solvent has no special requirements and can be selected according to actual needs. For example, in an embodiment of the present invention, the organic solvent is N,N-dimethylformamide, N,N-dimethylacetamide, N,N-dimethylpropanamide, N-methylpyrrolidone, acetonitrile , Acetone.

[0048] The solution containing the polymer is ultrasonically dispersed for sufficient dissolution. There is no special requirement for the ultrasonic dispersion time, which can be adjusted according to actual needs. For example, in an embodiment of the present invention, the ultrasonic dispersion time is 10 min-40 min. The solution incl...

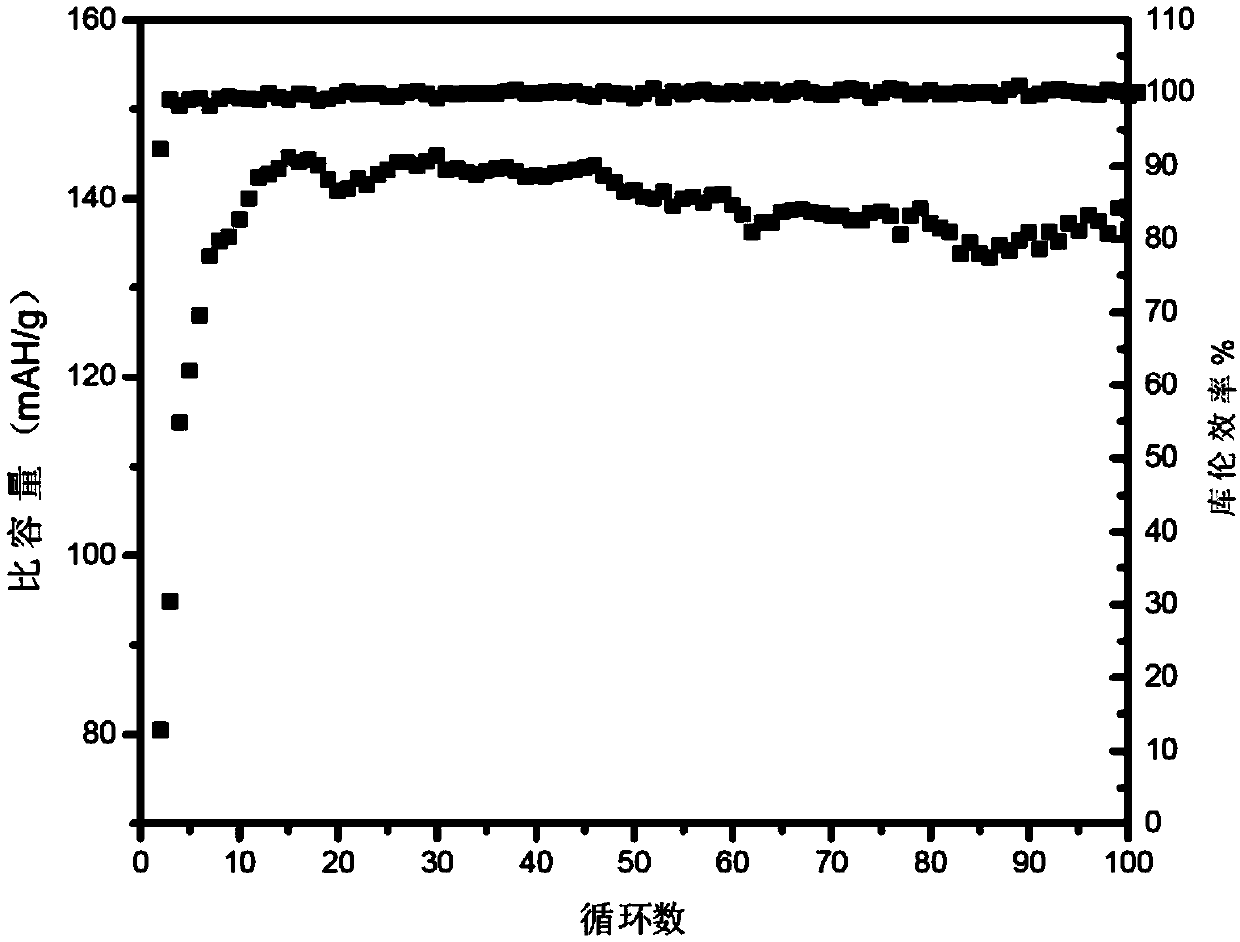

Embodiment 1

[0060] A composite solid electrolyte membrane, the electrolyte membrane is made of polyvinylidene fluoride (PVDF), lithium perchlorate (LIClO 4 ), nano palygorskite, bis(trifluoromethylsulfonyl) 1-ethyl-3-methylimidazole (EMITFSI), and dimethyl carbonate (DMC).

[0061] The preparation method is as follows: firstly, PVDF is dispersed in DMF solvent, and magnetically stirred at 50° C. for 6 hours to obtain a mixed solution. During this process, the mass concentration of the PVDF solution was kept at 15%. Then, add LIClO to the PVDF solution sequentially 4 , Nano palygorskite, EMITFSI and DMC. Added LIClO 4 accounted for LIClO 4 and 20% of the total mass of nano palygorskite, the added nano palygorskite accounts for 10wt% of the total mass of nano palygorskite and PVDF, the quality of EMITFSI added is 10wt% of the total mass of EMITFSI and PVDF mixture, the quality of added DMC 3wt% of the total mass of the mixture of DMC and PVDF, and then continue to stir for 12 hours to ...

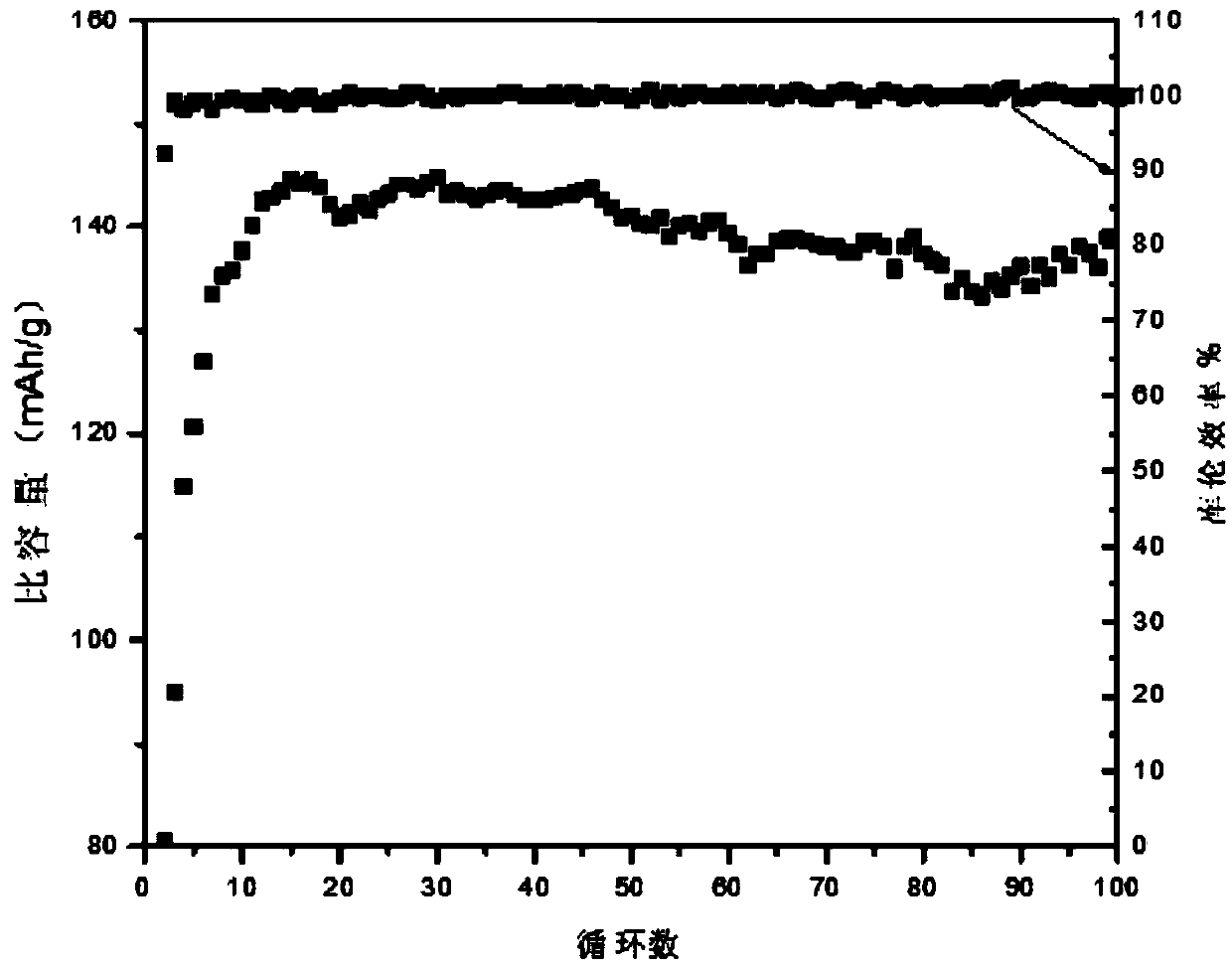

Embodiment 2

[0063] A composite solid electrolyte membrane, the electrolyte membrane is made of polyvinylidene fluoride (PVDF), lithium hexafluorophosphate (LIPF 6 ), nano palygorskite, bis(trifluoromethylsulfonyl) 1-ethyl-3-methylimidazole (EMITFSI), and ethylene carbonate (EC).

[0064] The preparation method is as follows: firstly, PVDF is dispersed in DMP solvent, and magnetically stirred at 60° C. for 6 hours to obtain a mixed solution. During this process, the mass concentration of the PVDF solution was kept at 10%. Then, add LIPF to the PVDF solution sequentially 6 , nano palygorskite, EMITFSI and EC. Joined LIPF 6 accounted for LIPF 6 and 20% of the total mass of nano palygorskite, the added nano palygorskite accounts for 15wt% of the total mass of nano palygorskite and PVDF, the quality of added EMITFSI is 10wt% of the total mass of EMITFSI and PVDF mixture, the quality of added EC 10wt% of the total mass of the mixture of EC and PVDF, and then continue to stir for 12 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com