Patents

Literature

74results about How to "Reduce the degree of crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of all-solid-state polymer electrolyte

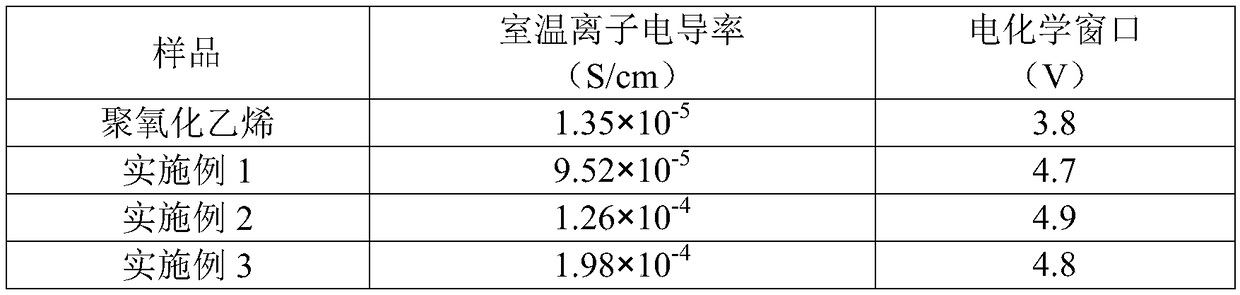

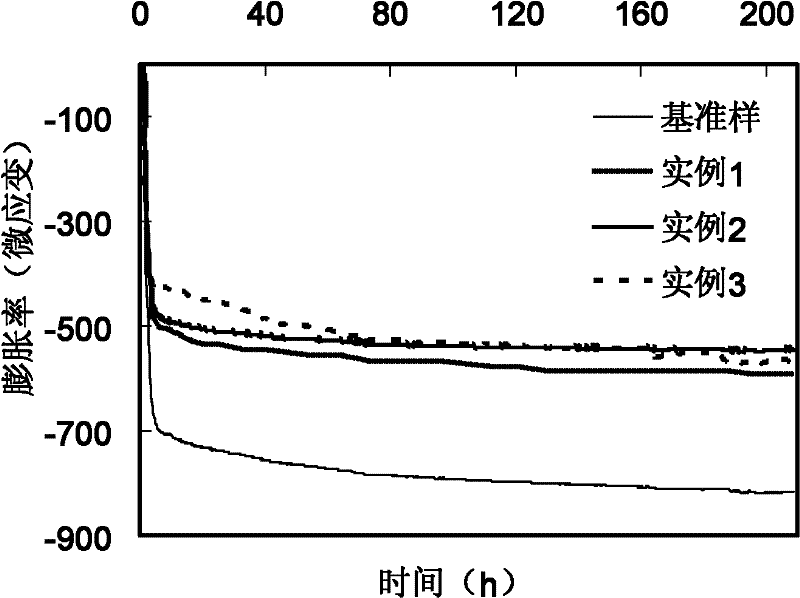

ActiveCN109037770AImprove mechanical propertiesImprove electrochemical stabilitySecondary cellsElectrolyte immobilisation/gelificationHigh energyElectrochemical window

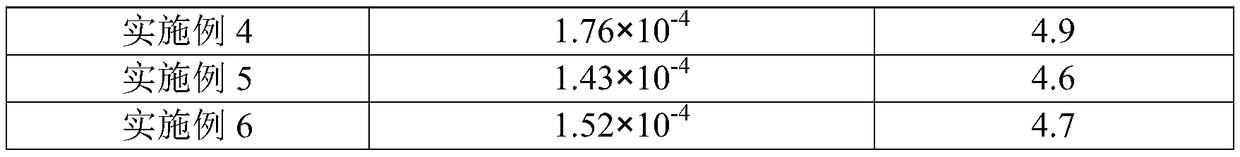

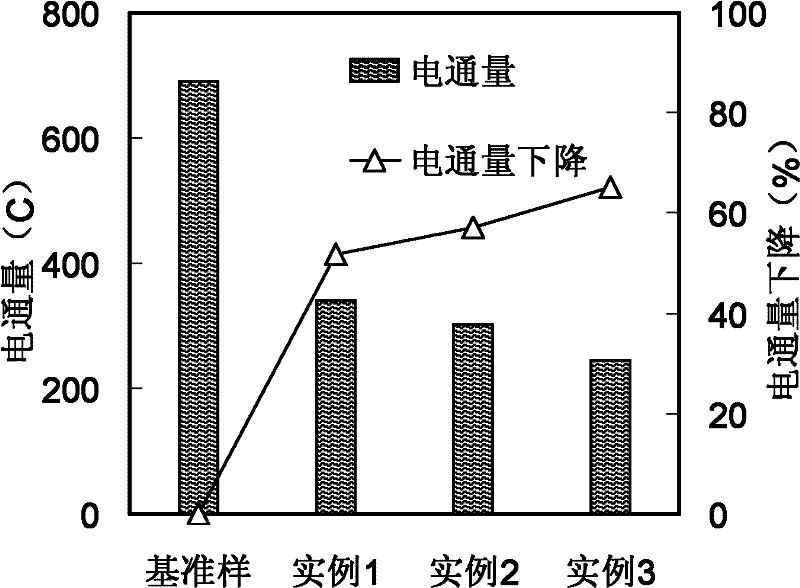

The preparation method of an all-solid-state polymer electrolyte comprises the following steps: adding a carbonic acid structure crosslinking agent, a polyether structure monomer, an olefine acid monomer and a functional polymer together with a solvent into a reactor for stirring to form a uniform precursor solution; Adding an initiator, a lithium salt, an inorganic filler and / or a fast ionic conductor to the precursor solution, stirring to obtain a mixed solution, uniformly coating the mixed solution on a mold, evaporating the solvent, and initiating a reaction under an inert gas; At that endof the initiation reaction, vacuum dry is carried out to obtain an all-solid polymer electrolyte. As that carbonate polyalkenyl structure monome is used as a crosslink agent, the polyether monomer and the olefine acid monomer are crosslinked and copolymerize, and the electrochemical window of the all-solid-state polymer electrolyte can be effectively improved by introducing the carbonate crosslinking structure, and the all-solid-state polymer battery with higher energy density and a better application range can be assembled.

Owner:ZHUHAI COSMX BATTERY CO LTD

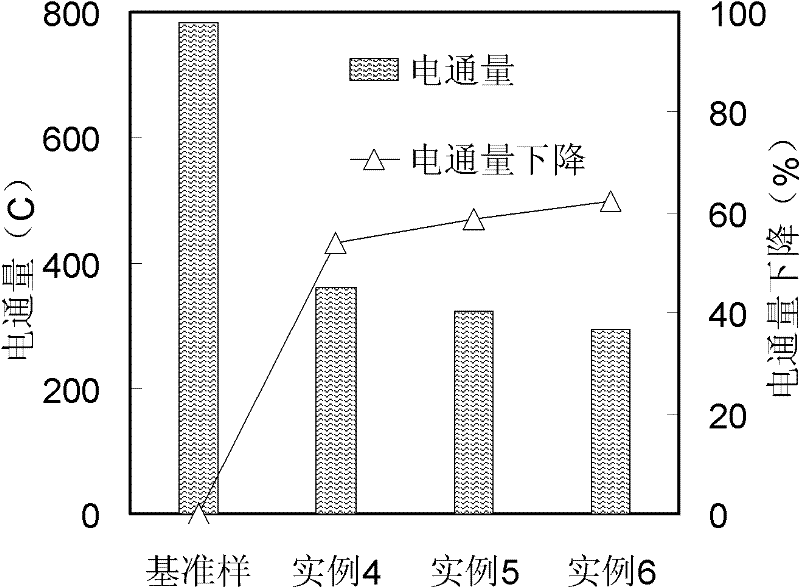

Modified metakaolin-based permeation-resistant and crack-resistant agent for concrete

The invention discloses a modified metakaolin-based permeation-resistant and crack-resistant agent for concrete. The modified metakaolin-based permeation-resistant and crack-resistant agent for concrete comprises: by mass, 10 to 75% of modified metakaolin, 5 to 40% of fine limestone powder, 4 to 40% of superfine coal ash, 1 to 20% of calcined hydrotalcite, 2 to 40% of fine quartz sand and 0.2 to 20% of solid silane powder. A preparation method of the modified metakaolin comprises the following steps of putting dry and washed kaolin into a bowl mill, carrying out grinding to obtain kaolin powder, carrying out calcination of the kaolin powder at a temperature of 500 to 1000 DEG C for 0.5 to 6.0 hours to obtain metakaolin, putting the metakaolin into a dispersion machine, adding an organic modifier of sulfamate or triethanolamine into the metakaolin, wherein a mass ratio of the metakaolin and the organic modifier is in a range of (5000: 1) to (100: 1), and carrying out dispersion to obtain the modified metakaolin having a contact angle of 50 to 100 degrees and a specific surface area of 8000 to 15000m<2> / kg. The modified metakaolin-based permeation-resistant and crack-resistant agentfor concrete can be utilized as a concrete additive, improves strength of concrete at different ages, does not produce obvious influences on concrete work performances, obviously improves anti-chloride ion penetration capability of concrete, reduces total shrinkage of concrete and improves crack resistance of concrete.

Owner:WUHAN UNIV OF TECH +1

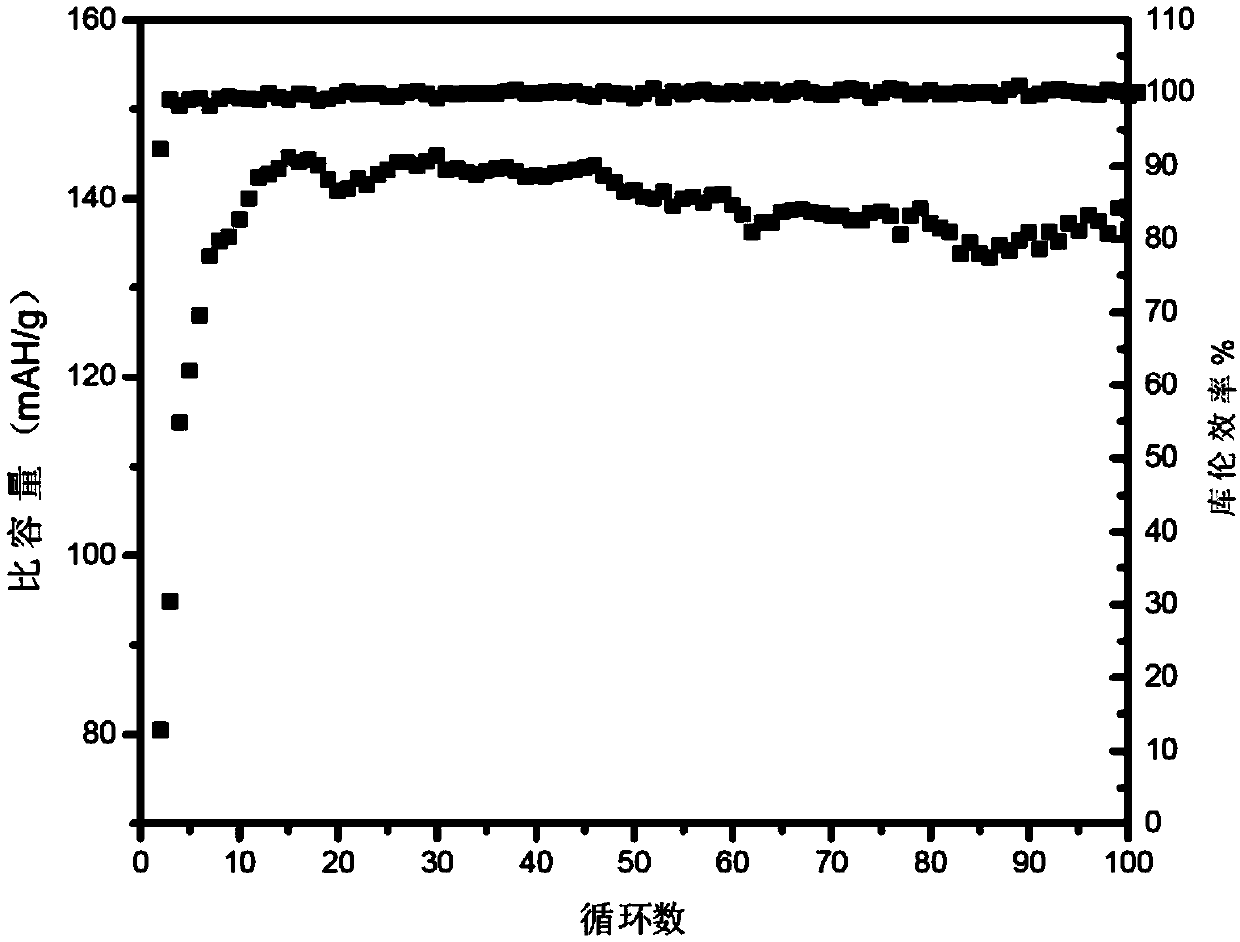

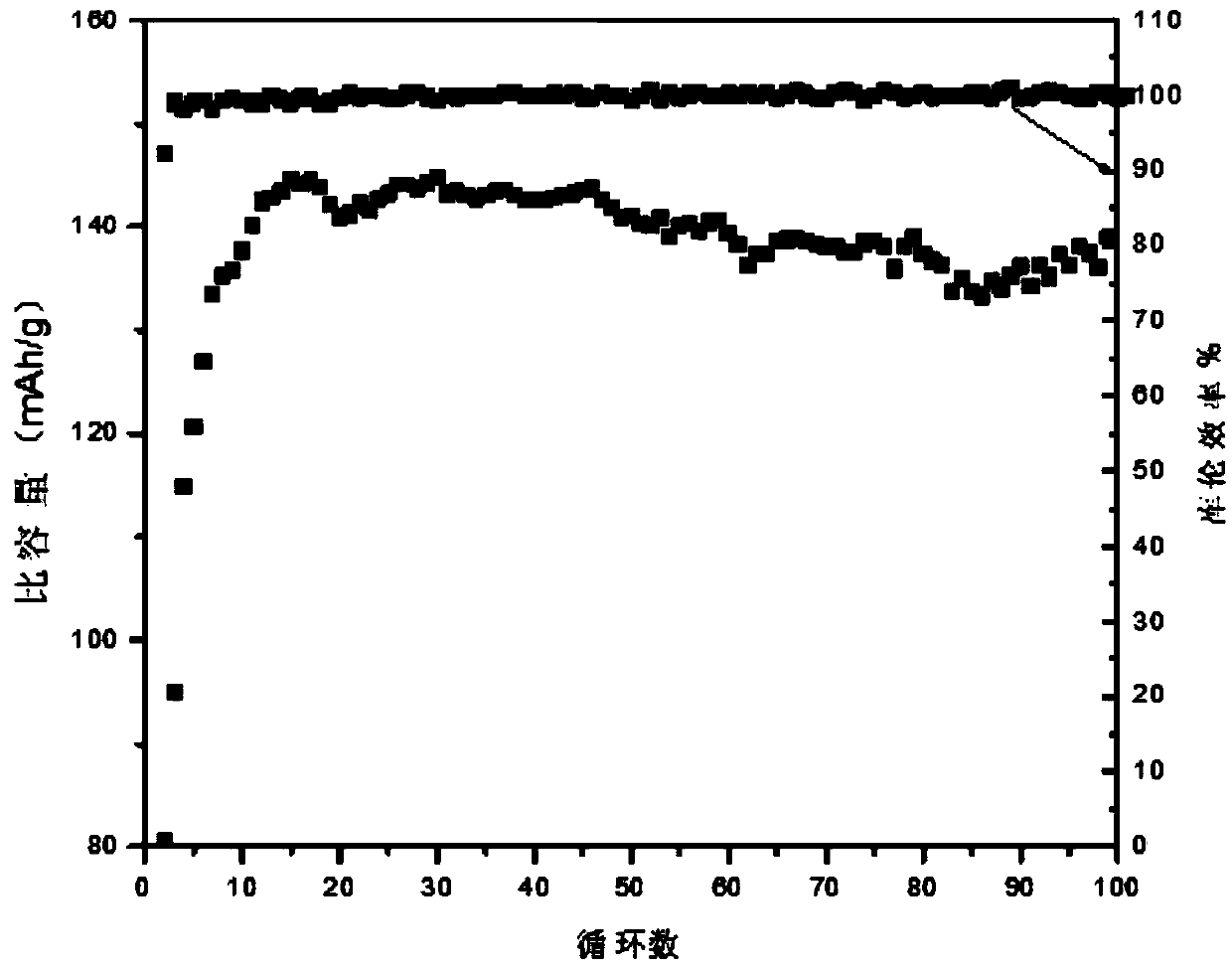

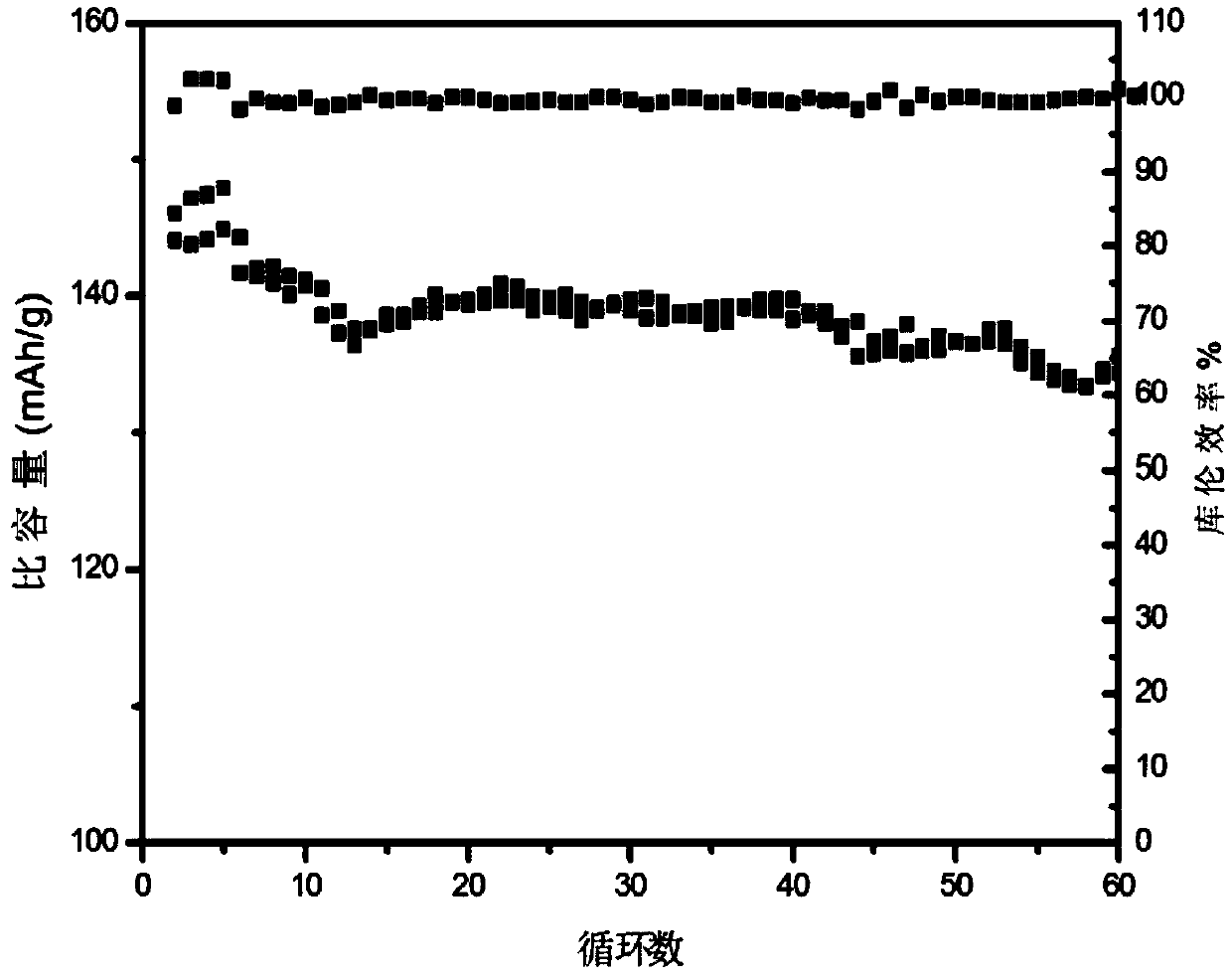

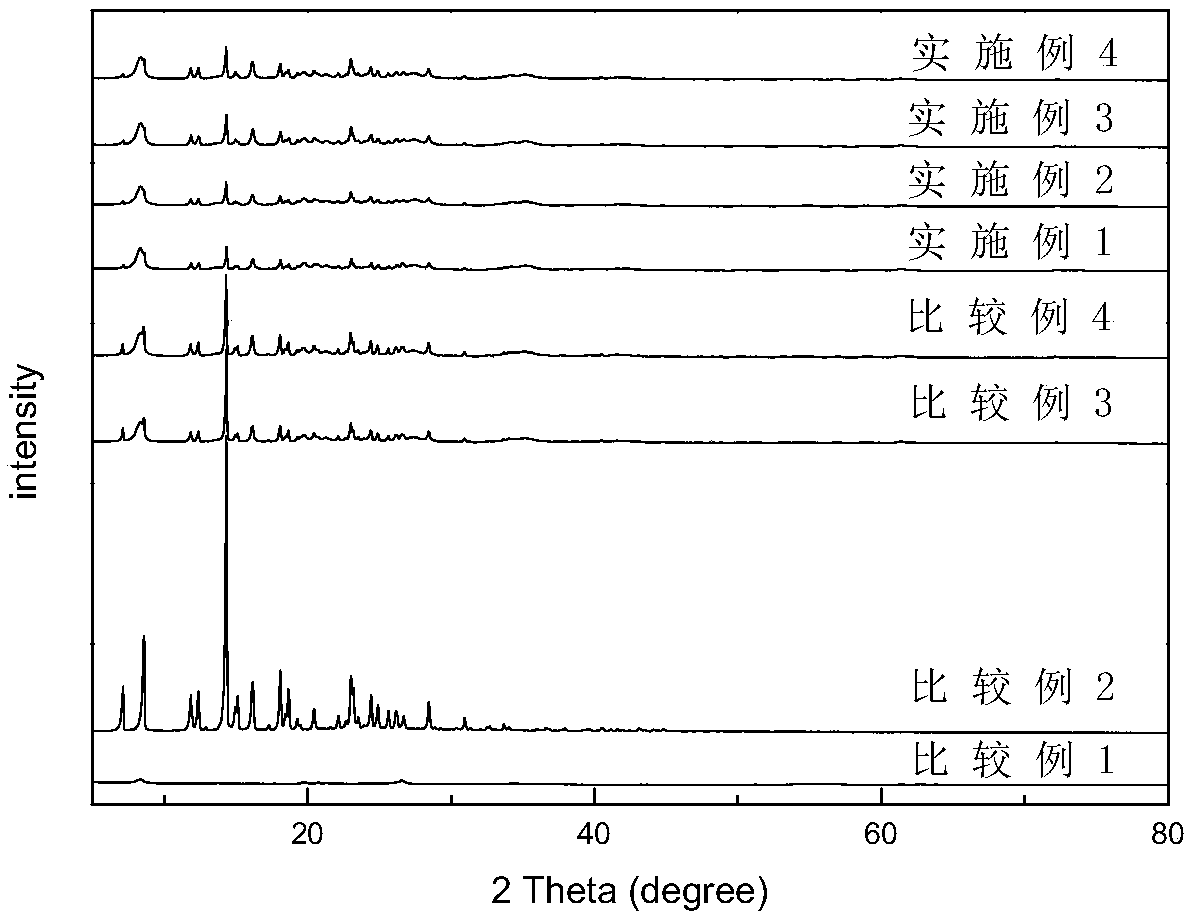

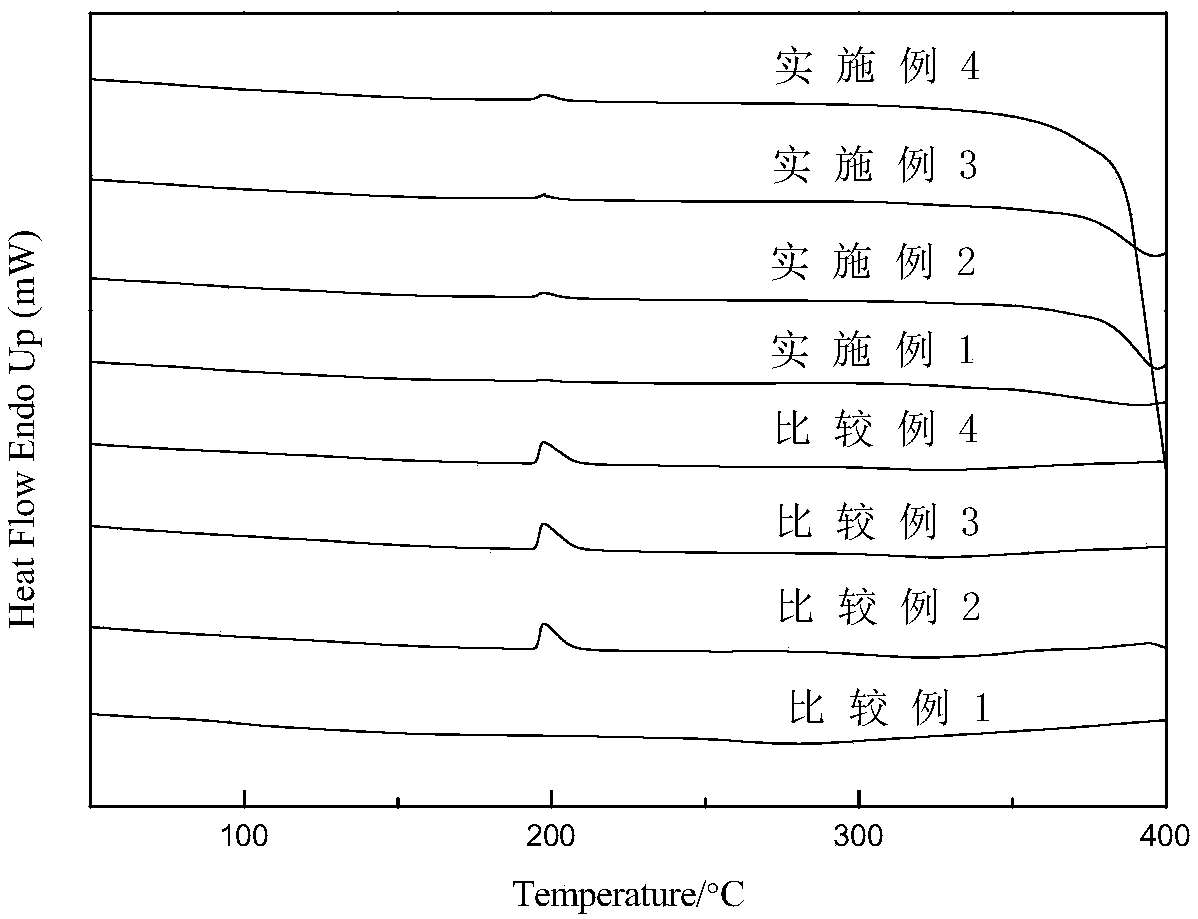

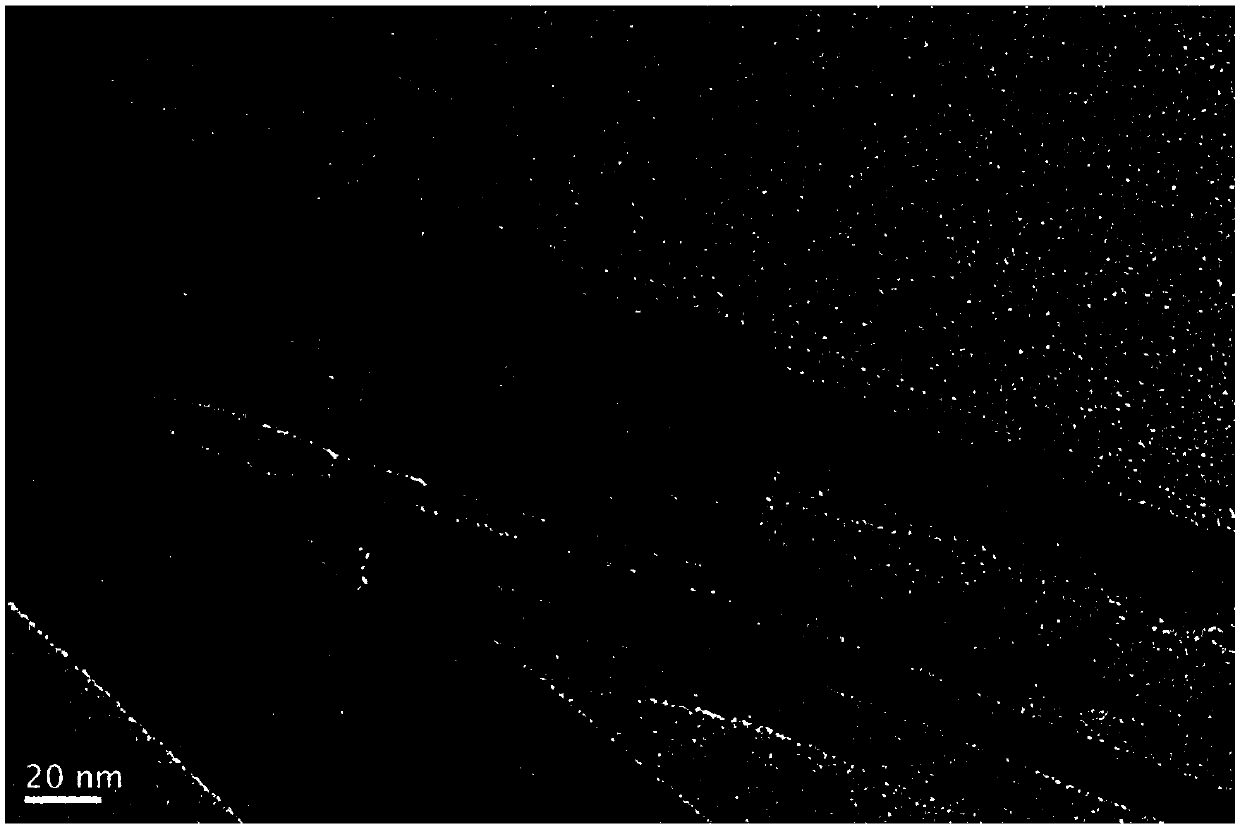

Composite solid polymer electrolyte film and preparation method and application thereof

InactiveCN109546207AReduce the degree of crystallizationHigh mechanical strengthSolid electrolytesSecondary cellsSlurryElectrochemistry

A composite solid polymer electrolyte film and a preparation method and an application thereof are provided. The preparation method includes the following steps: dissolving a polymer in an organic solvent, and stirring the solution evenly after ultrasonic dispersion; adding lithium salt, nano-ceramic particles, ionic liquid and plasticizer, and stirring the mixed solution evenly to form slurry; applying the slurry to a glass plate to form a liquid film; and drying the liquid film to obtain a composite solid polymer electrolyte film. The composite solid polymer electrolyte film of the inventionhas high room-temperature ionic conductivity and mechanical strength, is prepared through a simple process and can be mass-produced. Moreover, the composite solid polymer electrolyte film of the invention has good electrochemical performance when applied to lithium ion batteries.

Owner:XI AN JIAOTONG UNIV

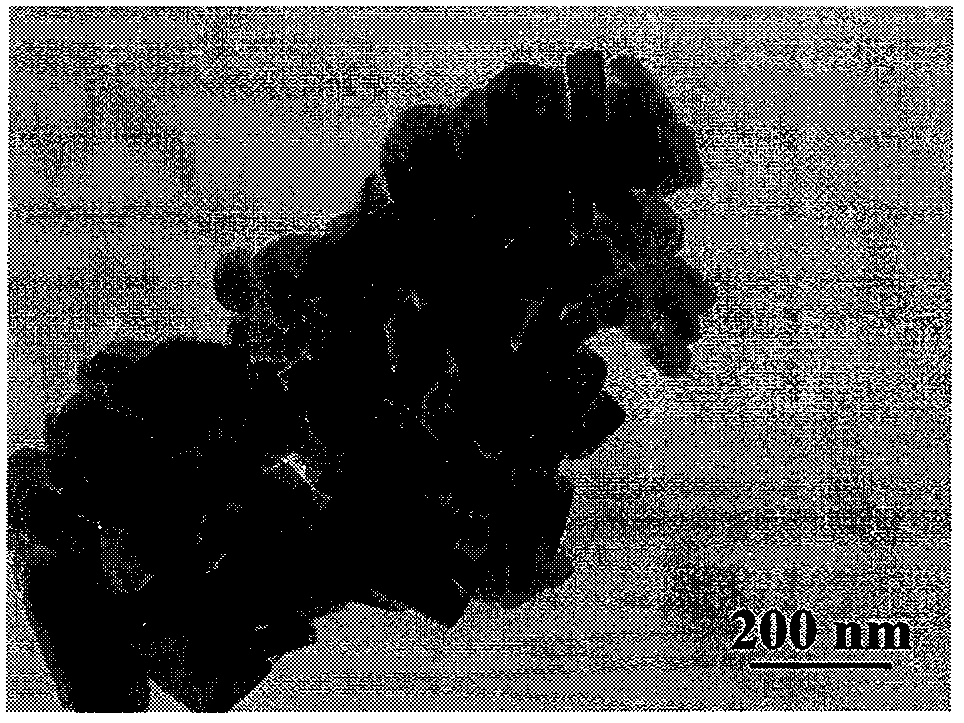

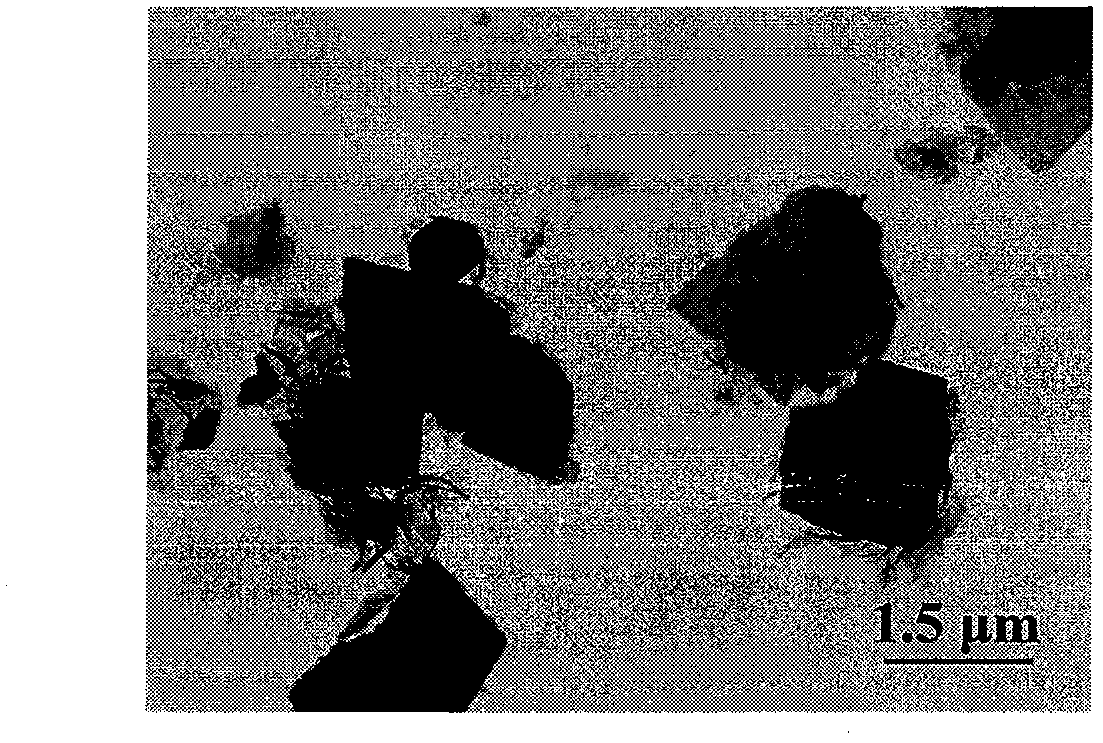

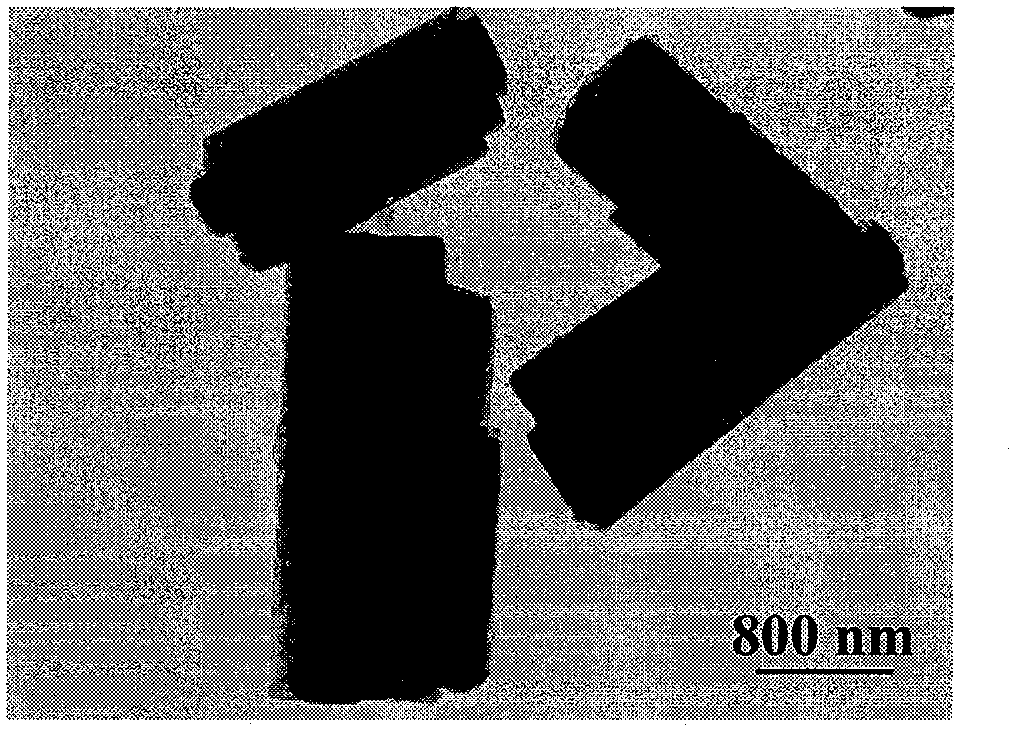

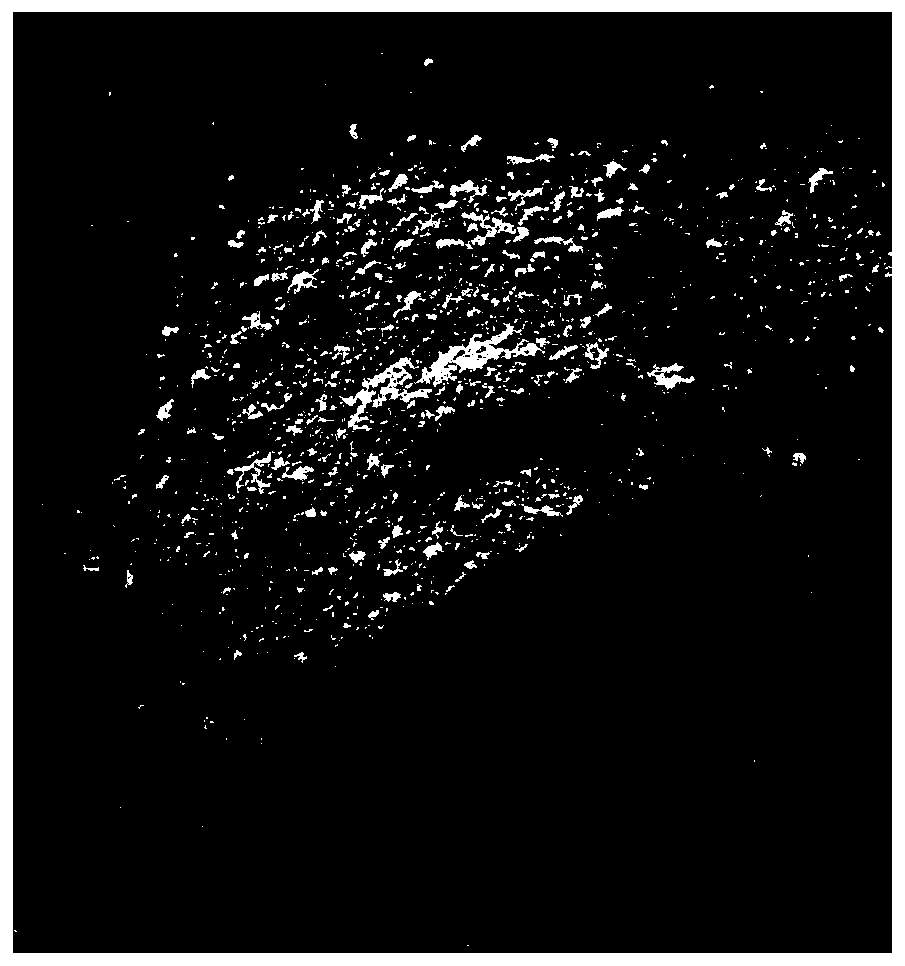

Efficient zinc phosphate micro-nano anticorrosion agent preparation method

InactiveCN103896235AUniform sizeGood dispersionMaterial nanotechnologyAnti-corrosive paintsWater bathsMicro nano

The invention belongs to the field of inorganic chemistry, and particularly relates to an efficient zinc phosphate micro-nano anticorrosion agent preparation method, wherein the product is applied in the field of metal heavy corrosion. According to the present invention, a cycle ultrasonic cavitation effect and a high-temperature high-pressure water bath thermal effect are adopted to perform synchronous and synergetic regulation to prepare the efficient zinc phosphate micro-nano anticorrosion agent, wherein the synchronous and synergetic effect of the two effects is adopted so as to make the product system be well dispersed, ensure the uniformity of crystal nucleation and effectively solve the difficult problem of difficult synchronous regulation on the particle size and the crystallization degree of the nanometer crystal, and a microwave heating mode is adopted to dry the product so as to reduce the agglomeration; the prepared micro-nano zinc phosphate product has advantages of high purity, complete crystallinity, narrow particle size distribution, good dispersion and the like, wherein the effective corrosion protection time of the zinc phosphate micro-nano anticorrosion agent is up to 1056 h and is far superior to the effective corrosion protection time of the commercially available zinc phosphate anticorrosion material; and the method has characteristics of simple process and low cost, and is suitable for large-scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

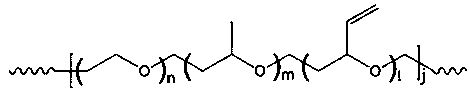

All-solid-state polymer electrolyte with semi-interpenetrating network structure, and preparation method of electrolyte

ActiveCN110233288AImprove mechanical propertiesHigh room temperature ionic conductivitySolid electrolytesSecondary cellsCross-linkPolymer science

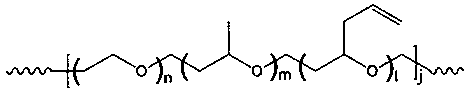

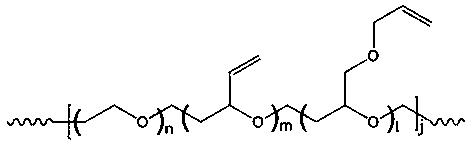

The invention discloses an all-solid-state polymer electrolyte with a semi-interpenetrating network structure, and a preparation method of the electrolyte. The all-solid-state polymer electrolyte is mainly prepared from the following raw materials in parts by weight: 50-95 parts of a modified block copolymer, 5-50 parts of a polyether acrylate oligomer monomer, a proper amount of a solvent, 0.1-1part of an initiator, 10-60 parts of lithium salt and 0-50 parts of an assistant. The all-solid-state polymer electrolyte is a polyether electrolyte with the semi-interpenetrating network structure; the modified block copolymer is used as a matrix; and the acrylate oligomer monomer containing multi-alkenyl functional groups is introduced to generate a cross-linking polymerization reaction so as toform two polyether semi-interpenetrating network structures. Compared with an existing polymer electrolyte, other inorganic fillers or toughening agents do not need to be doped; the obtained polymerelectrolyte has good mechanical properties; the ionic conductivity at the room temperature is greatly improved; and an electrochemical window is wider, so that the matching of high-voltage electrode materials is facilitated, and a lithium battery with higher energy density is obtained.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

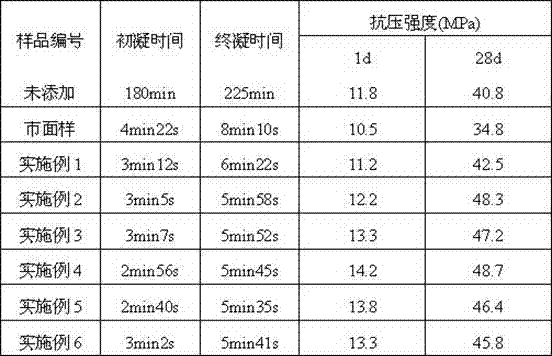

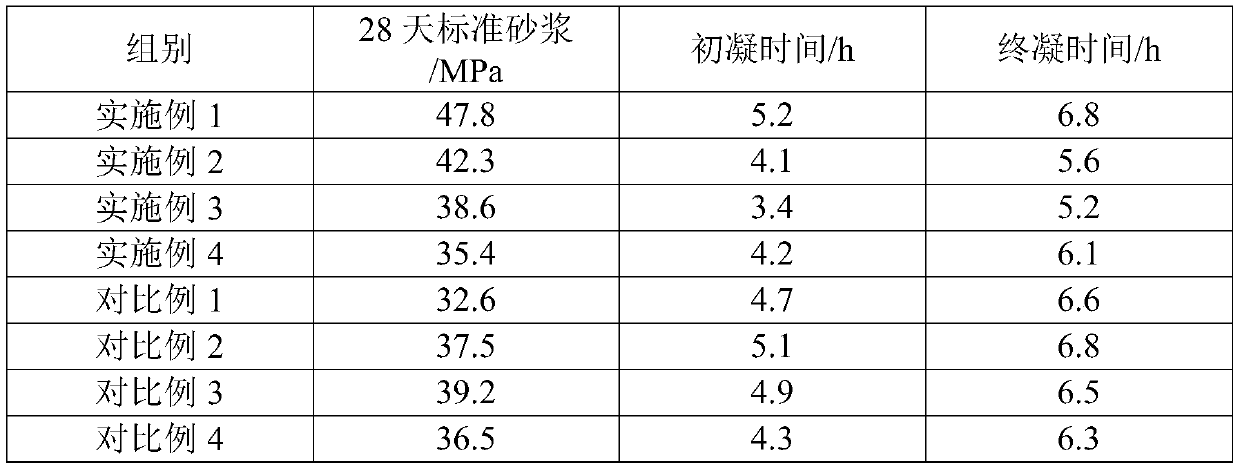

Organic-inorganic compound alkali-free flash setting admixture and preparation method thereof

ActiveCN107963827AReduce the degree of crystallizationIncreased degree of amorphousnessMetal sulfateAluminium salts

The invention discloses an organic-inorganic compound alkali-free flash setting admixture and a preparation method thereof. The alkali-free flash setting admixture is prepared by: subjecting a metal sulfate and alkanolamine to high temperature polymerization under the catalysis of inorganic acid, then attaching polyaluminum sulfate, low alcohol, a wetting agent and an anti-settling agent. Specifically, the organic-inorganic compound alkali-free flash setting admixture comprises: 1-3 parts of inorganic acid, 0.2-0.8 part of a complexing agent, 20-30 parts of a metal sulfate, 3.5-6.0 parts of alkanolamine, 20-25 parts of polyaluminum sulfate, 0.5-2.0 parts of low alcohol, 0.05-0.2 part of the wetting agent, 0.02-0.05 part of the anti-settling agent, and the balance water, with the total massfraction being 100 parts. The preparation method is carried out according to the steps of: 1. synthesis, 2. curing, 3. compounding and 4. filtration. Under the condition of a low dosage of the alkali-free flash setting admixture, the cement setting time and colloidal mortar strength can meet the requirements of the first grade product of JC477-2005 shotcrete flash setting admixture, as an inorganic and organic compounding way is adopted in terms of the synthesis and compounding system, the alkali-free flash setting admixture has strong adaptability and high cost performance.

Owner:HUBEI UNIV OF TECH

Tungsten tailings cementing material and preparation method thereof

ActiveCN110590198AIncrease the initial reaction rateHigh compressive strengthCement productionSlagPortland cement

The invention relates to the field of building materials, in particular to a tungsten tailings cementing material and a preparation method thereof. The tungsten tailings cementing material is characterized in that a mass ratio of the cementing material is as follows: 50%-70% of tungsten tailings, 5%-15% of hemihydrate gypsum, 10%-30% of slag, 1%-8% of steel slag, 1%-5% of an activator, and 0.1%-2%of a water reducing agent, wherein a mass ratio of the activator is 40%-80% of Portland cement, and 20%-60% of sulphoaluminate cement. The preparation method of the tungsten tailings cementing material comprises the following steps: (1) performing ball-milling on the tungsten tailings and performing drying to obtain tungsten tailings powder; (2) pouring the tungsten tailings powder, the slag, thesteel slag, the activator, the water reducing agent and water into a ball mill for ball-milling to obtain a mixed material; and (3) performing curing at room temperature. The cementing material usesthe tungsten tailings as the main raw material, the problem of tungsten tailings accumulation is effectively solved, and thereby secondary resource high-value utilization of the tungsten tailings is realized.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

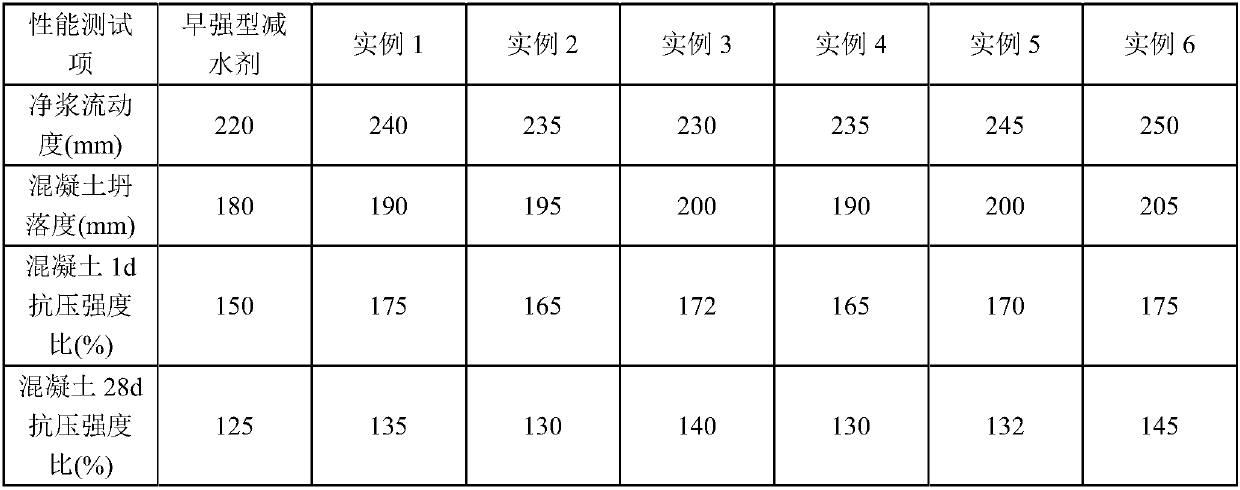

Early-strengthening type composition dispersing agent of cement-based cementitious material

The invention discloses an early-strengthening type composition dispersing agent of a cement-based cementitious material. The dispersing agent is prepared by mixing the following components in percentage by weight: 10-15% of alkylolamide ferroaluminum complex, 2-7% of cationic polymer, 0.5-2.0% of a metal ion chelating agent, 15-25% of metal sulfate, and the balance of water, wherein the alkylolamide ferroaluminum complex in the composition is prepared by synthesizing inorganic acid, a chelating agent, ferrous sulfate, aluminum sulfate and alkylolamide; the cationic polymer is prepared by synthesizing polyether macromonomer, cationic micromonomer, acrylamide, a double-bond-containing silane coupling agent, mercaptoethanol, hydrogen peroxide, ammonium persulfate, sodium formaldehyde sulfoxylate, sodium hypophosphite hydrate and caustic soda liquid. With the adoption of the early-strengthening type composition dispersing agent, the early strength of the cement-based cementitious materialcan be obviously improved under low doping quantity and on the premise that the working mobility of the cement-based cementitious material is basically not influenced.

Owner:HUBEI UNIV OF TECH

Preparation method of waterborne polyurethane free of cosolvent

InactiveCN106750126AReduce the degree of crystallizationPromote environmental protectionEthylenediamineSolvent

The invention relates to a preparation method of waterborne polyurethane free of a cosolvent. The method comprises the steps of blending 2,2-dimethylolpropionic acid DMPA with aliphatic diol at room temperature, heating a mixture until DMPA is completely melted under the conditions of stirring and nitrogen protection and cooling to room temperature to obtain a low-melting point chain extender; mixing the low-melting point chain extender with oligomer polyol and then carrying out decompression dehydration; adding diisocyanate, reacting at 70-90 DEG C under the condition of nitrogen protection for 1-3h to obtain a polyurethane prepolymer; cooling the polyurethane prepolymer to the room temperature, adding triethylamine to neutralize, adding deionized water, dispersing the triethylamine into the deionized water; adding ethylenediamine for chain extension to obtain the waterborne polyurethane. The method is simple; and the prepared waterborne polyurethane is safe, environment-friendly and suitable for industrial production.

Owner:DONGHUA UNIV

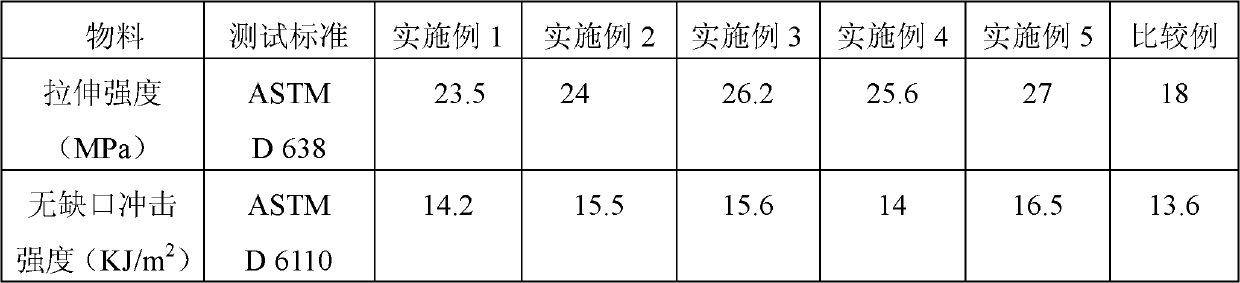

Polylactic acid-starch blended material and preparation method thereof

The invention belongs to the field of modification of high polymer blended plastics, and discloses a polylactic acid-starch blended material and a preparation method thereof. The polylactic acid-starch blended material disclosed by the invention comprises the following components in parts by weight: 448-8207 parts of polylactic acid, 1000 parts of starch, 10-114 parts of grafting agent, 36-286 parts of plasticizer, 2-29 parts of coupling agent and 3-97 parts of antioxidant. The preparation method comprises the following steps: (1) adding 1000 parts of pretreated starch, 10-114 parts of grafting agent, 36-286 parts of plasticizer and 2-29 parts of coupling agent into a high-speed mixer, and mixing at normal temperature for 10-50 minutes; and (2) granulating 1053-1429 parts of the mixture obtained in the step (1) by a double screw extruder, mixing with 448-8207 parts of polylactic acid and 3-97 parts of antioxidant and granulating, or directly mixing the mixture obtained in the step (1) with 448-8207 parts of polylactic acid and 3-97 parts of antioxidant and granulating by the double screw extruder. The product disclosed by the invention has the advantages of favorable mechanical properties and low cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

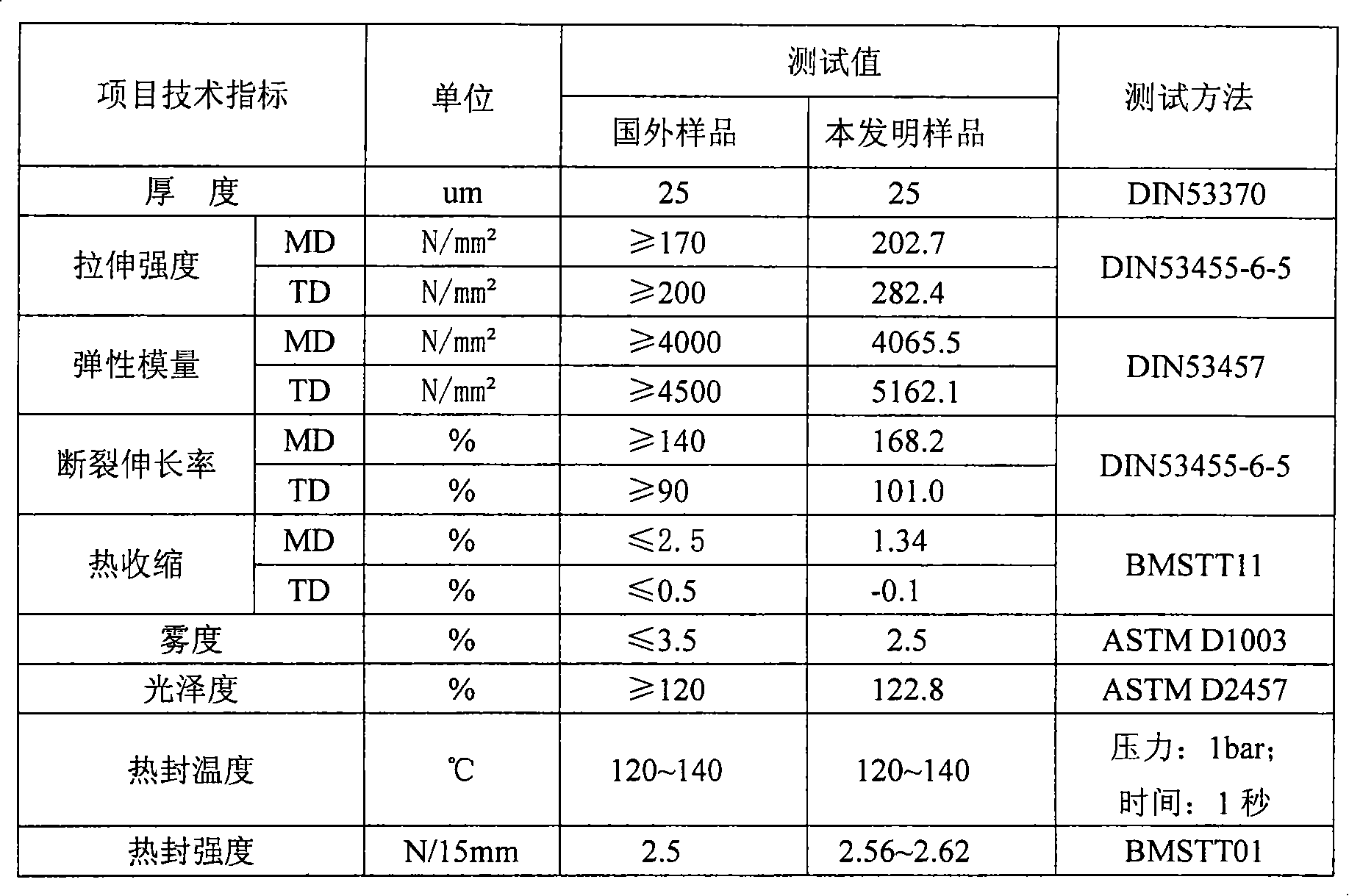

BOPET film capable of being directly heat-sealed

ActiveCN101607459AReduce the degree of crystallizationNot easy to crystallizeSynthetic resin layered productsMasterbatchBoPET

The invention relates to a BOPET film capable of being directly heat-sealed, which consists of a surface heat-sealing layer, a sandwich layer and a bottom layer, wherein the surface heat-sealing layer comprises the following components in percentage by weight: 85 percent of copolyester PETG, and 15 percent of silicon masterbatch; the sandwich layer comprises the following components in percentage by weight: 80 percent of PET light material, and 20 percent of PET regenerated granules, or 85 percent of PET light material, and 15 percent of PET regenerated granules; and the bottom layer comprises the following components in percentage by weight: 100 percent of anti-adhesive silicon masterbatch. The surface heat-sealing layer of the film has lower melting point; the heat sealing temperature is 130 DEG C or so after the folding; the heat-sealing temperature of the film is equivalent to those (between 120 and 140 DEG C) of heat-sealing layer materials which are commonly used in soft packaging industry such as CPP, PE and the like; main technical indexes have already reached the level of similar products abroad; and the heat-sealing strength of the film is superior to those of BOPET films with the same specification abroad. In addition, the film is applicable for the mass production by the prior three-runner three-layer coextrusion and bidirectional stretching equipment, and has the outstanding advantages of low investment and steady quality.

Owner:TIANJIN WANHUA CO LTD

Modified polyvinylidene fluoride material used for solar cell protective films and preparation method thereof

ActiveCN102408649AReduce the degree of crystallizationImprove processing plasticityPhotovoltaic energy generationSemiconductor devicesPolymer scienceSolar battery

The invention provides a modified polyvinylidene fluoride (PVDF) material used for solar cell protective films and a preparation method thereof. The material comprises: 55-70% of PVDF, 10-20% of high density polyethylene (HDPE), 3-6% of polyethylene grafted maleic anhydride, 10-20% of an ethane-octylene copolymer, 0.3-0.6% of an anti-oxidant, and 0.2-0.5% of a lubricant. The preparation process consists of: first adding each component material into a high speed mixing bucket according to the ratio for uniform mixing; adding the obtained mixture into a double-screw extruder for mixing; controlling the extrusion temperature of the first and second segment of the double-screw extruder composed of six segments at 150-170DEG C, and controlling the extrusion temperature of the other segments at 170-200DEG C; leaving the reactant to stay in the double-screw extruder for 3-6min totally, and keeping the rotating speed of the double-screw extruder at 300-350r.min<-1>; conducting cooling and pelletizing to the obtained material after extrusion, thus obtaining the modified polyvinylidene fluoride material used for solar cell protective films. The adding of HDPE into PVDF for modification can obviously reduce the crystallization degree of PVDF, and enhance the processibility of PVDF.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

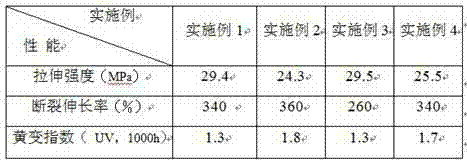

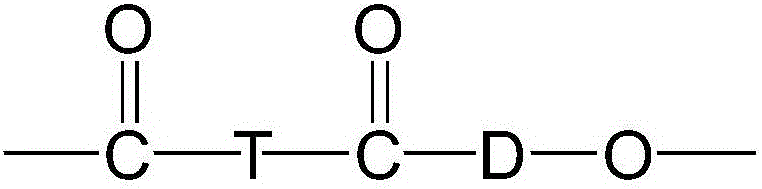

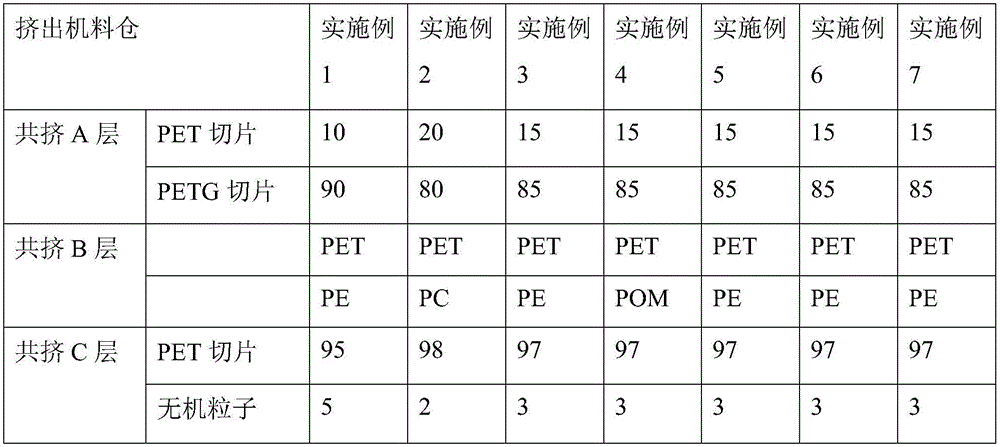

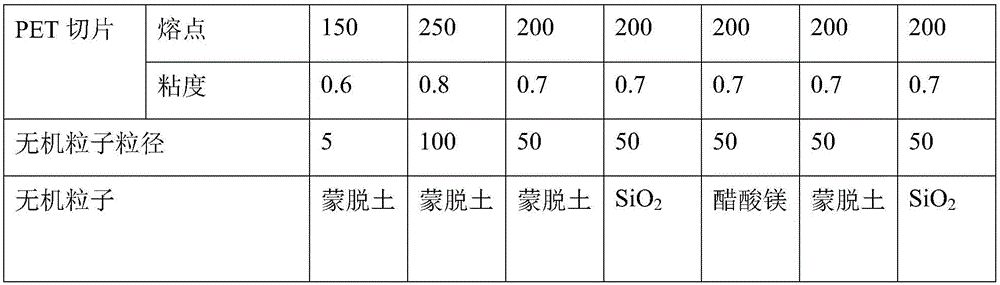

Heat-sealable high-barrier packaging film

The invention discloses a heat-sealable high-barrier packaging film. The heat-sealable high-barrier packaging film is of an A, B and C type three-layer composite structure, wherein the A layer is a PETT / PETG polyester layer, the B layer is made of two thermoplastic resin materials through a co-extrusion process, and the C layer comprises PET chips and inorganic particles. The packaging film has a good barrier property and can be directly heat-sealed. The three-layer heat-sealable high-barrier packaging film is compact in structure, and the barrier property of the packaging film can be substantially improved; besides, the packaging film can be heat-sealed, is safe and nontoxic and can be applied to the food packaging industry.

Owner:SUZHOU KECHUANG ELECTRONICS MATERIAL CO LTD

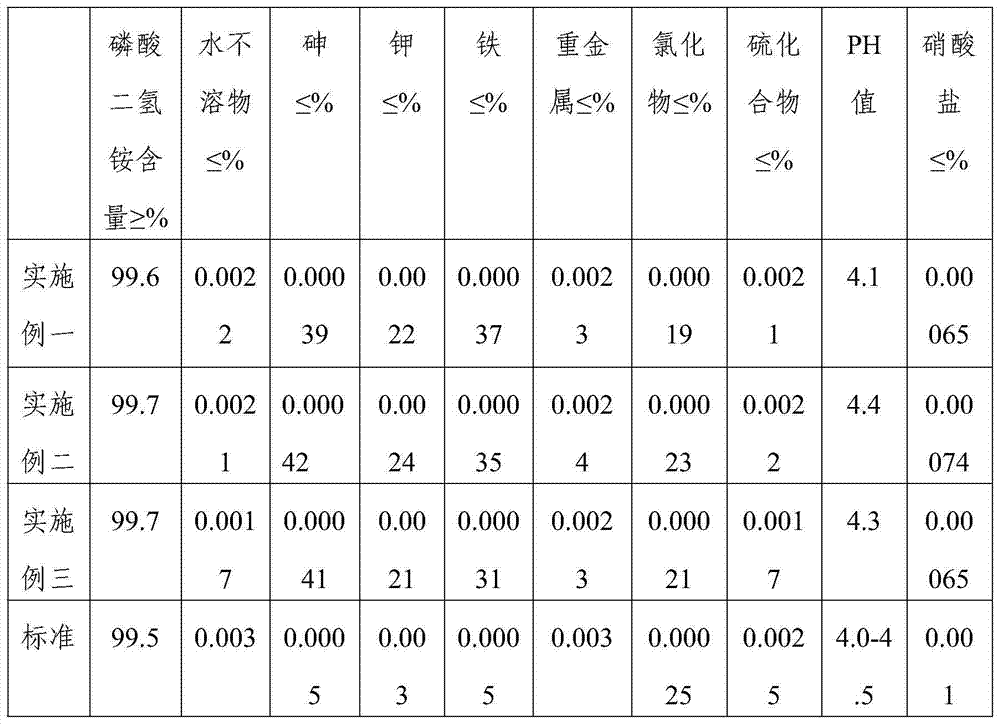

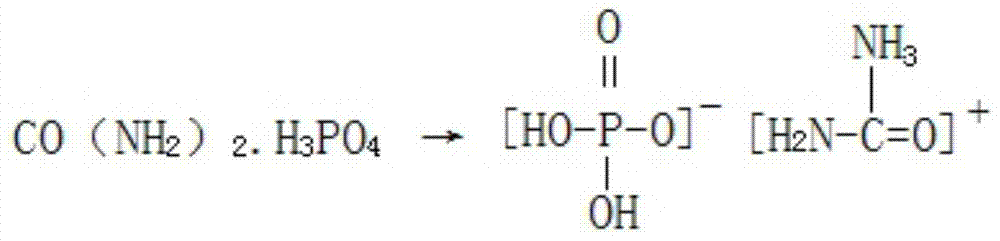

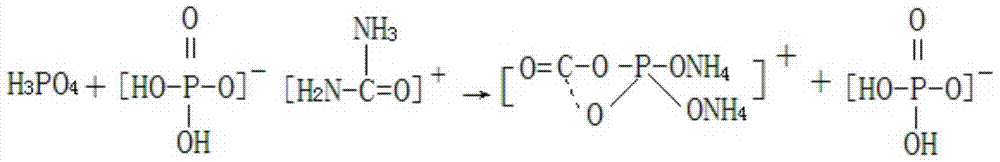

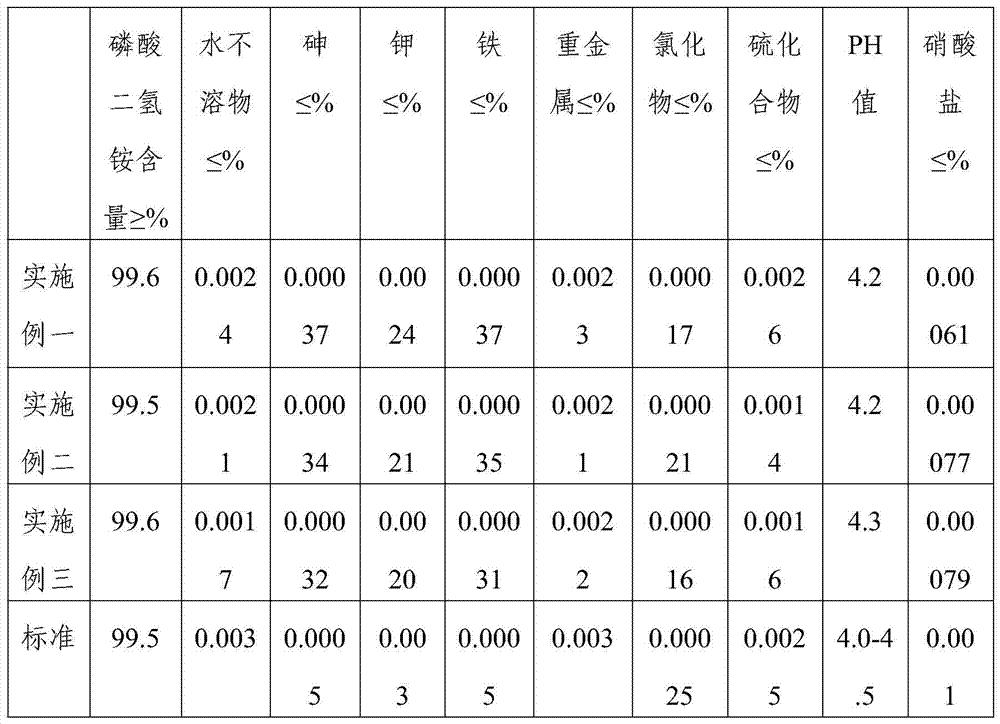

Method for preparing dendrobium officinale nutrient fertilizer

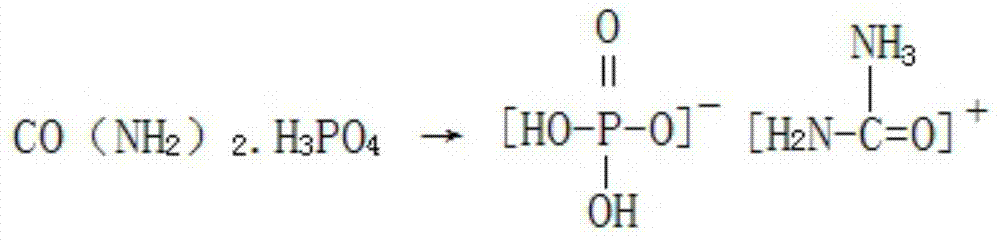

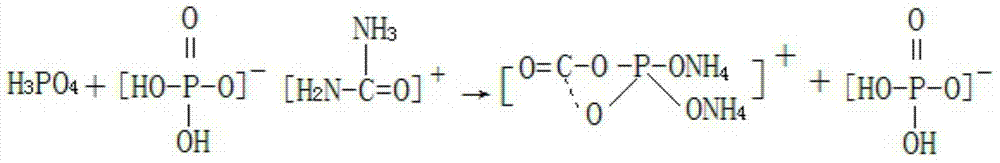

InactiveCN104291903AReduce the degree of crystallizationHigh purityCalcareous fertilisersMagnesium fertilisersChemical industryAmmonia production

The invention relates to the technical field of chemical industry, and discloses a method for preparing a dendrobium officinale nutrient fertilizer. The method comprises the following steps: determining the proportion of nutritive elements in the dendrobium officinale nutrient fertilizer by analyzing various nutritive elements absorbed in a growth process of dendrobium officinale, reacting phosphoric acid with carbamide to generate an intermediate, then introducing ammonia gas into the intermediate to produce ammonium dihydrogen phosphate, separating part of ammonium dihydrogen phosphate by crystallization so as to control the content of nitrogen and phosphorus in a solution to meet the proportion required by the growth of dendrobium officinale, and then adding potassium and other medium trace element compounds into the solution to prepare a fertilizer special for dendrobium officinale. According to a production method disclosed by the invention, raw materials can be fully used, produced ammonium dihydrogen phosphate is relatively good in quality, and the prepared fertilizer special for dendrobium officinale is relatively low in cost.

Owner:GUIZHOU UNIV +2

Method of preventing high fructose syrup from crystallizing

InactiveCN1974790AReduce the degree of crystallizationDoes not affect normal useSugar productsHigh fructoseCrystallization

The present invention relates to production of no-crystallization high fructose syrup, and is especially method of adding small amount of crystallization inhibiting matter to inhibit the crystallization of 42 % concentration high fructose syrup in low temperature condition. Into 44 % concentration high fructose syrup, maltodextrin with the DE value of 16-18 % and in the amount of 4 % is added. When there is no requirement of fructose content not lower than 42 %, 42 % concentration high fructose syrup may be added. Adding small amount of maltodextrin or high fructose syrup has no influence on the quality of the high fructose syrup and can reduce the crystallization tendency obviously.

Owner:鲁洲生物科技(陕西)有限公司

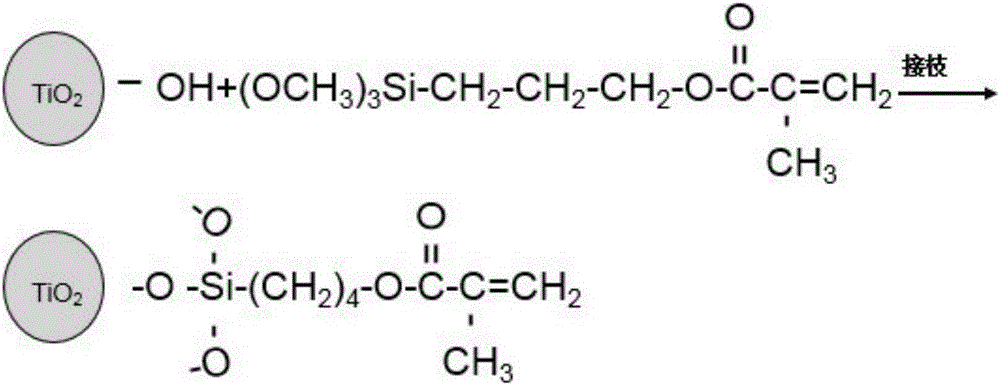

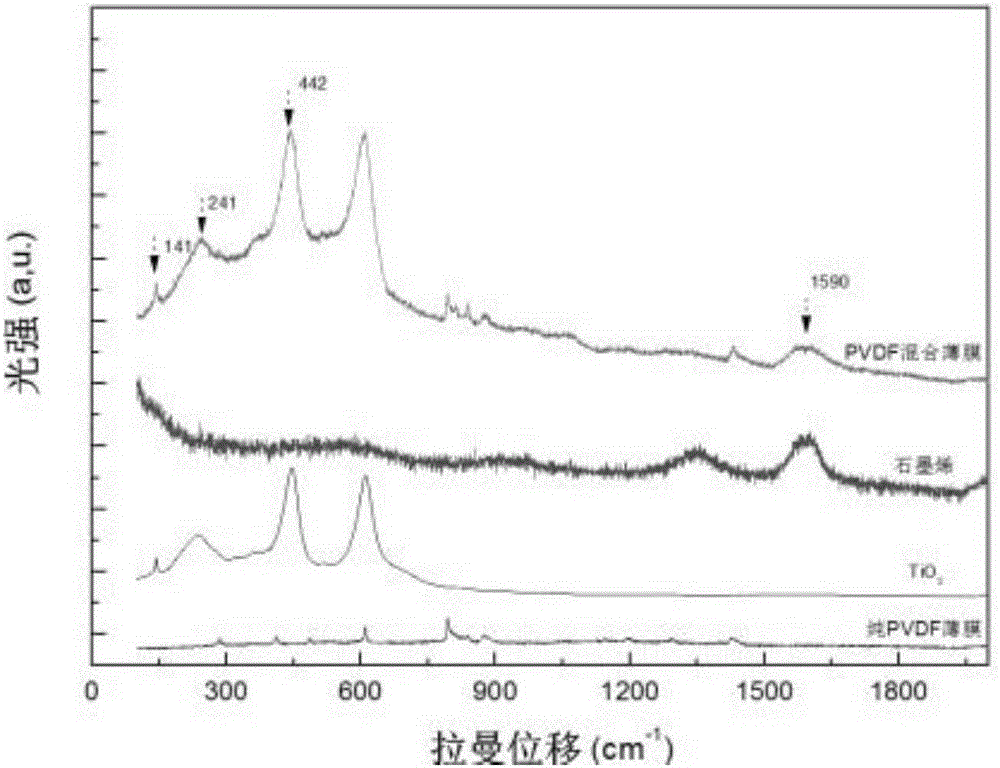

Blend film containing graphene and preparation method thereof

InactiveCN105218987AGood anti-light aging performanceHigh thermal conductivityPhotovoltaic energy generationSemiconductor devicesAging resistanceSolar cell

The invention is suitable for preparing a solar cell back film, and provides a blend film containing graphene and a preparation method thereof. The blend film is a blend membrane of titanium dioxide graft, PVDF, PMMA, PPA and graphene, and the titanium dioxide graft is modified titanium dioxide with a silane coupling agent KH570 grafted on the surface. In the existence of the graft, the titanium dioxide has non-uniformity phenomenon in the blend membrane, so that when the blend membrane is used as the solar cell back film, the cohesive force between the film and other backboard base materials is greatly increased, and the existence of the PMMA, PPA and graphene also improves the aging resistance, heat conductivity and surface smoothness of the solar cell back membrane. The preparation method comprises the following steps: first grafting the silane coupling agent KH570 onto the surface of the titanium dioxide, mixing weighted TiO2 graft, PVDF, PMMA, PPA and graphene, uniformly mixing, extruding to form strips, cutting the strips into granules, drying the granules, extruding the granules by virtue of a single screw, and tape casting to obtain the blend film.

Owner:SHENZHEN UNIV

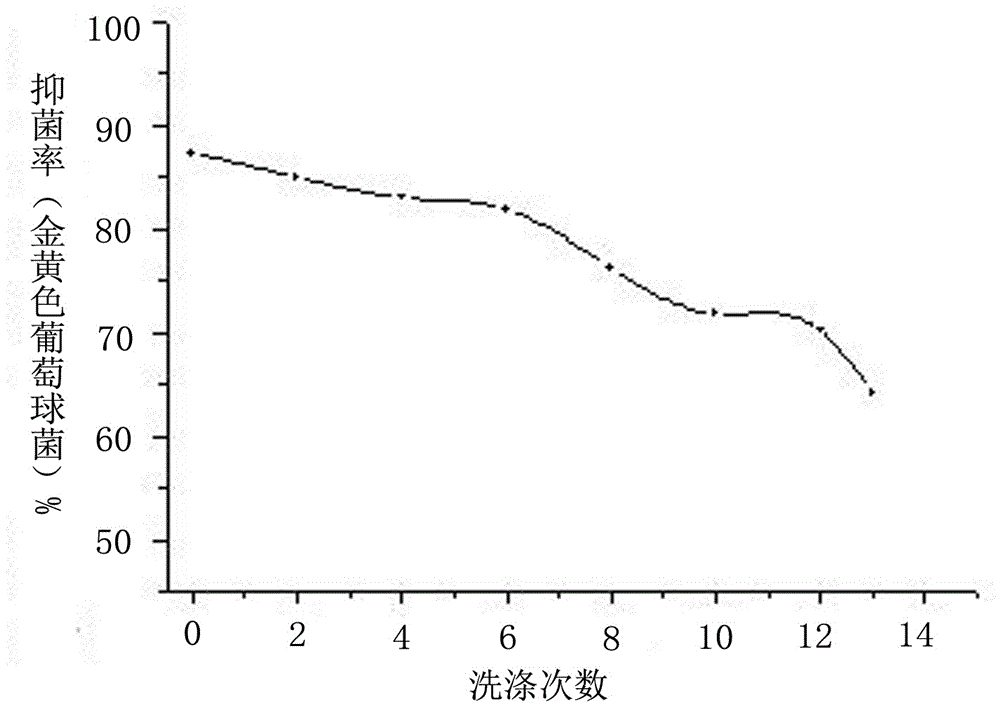

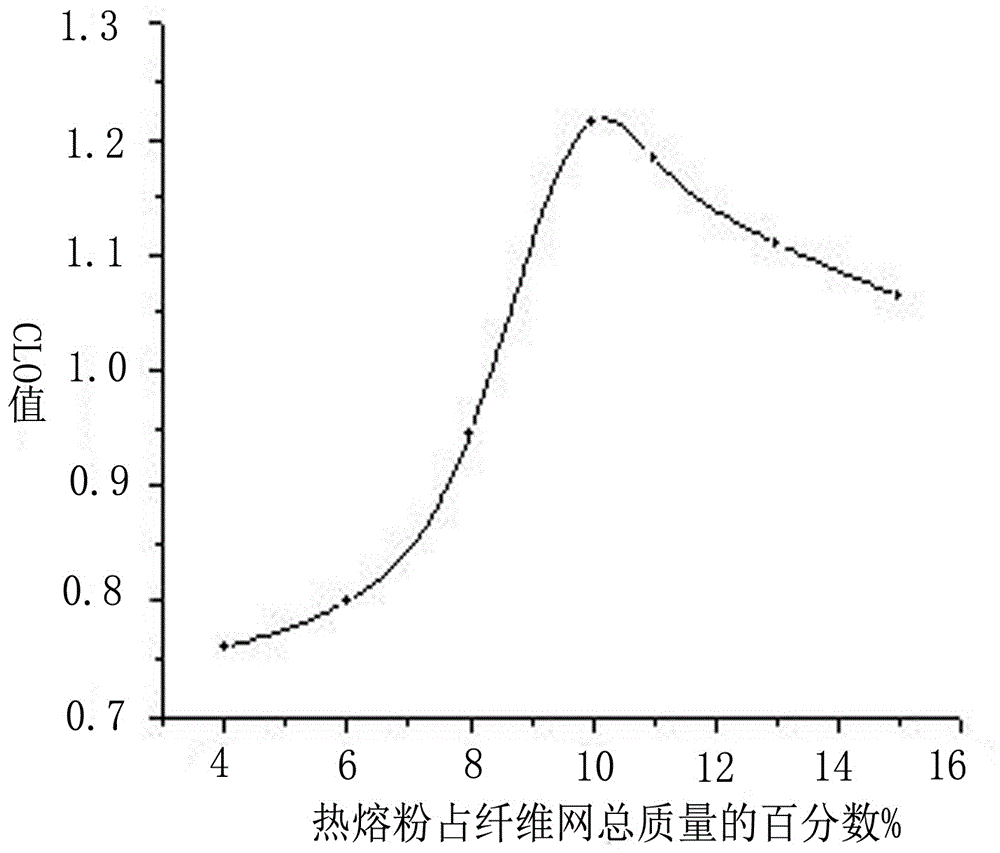

Functional antibacterial composite wool flocculus and preparation method thereof

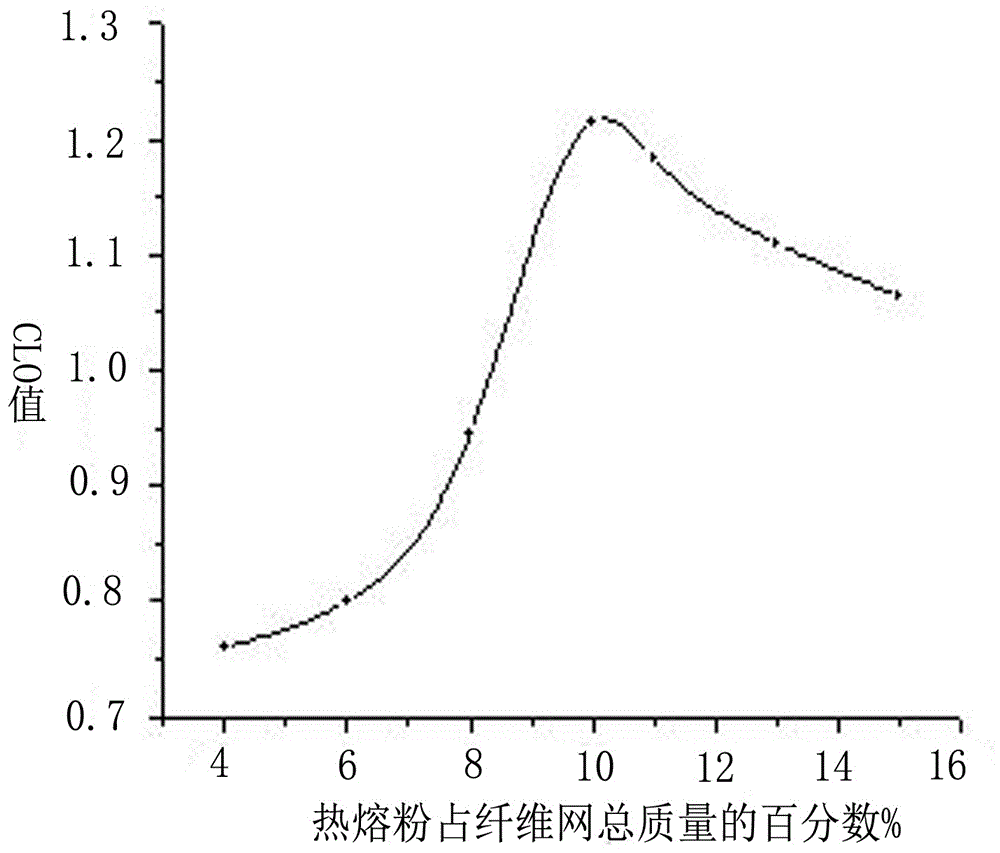

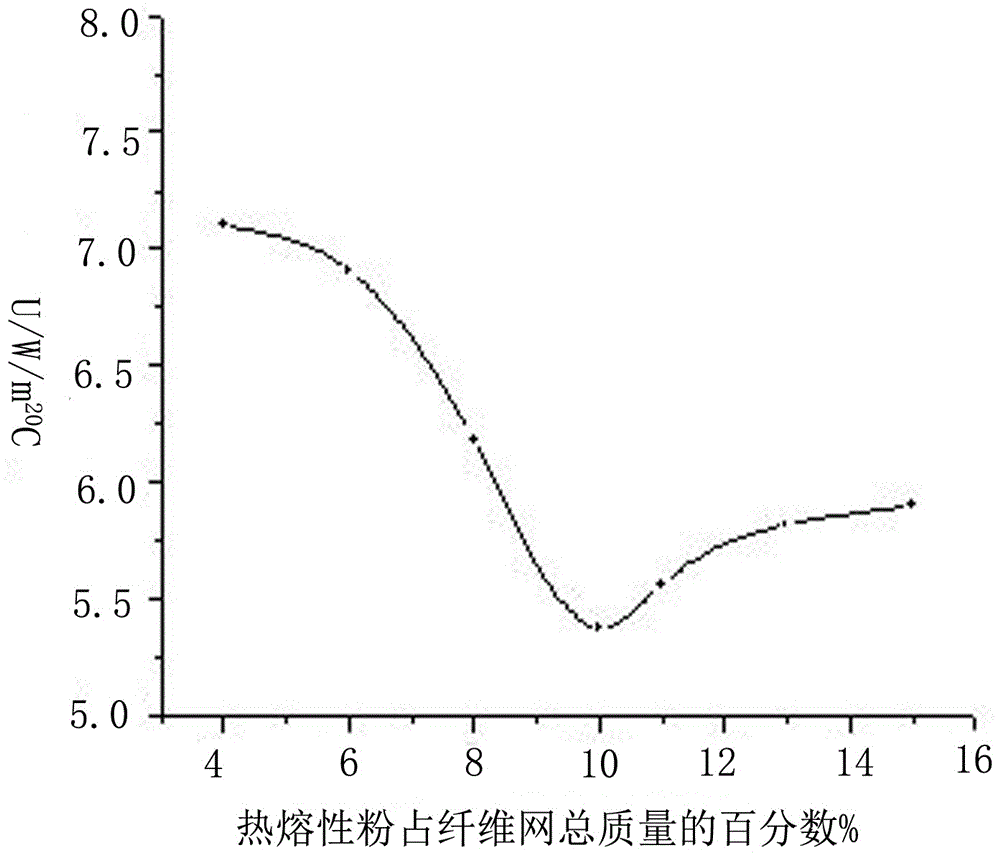

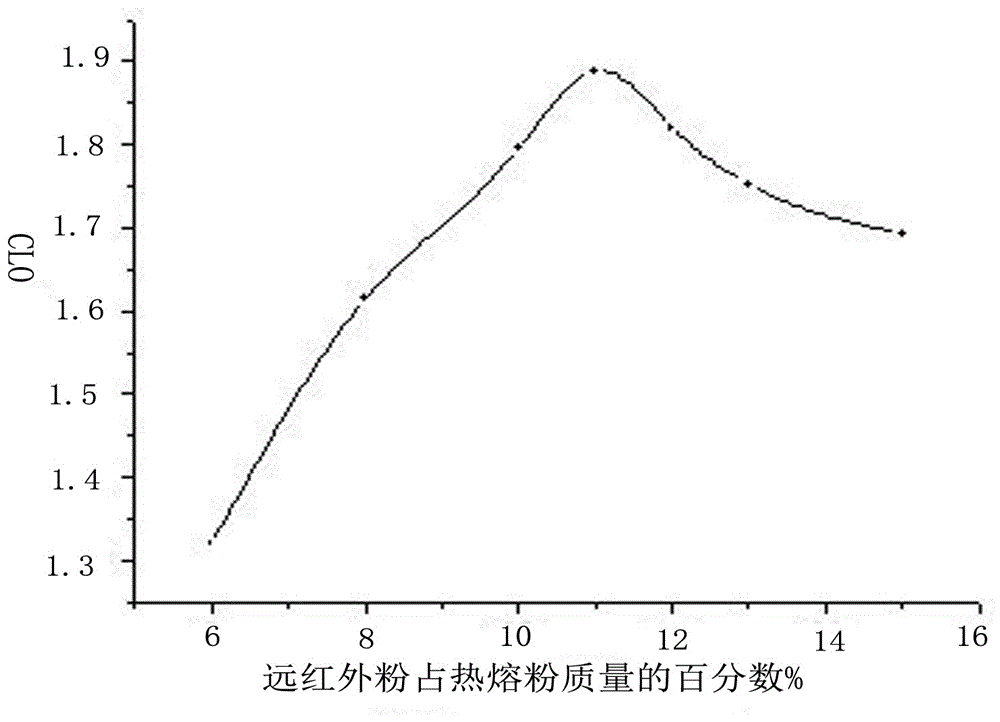

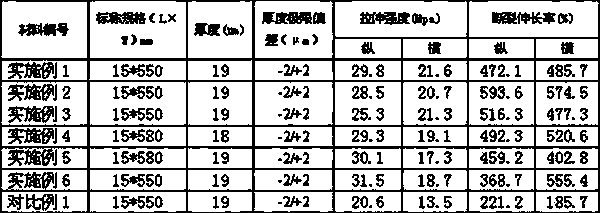

InactiveCN106319754ABreathableImprove dehumidification effectBiochemical fibre treatmentNon-woven fabricsFiberCell metabolism

The invention provides a functional antibacterial composite wool flocculus. The functional antibacterial composite wool flocculus is mainly prepared from wool composite fiber webs, hot melting powder and silver nanoparticles, wherein the mass of the hot melting powder accounts for 7%-13% of the total mass of the wool composite fiber webs. The functional antibacterial composite wool flocculus has the advantages of being breathable, high in moisture removal property and capable of promoting sleep, enhancing the vitality, promoting cell metabolism, delaying ageing and inhibiting pathogenic bacteria and can effectively prevent many skin lesions and pruritus. The invention further provides a preparation method of the functional antibacterial composite wool flocculus. The method is simple, easy to operate and suitable for large-scale automated production.

Owner:HENAN INST OF ENG

Preparation method of attapulgite-based full-wave-band ultraviolet shielding material

ActiveCN107722362AAvoid reunionLow priceCosmetic preparationsToilet preparationsAcetic acidFull wave

The invention belongs to the technical field of preparation of materials with protection functions, and particularly relates to a preparation method of an attapulgite-based full-wave-band ultravioletshielding material. The preparation method comprises the steps that a cation surfactant solution is added into attapulgite slurry, then a coupling agent solution is added, full mixing and heat-preservation curing are conducted, and organic surface-modified attapulgite is prepared; obtained attapulgite is dispersed in ethyl acetate, MBBT is added, full mixing and heating are conducted to remove ethyl acetate, and the ATPatMBBT composite material, namely the attapulgite-based full-wave-band ultraviolet shielding material, is obtained.

Owner:常州大学盱眙凹土研发中心

Wear-resisting tile glaze

The invention mainly relates to the technical field of ceramic glaze processing and discloses a wear-resisting tile glaze. The wear-resisting tile glaze is prepared from the following raw materials: 41-43 parts of silicon dioxide, 35-37 parts of dolomite, 15-17 parts of anorthose, 11-13 parts of modified white mica, 10-12 parts of olivine, 6.3-6.5 parts of magnesium oxide, 5.6-5.8 parts of lutecia, 4.2-4.4 parts of titanium dioxide, 3.7-3.9 parts of zirconium oxide and 2.6-2.8 parts of boron oxide. The wear-resisting tile glaze provided by the invention is smooth and fine, is high in wearing resistance, is capable of keeping the tile surface bright and fine, is anti-corrosion and is capable of promoting the quality and grade of tiles. The dolomite is firstly smashed, heated and calcined and then is added into a salt solution and is heated and calcined again so as to modify the dolomite, promote the fineness and smoothness of the dolomite, guarantee the smooth flowing during the glazingprocess and keep the tile surface smooth and flawless.

Owner:安徽省德邦瓷业有限公司

Electrically controlled solid propellant and preparation method thereof

ActiveCN109942356AReduce the intensity of actionReduce the degree of crystallizationNon-explosive/non-thermic compositionsPressure gas generationCross-linkHydroxylamine

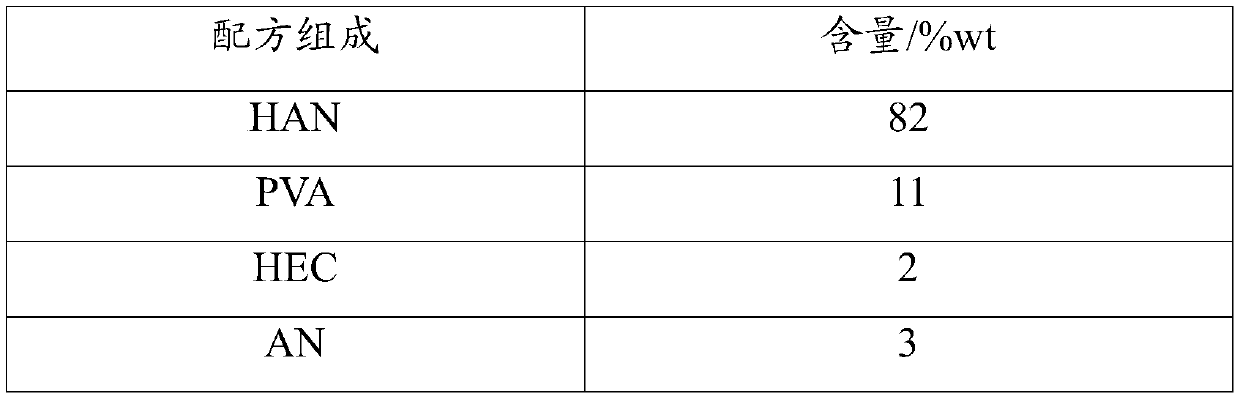

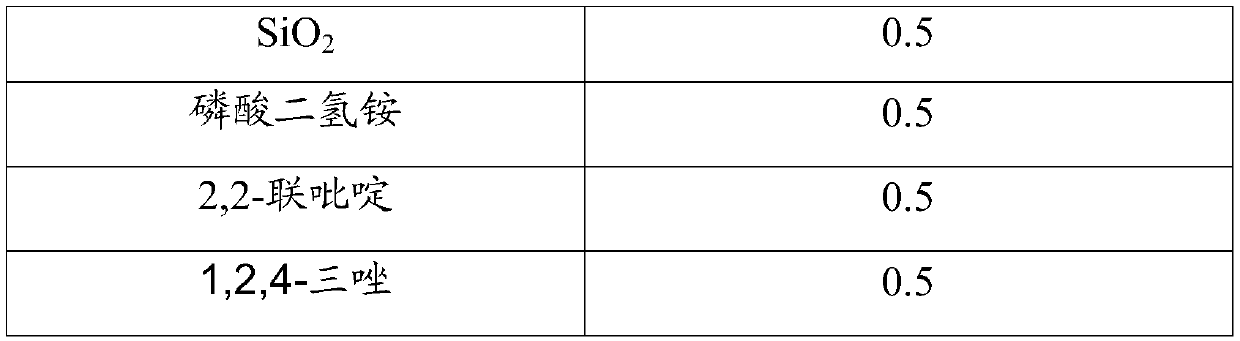

The invention relates to an electronically controlled solid propellant and a preparation method thereof, and belongs to the field of solid propellants. The electronically controlled solid propellant is prepared from, by mass, 10-14% of a binder containing hydroxyl, 80-85% of a main oxidant, 1%-4% of a secondary oxidant, 0.5%-2% of a cross-linking agent and 1%-2.5% of functional additives, whereinthe main oxidant is a hydroxylamine nitrate aqueous solution with the mass concentration being 5-10%, the cross-linking agent is one of or a combination of silicon-containing compounds and organic titanium chelates. Accordingly, the phenomenon that a large number of gel clusters and bubbles are generated in slurry can be avoided, and the uniformity of the electrically controlled solid propellant is significantly improved.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

High-flatness, high-barrier, high-strength and cooking-resistant stretch film and production method thereof

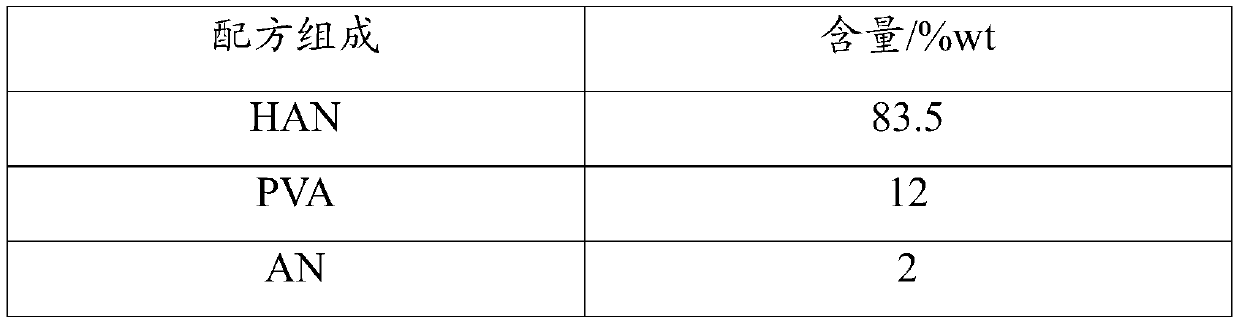

InactiveCN111993732AImprove efficiencyAvoid issues like curlSynthetic resin layered productsDomestic containersManufactured materialThin membrane

The invention discloses a high-flatness, high-barrier, high-strength and cooking-resistant stretch film. The film sequentially comprises an outer surface layer, a primary outer layer, a secondary outer layer, a first bonding layer, a first PA layer, a high-barrier layer, a second PA layer, a second bonding layer, a secondary heat-seal layer, a primary heat-seal layer and a heat-seal layer from topto bottom, the structure of the product is PP / PP / PP / TIE / PA / EVOH / PA / TIE / PE / PE / PE; according to the invention, the film curling degree caused by the structure can be reduced; the preparation method provided by the invention uses a tape casting process for production; most of the selected materials are low in crystallization degree, rapid crystallization can be achieved, the influence of secondary crystallization of the materials on film curling can be reduced, and through selection of the raw materials, integration of excellent properties such as high barrier, high strength and steaming resistance is achieved.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

A kind of preparation method of solvent-free aqueous polyurethane

InactiveCN106750126BReduce the degree of crystallizationPromote environmental protectionEthylenediaminePolyol

The invention relates to a preparation method of waterborne polyurethane free of a cosolvent. The method comprises the steps of blending 2,2-dimethylolpropionic acid DMPA with aliphatic diol at room temperature, heating a mixture until DMPA is completely melted under the conditions of stirring and nitrogen protection and cooling to room temperature to obtain a low-melting point chain extender; mixing the low-melting point chain extender with oligomer polyol and then carrying out decompression dehydration; adding diisocyanate, reacting at 70-90 DEG C under the condition of nitrogen protection for 1-3h to obtain a polyurethane prepolymer; cooling the polyurethane prepolymer to the room temperature, adding triethylamine to neutralize, adding deionized water, dispersing the triethylamine into the deionized water; adding ethylenediamine for chain extension to obtain the waterborne polyurethane. The method is simple; and the prepared waterborne polyurethane is safe, environment-friendly and suitable for industrial production.

Owner:DONGHUA UNIV

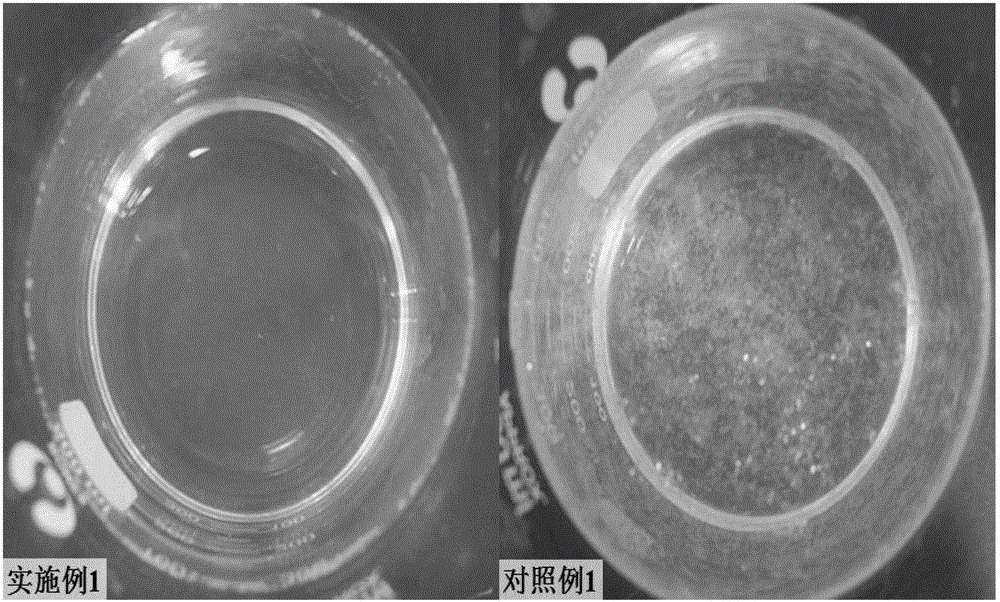

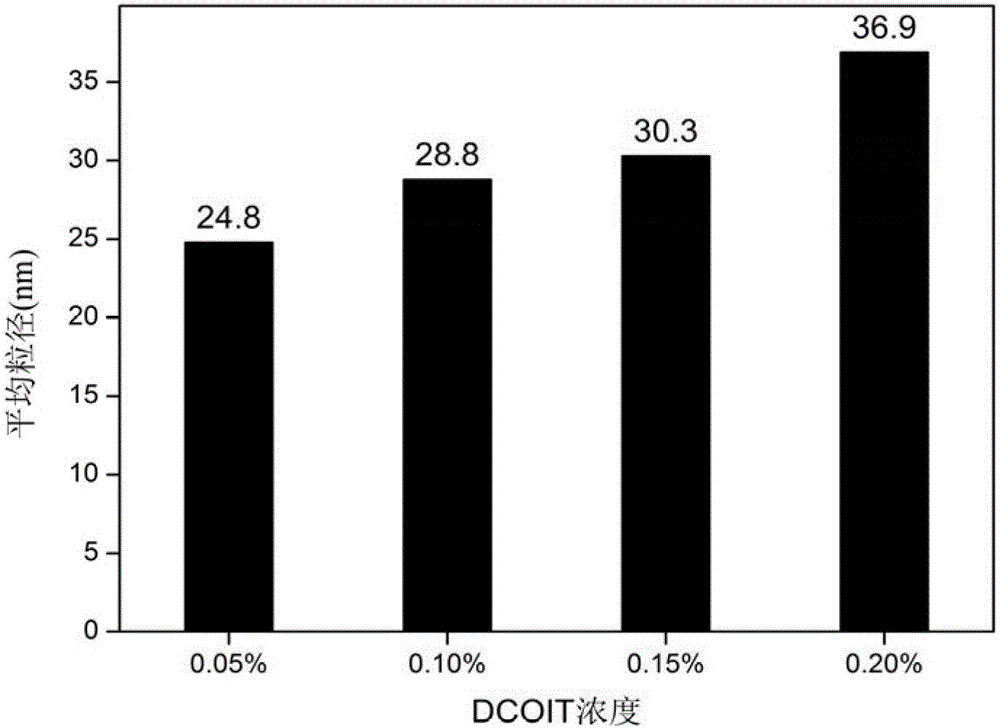

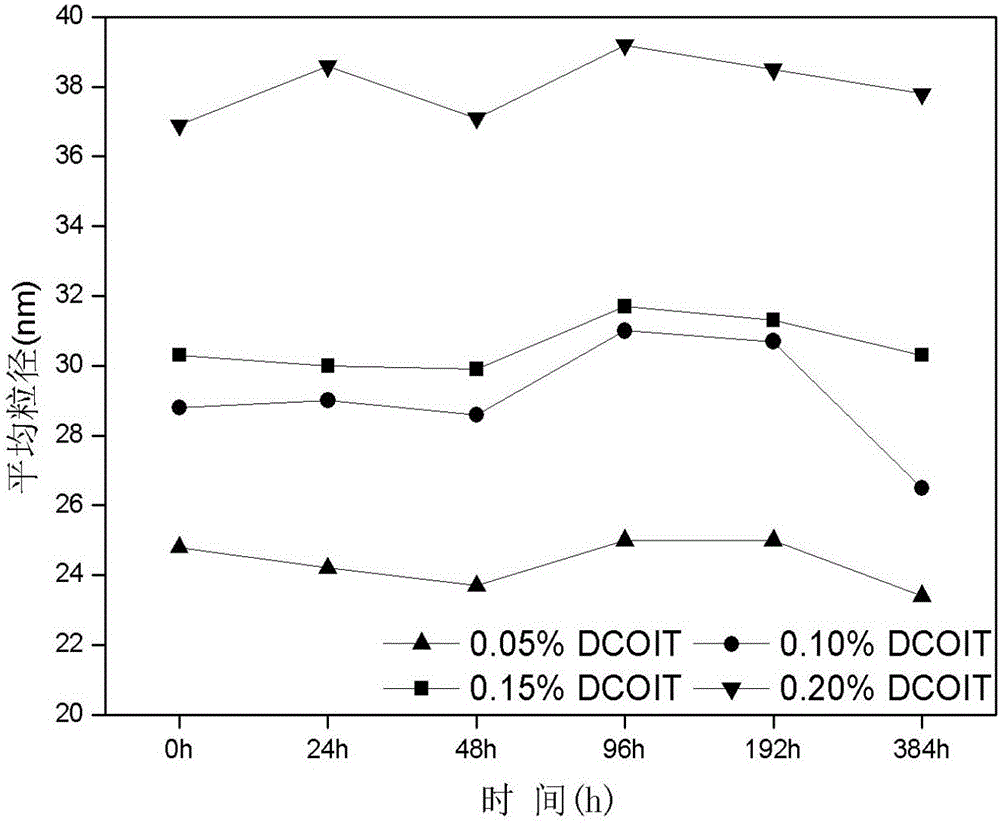

A kind of microemulsion wood and bamboo antifungal agent, its preparation method and application

ActiveCN103317566BMeet environmental protection and non-toxic requirementsSimple preparation processBiocideAnimal repellantsEnvironmental resistanceAnti fungal

The invention relates to a micro-emulsion-type wood and bamboo mould-proof agent, as well as a preparation method and application thereof. The micro-emulsion-type wood and bamboo mould-proof agent comprises the following components in parts by weight: 1 to 200 parts of isothiazolinone original medicaments, 1 to 1,000 parts of ester solvents, 1 to 500 parts of alcohol or ester cosolvents, 1 to 1,500 parts of polyoxyethylene non-ionic surfactants, 1 to 150 parts of succinate or polyoxyethylene ether salt non-ionic surfactants, 1 to 100 parts of long-chain carboxylic acid additives, and 1 to 1,000,000 parts of water. The micro-emulsion-type wood and bamboo mould-proof agent disclosed by the invention has the advantages that the chemical agents meet the requirements on environment friendliness and no toxicity; the preparation process is simple; the crystallization degree is low; the stability is high; the particle size is small; the permeability and the mould-proof performance are high; the volume expansibility of the processed bamboo and wood is reduced and the like; the micro-emulsion-type wood and bamboo mould-proof agent is stable, effective and environmentally-friendly, and is much better than that in the prior art.

Owner:BEIJING FORESTRY UNIVERSITY

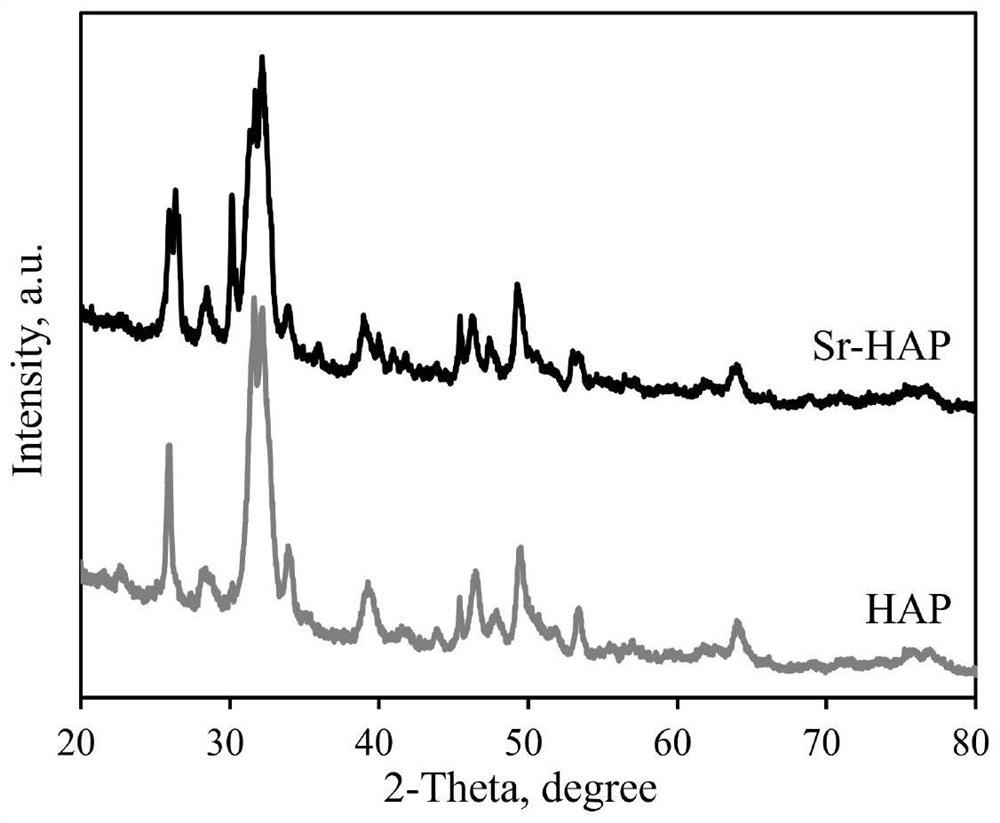

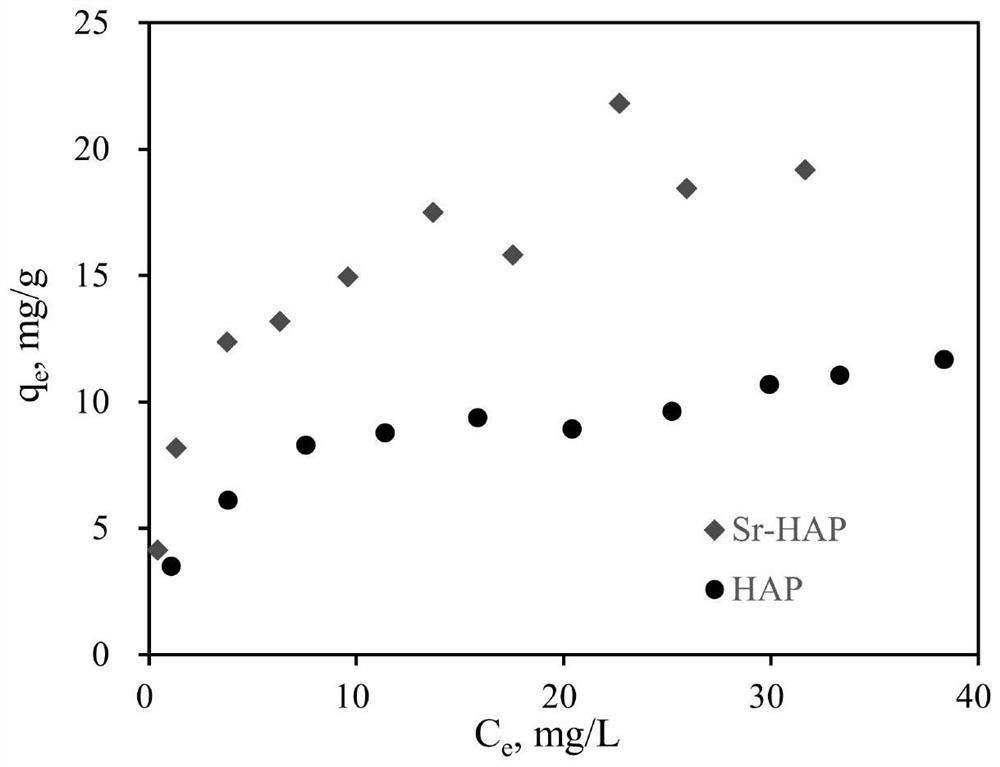

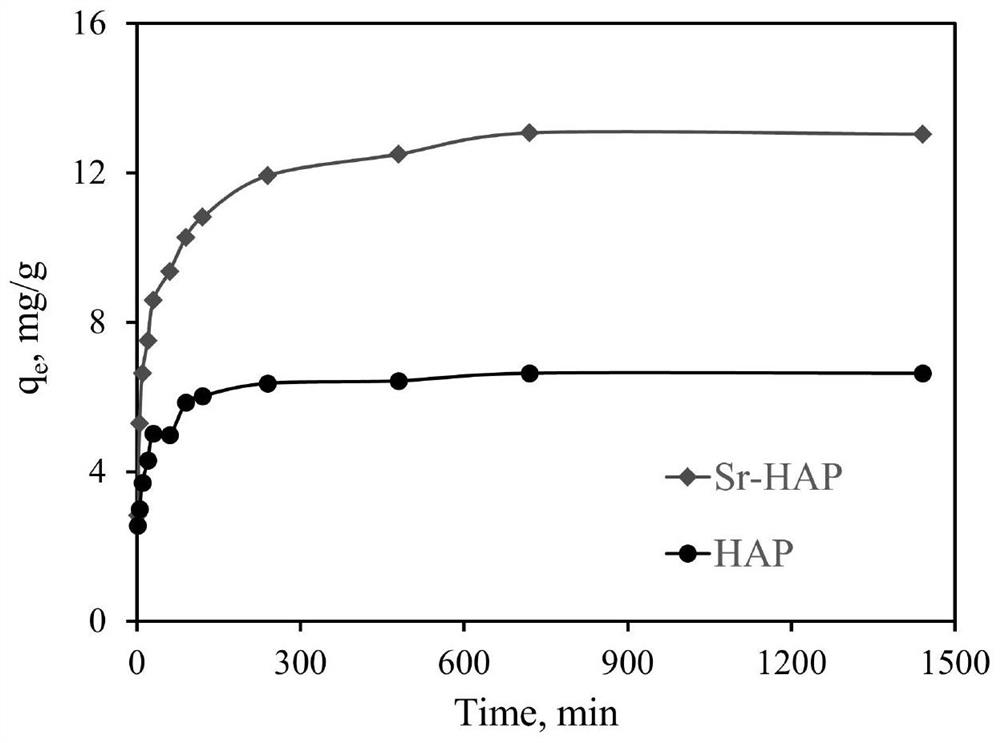

Strontium modified hydroxyapatite as well as synthesis and application methods thereof

PendingCN114229819AReduce the degree of crystallizationHigh specific surface areaOther chemical processesWater contaminantsHydroxyapatitesAqueous solution

The invention discloses strontium modified hydroxyapatite and a synthesis and application method thereof.The synthesis method comprises the steps that a first mixed solution containing calcium ions and strontium ions and a sodium dihydrogen phosphate aqueous solution are mixed to obtain a second mixed solution, the pH of the second mixed solution is adjusted to 6.0-7.0 for a reaction, then aging is conducted for 6-18 h, and the strontium modified hydroxyapatite is obtained. The strontium modified hydroxyapatite is obtained. The synthesis method disclosed by the invention is simple in process, low in cost and environment-friendly, and the obtained product has efficient fluorine adsorption capacity.

Owner:SICHUAN UNIV

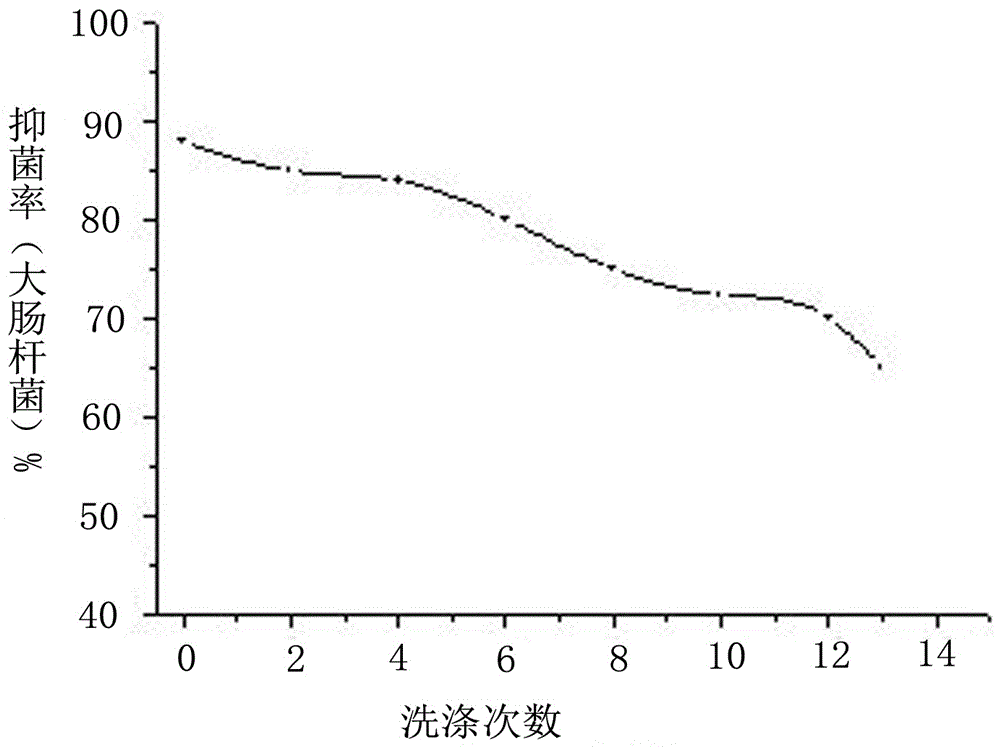

Composite antibacterial wool flocculus and preparation method thereof

InactiveCN106283384ABreathableImprove dehumidification effectBed linenNon-woven fabricsHot meltCell metabolism

The invention provides a composite antibacterial wool flocculus which mainly comprises the following raw materials: composite wool fiber web, hot melt powder and insoluble chitosan, wherein the mass of the hot melt powder accounts for 7-13% of the total mass of the composite wool fiber web; and the mass of the insoluble chitosan accounts for 5-11% of the mass of the hot melt powder. The composite antibacterial wool flocculus has the characteristics of air permeability, high moisture adsorption property and effects of promoting sleep, enhancing vigor, promoting cell metabolism, delaying ageing and inhibiting bacteria, and can effectively prevent skin lesions and pruritus. The invention also provides a method for preparing the composite antibacterial wool flocculus. The method is simple, feasible and suitable for large-scale automatic production.

Owner:HENAN INST OF ENG

Steamed vermicelli roll quality improver and using method thereof

The invention discloses a steamed vermicelli roll quality improver which is prepared from the following components: 0.05-0.2 part of sodium polyacrylate, 1-2 parts of maltogenic amylase, 1.5-3 parts of xanthan gum, 2-2.8 parts of konjac manan, 1.5-3.2 parts of glucamylase, 2-3 parts of papain, 0.8-1.5 parts of hemicellulase and 0.2-0.5 part of a defoamer. A using method of the steamed vermicelli roll quality improver comprises the following operation steps: selecting fresh rice produced in current year, and picking out impurities; cleaning and pulping the soaked rice to obtain rice milk, and measuring the concentration of the rice milk to enable the concentration of the rice milk to be maintained at 10-16 baume degrees; and adding the steamed vermicelli roll quality improver in the rice milk, stirring for 5-10 min, and performing standing for 1.5-2 h, then stirring again, and performing steaming. Through the addition of the steamed vermicelli roll quality improver, the ageing, retrogradation and precipitation and solidification of a starch product can be prevented; and the softness of a rice flour product is maintained, the water evaporation is inhibited, the size is increased, andthe taste and the softness are improved.

Owner:上海菩圆生物科技有限公司

Preparation method of silicon beads with high hydration activity

InactiveCN109053002AImproved particle size distributionImprove performanceCement productionGas phaseOxygen

The invention relates to the technical field of preparation of cement raw materials and in particular relates to a preparation method of silicon beads with high hydration activity. According to the method provided by the invention, sodium silicate hydrate in sodium silicate alkali dreg is transformed into sodium carbonate and silicon dioxide; silicon dioxide is ultrafine powder and directly reactswith a gas phase; the crystallization degree is relatively low and the reaction activity is relatively high; original silicon dioxide in the sodium silicate alkali dreg is a product obtained by quenching at 1300 to 1500 DEG C; high-temperature gas is decomposed into water and oxygen through hydrogen peroxide in a polycrystalline silicon powder raw material at the same time, and concrete is not expanded any more; the reaction activity of the polycrystalline silicon waste material is improved through local oxidization in the high-temperature gas. The granularity of the ground sodium silicate alkali dreg is mainly in a range of 10 to 30 mu m, and the granularity of the polycrystalline silicon waste material is mainly in a range of 1 to 3mu m; the ground sodium silicate alkali dreg and the polycrystalline silicon waste material are matched, so that final grain size gradation of a product is optimized and the performance of the silicon beads with high hydration activity is improved.

Owner:江苏恒大高性能材料有限公司

Numerical control polishing method for sapphire wafer for LED based on high-ratio polishing solution

The invention discloses a numerical control polishing method for a sapphire wafer for an LED based on a high-ratio polishing solution. The method comprises the following steps that 1, the high-ratio polishing solution is prepared and serves as a polishing solution fresh material; 2, circular polishing is adopted for grinding and polishing the surface of the sapphire wafer; 3, the remaining polishing solution generated by one-time circular grinding and polishing is recovered and treated to serve as a polishing solution old material; and 4, in the circular grinding and polishing process of the next time, the polishing solution old material is added to supplement the solution according to the volatilization amount of the polishing solution fresh material. The high-ratio solution comprises polishing stock solution and water, the high-ratio polishing solution is obtained by uniformly mixing the polishing stock solution and the water according to the volume ratio of 1:n, and the value rangeof n is 1-3. According to the technical scheme, the method solves the problems that a present method for polishing the sapphire wafer for the LED is high in single-wafer polishing cost, the crystallization degree is high, and cleaning and sweeping are not easy.

Owner:YUNNAN CRYSTALAND

Poly(butylene succinate) and preparation method thereof

The invention discloses a poly(butylene succinate) which is prepared by copolymerizing succinic acid, butylene glycol and cyclic dibasic alcohol. The poly(butylene succinate) comprises succinic acid residue, butylene glycol residue and cyclic diol residue, wherein the butylene glycol residue accounts for 90-98% of the total dibasic alcohol, and the cyclic diol residue accounts for 2-10% of the total dibasic alcohol. The preparation method comprises the following steps: reacting succinic acid, butylene glycol and cyclic dibasic alcohol at 200-230 DEG C under the action of a catalyst to perform direct esterification, thereby obtaining an esterified substance; adding a stabilizer, and carrying out pre-polycondensation reaction at 220-250 DEG C to obtain a prepolymer; carrying out polycondensation reaction on the prepolymer at 235-250 DEG C while gradually reducing the vacuum degree of the reaction system to less than 150Pa; and after the polycondensation finishes, adding carbodiimide compounds into the reaction product, and mixing for 2-15 minutes, thereby obtaining the poly(butylene succinate). The polyester synthesized by the method disclosed by the invention has the advantages of high heat resistance, high melting point, controllable degradation rate, excellent mechanical properties and excellent processability.

Owner:KINGFA SCI & TECH CO LTD +2

A kind of preparation method of special fertilizer for cockscomb

InactiveCN104310332BReduce manufacturing costReduce the degree of crystallizationPhosphatesAlkali orthophosphate fertiliserPhosphatePhosphoric acid

The invention discloses a method for preparing a special fertilizer for cockscomb. The method is to generate an intermediate by reacting phosphoric acid and carbonamide, and then inject ammonia gas into the intermediate to produce ammonium dihydrogen phosphate, so that a part of the dihydrogen phosphate Ammonium crystallization is used to adjust the ratio of nutrient elements in the reaction solution to meet the growth requirements of cockscomb, and add other nutrient elements required by cockscomb to prepare special fertilizer for cockscomb. This production method makes full use of raw materials, and no waste liquid is discharged to pollute the environment. By strictly controlling the amount of various parameters in the production process, the quality of the produced ammonium dihydrogen phosphate is better, and the cost of the prepared special fertilizer for cockscomb is lower. .

Owner:GUIZHOU UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com