A kind of microemulsion wood and bamboo antifungal agent, its preparation method and application

A technology of microemulsion and antifungal agent, applied in the direction of botanical equipment and methods, application, impregnation of wood, etc., can solve the problem of the lack of experimental results to support the performance and effect of treating wood and bamboo wood, and the lack of comprehensive evaluation of the stability of wood and bamboo wood protective agents , the effect is not very ideal and other problems, to achieve the effect of low equipment technical requirements, low crystallization degree, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

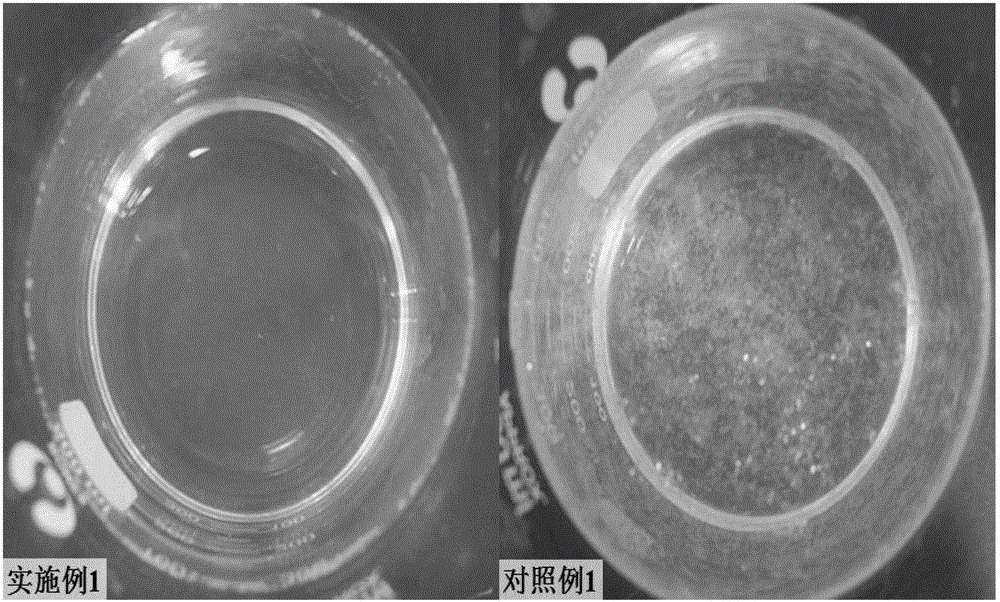

Embodiment 1

[0050] 1. Materials

[0051] DCOIT (Shanghai Sanbo Biochemical Technology Co., Ltd.), 2,2,4-trimethyl-1.3 pentanediol monoisobutyrate, sodium dioctyl sulfosuccinate and castor oil polyoxyethylene ether 40 (industrial product , without purification), benzyl alcohol and oleic acid (analytical grade), deionized water.

[0052] 2. Preparation method

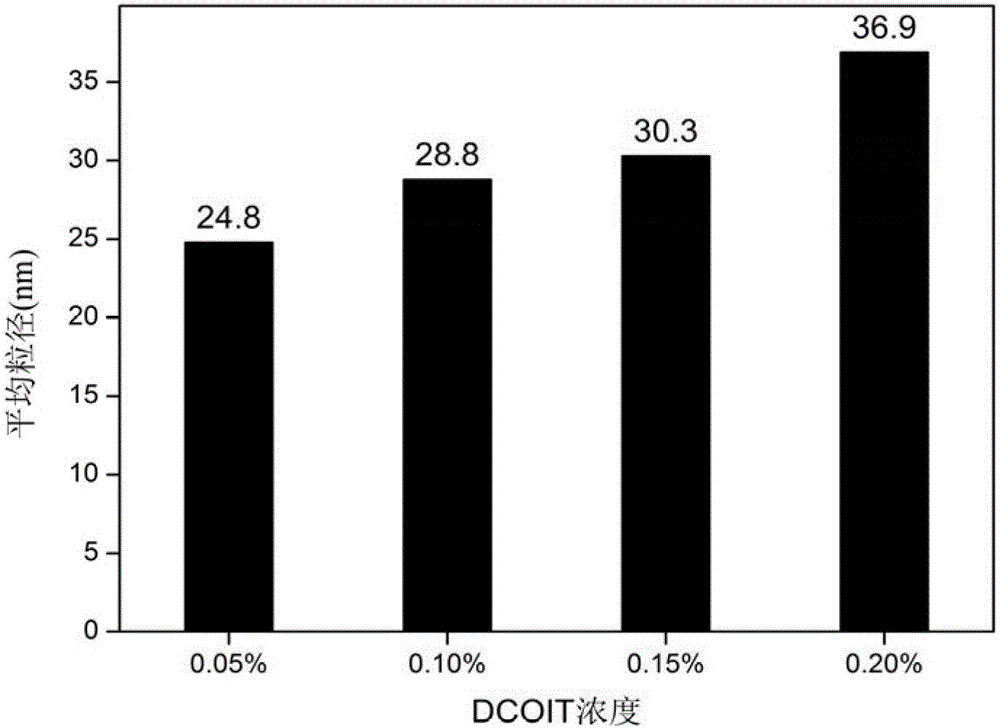

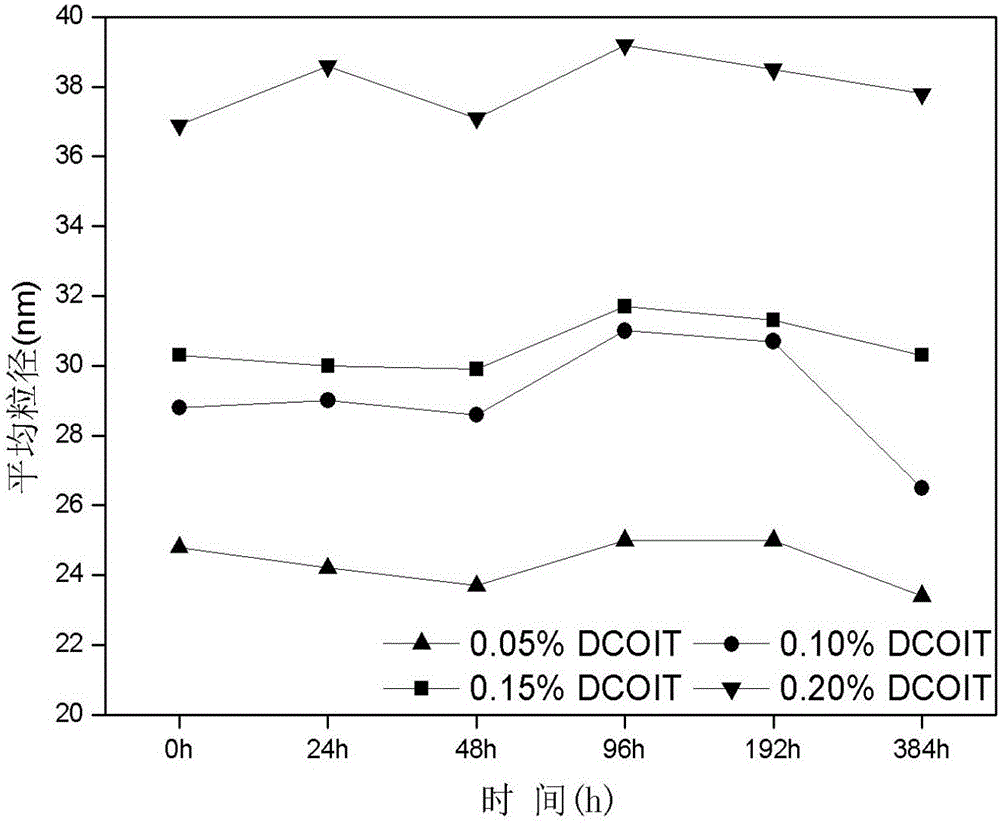

[0053] Take 2.5g of the original drug DCOIT and dissolve it in 5g of 2,2,4-trimethyl-1.3pentanediol monoisobutyrate. The dissolution process is completed in a water bath at 60°C. After the original drug is completely dissolved, add 1.8 g benzyl alcohol, after forming a stable oil phase, slowly add 9.5 g castor oil polyoxyethylene ether 40, 1.8 g oleic acid and 1 g dioctyl sodium sulfosuccinate in turn while stirring, and heat in a water bath at 60 °C Stir at a speed of 200rpm for 3 minutes. The preparation of the emulsifiable concentrate is completed. After freezing for 24 hours, take 1g of the emulsifiable concentrate and add deio...

Embodiment 2

[0055] Others are the same as embodiment 1, the difference is:

[0056] 2. Preparation method

[0057] Take 2g of the original drug DCOIT and dissolve it in 6g of 2,2,4-trimethyl-1.3pentanediol monoisobutyrate. The dissolution process is completed in a water bath at 70°C. After the original drug is completely dissolved, add 1.5g of benzene Methanol, after forming a stable oil phase, slowly add 10g castor oil polyoxyethylene ether 40, 2.5g oleic acid and 2g sodium dioctyl sulfosuccinate in sequence while stirring, heat in a water bath at 80°C and set the temperature at 600rpm Stir at the speed of 10 minutes, the emulsifiable concentrate is prepared, and after freezing for 24 hours, take 1 g of the emulsifiable concentrate and add deionized water to 170 g to obtain a microemulsion wood and bamboo fungicide with a DCOIT concentration of 0.05%.

Embodiment 3

[0059] Others are the same as embodiment 1, the difference is:

[0060] 2. Preparation method

[0061] Take 3g of the original drug DCOIT and dissolve it in 5.5g of 2,2,4-trimethyl-1.3pentanediol monoisobutyrate. The dissolution process is completed in a water bath at 80°C. After the original drug is completely dissolved, add 2.5g Benzyl alcohol, after forming a stable oil phase, slowly add 9.0g castor oil polyoxyethylene ether 40, 2g oleic acid and 1g dioctyl sodium sulfosuccinate in turn while stirring, heat in a water bath at 70°C and Stir at a speed of 1000rpm for 5 minutes, and the preparation of the EC is completed. After freezing for 24 hours, take 1 g of the EC and add deionized water to 87 g to obtain a microemulsion wood and bamboo fungicide with a DCOIT concentration of 0.15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com