Preparation method of all-solid-state polymer electrolyte

An all-solid-state polymer and electrolyte technology, applied in the direction of electrolyte immobilization/gelation, circuits, electrical components, etc., can solve the problem of unsuitable use of high-voltage cathode material systems, the low electrochemical window of all-solid polymer electrolytes, and the inability to The combination of high-voltage cathode material system and other issues can achieve the effects of good mechanical processing performance, high electrochemical stability and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

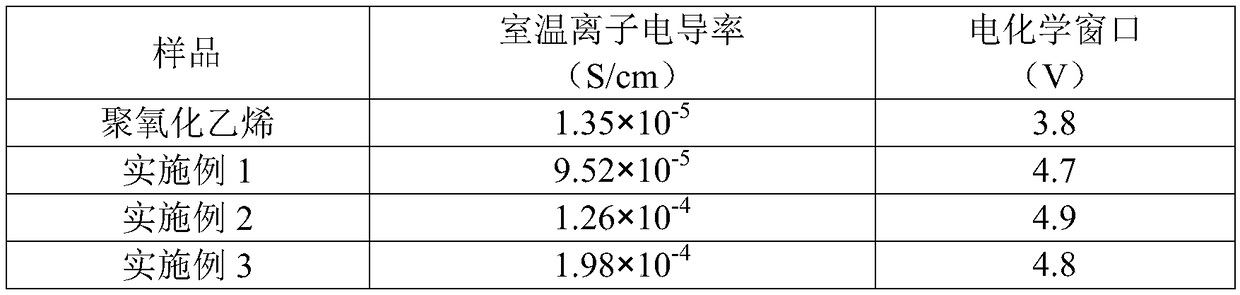

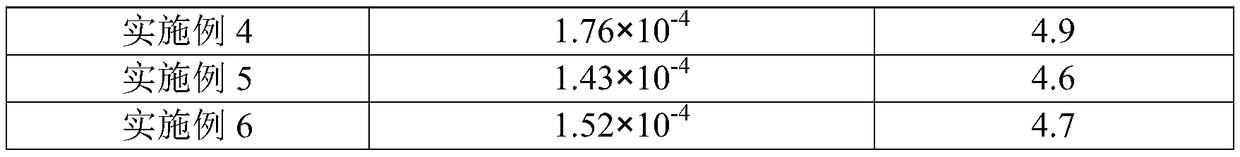

Examples

preparation example Construction

[0024] The preparation method of the all-solid polymer electrolyte of the present invention comprises the following steps:

[0025] S1. Combine 1-10 parts by mass of carbonic acid structure crosslinking agent, 70-95 parts by mass of polyether structural monomer, 0-2 parts by mass of alkene monomer, and 0-5 parts by mass of functional polymer together with solvent Add to the reactor, continue to flow nitrogen into the reactor, and keep stirring at a speed of 100-500r / min for 1h-5h to form a uniform precursor solution;

[0026] The carbonic acid structure cross-linking agent in this step is to have the polymeric monomer of carbonic acid structure and polymerizable polyene group at the same time, and its structural formula is as follows:

[0027] Among them, R1, R2, R3, R4 are C x h y o z , x, y, z∈integer, and x≥0, y≥0, z≥0;

[0028] The carbonic acid structure crosslinking agent can specifically be bis(vinyl)carbonate, 2-ethoxycarbonyloxyethyl-2-methylpropyl-2-enoate, 2-p...

Embodiment 1

[0041] S1, the bis (vinyl) carbonate of 6 mass parts, the polyethylene glycol methyl ether methacrylate (molecular weight 300) of 70 mass parts, the acrylic acid of 1 mass part, the polyvinylidene fluoride and tetrahydrofuran of 1 mass part Add to the reactor, continue to pass nitrogen into the reactor and continue to stir at a speed of 100r / min for 1h to obtain a uniform precursor solution;

[0042] S2. Add 0.1 parts by mass of 2-hydroxy-2-methyl-1-phenylmethanone, 10 parts by mass of lithium bisoxalate borate and 5 parts by mass of methoxypolyethylene glycol boric acid Esters were continuously stirred at a speed of 200r / min for 2h to obtain a mixed solution, and the mixed solution was evenly coated on the mold, and after the solvent was evaporated, an ultraviolet lamp was used to initiate the reaction under an inert gas, and the initiation time was 300min; In addition to the light-induced reaction, thermal initiation can also be used. The temperature of thermal initiation is...

Embodiment 2

[0046] S1, 1 mass part of 2-ethoxycarbonyloxyethyl-2-methylpropyl-2-enoic acid ester, 80 mass parts of polyethylene glycol methyl ether methacrylate (molecular weight 20000), 2 mass parts Parts of polyethylene oxide (molecular weight: 5,000,000) and methylpyrrolidone were added to the reactor, nitrogen was continuously passed into the reactor and stirred at a speed of 200r / min for 2h to obtain a uniform precursor solution;

[0047] S2. Add 0.5 parts by mass of 4-methylbenzophenone, 3 parts by mass of nano-silicon dioxide, 2 parts by mass of lithium tantalate, and 40 parts by mass of bistrifluoromethanesulfonyl to the precursor solution Lithium amine, 20 mass parts of malonate lithium oxalate borate, 5 mass parts of methoxy polyethylene glycol aluminate, 3 mass parts of succinonitrile, 2 mass parts of ethylene carbonate, with 500r / Continue stirring at a speed of min for 4 hours to obtain a mixed solution. Spread the mixed solution evenly on the mold, evaporate the solvent, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com