Functional antibacterial composite wool flocculus and preparation method thereof

A compound antibacterial and functional technology, applied in the fields of biochemical fiber treatment, non-woven fabrics, textiles and papermaking, etc., can solve the problems of skin allergy and damage, and achieve the effect of promoting sleep, promoting cell metabolism and strong moisture removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

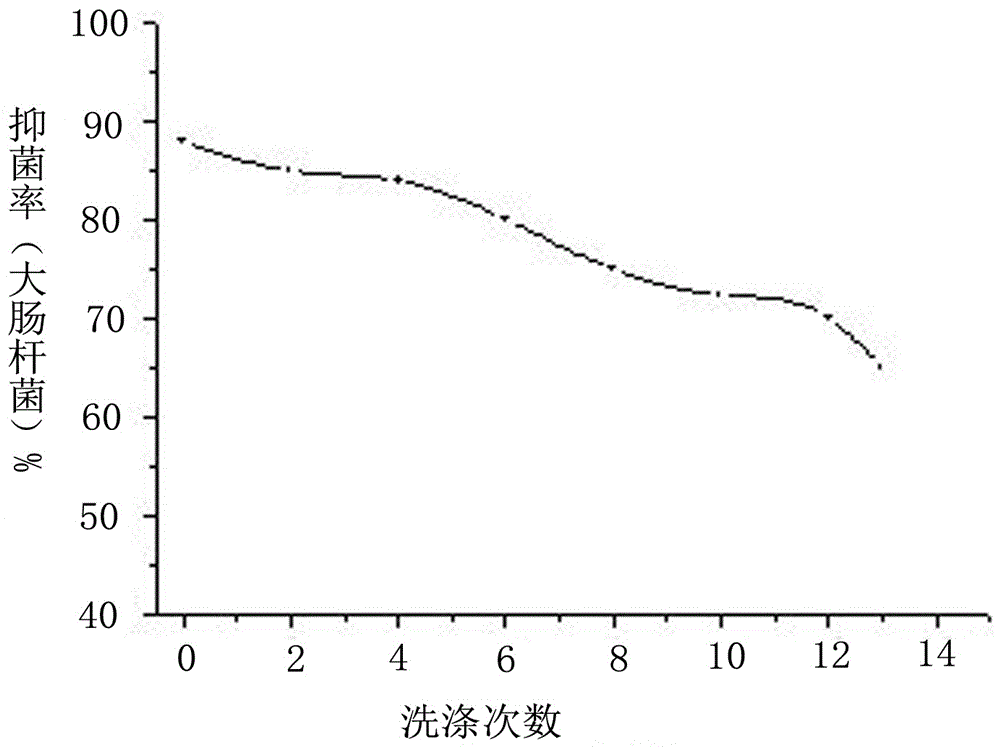

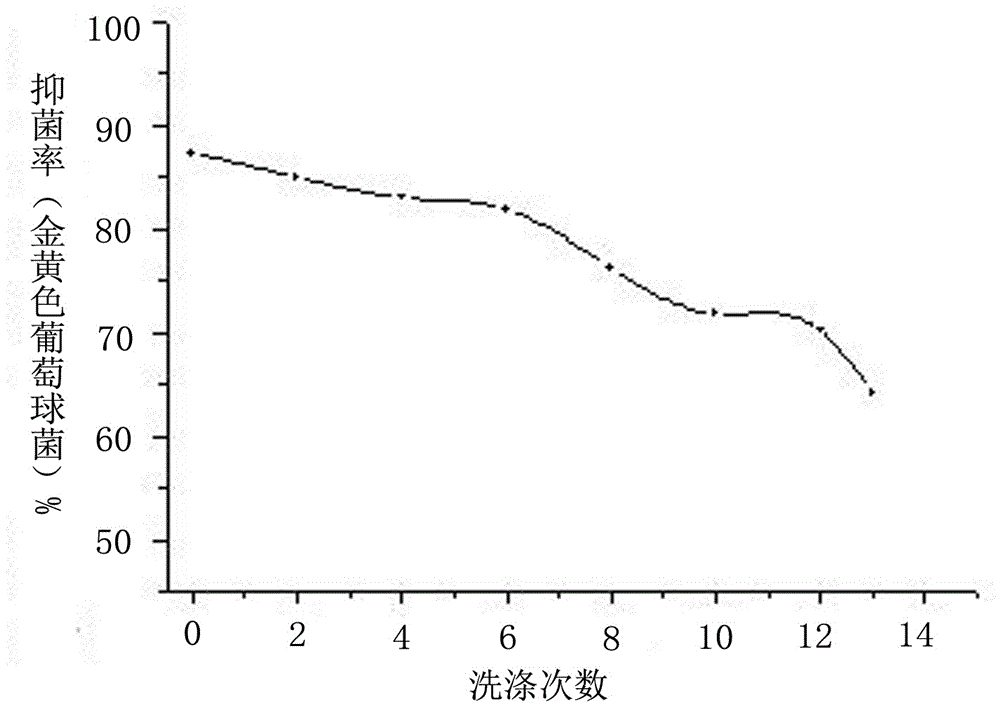

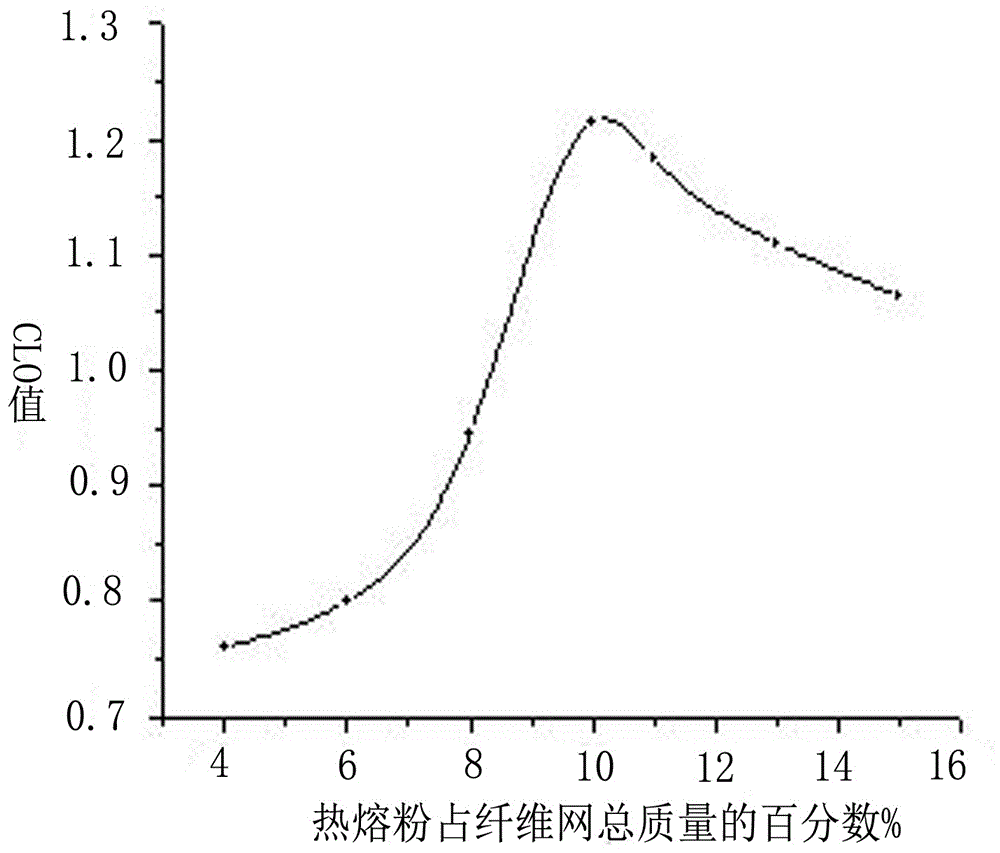

[0033] This embodiment provides a functional composite antibacterial wool flake, which mainly includes the following materials: a single-layer wool composite wool fiber, hollow fiber and far-infrared fiber with a mass ratio of 8:1:1 obtained through non-woven technology. Fiber mesh, hot melt powder and nano silver particles.

[0034]Wherein, the hot-melt powder is a polyether-modified polyester with a particle size of 100 microns, and the mass of the polyether-modified polyester accounts for 10% of the total mass of the wool composite fiber web. The nano-silver ion is prepared by immersing the single-layer wool composite fiber web in a nano-silver solution and drying.

[0035] Preferably, the preparation method of described nano-silver solution comprises: at first concentration is the AgNO of 1.5 g / L 3 The solution was added to the PVA solution with a concentration of 1.0 g / L to form AgNO 3 dispersion solution, and then to the AgNO 3 A hydrogen peroxide solution with a conc...

Embodiment 2

[0041] This embodiment provides a functional composite antibacterial wool flake, which mainly includes the following materials: wool fibers, hollow fibers, far-infrared fibers and bamboo charcoal fibers with a mass ratio of 7:1:1:1 are obtained through non-woven fabric technology Single-layer wool composite fiber mesh, hot-melt powder and nano-silver particles.

[0042] Wherein, the hot-melt powder is a polyether-modified polyester with a particle size of 20 microns, and the quality of the polyether-modified polyester accounts for 10% of the total mass of the wool composite fiber web, and the nano-silver ions It is prepared by immersing the single-layer wool composite fiber web in a nano-silver solution and drying, and the preparation steps of the nano-silver solution are the same as those in Example 1.

[0043] This embodiment also provides a method for preparing the functional composite antibacterial wool flakes, which has the same preparation steps as those in Example 1.

Embodiment 3

[0045] This embodiment provides a functional composite antibacterial wool flake, which mainly includes the following materials: wool fibers, hollow fibers, far-infrared fibers and bamboo charcoal fibers with a mass ratio of 6.8:1.2:1:1 are obtained through non-woven fabric technology Single-layer wool composite fiber mesh, hot-melt powder and nano-silver particles.

[0046] Wherein, the hot-melt powder is composed of copolyamide and polyether-modified polyester with a particle size of 20 microns and a mass ratio of 1:1, and the mass of the hot-melt powder accounts for the total mass of the wool composite fiber web. 11%. The nano-silver ions are prepared by immersing the single-layer wool composite fiber web in a nano-silver solution and drying, and the preparation steps of the nano-silver solution are the same as those in Example 1.

[0047] This embodiment also provides a method for preparing the functional composite antibacterial wool flakes, which has the same preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com