Tungsten tailings cementing material and preparation method thereof

A technology of cementitious materials and tungsten tailings, which is applied in the field of building materials, can solve problems such as endangering human health, occupying land, and polluting the environment, and achieves the effects of low cost, improved compressive strength, and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

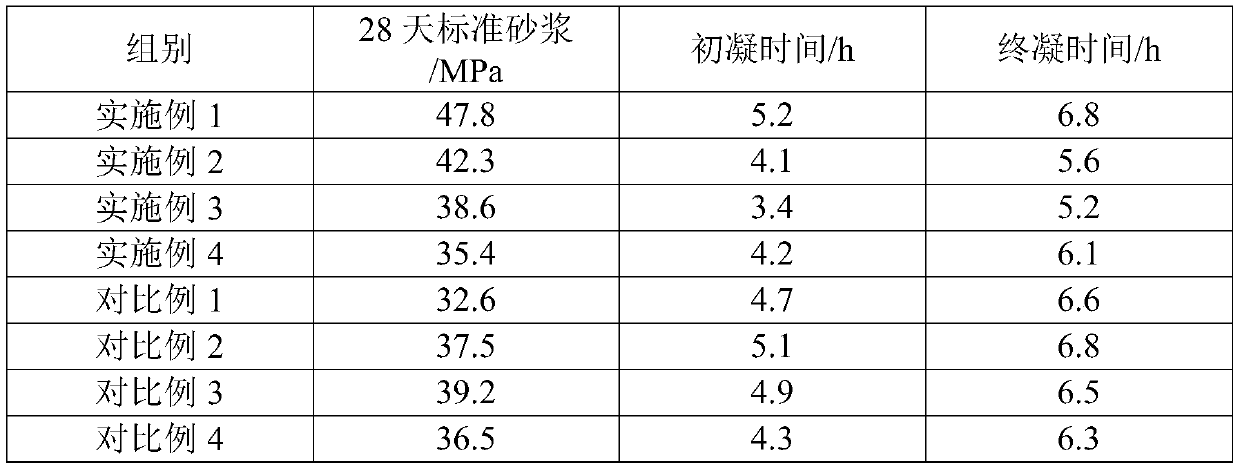

Embodiment 1

[0025] A cementitious material for tungsten tailings, the mass ratio of which is as follows: 50kg of tungsten tailings, 10kg of hemihydrate gypsum, 25kg of S95 grade slag, 8kg of steel slag with a particle size of ≤75μm, 5kg of activator, 2kg of polycarboxylate superplasticizer, The mass ratio of the activator is Portland cement 2kg, sulphoaluminate cement 3kg. The preparation method of the tungsten tailings cementitious material comprises the following steps: (1) using zirconia ceramic balls to grind the tungsten tailings for 8 hours and drying them to obtain tungsten tailings powder; (2) mixing the tungsten tailings powder and slag , steel slag, activator, and polycarboxylate superplasticizer are poured into a ball mill, and ordinary ceramic balls are used for ball milling for 2 hours to obtain the tungsten tailings cementitious material.

Embodiment 2

[0027] A cementitious material for tungsten tailings, the mass ratio of which is as follows: 58kg of tungsten tailings, 5kg of hemihydrate gypsum, 30kg of S95 grade slag, 1.5kg of steel slag with a particle size of ≤75μm, 4kg of activator, and 1.5kg of polycarboxylate superplasticizer kg, the mass ratio of the activator is Portland cement 3.2kg, sulphoaluminate cement 0.8kg. The preparation method of the tungsten tailings cementitious material comprises the following steps: (1) using zirconia ceramic balls to grind the tungsten tailings for 12 hours and drying them to obtain tungsten tailings powder; (2) mixing the tungsten tailings powder and slag , steel slag, activator, and polycarboxylate superplasticizer are poured into a ball mill, and ordinary ceramic balls are used for ball milling for 0.5 h to obtain the tungsten tailings cementitious material.

Embodiment 3

[0029] A tungsten tailings cementitious material, the mass ratio of which is as follows: tungsten tailings 65kg, hemihydrate gypsum 8kg, S95 grade slag 18kg, steel slag with particle size ≤75μm 6.2kg, activator 2kg, polycarboxylate superplasticizer 0.8 kg, the mass ratio of the activator is Portland cement 1.2kg, sulphoaluminate cement 0.8kg. The preparation method of the tungsten tailings cementitious material comprises the following steps: (1) using zirconia ceramic balls to grind the tungsten tailings for 16 hours and drying them to obtain tungsten tailings powder; (2) mixing the tungsten tailings powder and slag , steel slag, activator, and polycarboxylate superplasticizer are poured into a ball mill, and ordinary ceramic balls are used for ball milling for 1 hour to obtain the tungsten tailings cementitious material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com