Patents

Literature

30results about How to "High degree of gelatinization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing vermicelli convenient food and vermicelli convenient food

ActiveCN101084783AHigh degree of gelatinizationSimple methodFood preservationFood preparationConvenience foodMouthfeel

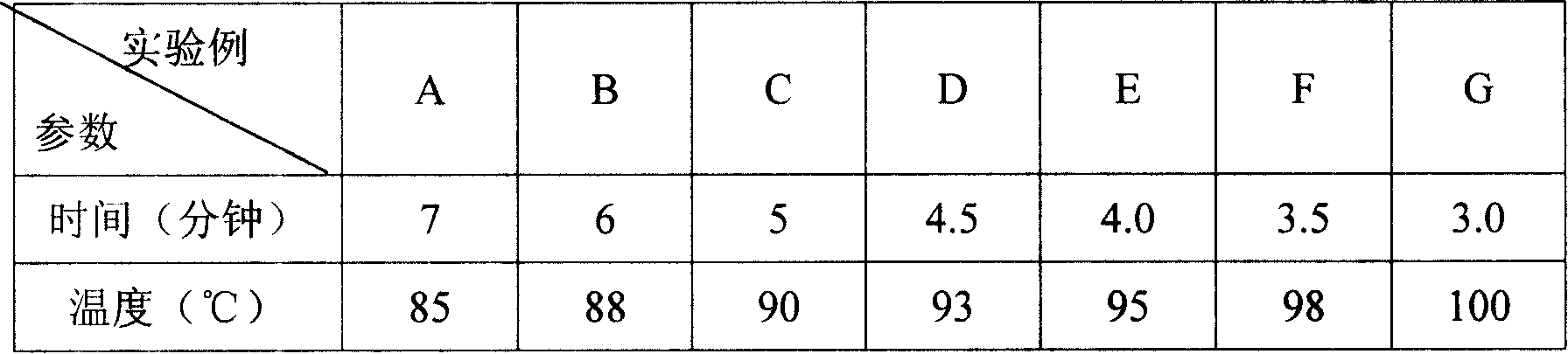

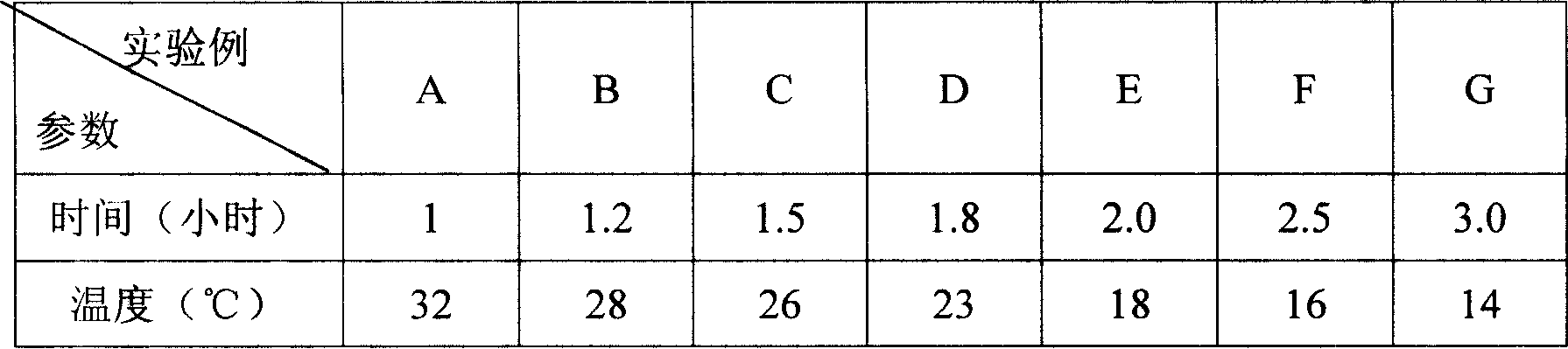

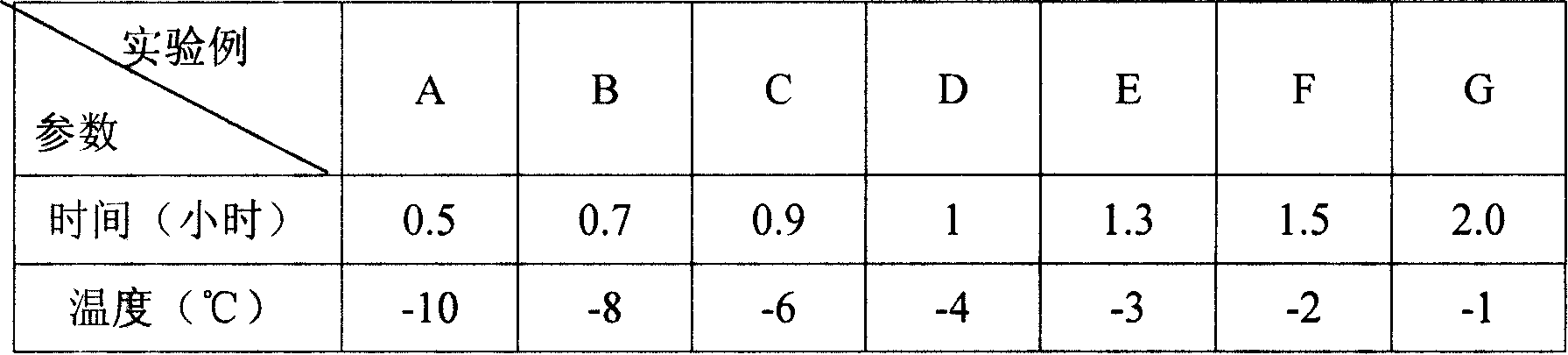

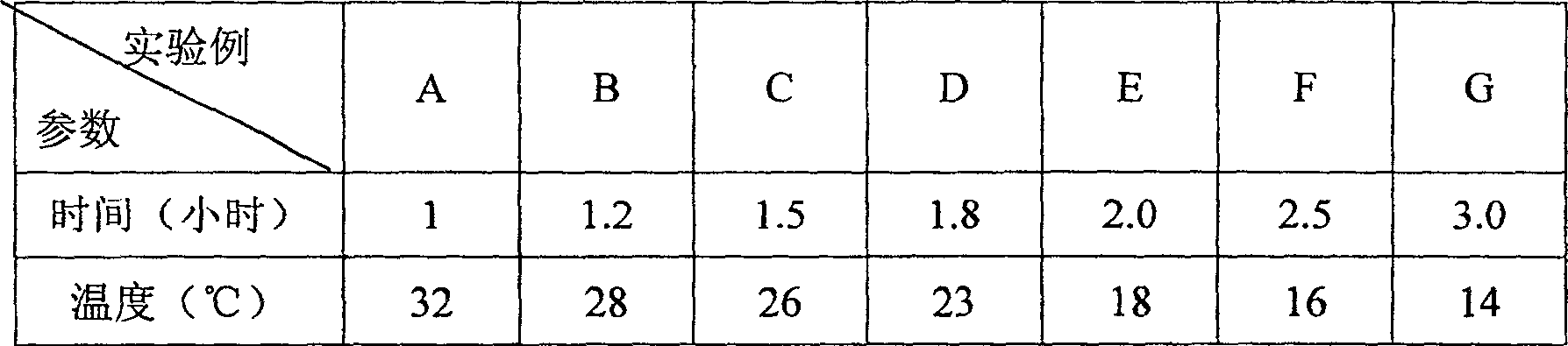

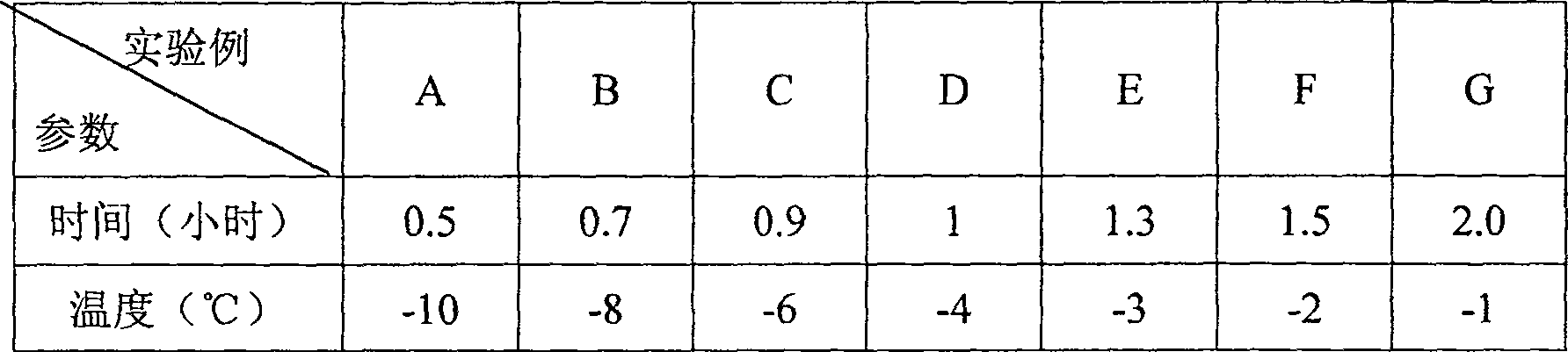

The invention belongs to food processing field and mainly provides a preparation method of vermicelli instant food. The method comprises preparing raw material, pulp mixing, spreading, and steaming to give sheet jelly, forecooling at room temperature, freezing at -8--1deg.C for 1.5-2h, cutting, and drying to give final product. The inventive method has simple operation, high efficiency, no requirement of gelatinizing, defreezing and additive, reduced production period and energy consumption, and reduced cost. The inventive vermicelli instant food has the advantages of good appearance, high diaphaneity, good taste and mouthfeel, no additive, and high safety.

Owner:四川白家阿宽食品产业股份有限公司

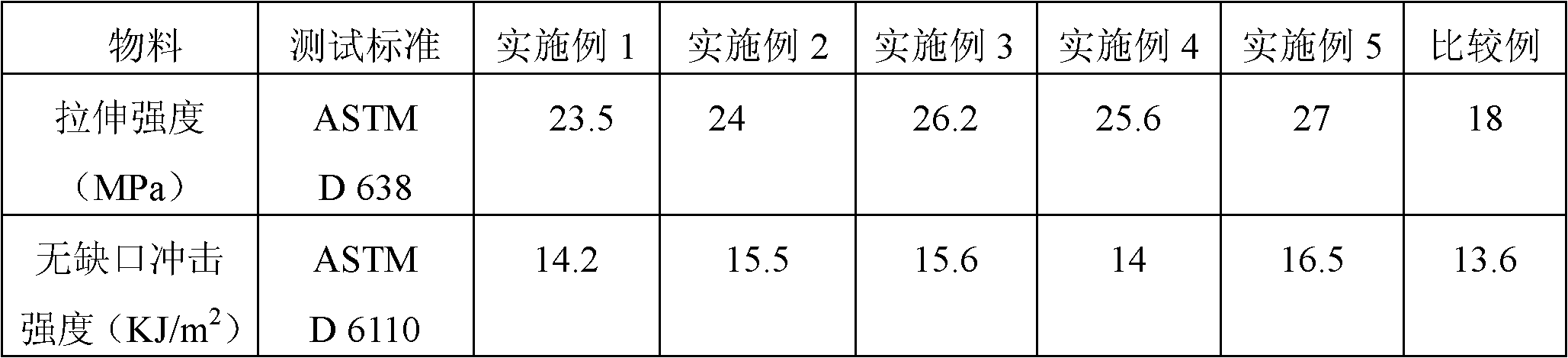

Polylactic acid-starch blended material and preparation method thereof

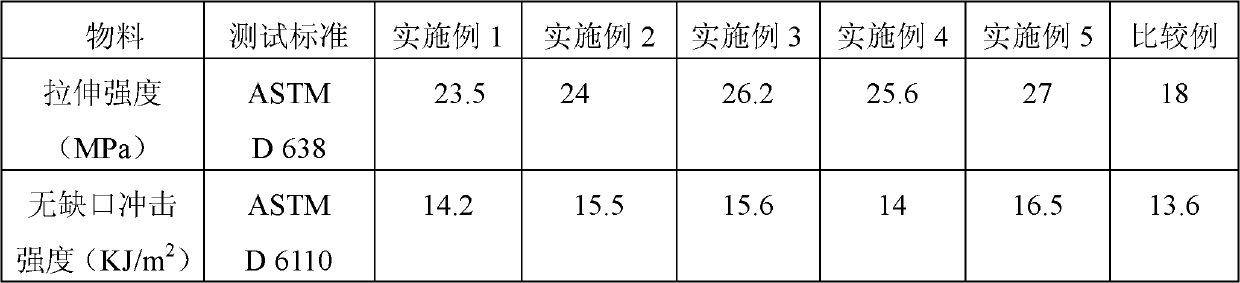

The invention belongs to the field of modification of high polymer blended plastics, and discloses a polylactic acid-starch blended material and a preparation method thereof. The polylactic acid-starch blended material disclosed by the invention comprises the following components in parts by weight: 448-8207 parts of polylactic acid, 1000 parts of starch, 10-114 parts of grafting agent, 36-286 parts of plasticizer, 2-29 parts of coupling agent and 3-97 parts of antioxidant. The preparation method comprises the following steps: (1) adding 1000 parts of pretreated starch, 10-114 parts of grafting agent, 36-286 parts of plasticizer and 2-29 parts of coupling agent into a high-speed mixer, and mixing at normal temperature for 10-50 minutes; and (2) granulating 1053-1429 parts of the mixture obtained in the step (1) by a double screw extruder, mixing with 448-8207 parts of polylactic acid and 3-97 parts of antioxidant and granulating, or directly mixing the mixture obtained in the step (1) with 448-8207 parts of polylactic acid and 3-97 parts of antioxidant and granulating by the double screw extruder. The product disclosed by the invention has the advantages of favorable mechanical properties and low cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

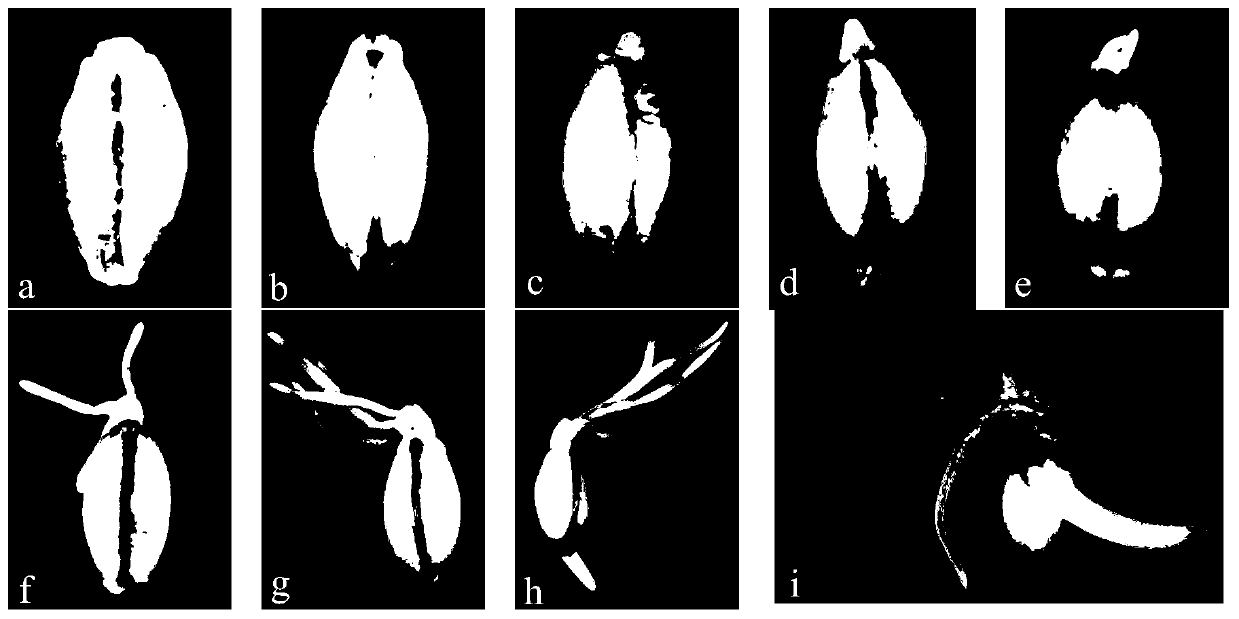

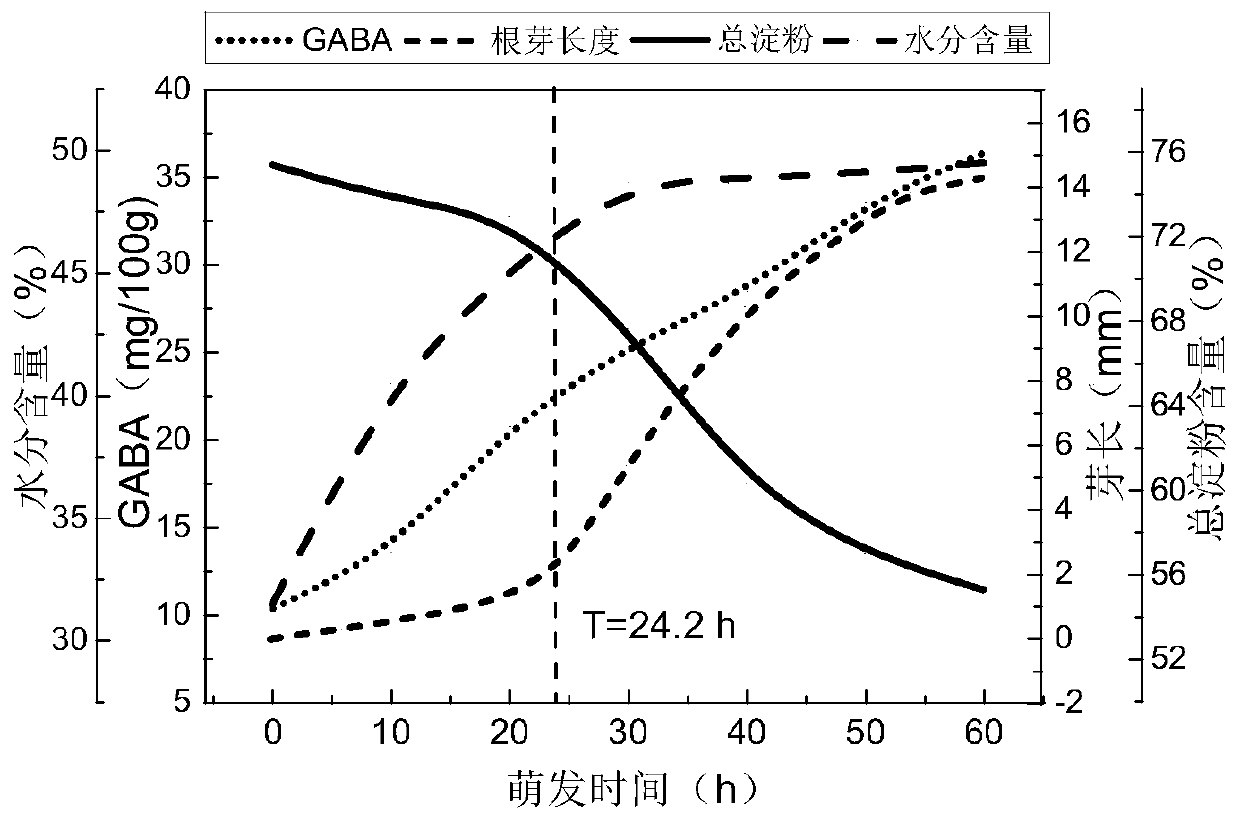

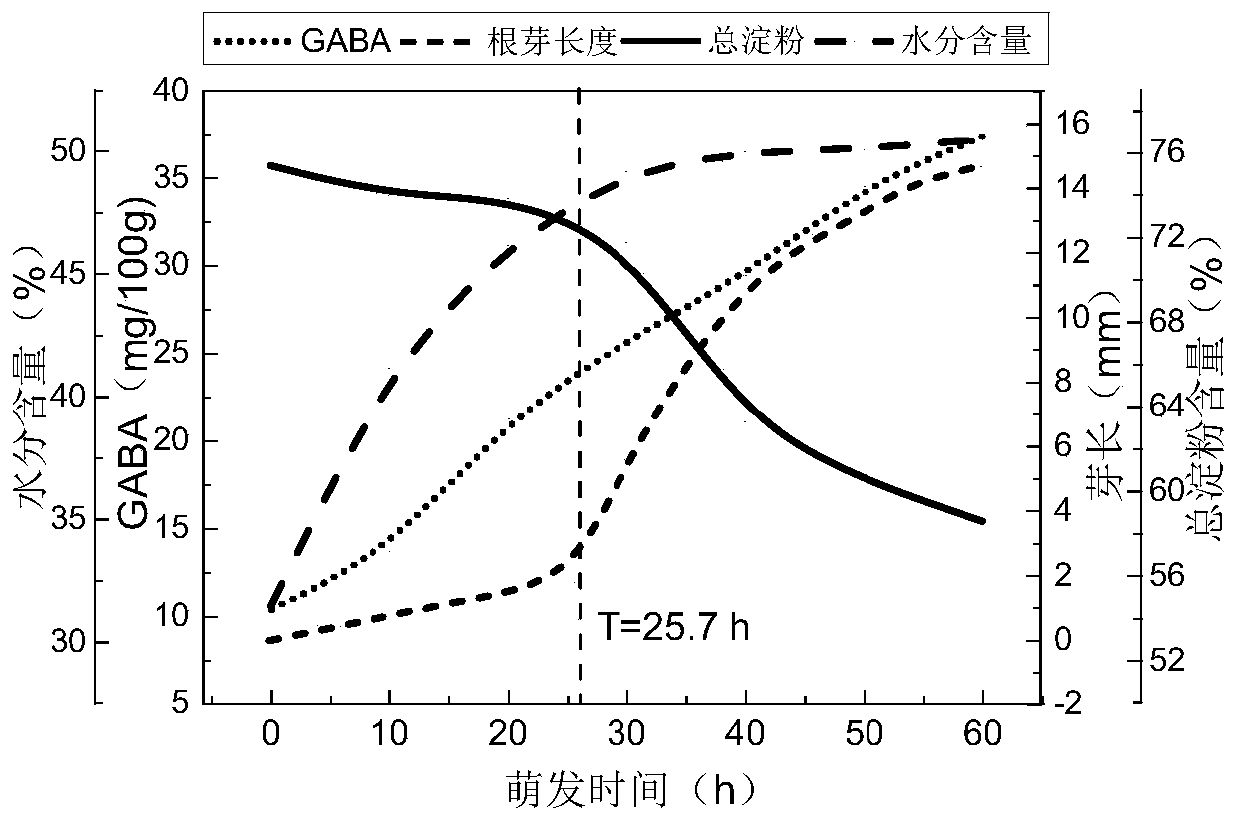

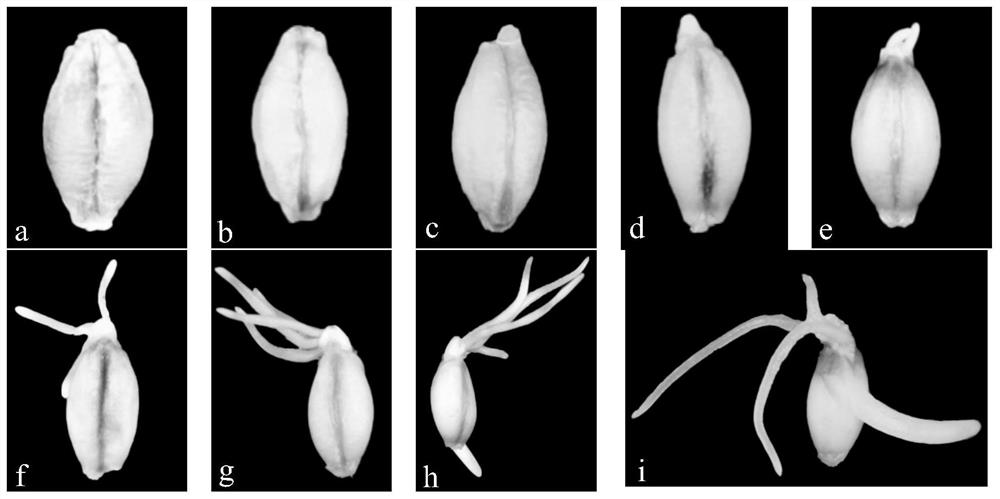

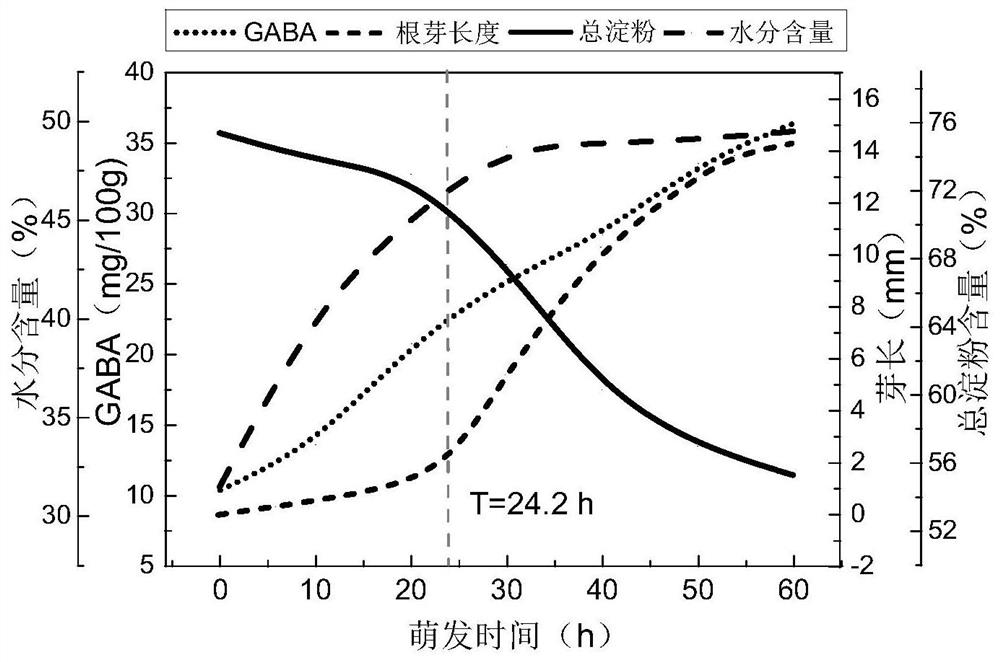

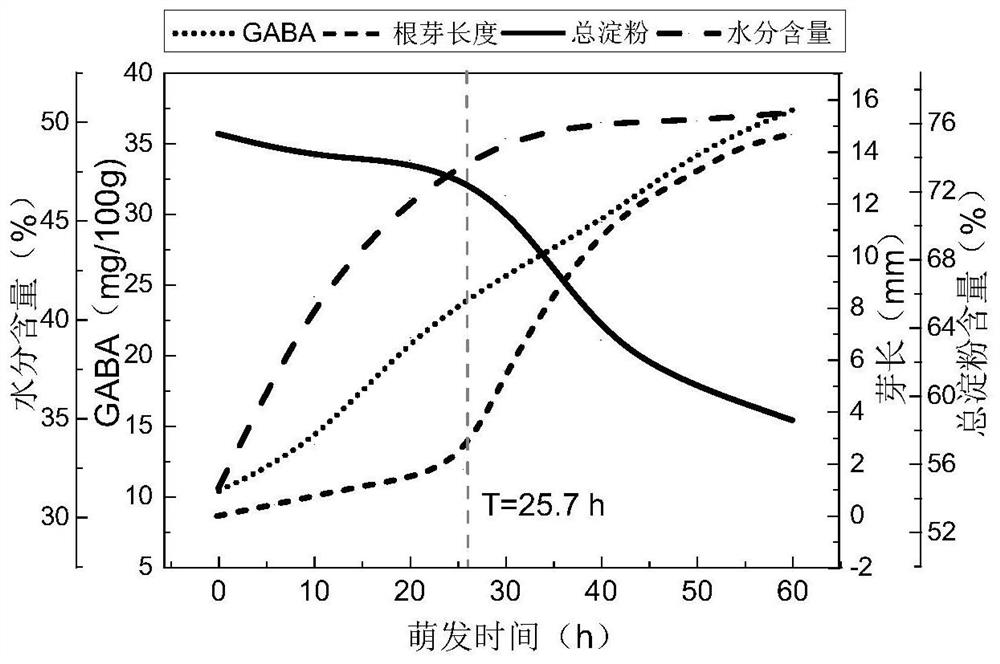

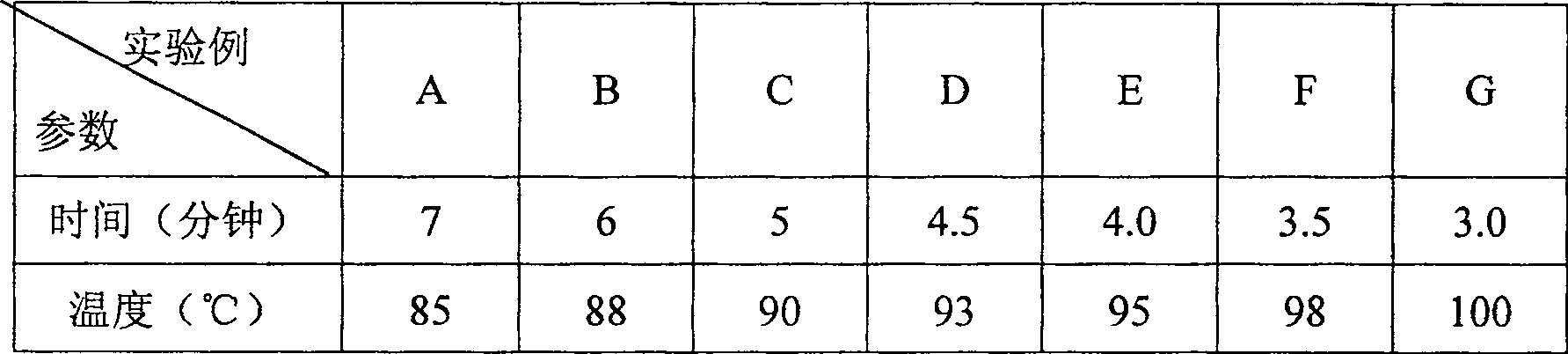

Production method for high yield ripened highland barley powder rich in gamma-aminobutyric acid

ActiveCN110089684AIncrease profitReduce lossesDough/pre-mixesFood thermal treatmentGamma-Aminobutyric acidSterile water

The invention discloses a production method for high yield ripened highland barley powder rich in gamma-aminobutyric acid. The method includes the following steps: placing highland barley seeds into agermination tank after pretreatment, and using sterile water to perform immersing for 3-4 h; pouring the sterile water in the germination tank, and performing germination culture for 24.0-26.8 h so that the seeds can be obtained; performing hot air baking and ripening treatment after the draining of the obtained highland barley seeds, and performing milling to obtain powder. The method studies the change rules of powder yield during the germination of the highland barley seeds, and selects appropriate germination conditions to perform follow-up ripening processing on the germination seeds; and the GABA enrichment ratio of the prepared highland barley ripened powder is 24-38%, and the powder yield is more than 80%, so that the loss of the powder during powder making can be greatly reduced,and the utilization rates of the seeds can be enhanced.

Owner:SOUTH CHINA UNIV OF TECH

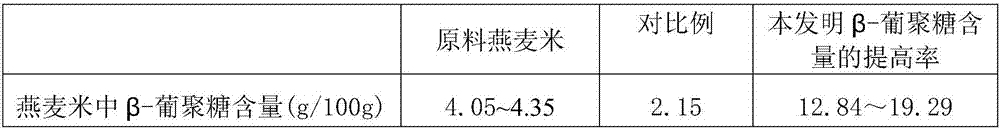

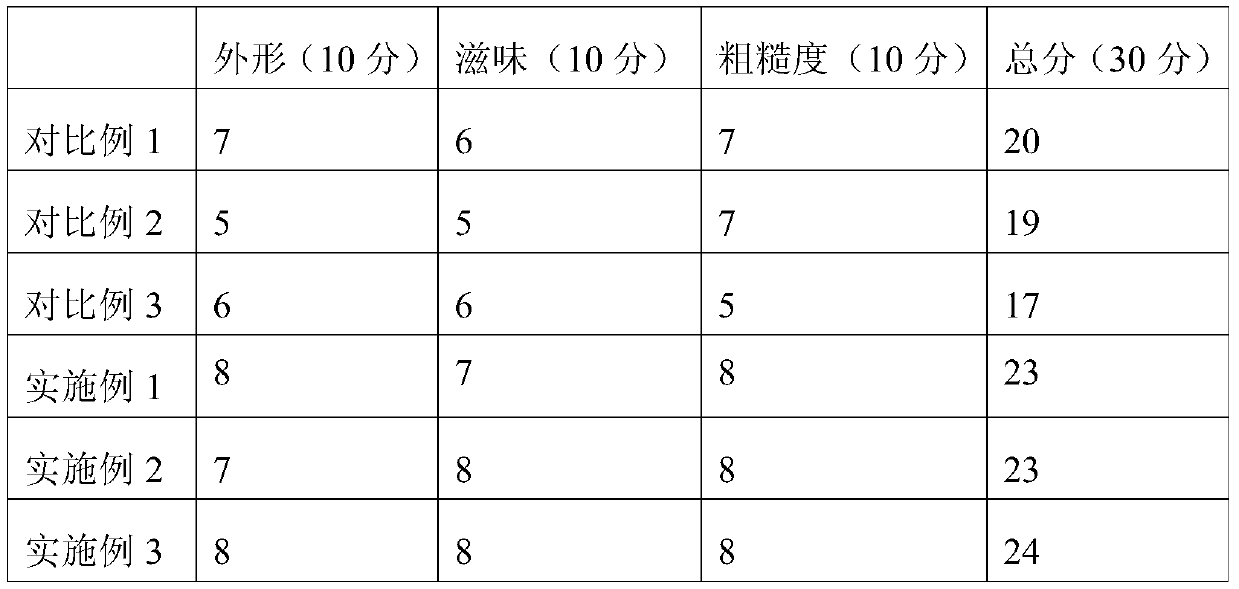

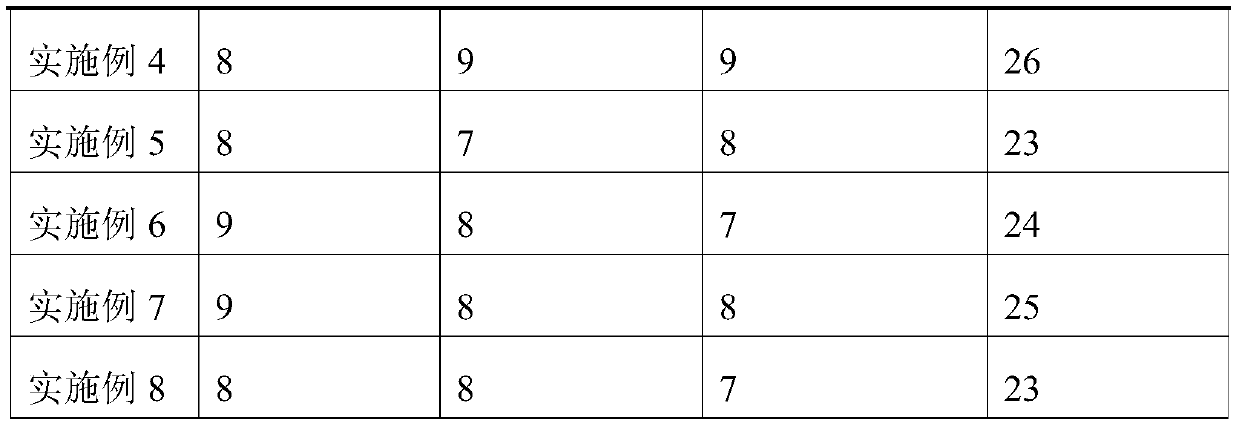

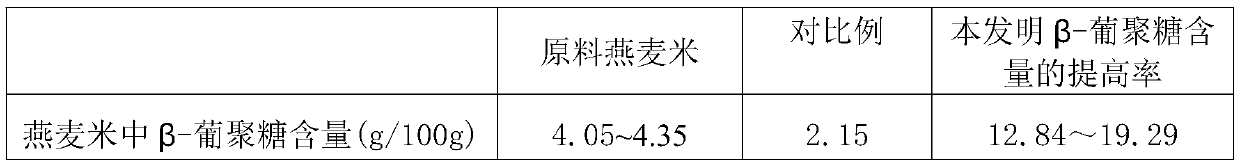

Manufacture method of steamed oat grains

ActiveCN107484949AModerate hardnessImprove sensory qualityFood ingredient as mouthfeel improving agentHydrogen phosphateMonobasic calcium phosphate

The present invention discloses a manufacture method of steamed oat grains. The method is as follows: oats are cleaned, hairs are removed, the treated oats are soaked for a first time using a mixed aqueous solution of citric acid, calcium hydrogen phosphate and calcium dihydrogen phosphate, the soaked oats are then steamed, then the oat grains are subjected to a shelling, then the shelled oats are soaked for a second time using a sodium chloride aqueous solution, and finally the soaked oat grains are subjected to a hot steam treatment. Compared with the prior art, the manufacture method improves a nutritional value of the oat grains and is simple in operations. The prepared product has advantages of being convenient in consumption and superior in taste compared with the existing product.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

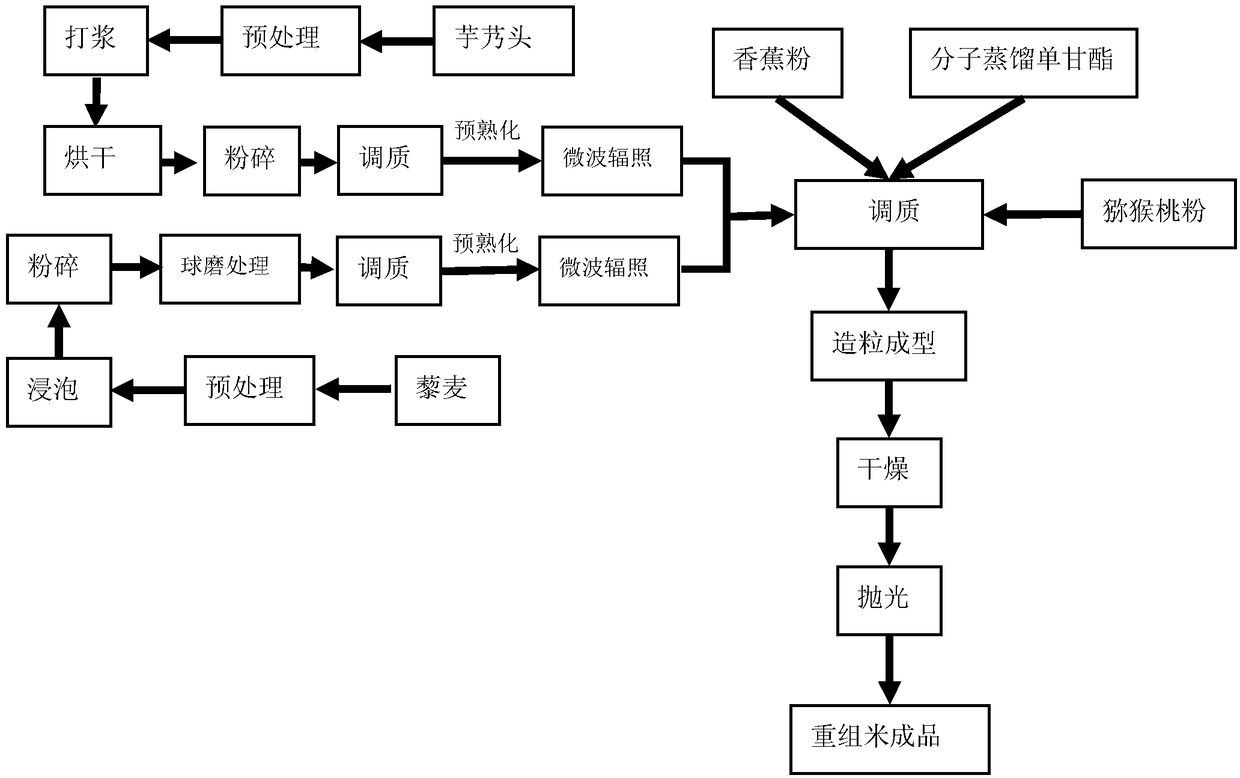

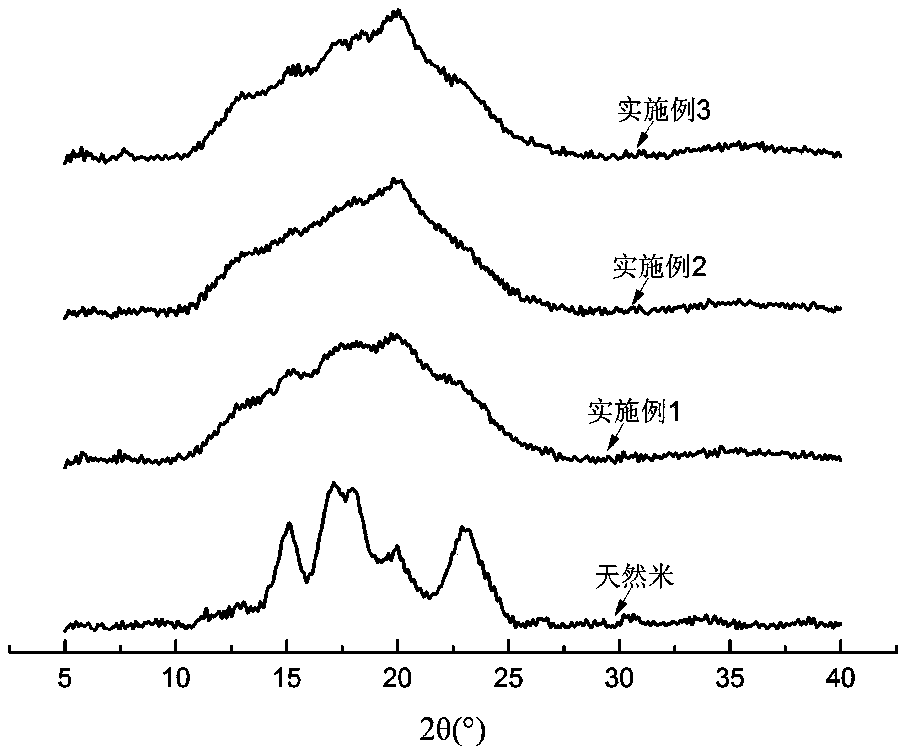

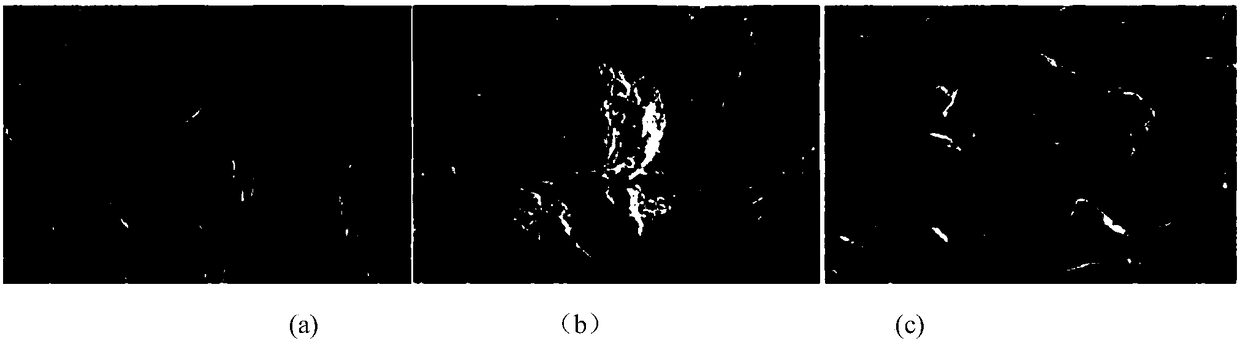

Nutritional recombinant rice and preparation method

InactiveCN108967895AHigh degree of gelatinizationEasy to shapeNatural extract food ingredientsFood ingredient functionsChemistryDigestion

The invention discloses recombinant rice and a preparation method. The method comprises the following steps: pretreating chenopodium quinoa and taros, then, carrying out microwave pre-cooking, uniformly mixing the pre-cook taro full powder and the pre-cook chenopodium quinoa powder with banana flour, kiwi fruit powder and molecular distilled monoglyceride, quantitatively adding conditioned composite materials into a twin-screw extruder by a feeder, setting a working temperature of a chamber of each section of the twin-screw extruder in a manner that a temperature gradient of an area I is 45 DEG C to 65 DEG C, a temperature gradient of an area II is 75 DEG C to 95 DEG C, a temperature gradient of an area III is 115 DEG C to 135 DEG C, a temperature gradient of an area IV is 105 DEG C to 115DEG C, a temperature gradient of an area V is 20 DEG C to 35 DEG C, and a screw revolution speed is 120rpm to 370rpm, and carrying out drying and polishing, thereby obtaining the recombinant rice. The recombinant rice and the preparation method have the advantages that the recombinant rice is rich in nutrition and neat in grain appearance. The recombinant rice prepared by the method has a relatively good digestion resisting property, the content of fast digestible starch is lowered, and the content of slowly digestible starch is increased, so that the improvement of satiety is facilitated; the recombinant rice is applicable to weight reducing people and is particularly suitable for being eaten by diabetics, and a new method and a novel way of think are provided for the development of riceproducts.

Owner:SHENYANG NORMAL UNIV

Meal replacement powder for invigorating spleen, nourishing stomach and controlling energy and preparation method of meal replacement powder

PendingCN108391817AControl energy intake wellIncrease satietyFood ingredient as colourFood preservationBearded toothSpleen

The invention relates to the field of food processing, in particular to meal replacement powder for invigorating the spleen, nourishing the stomach and controlling energy and a preparation method of the meal replacement powder. The meal replacement powder comprises the following components in parts by weight of 55-70 parts of rice, 10-20 parts of black rice, 5-10 parts of black beans, 1-2 parts ofblack sesame seeds, 1-2 parts of Chinese wolfberry fruits, 1-2 parts of hericium erinaceus, 1-2.5 parts of coix seeds, 1-2.5 parts of poria cocos, 0.5-1 part of lotus seeds, 1-2 parts of Chinese yams, 0.5-1 part of (artificially planted) ginseng, 5-10 parts of konjaku flour, 2.5-5.0 parts of xylooligosaccharide and 0.25-0.5 part of fish collagen peptide. The meal replacement powder has the advantages of being good in reconstituability, easy to digest and absorb, capable of invigorating the spleen, nourishing the stomach, controlling energy and the like.

Owner:江西德煦实业有限公司

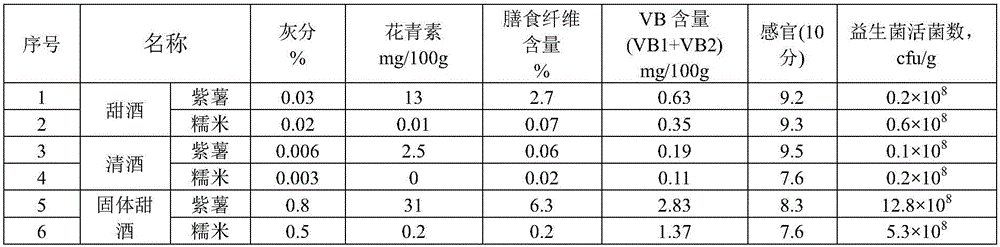

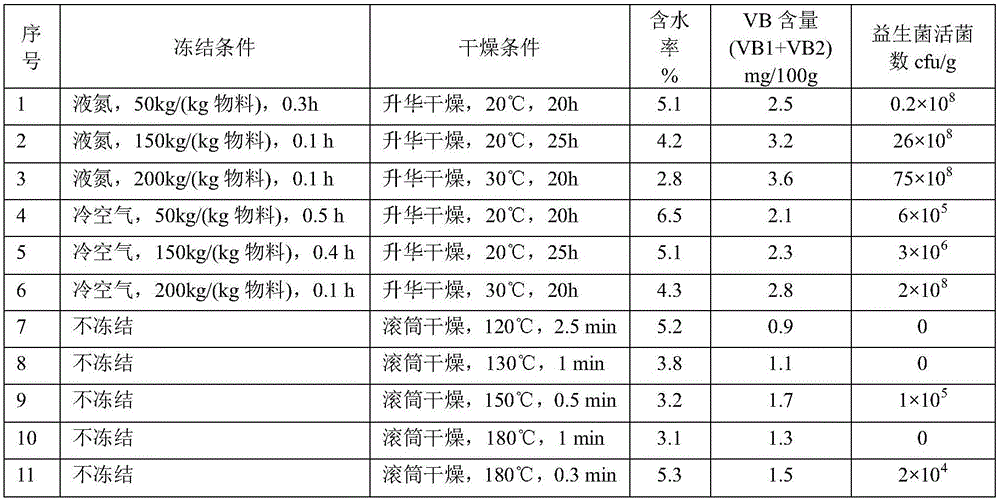

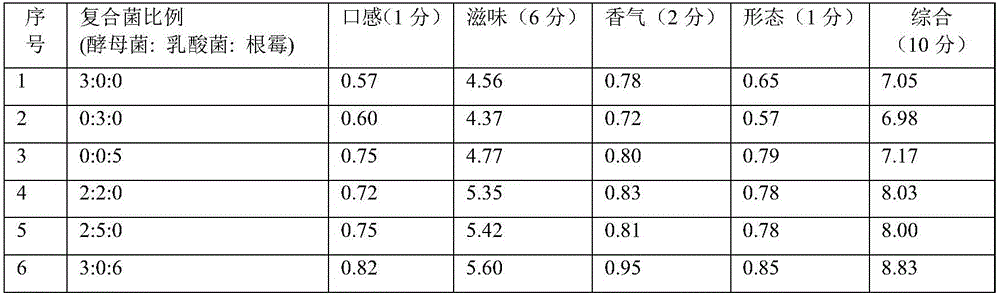

Cereal sweet wine, solid-state cereal sweet wine, cereal clear wine and preparation method thereof

InactiveCN105754789ARipe fullyRetain nutritionAlcoholic beverage preparationMicroorganism based processesSodium GlutamateSugar

The invention relates to the field of fermented food processing, in particular to cereal sweet wine, solid-state cereal sweet wine, cereal clear wine and a preparation method thereof. The sweet wine comprises the following components in parts by weight: 100 parts of sticky rice, 20-200 parts of cereal rice, 0.5-2 parts of compound bacteria as well as modulating matters comprising 1-15 parts of white sugar, 1-15 parts of proteins, 1-5 parts of dietary fiber powder, 0.0001-0.003 part of vitamin, 1-25 parts of fruit-vegetable powder, nutrient substances comprising 0.0001-0.0003 part of sodium glutamate and 0.0001-0.002 part of calcium salt. According to the cereal sweet wine and the preparation method thereof, cereal subjected to soaking and sprouting treatment as well as extrusion forming is heated and pasted, and the compound bacteria is added into the cereal for being fermented to prepare the cereal sweet wine. The cereal sweet wine, solid-state cereal sweet wine and cereal clear wine prepared by the preparation method contain live bacteria, are beneficial to improvement on functions of human intestinal tracts and promoting digestive absorption, are good in instant-food property, and are rich in nutrient.

Owner:WUHAN BOSIDE TECH

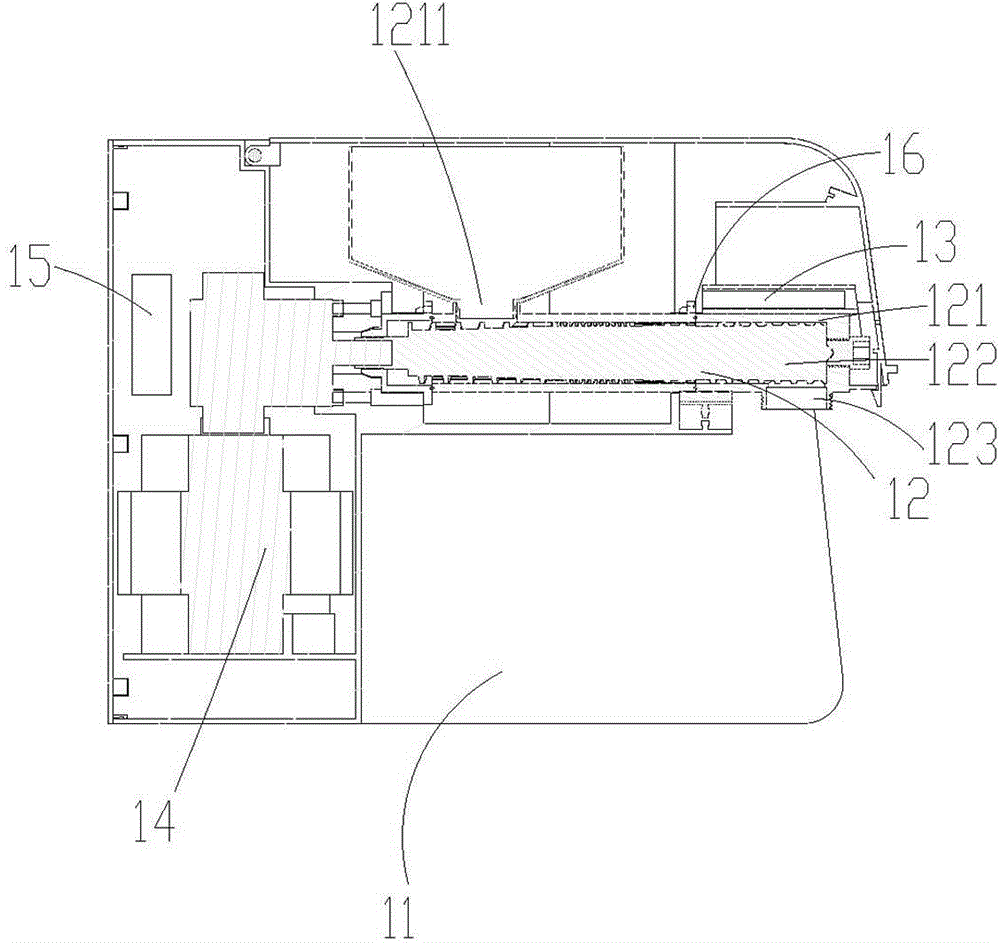

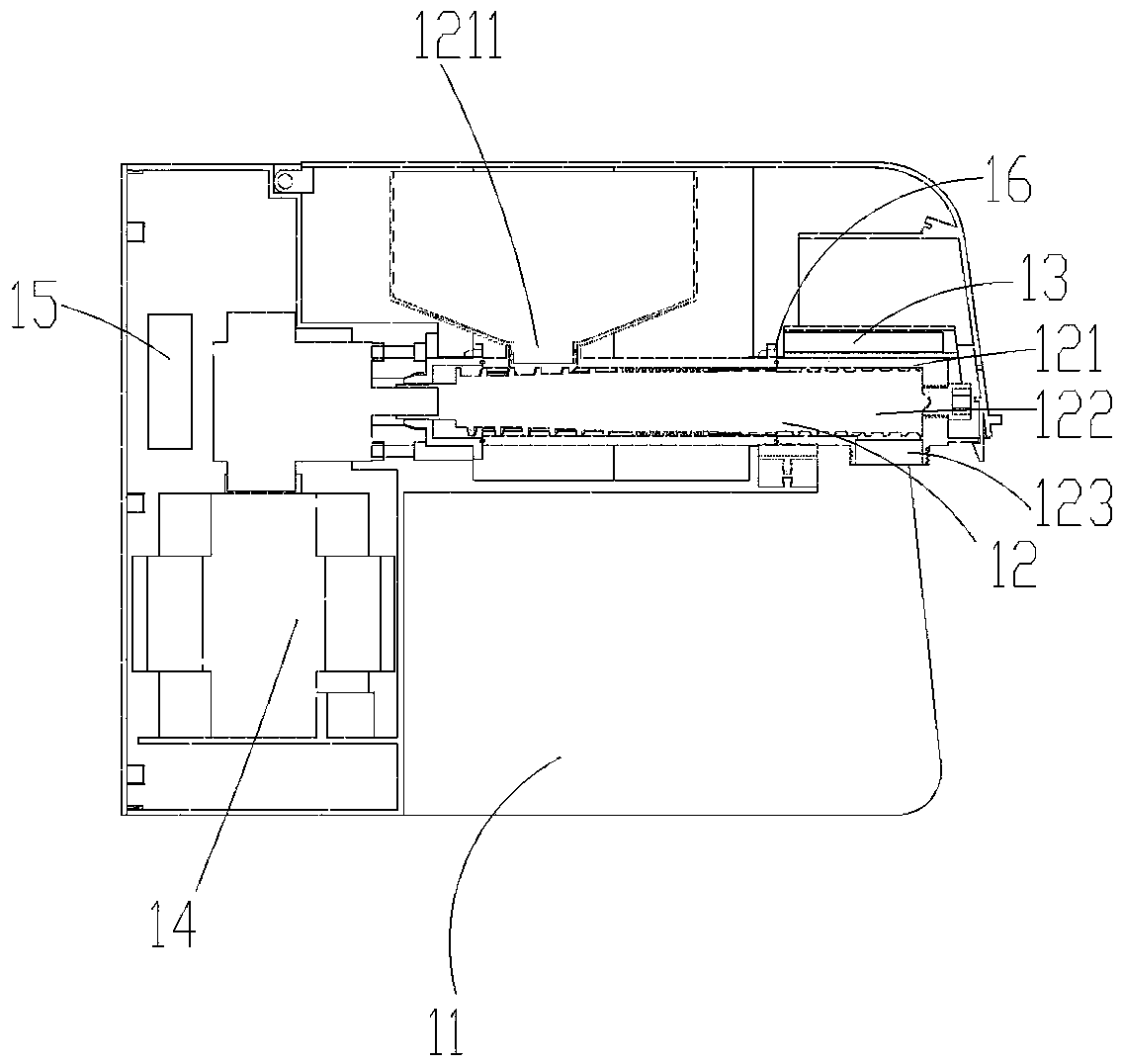

Rice noodle preparation method of household rice noodle machine and household rice noodle machine

ActiveCN104621443AHelp shapeImprove gelatinization efficiencyFood shapingFood preparationWarming processEngineering

The invention relates to a rice noodle preparation method of a household rice noodle machine and the household rice noodle machine. The rice noodles preparation method of the household rice noodle machine comprises the following steps: a feeding stage, namely driving a screw rod to rotate by a drive system and feeding raw materials into an extrusion grinding cavity by the screw rod; a curing and noodle-extruding stage, namely driving the screw rod to rotate by the drive system, grinding the raw materials by the screw rod, mixing, simultaneously curing the raw materials, and extruding into rice noodles from the ground, crushed, mixed and cured raw materials through a molding die head; and a once warming process, namely heating a extrusion crushing cavity by a heating device before the curing and noodle-extruding stage, so that the temperature of the extrusion crushing cavity ascends to T1, and the range of T1 is 80-110 DEG C, and feeding the rice material into the extrusion grinding cavity for curing after the once warming process is additionally added in the rice noodle preparation process, so that the hardness of the rice material is reduced, and the crushing of the rice material by virtue of a crushing, extruding and molding system in the curing and noodle-extruding stage is facilitated, and forming of the rice noodles are facilitated.

Owner:JOYOUNG CO LTD

Acid-alkali adjusting method in starch hydrolysis technology during production of starch noodle

InactiveCN103907809AGood transparencyImprove strength and toughnessFood preparationFood ingredient as pH modification agentSlurryAlum

A disclosed acid-alkali adjusting method in starch hydrolysis technology during production of starch noodle comprises steps: preparing a mixed solution of starch and water slurry and a starch dry material, adding an acidity adjusting agent, and determining pH value. The method replaces a method for using alum to perform starch acid-alkali adjusting in conventional starch noodle production technology, is low in cost and simple in operation method, is capable of adjusting the acidity of starch for increasing the gelatinization degree of starch, and also helps to guarantee produced starch noodle to have performances being same as those of starch noodle prepared by adding alum and to have good transparence, high chewiness and toughness and strong water-holding capacity.

Owner:卢建军

Automatic bowl porridge sterilizing process

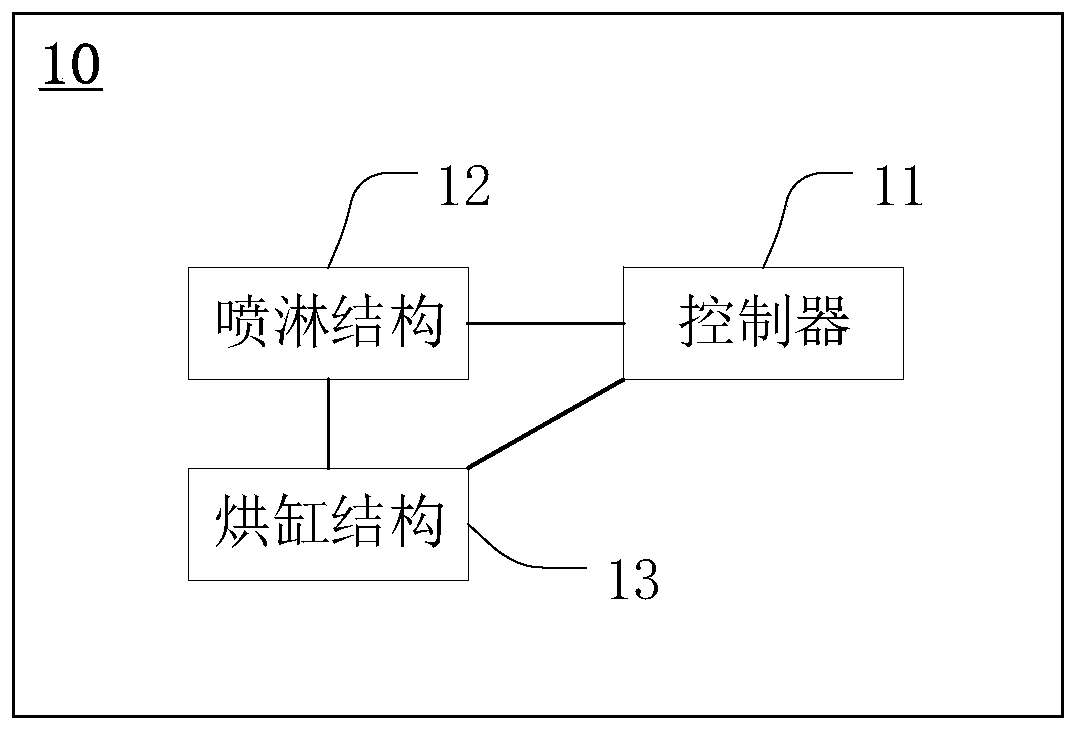

InactiveCN104698963ASolve the technical problems of high temperature and high pressure sterilization and explosionHigh degree of gelatinizationFood preservationProgramme control in sequence/logic controllersAutomatic controlControl system

The invention provides an automatic bowl porridge sterilizing process. The automatic bowl porridge sterilizing process comprises the following steps: a cooling and heating stage; a sterilizing stage; a back-pressure cooling stage. The automatic bowl porridge sterilizing process is realized by setting corresponding sterilizing parameter values through a PLC automatic control system. Compared with the similar technologies, the automatic bowl porridge sterilizing process is low in sterilizing temperature, short in sterilizing time, capable of turning over porridge cans, high in heat conductions speed and regular in pressure changes. The automatic bowl porridge sterilizing process is adopted to sterilize plastic bowl porridge cans, so that the content is pasted and high in pasting degree, and thus, the porridge bowel is ensured to not deform, and the optimal sterilizing effect is achieved.

Owner:ANHUI TONGFU FOOD

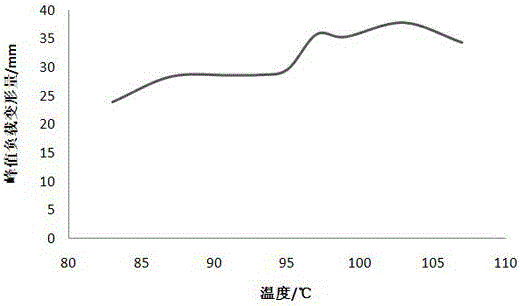

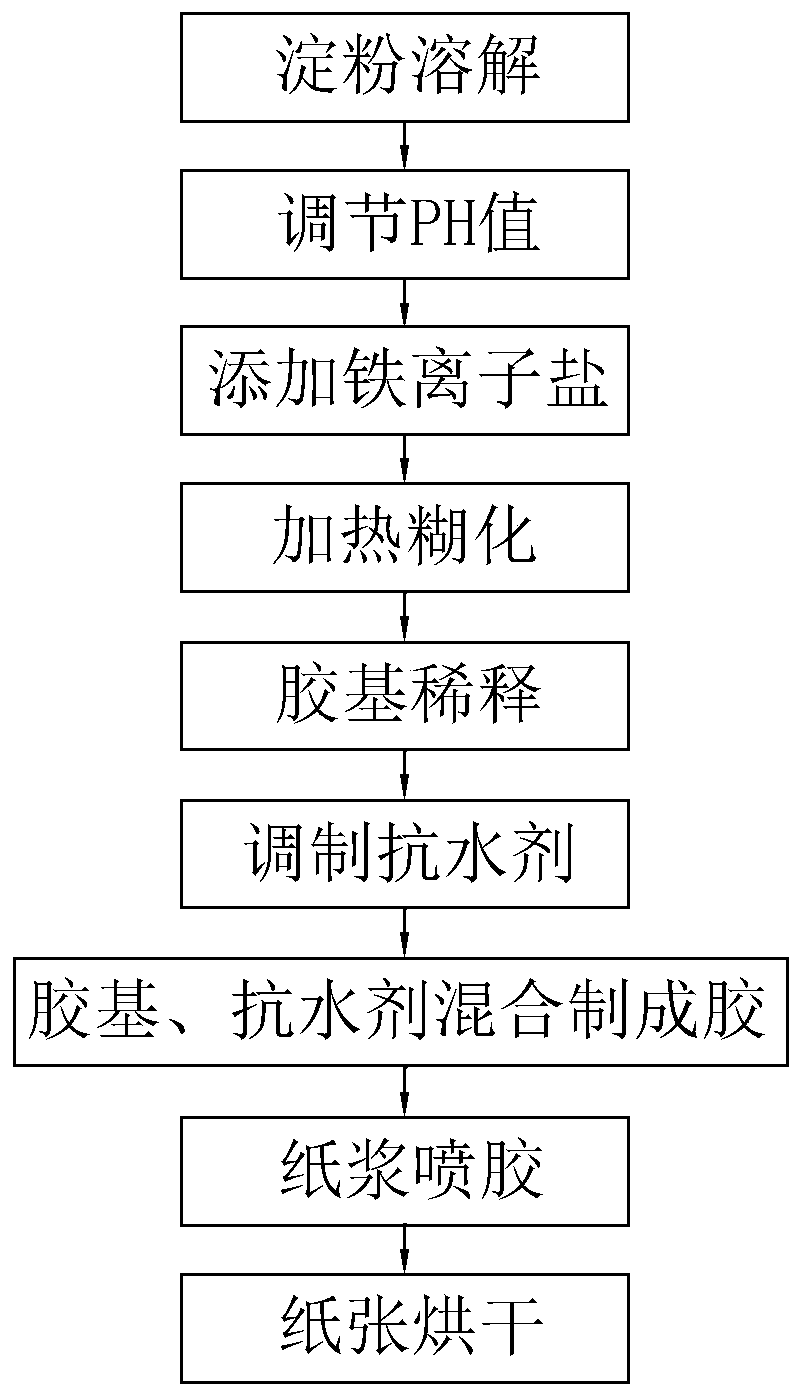

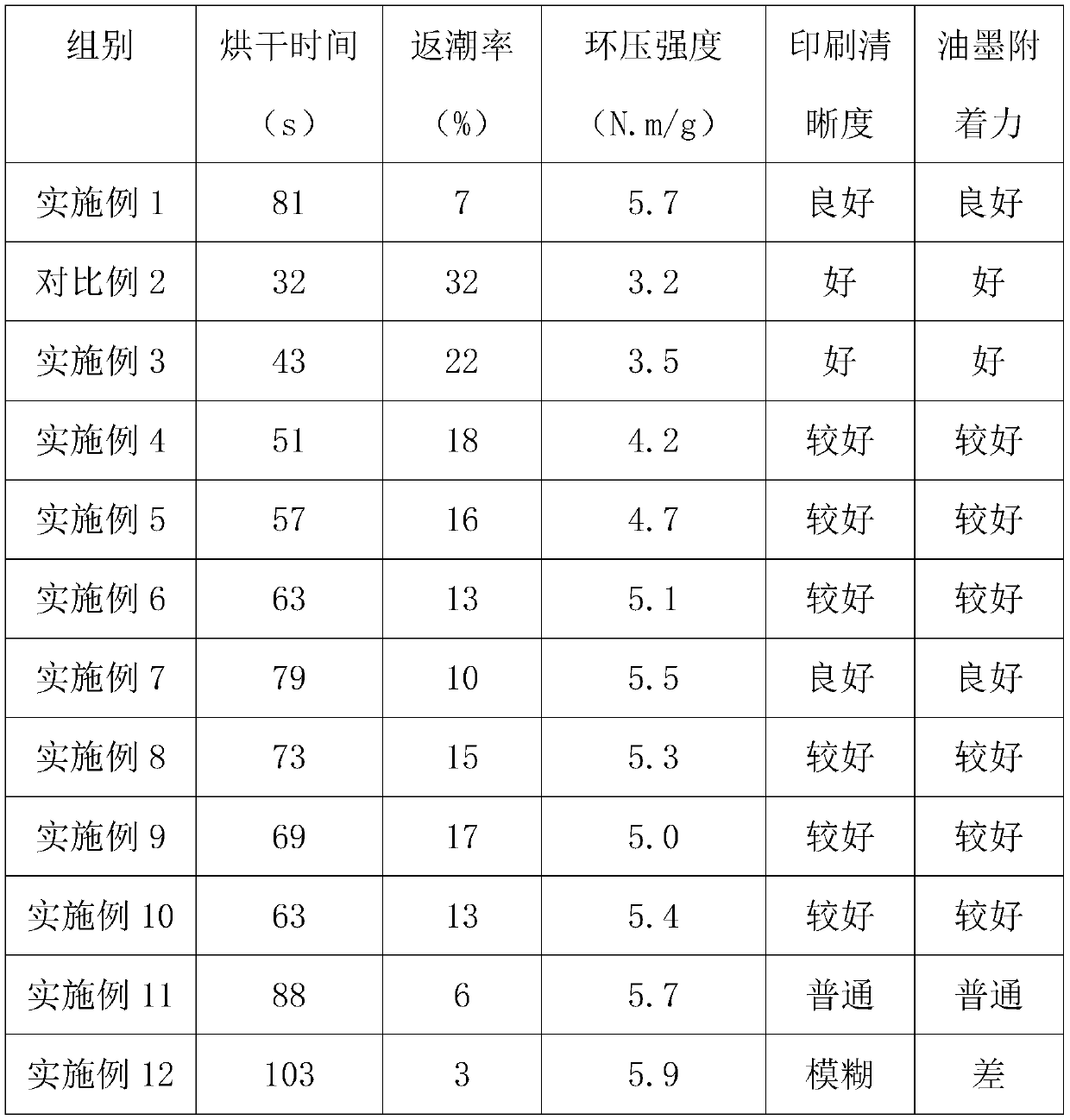

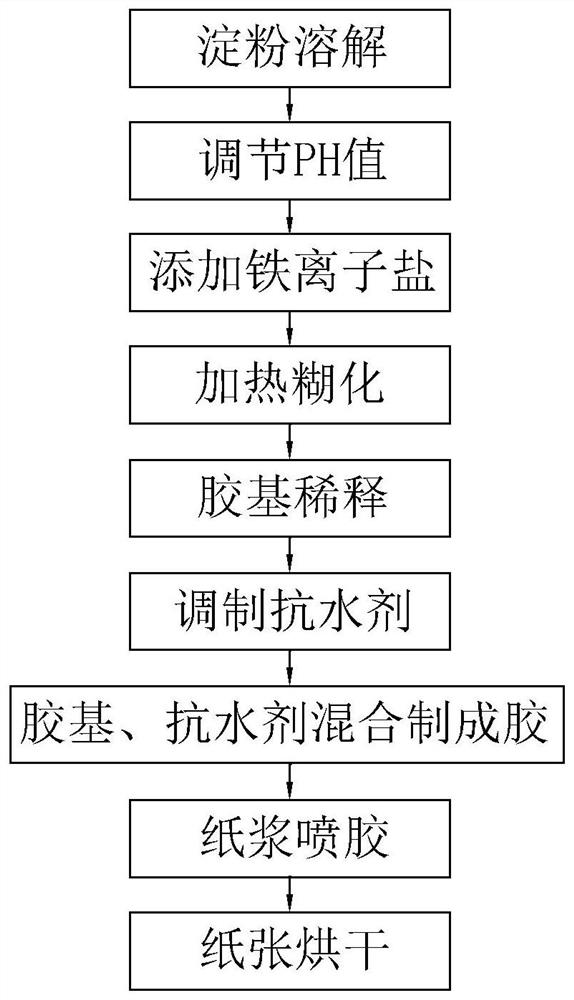

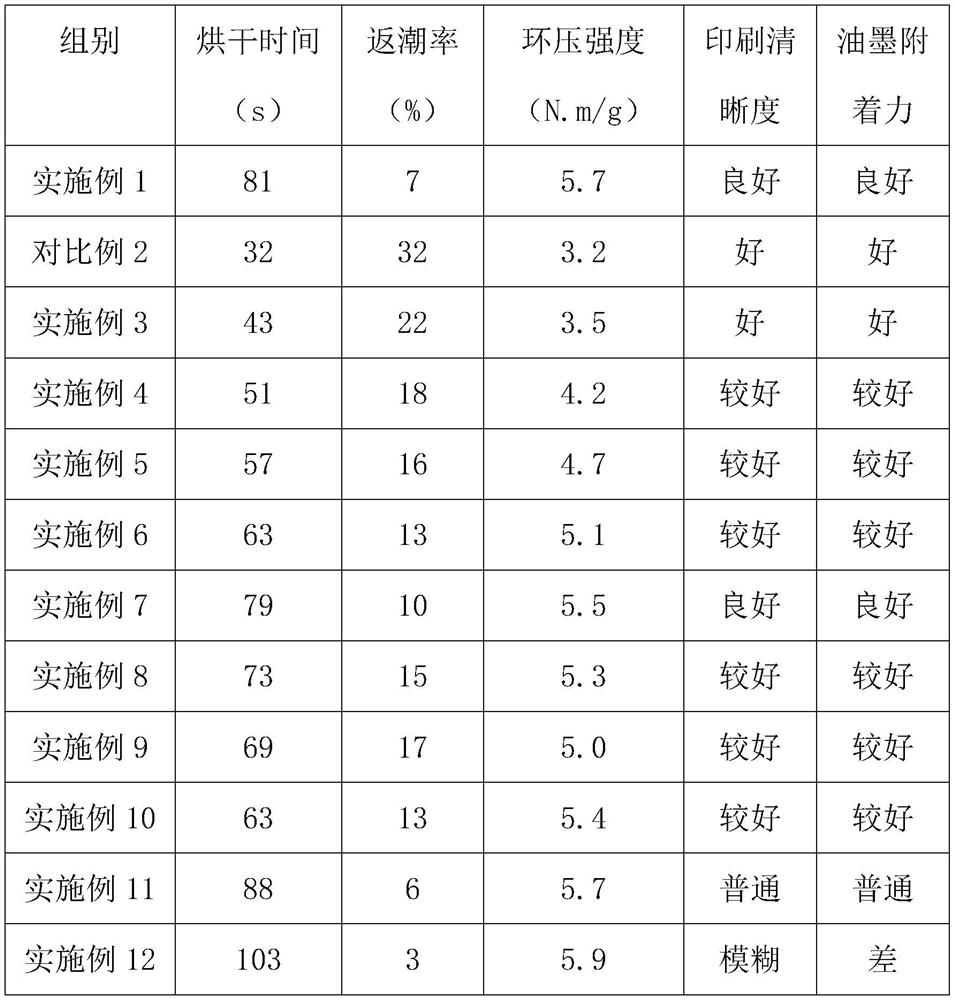

Corrugated base paper moisture-proof process

ActiveCN110344278AImprove water resistanceImprove moisture resistanceWater-repelling agents additionPaper/cardboardCartonMoisture regain

The invention discloses a corrugated base paper moisture-proof process, relates to papermaking technology, and is used for solving the problem of high moisture regain rate of paper produced by a common process. The process comprises the following steps: preparing a glue dissolving starch and an iron ion salt in water, and performing heating gelatinization to obtain the glue base; diluting the glue diluting the glue base for standby application; preparing finished glue: adding a water-repellent agent to the diluted glue base to obtain the finished glue; and sizing pulp: spraying thefinished glue onto wet paper, and performing oven-drying to obtain corrugated base paper. The process has the following advantages and effects: the corrugated base paper produced by the process has better water-repellent and moisture-proof properties compared with ordinary corrugated paper because the corrugated base paper contains a water-repellent agent component, so that during the rainy season, the corrugated base paper is not easy to absorb moisture in air to generate softness, a corrugated carton is not easy to collapse, and thereby the purpose of reducing the incidence of quality accidents is achieved.

Owner:TAIZHOU YONGFENG PAPER CO LTD

Prawn feed and preparation technology thereof

The invention discloses a prawn feed and a preparation process thereof. The operation steps are as follows: 1. Pretreatment of raw and auxiliary materials: pulverization, sieving, removal of impurities, iron filings, and standby; 2. Superfine pulverization: pulverization to a certain particle size; 3. Mixing: The ultra-finely pulverized material is mixed several times to make the material have good processing performance; 4. Added water: the water content of the raw material has a significant impact on the yield and processing of the pellet feed, and the added water makes the powder humidity Moderate; 5. Tempering temperature and moisture: the feed is subjected to hydrothermal treatment, and the temperature and moisture during conditioning are mainly obtained by adding steam; 6. Granulation: adjust the gap between the pressure roller and the ring die, and Granulation is carried out at a certain temperature; 7. Post-curing: after the pellets leave the granulator, a post-curing process of heat preservation and tempering is carried out; 8. Cooling: the heat and part of the moisture of the feed are taken away by a large amount of cold air, and the cooled pellets Moisture content reaches a certain requirement. The invention can make the starch gelatinization degree high, the protein fully denatured, the loss of nutrients is less, the product has good digestion and absorption, is not easy to be lost in water, is not easy to pollute the water quality, and can also reduce energy consumption and equipment loss, high production efficiency and low product cost. Low, suitable for industrial production, and has a good application prospect.

Owner:TIANJIN JINHAIMA AQUACULTURE

Preparation method of preboiled rice

InactiveCN109730251AHigh nutritional valueHigh meal rateSeed preservation by heatingUltra high pressureHigh pressure

The invention relates to a preparation method of preboiled rice, and belongs to the technical field of food processing technologies. The preparation method comprises the following steps of cleaning and grading, segmented soaking, ultra-high-pressure treatment, steaming and gelatinization, drying and rice husking and milling; wherein segmented soaking comprises the steps that firstly, rice after cleaning and grading is soaked for 0.5-1 h at 80-90 DEG C and then soaked for 1-2 h at 50-70 DEG C until the moisture content of the rice reaches 32-35%. The preparation method of the preboiled rice hasthe advantages that adopted temperature varying soaking can greatly shorten the soaking time of the preboiled rice; the combination of the ultra-high-pressure treatment can make the distribution of the moisture in the rice more uniform, thereby improving the gelatinization degree of the preboiled rice, and shortening the steaming time, so that the gelatinization of the preboiled rice is more uniform, the white heart grains of the preboiled rice is eliminated, the rice color also becomes light, the appearance of the preboiled rice is more uniform, and the acceptability of customers can be greatly improved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Red bean pre-curing treatment method

PendingCN111543592AIncreased amount of soluble dietary fiberHigh degree of gelatinizationFood scienceMicrowave powerJaponica rice

The invention discloses a red bean pre-curing treatment method. The method comprises the following steps of: red beans are treated for 5-40 min under the conditions that a direct-current power sourceis 1-5 kV, the constant current is 1-3 mA and the vacuum degree is 5-20 Torr, microwave treatment is conducted for 40-100 s under the microwave power of 650-1000 W, drying is conducted for 4-10 h at the temperature of 45-65 DEG C, the moisture content after drying is not higher than 10%, and pre-cured red beans are obtained. The pre-cooked red beans prepared by the method disclosed by the invention can be mixed with polished round-grained rice for co-cooking, so that a co-cooking effect is achieved, the cooking time is shortened by 70-90% compared with that of common red beans, and the shelf life of the co-cooked red beans is not influenced.

Owner:ZHEJIANG UNIV OF TECH

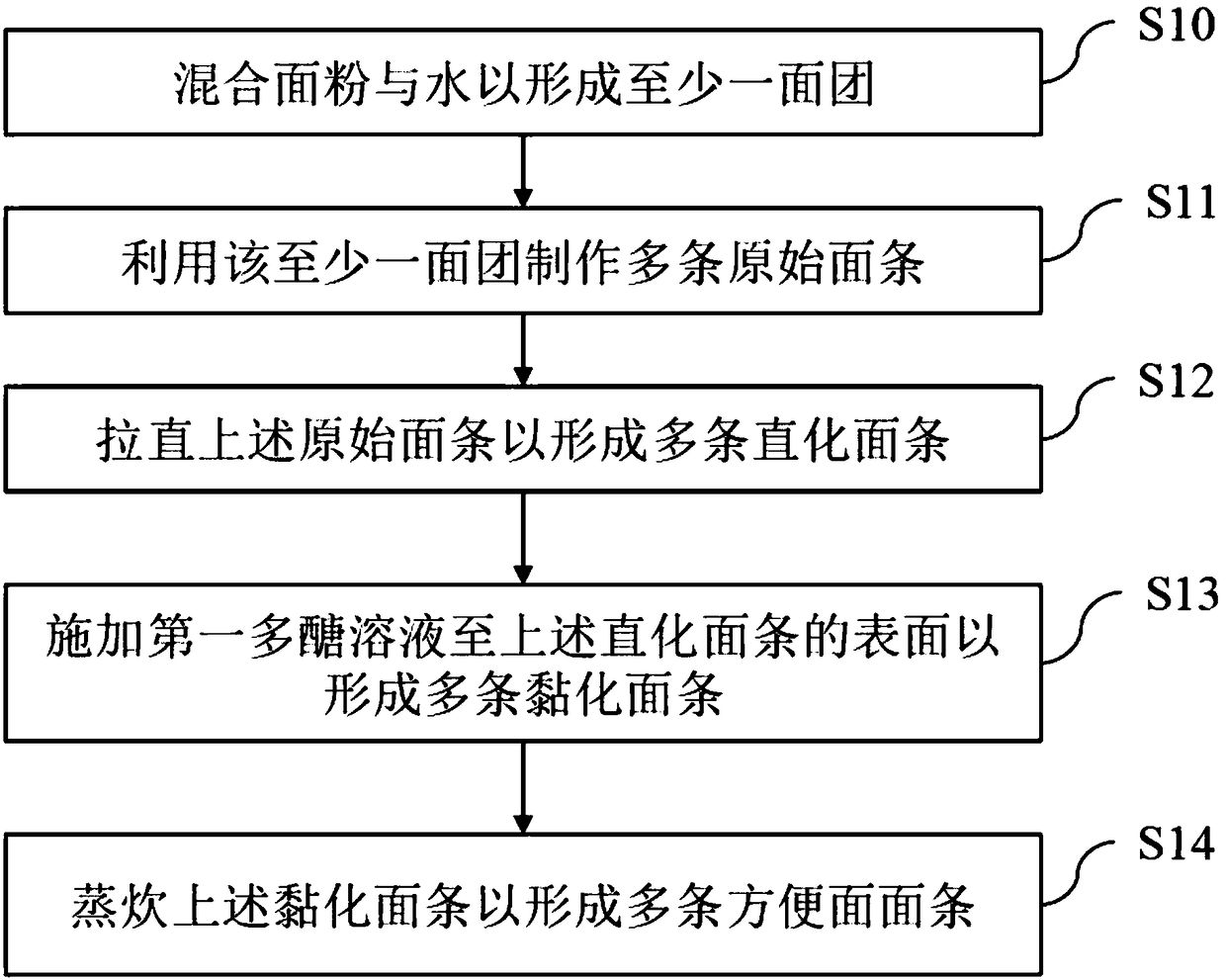

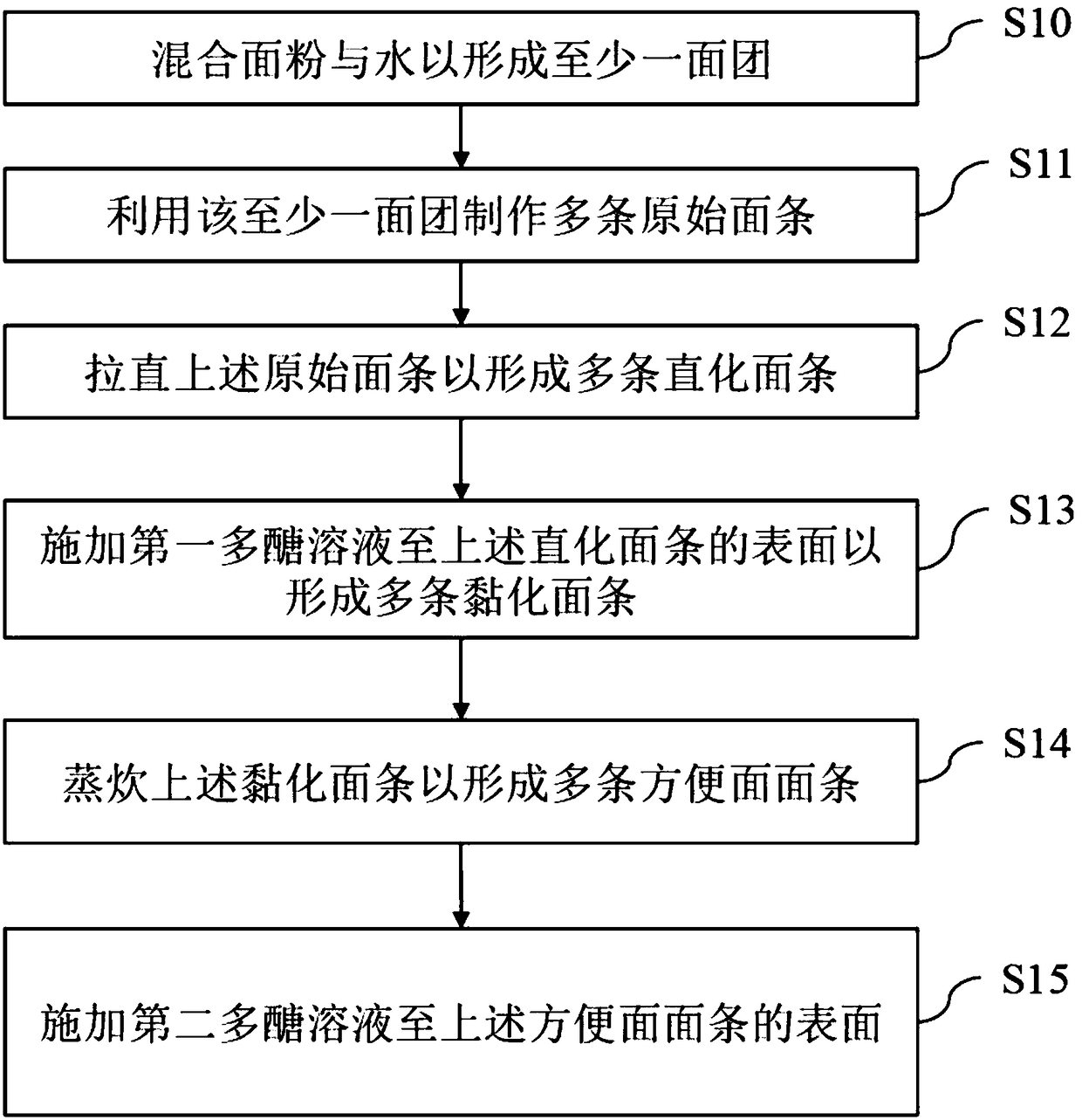

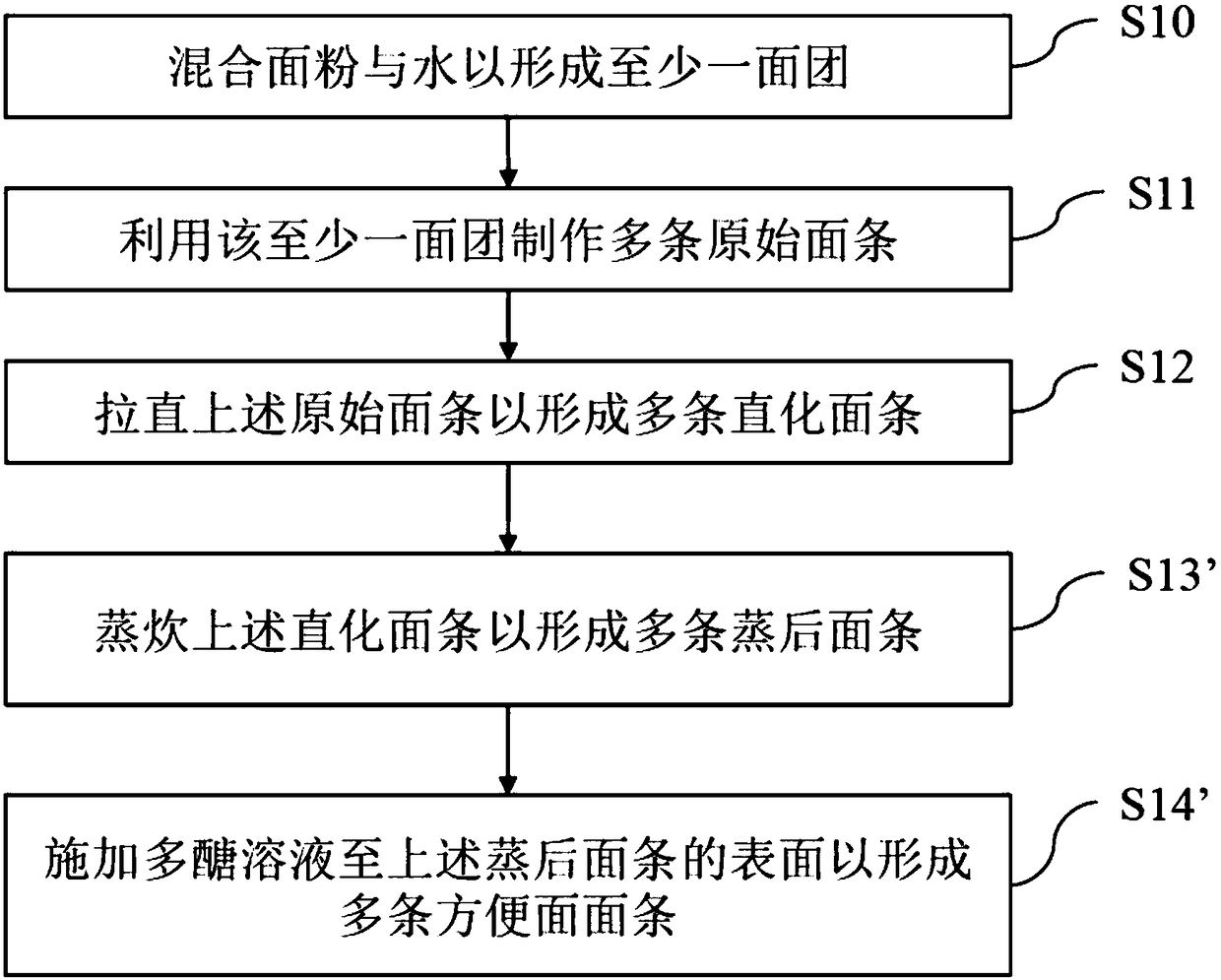

Instant noodle and instant noodle production method

InactiveCN108419996AEasy to brewHigh degree of gelatinizationFood coatingWater soluble polysaccharidesInstant noodle

The invention relates to an instant noodle production method, which comprises: mixing flour and water to form at least one dough, making a lot of raw noodles by using the dough, straightening the rawnoodles to form straight noodles, applying a polysaccharide solution onto the surfaces of the straight noodles to form sticky noodles, and steaming the sticky noodles to form instant noodles, whereinthe polysaccharide solution comprises a water soluble polysaccharide component. According to the present invention, the obtained instant noodle block is easy to stew, and the appearance of the stewednoodle is close to the cooked noodle.

Owner:UNI PRESIDENT ENTERPRISES CORP

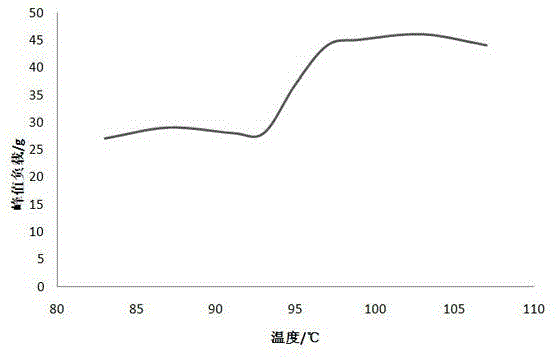

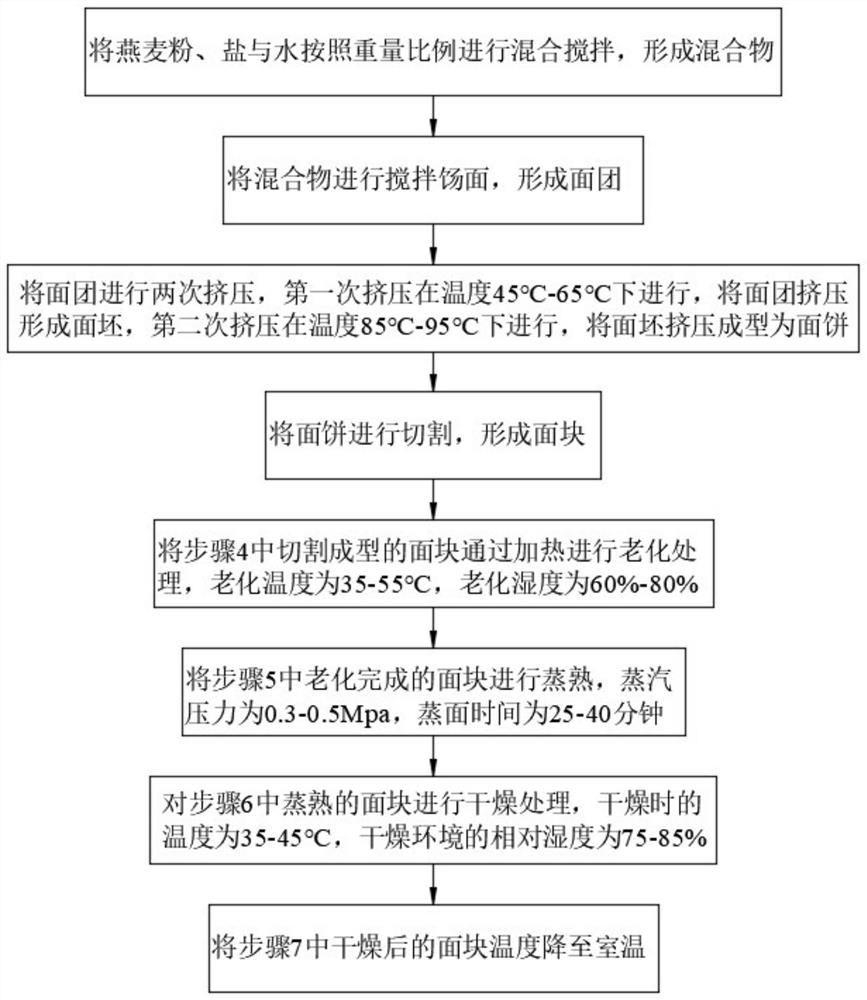

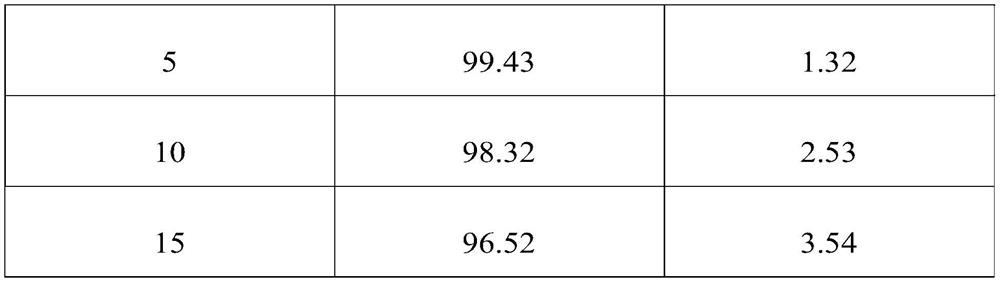

Oat instant noodle production method and oat instant noodles

PendingCN111820371AUniform moisture contentEliminate internal stressFood scienceEngineeringProcess engineering

The invention provides an oat instant noodle production method and oat instant noodles, and belongs to the technical field of oat noodle production. The oat instant noodle production method comprisesthe steps that oat flour, salt and water are mixed and stirred, stirring and dough softening are conducted, and dough is extruded twice, wherein the first extrusion is conducted at the temperature of45-65 DEG C, and the second extrusion is carried out at the temperature of 85-95 DEG C; the dough cake is cut to form dough blocks, the cut dough blocks are subjected to aging treatment through heating at the aging temperature of 35-55 DEG C and the aging humidity of 60-80%; the dough blocks aged in the step 5 are steamed, wherein the steam pressure is 0.3-0.5 Mpa, and dough steaming time is 25-40minutes; the steamed dough blocks in the step 6 are dried, wherein the drying temperature is 35-45 DEG C, the relative humidity of the drying environment is 75-85%, and the temperature of the dried dough blocks in the step 7 is reduced to the room temperature. The oat instant noodles produced by the production method are not prone to turbid soup, chewy in noodle quality and smooth in mouth feel.

Owner:内蒙古星华源食品股份有限公司

Anti-freezing corn paste and preparation method thereof

PendingCN113826697AHigh degree of gelatinizationHigh viscosityMilk preparationBiotechnologySweet flavor

The invention provides an anti-freezing corn paste and a preparation method thereof. The anti-freezing corn paste is prepared by taking corn grit as a raw material through raw material acceptance check, crushing, sieving, blending, steaming, auxiliary material adding, sterilizing and packaging, wherein the crushing is performed for 10-15 minutes by using a crusher, and the blending is performed by using the following components in percentage by weight: 10-20% of corn flour, 10-20% of milk powder, 2-5% of xylitol, 0.1-0.2% of composite antifreeze agent, 5-10% of auxiliary additive and 50-70% of water, the steaming temperature is 75-95 DEG C, steaming time is 10-20 minutes, and auxiliary materials are unsalted butter or butter and a composite anti-freezing agent. The obtained corn paste product has the advantages of a high protein content, good frozen storage stability, delicate taste, fragrant and sweet flavor and uniform texture, and can be applied to infant complementary food.

Owner:吉林省农嫂食品有限公司

Barley type nursing pig feed and production method thereof

InactiveCN108244342AImprove utilizationEfficient use ofFood processingAnimal feeding stuffNutrients substancesRaw material

The invention relates to a barley type nursing pig feed. The barley type nursing pig feed comprises the following raw materials in a compounding ratio of corn, puffed corn, aged dehuked barley, puffedsoybean meal, soy protein concentrate, fish meal, soybean oil, whey powder, glucose, white granulated sugar, composite organic acid, a premix, zinc oxide, beta-glucanase, xylanase, complex enzymes, 98.5% of L-lysine monohydrochloride, 98% of L-threonine, 98.5% of L-tryptophan, 60% of choline chloride, table salt, 0.56% of stone powder and calcium monohydrogenphosphate. The aged dehuked barley isadopted, so that the efficient utilization of the barley by nursing pigs can be effectively increased, the disadvantage that only the corn is used as a feed energy source is effectively overcome, andthe gelatinizing degree of starch is strengthened; the beta-glucanase and the xylanase are combined for addition, so that nutrition resistant factors namely beta-glucan in the barley can be effectively reduced, the beta-glucan becomes prebiotics, and the balance degree of microorganism microbial populations in intestinal tracts of the nursing pigs and the immunity of piglets are enhanced; and besides, the complex enzymes are added, so that the utilization rate of the barley by the nursing pigs is increased, the absorption of nutrient substances in improved, and normal production properties areguaranteed.

Owner:环山集团股份有限公司

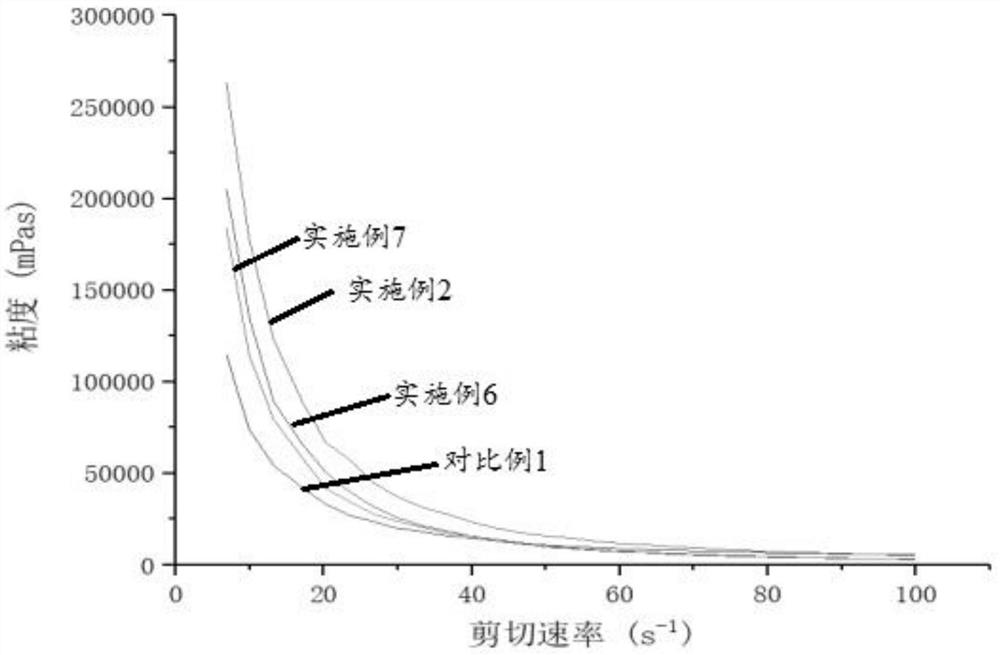

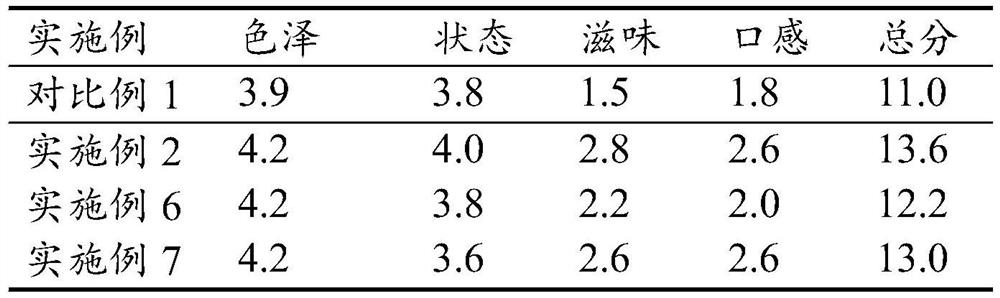

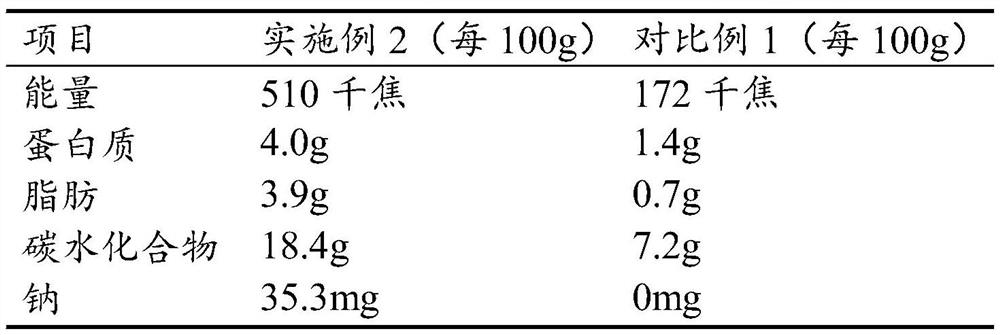

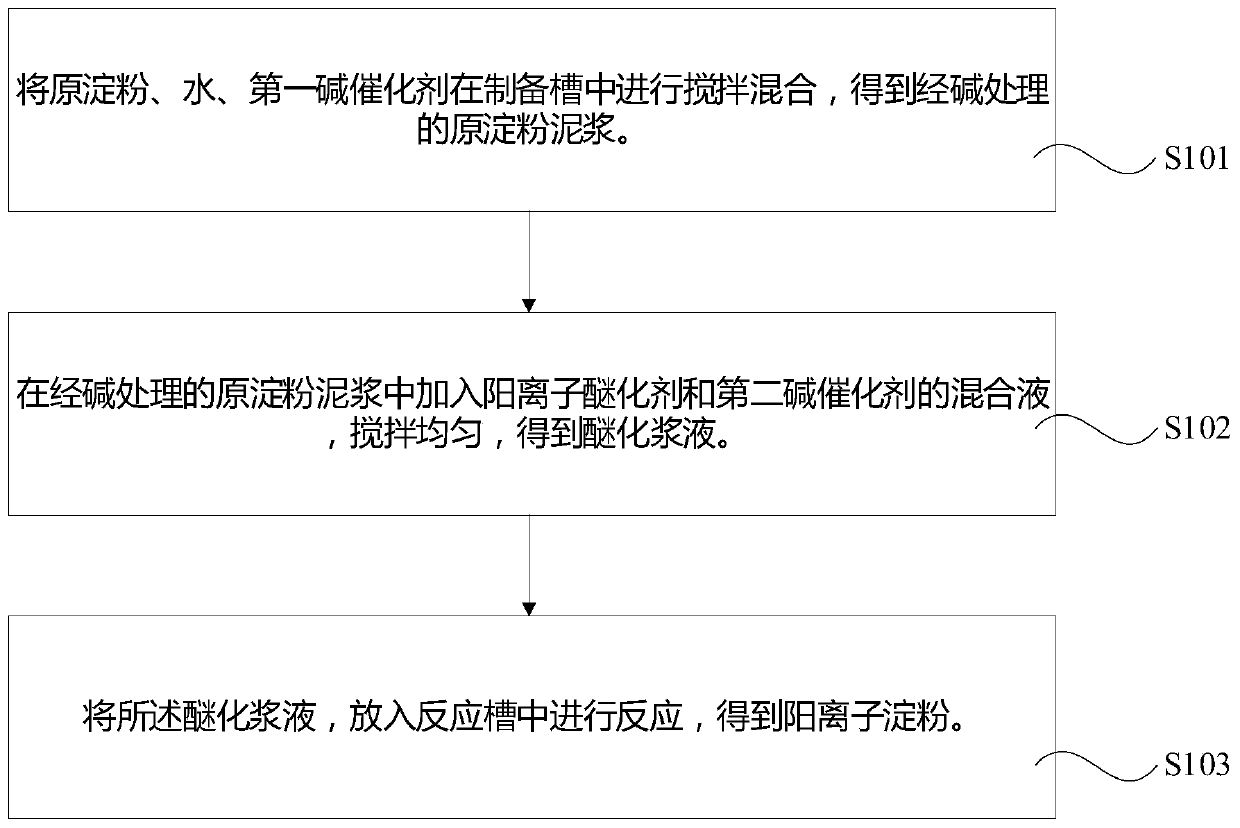

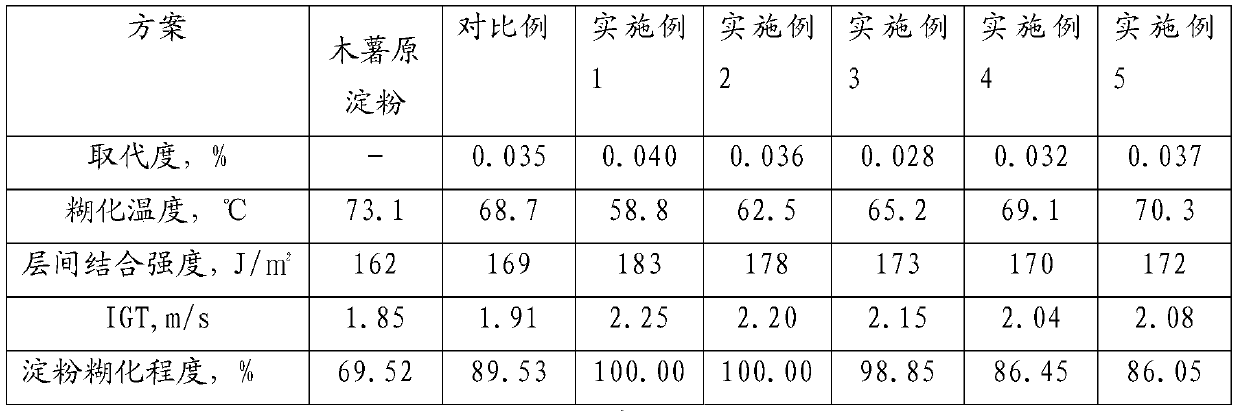

High-speed paper machine, cationic starch and preparation method of cationic starch

InactiveCN111072789ALow gelatinization temperatureHigh degree of gelatinizationPaper coatingPaper/cardboardPtru catalystMaterials science

The invention discloses a high-speed paper machine, cationic starch and a preparation method thereof. The method comprises the following steps: stirring and mixing native starch, water and a first alkali catalyst in a preparation tank to obtain native starch slurry subjected to alkali treatment, adding a mixed solution of a cationic etherifying agent and a second alkali catalyst into the native starch slurry subjected to alkali treatment, uniformly stirring to obtain etherified slurry, and putting the etherified slurry into a reaction tank for reaction to obtain the cationic starch. The invention further discloses the cationic starch prepared on the basis of the method and a high-speed paper machine applying the cationic starch for spraying. Through the manner, the gelatinization temperature of the cationic starch can be reduced, so that the gelatinization degree of the cationic starch in a high-speed paper machine can be improved, and the interlayer bonding strength of paper is improved.

Owner:NINGBO ASIA PULP & PAPER

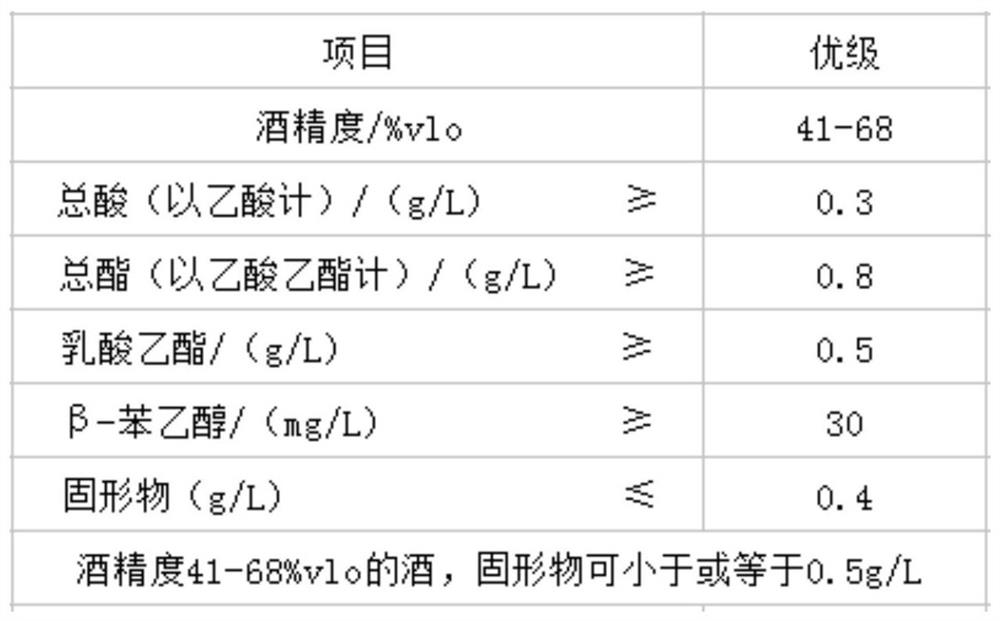

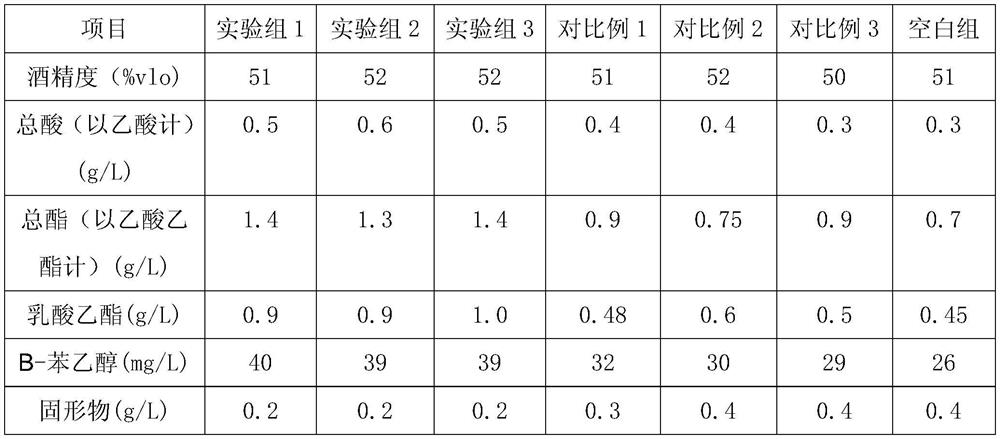

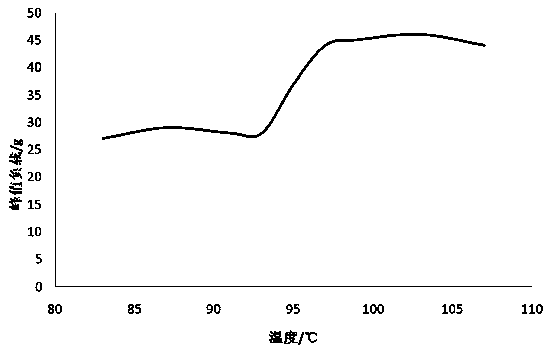

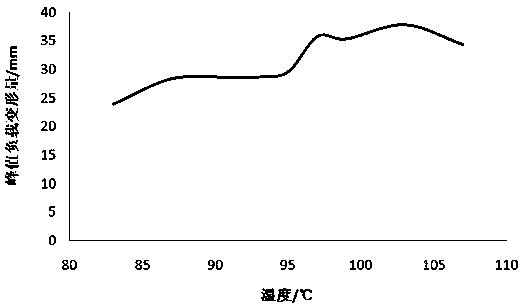

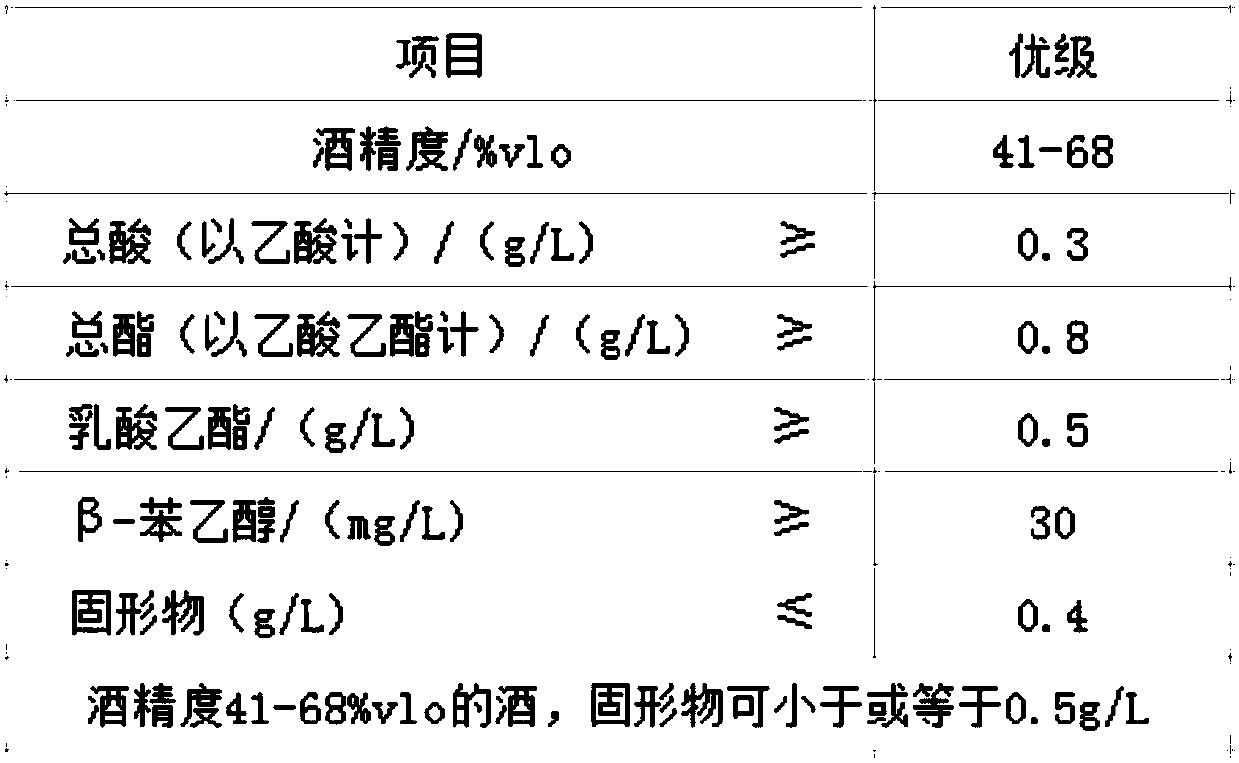

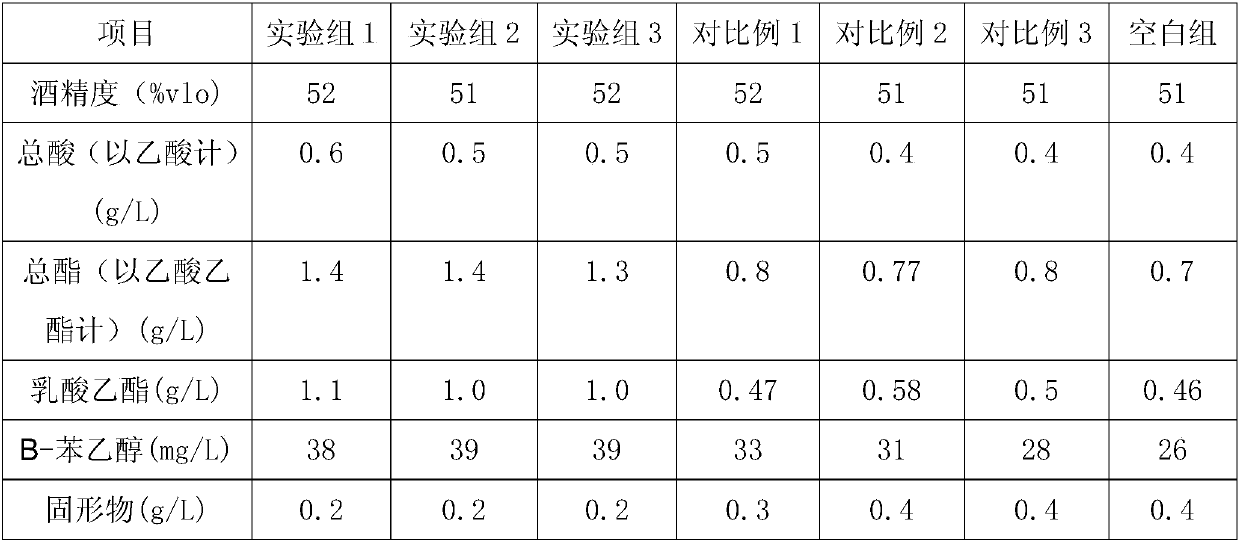

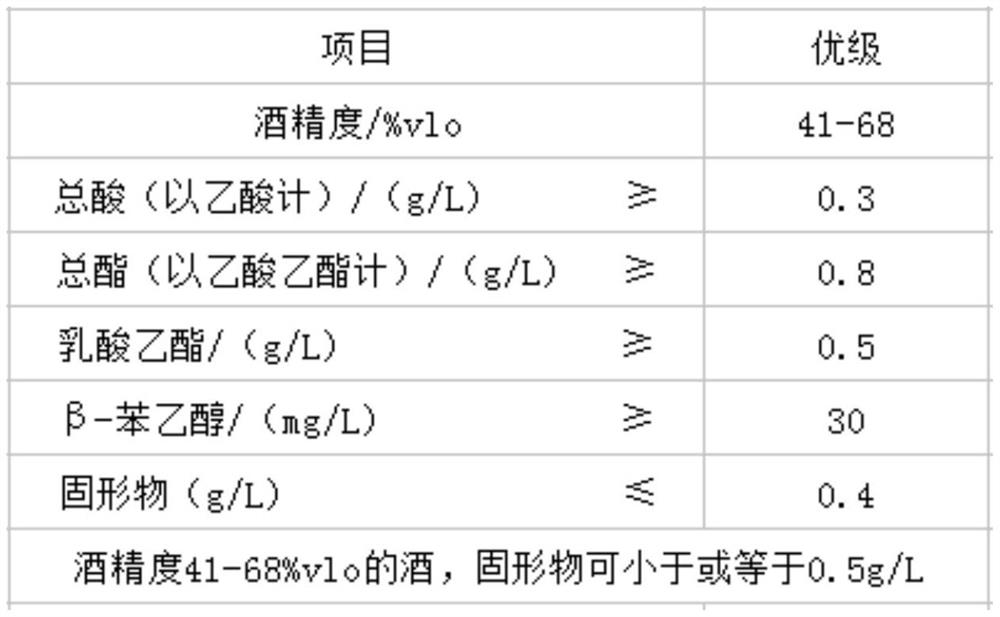

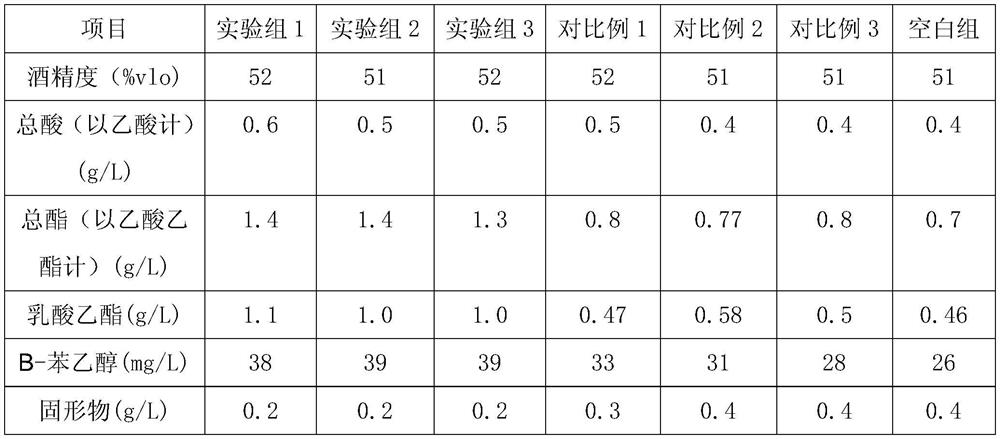

A kind of brewing method of Sanhua wine

ActiveCN107699432BDestroy crystal structureCrystalline structure releasedDigestive systemAlcoholic beverage preparationUltrasonic assistedChaptalization

The invention belongs to the technical field of food processing, and specifically discloses a brewing method of Sanhua wine. The brewing method of Sanhua wine of the present invention comprises the following steps: (1) selecting rice; (2) washing rice; (3) pretreatment: adopting ultrasonic auxiliary treatment; (4) soaking rice; (6) Spreading to dry; (7) Mixing koji: evenly mixing in medicinal koji powder; (8) Saccharification in the lower vat; (9) Fermentation; (10) Distilling; (11) Aging blending. The Sanhua liquor brewed by the brewing method of the present invention has a high rate of superior grade and high quality of the Sanhua liquor, can effectively meet people's requirements for liquor quality, and has high production efficiency.

Owner:桂林国农生态农业科技有限公司

A method for making rice noodles in a household rice noodle machine and a household rice noodle machine

The invention relates to a rice noodle preparation method of a household rice noodle machine and the household rice noodle machine. The rice noodles preparation method of the household rice noodle machine comprises the following steps: a feeding stage, namely driving a screw rod to rotate by a drive system and feeding raw materials into an extrusion grinding cavity by the screw rod; a curing and noodle-extruding stage, namely driving the screw rod to rotate by the drive system, grinding the raw materials by the screw rod, mixing, simultaneously curing the raw materials, and extruding into rice noodles from the ground, crushed, mixed and cured raw materials through a molding die head; and a once warming process, namely heating a extrusion crushing cavity by a heating device before the curing and noodle-extruding stage, so that the temperature of the extrusion crushing cavity ascends to T1, and the range of T1 is 80-110 DEG C, and feeding the rice material into the extrusion grinding cavity for curing after the once warming process is additionally added in the rice noodle preparation process, so that the hardness of the rice material is reduced, and the crushing of the rice material by virtue of a crushing, extruding and molding system in the curing and noodle-extruding stage is facilitated, and forming of the rice noodles are facilitated.

Owner:JOYOUNG CO LTD

Sanhua liquor brewing method

ActiveCN107815386ADestroy crystal structureCrystalline structure releasedAlcoholic beverage preparationSteepingUltrasonic assisted

The invention belongs to the technical field of food processing and particularly discloses a Sanhua liquor brewing method. The Sanhua liquor brewing method comprises the following steps of (1) rice selection; (2) rice washing; (3) pretreatment: adopting ultrasonic assisted treatment; (4) rice steeping; (5) rice steaming: adopting steaming to perform rice steaming at three stages; (6) spreading anddrying; (7) ditty mixing: uniformly mixing drug ditty powder in the dried rice; (8) vat entering for saccharification; (9) fermentation; (10) distillation; and (11) ageing and blending. A Sanhua liquor brewed by the brewing method provided by the invention is high in excellent grade rate, good in quality and high in production benefit and can effectively meet the requirements of people for the quality of a liquor.

Owner:桂林国农生态农业科技有限公司

A moisture-proof technology for corrugated base paper

ActiveCN110344278BImprove water resistanceImprove moisture resistanceWater-repelling agents additionPaper/cardboardMoisture resistanceMoisture regain

The invention discloses a moisture-proof process for corrugated base paper, which relates to papermaking technology and is used to solve the problem of high moisture return of paper produced by ordinary processes. The process steps include: making gum base, dissolving starch and iron ion salt with water, and heating for gelatinization Obtain gum base; dilute the gum base, dilute the gum base for later use; prepare glue, add water-resistant agent to the diluted gum base to make glue; pulp sizing, spray the glue on wet paper, and dry it Obtain corrugated base paper; the present invention has the following advantages and effects: the corrugated base paper manufactured by this process can have better water resistance and moisture resistance than ordinary corrugated paper because it contains water-resistant agent components, so that it can be used in the rainy season It is not easy to absorb the water vapor in the air and become soft, so that the corrugated box is not easy to collapse, so as to achieve the purpose of reducing the incidence of quality accidents.

Owner:TAIZHOU YONGFENG PAPER CO LTD

A kind of brewing method of Sanhua wine

ActiveCN107815386BDestroy crystal structureCrystalline structure releasedAlcoholic beverage preparationUltrasonic assistedChaptalization

The invention belongs to the technical field of food processing, and specifically discloses a brewing method of Sanhua wine. The brewing method of Sanhua wine of the present invention comprises the following steps: (1) selecting rice; (2) washing rice; (3) pretreatment: adopting ultrasonic auxiliary treatment; (4) soaking rice; (6) Spreading to dry; (7) Mixing koji: evenly mixing in medicinal koji powder; (8) Saccharification in the lower vat; (9) Fermentation; (10) Distilling; (11) Aging blending. The Sanhua liquor brewed by the brewing method of the present invention has a high rate of superior grade and high quality of the Sanhua liquor, can effectively meet people's requirements for liquor quality, and has high production efficiency.

Owner:桂林国农生态农业科技有限公司

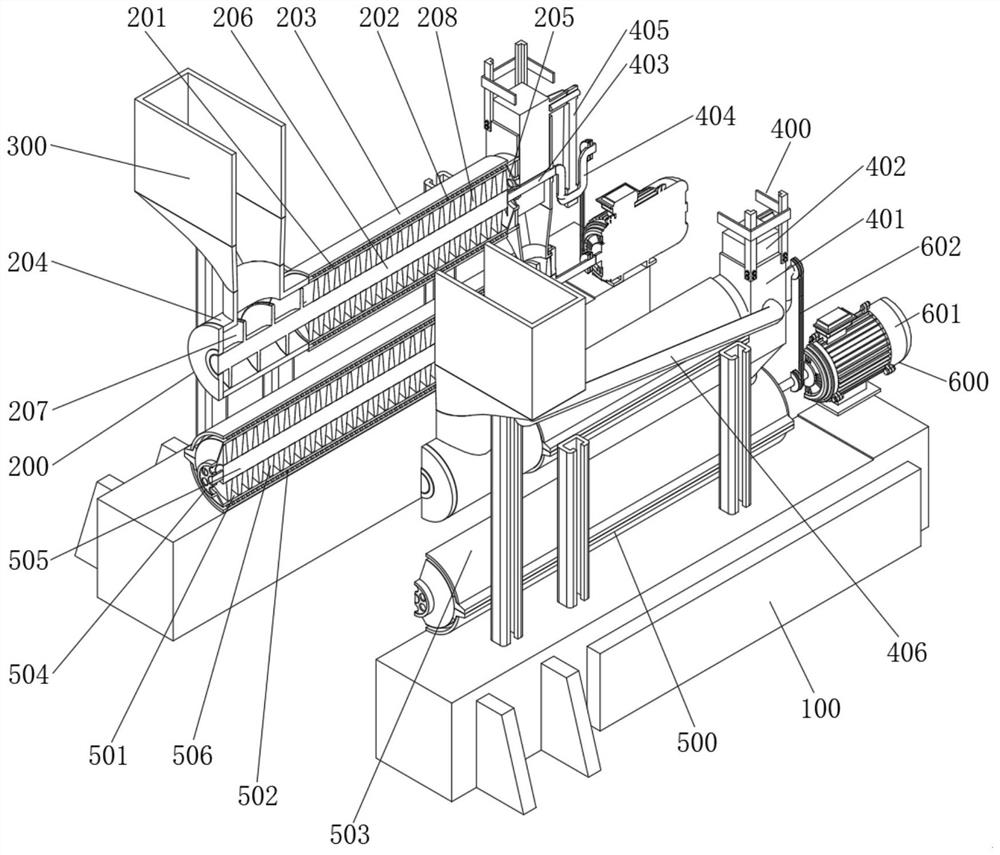

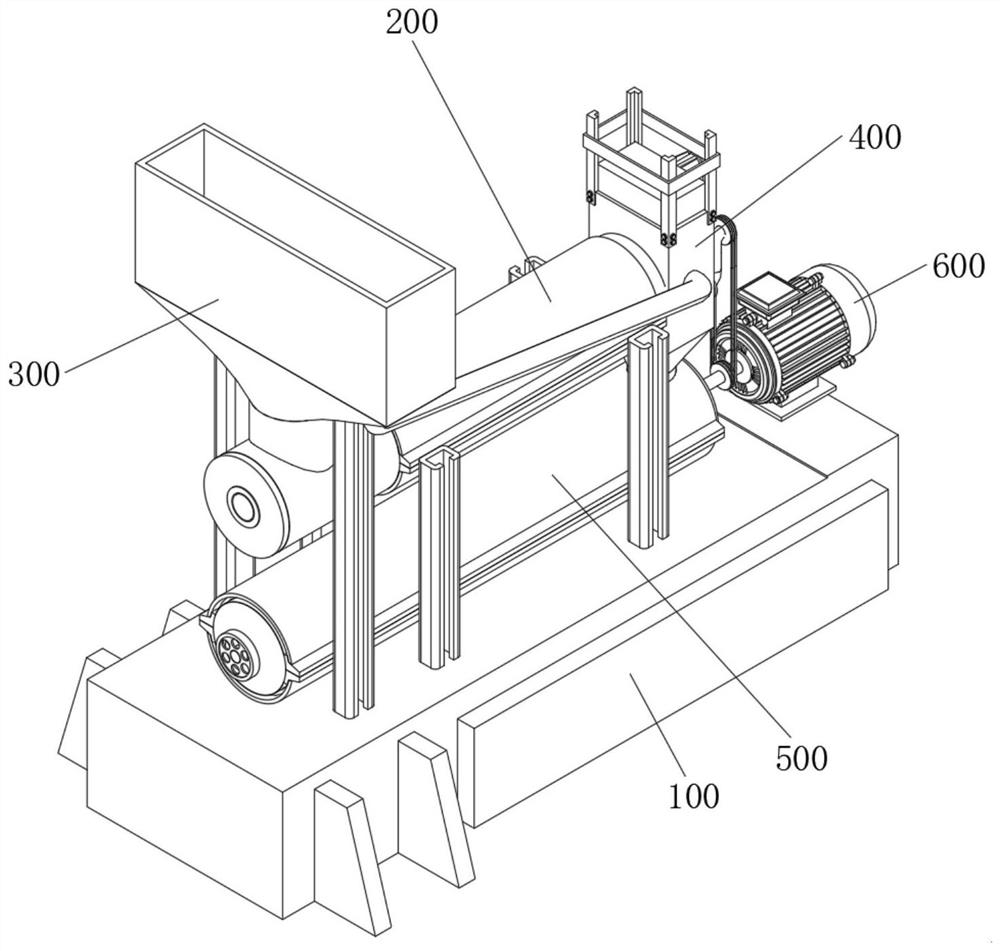

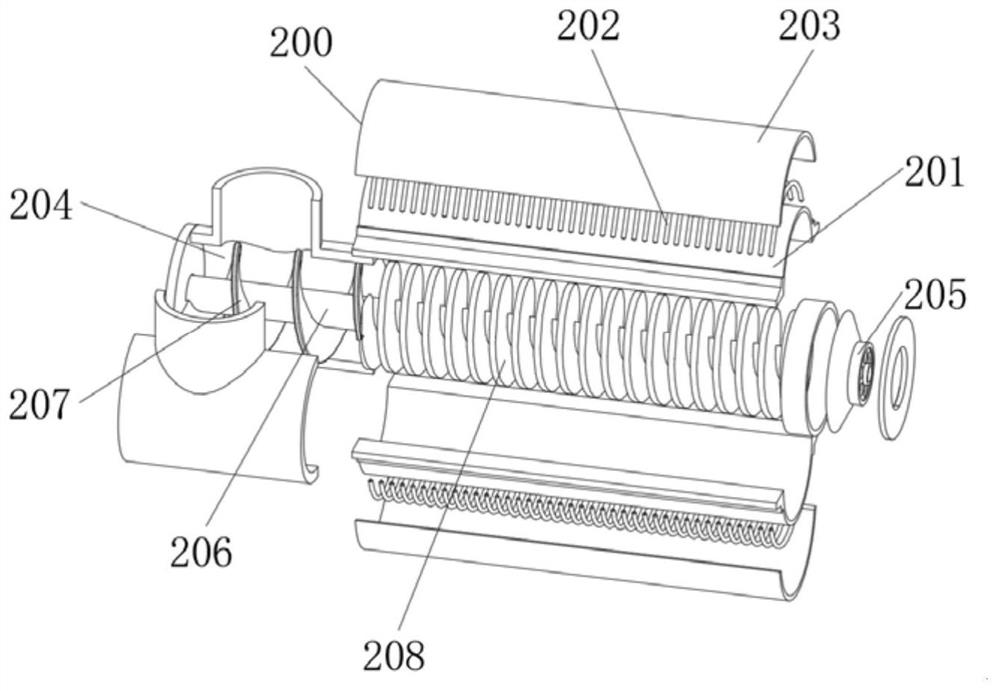

Feed processing bulking machine capable of improving material gelatinization degree and Ophiocealu sargus feed processing technology

InactiveCN113383977AHigh degree of gelatinizationImprove puffing efficiencyFeeding-stuffClimate change adaptationBiotechnologyAnimal science

The invention relates to the technical field of processing of Ophiocealu sargus feed, in particular to a feed processing bulking machine capable of improving the gelatinization degree of materials and a Ophiocealu sargus feed processing technology. The bulking machine comprises a base, the top of the base is fixedly provided with a section of bulking mechanism through a support, and the top of one end of the front face of the section of bulking mechanism is fixedly connected with a feeding hopper; one end of the back surface of the first-section bulking mechanism is connected with a second-section bulking mechanism through a switching mechanism, and a power mechanism is fixedly mounted at the top of one end of the back surface of the base. The first-section puffing mechanism and the second-section puffing mechanism are communicated with each other, cereal raw materials are subjected to puffing operation in advance by means of the first-section puffing mechanism, and then secondary gelatinization puffing is performed by means of the second-section puffing mechanism, so that the gelatinization degree of the cereal raw materials is effectively improved when the device is used for processing the Ophiocealu sargus feed, and the puffing efficiency of the Ophiocealu sargus feed during production and processing can be conveniently improved.

Owner:佛山市顺德区旺海饲料实业有限公司

A kind of production method of high-yield mature highland barley whole powder rich in γ-aminobutyric acid

ActiveCN110089684BIncrease profitReduce lossesDough/pre-mixesFood thermal treatmentSterile waterBARLEY GRAIN

The invention discloses a method for producing high-yield mature highland barley whole powder rich in γ-aminobutyric acid. The method comprises the following steps: after the highland barley grains are pretreated, they are placed in a germination tank, and soaked in sterile water for 3 times. ~4h; then pour out the sterile water in the germination tank, germinate and cultivate for 24.0~26.8h to obtain grains; drain the obtained highland barley grains, carry out hot air baking and curing treatment, and finally grind to obtain powder. In the present invention, the variation law of the yield of powder material during the germination of highland barley grains is studied, and suitable germination conditions are selected to carry out subsequent maturation processing of the germinated grains, and the GABA enrichment rate of the prepared highland barley cooked powder is 24-38% , the powder yield is above 80%, which can greatly reduce the powder loss in the milling process and improve the utilization rate of grains.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing vermicelli convenient food and vermicelli convenient food

ActiveCN100500022CHigh degree of gelatinizationSimple methodFood preservationFood preparationFood safetyProcess engineering

The invention belongs to food processing field and mainly provides a preparation method of vermicelli instant food. The method comprises preparing raw material, pulp mixing, spreading, and steaming to give sheet jelly, forecooling at room temperature, freezing at -8--1deg.C for 1.5-2h, cutting, and drying to give final product. The inventive method has simple operation, high efficiency, no requirement of gelatinizing, defreezing and additive, reduced production period and energy consumption, and reduced cost. The inventive vermicelli instant food has the advantages of good appearance, high diaphaneity, good taste and mouthfeel, no additive, and high safety.

Owner:四川白家阿宽食品产业股份有限公司

Polylactic acid-starch blended material and preparation method thereof

ActiveCN102558795BHigh degree of gelatinizationReduce the degree of crystallizationPolymer sciencePlasticizer

The invention belongs to the field of modification of high polymer blended plastics, and discloses a polylactic acid-starch blended material and a preparation method thereof. The polylactic acid-starch blended material disclosed by the invention comprises the following components in parts by weight: 448-8207 parts of polylactic acid, 1000 parts of starch, 10-114 parts of grafting agent, 36-286 parts of plasticizer, 2-29 parts of coupling agent and 3-97 parts of antioxidant. The preparation method comprises the following steps: (1) adding 1000 parts of pretreated starch, 10-114 parts of grafting agent, 36-286 parts of plasticizer and 2-29 parts of coupling agent into a high-speed mixer, and mixing at normal temperature for 10-50 minutes; and (2) granulating 1053-1429 parts of the mixture obtained in the step (1) by a double screw extruder, mixing with 448-8207 parts of polylactic acid and 3-97 parts of antioxidant and granulating, or directly mixing the mixture obtained in the step (1) with 448-8207 parts of polylactic acid and 3-97 parts of antioxidant and granulating by the double screw extruder. The product disclosed by the invention has the advantages of favorable mechanical properties and low cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

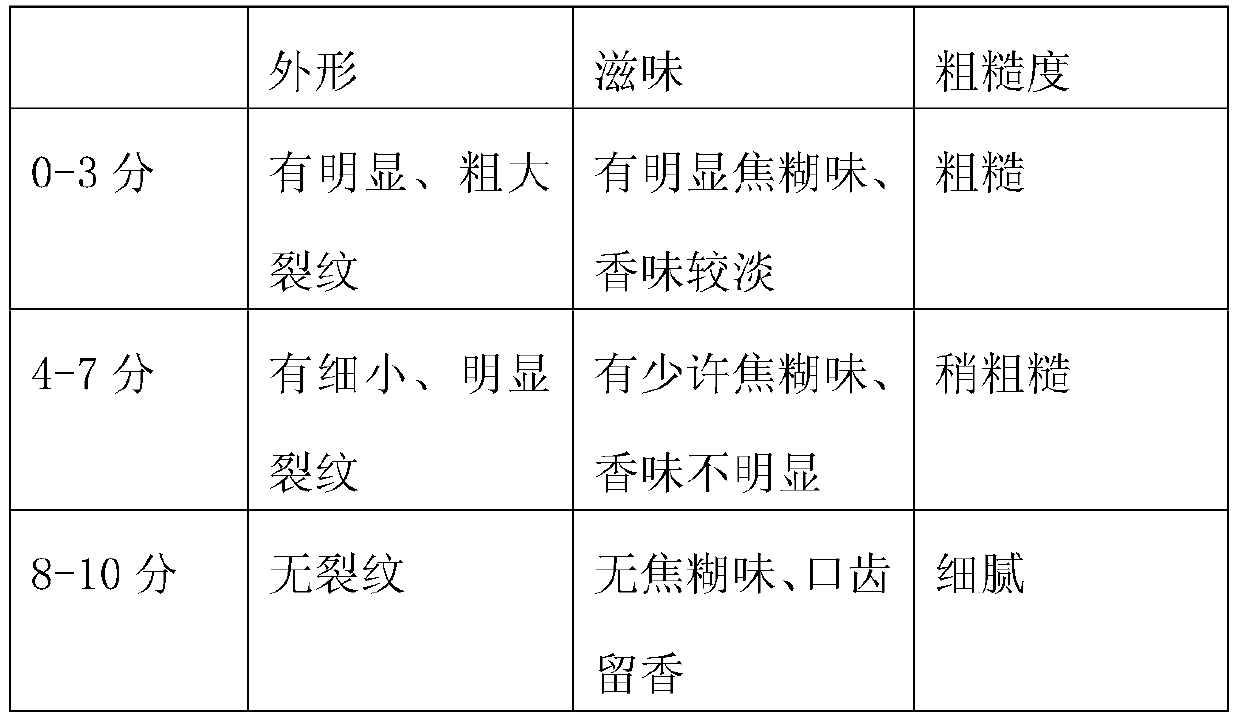

A kind of preparation method of banana-flavored biscuit for children

ActiveCN106889147BReduced resistance to digestionPromote absorptionDough treatmentModified nutritive productsCooking & bakingBanana powder

The invention discloses a preparation method of banana-flavor edible biscuits for children. The method includes the following steps that 1, banana powder is prepared, wherein after being peeled, 120-150 parts by weight of bananas are cut into segments and placed in water of which the temperature is 90-100 DEG C to be boiled for 10-15 seconds, 200-300 parts by weight of deionized water and 1 part by weight of compound enzyme are added into boiled bananas, pulp is prepared and placed in a high-pressure reactor, nitrogen is introduced, enzymolysis is conducted for 10-15 minutes at the temperature of 374-400 DEG C and under the pressure of 25-30 MPa, after centrifugation is conducted for 5-10 minutes at the speed of 4000-6000 r / min, sediment at the lower layer is taken out and dried, and the banana powder is obtained; 2, raw biscuits are prepared; 3, baking and packaging are conducted. According to the preparation method, the prepared biscuits have a unique banana flavor, are abundant in nutrition, moderate in hardness and conductive to children's digestion and absorption, and have wide application prospects.

Owner:BAISE UNIV

A kind of preparation method of oat parboiled rice

ActiveCN107484949BModerate hardnessImprove sensory qualityFood ingredient as mouthfeel improving agentBiotechnologyNutritive values

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com