Patents

Literature

36results about How to "Improve puffing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

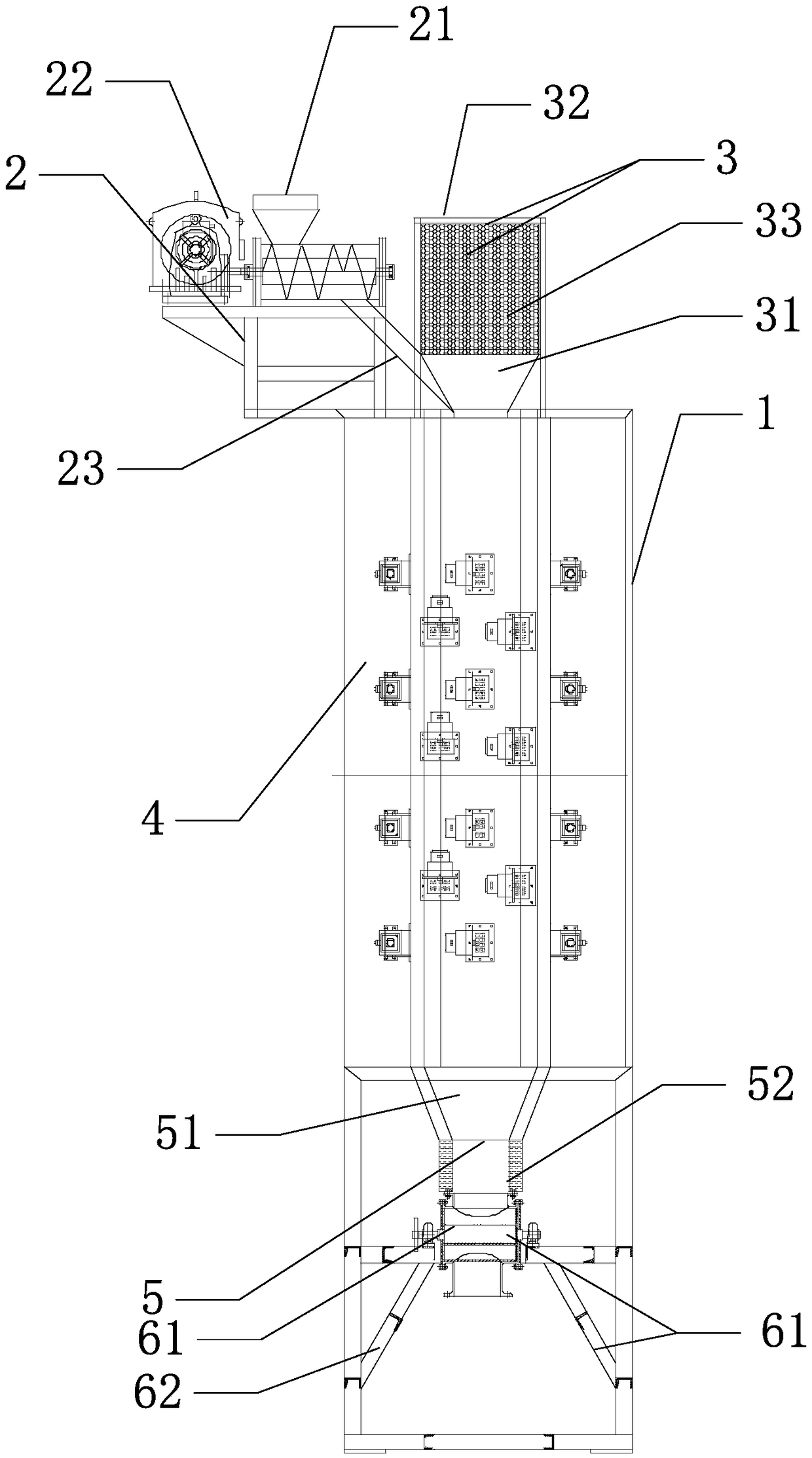

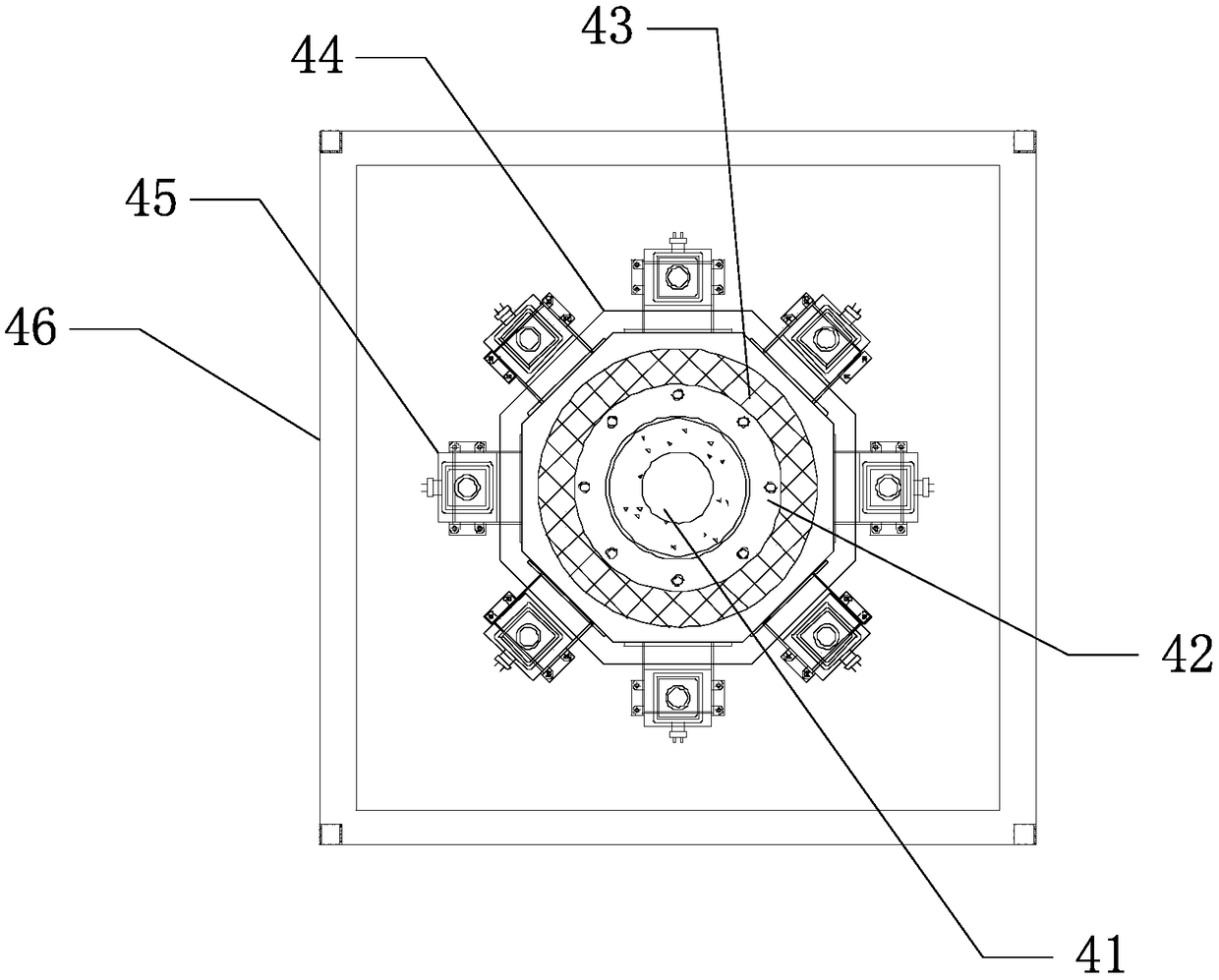

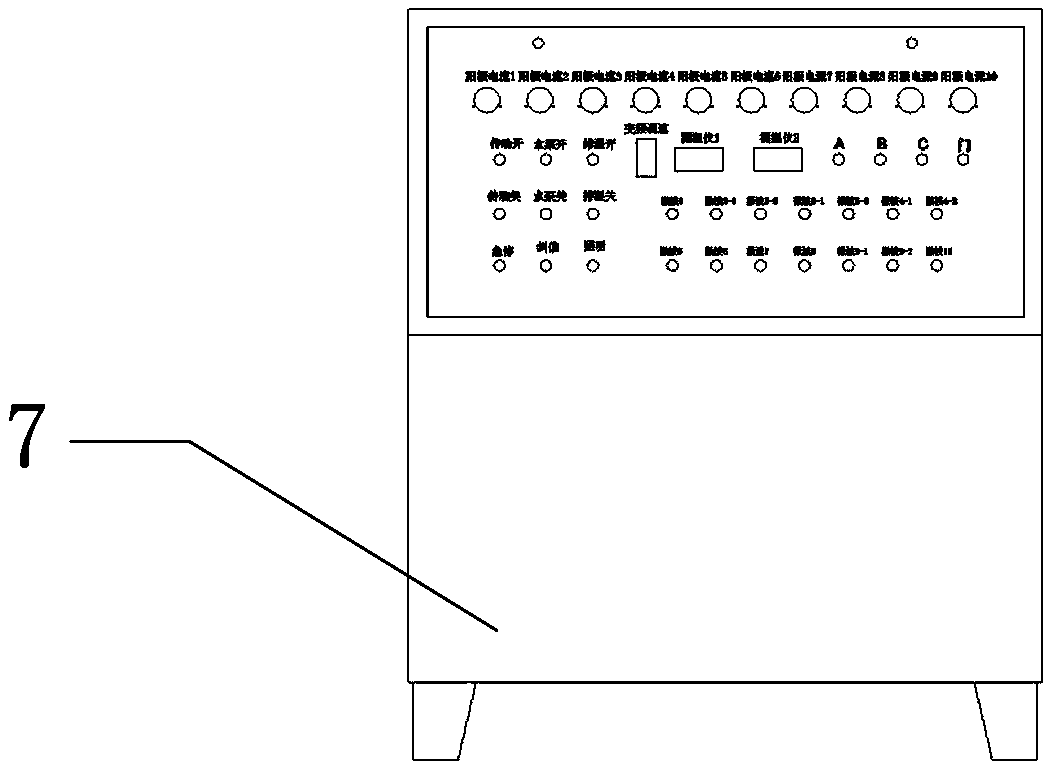

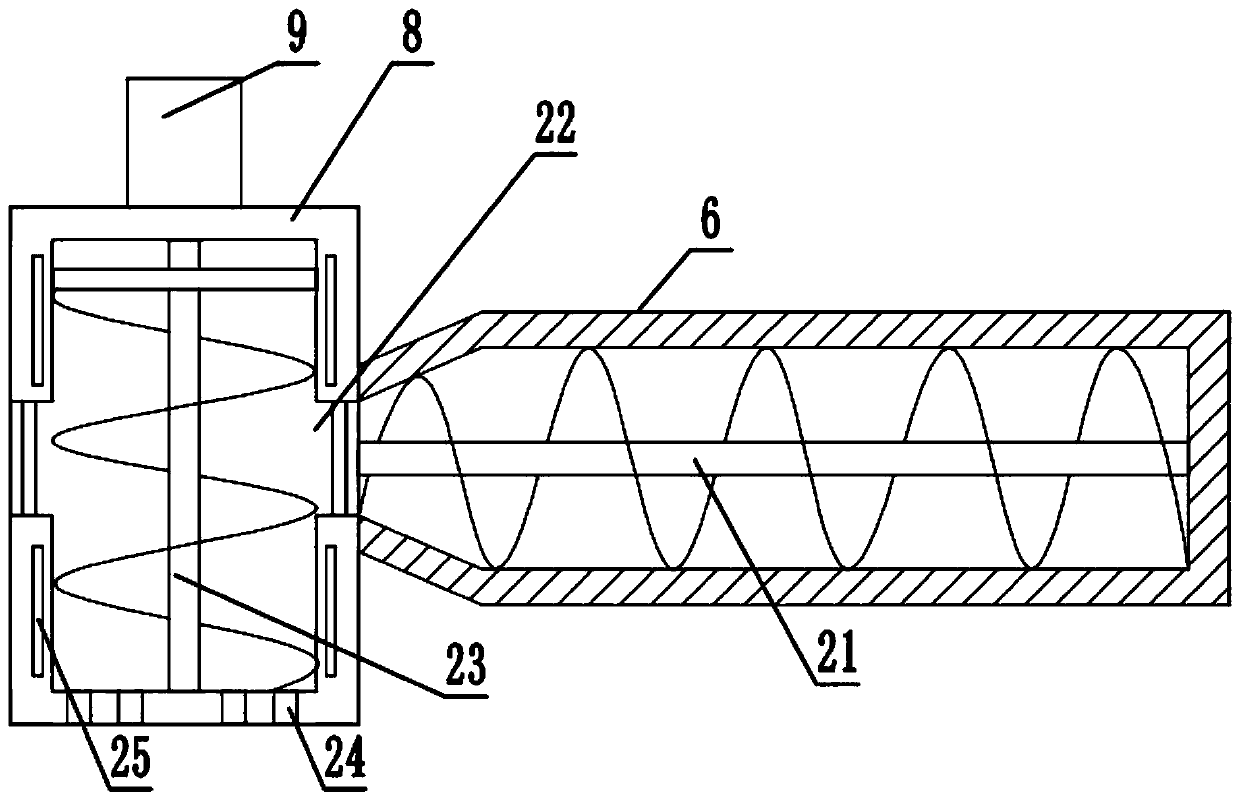

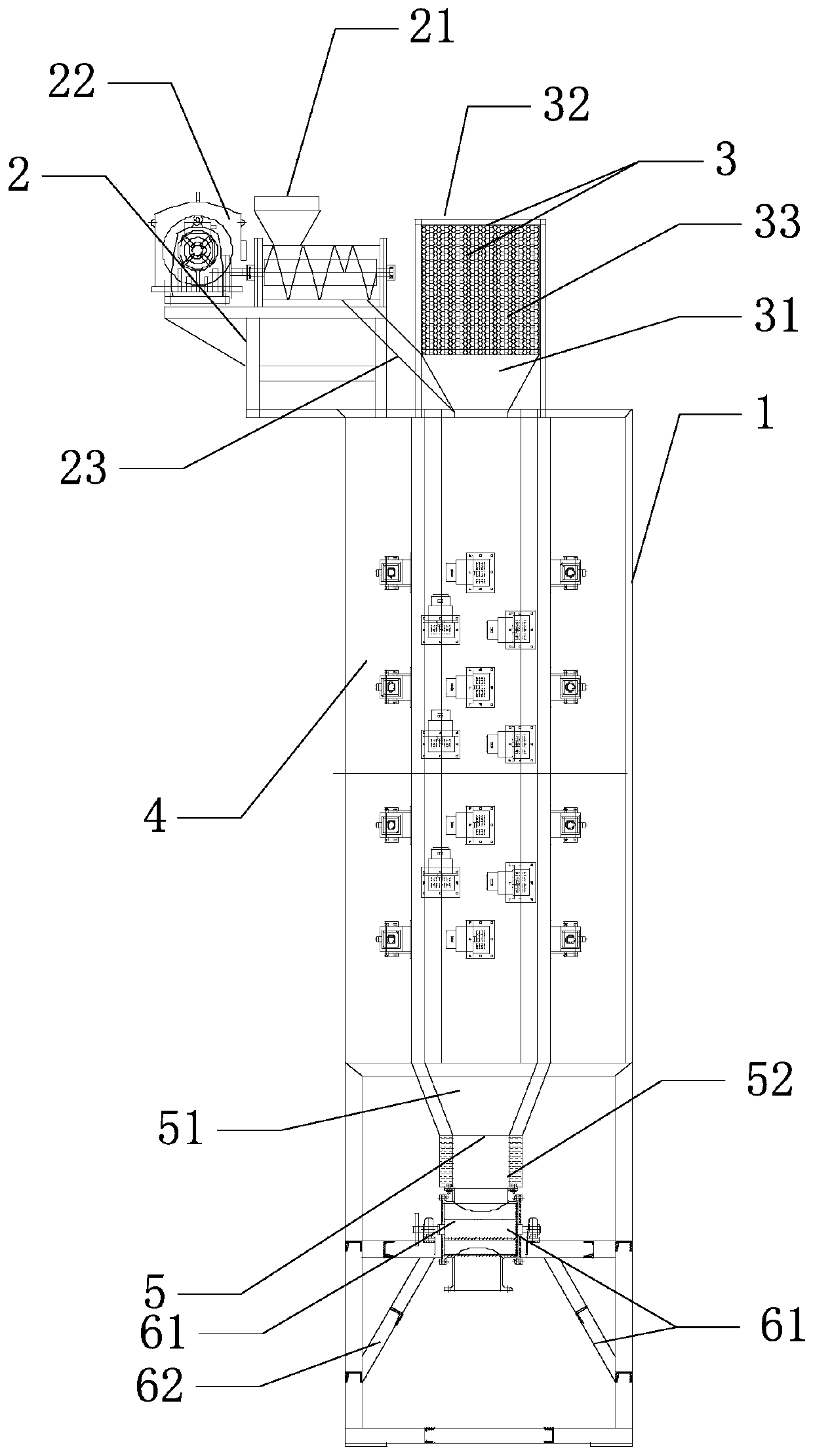

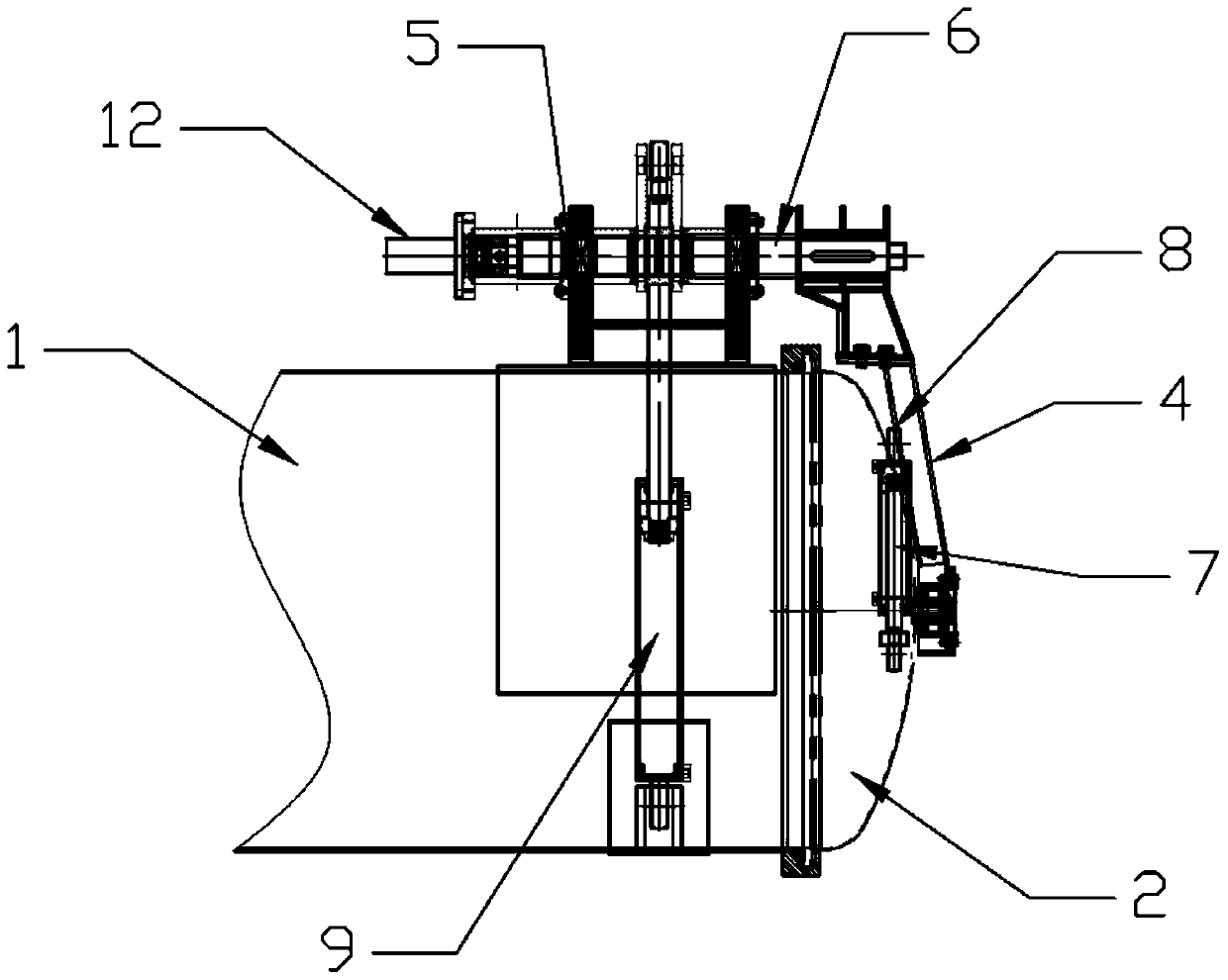

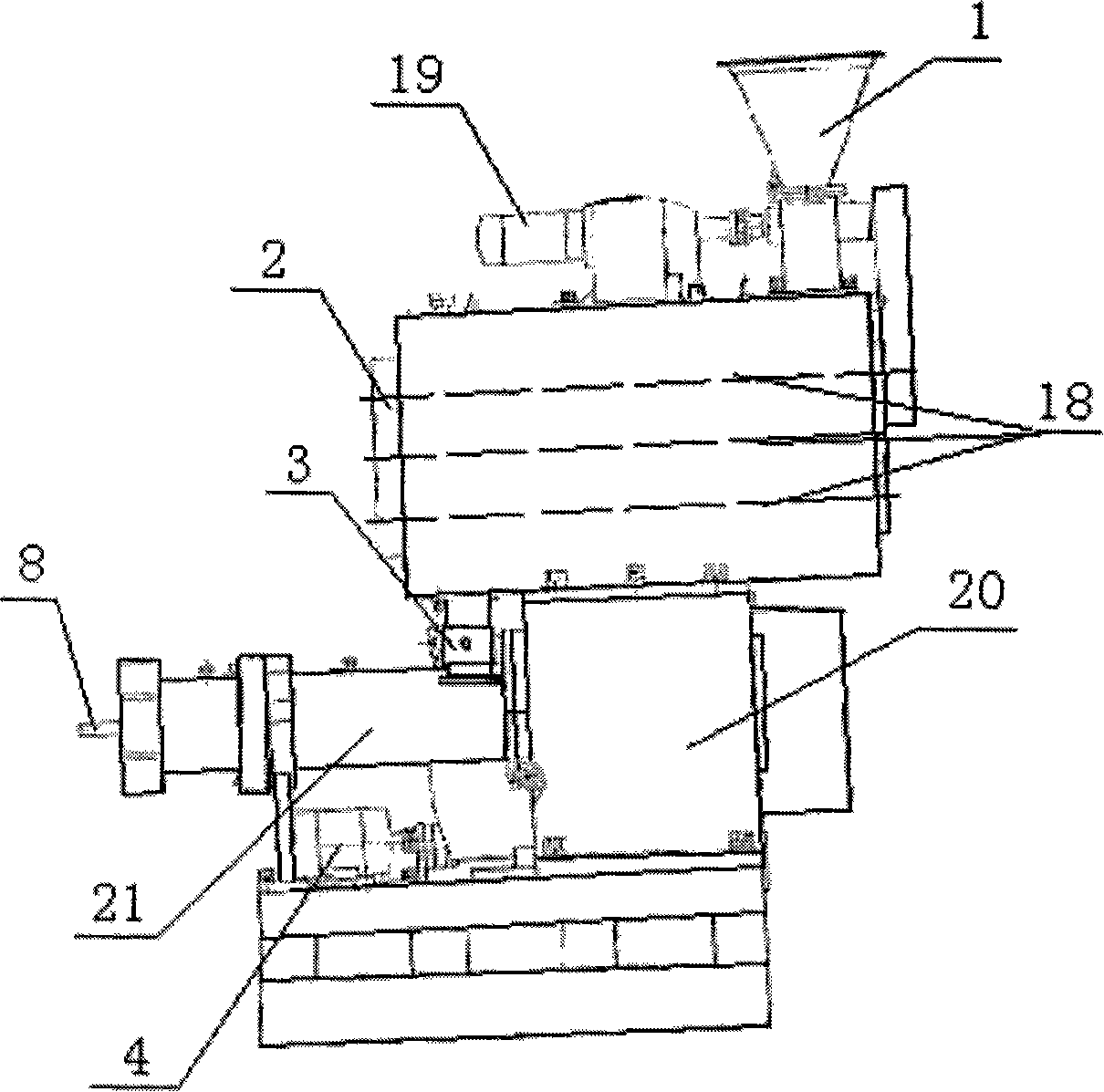

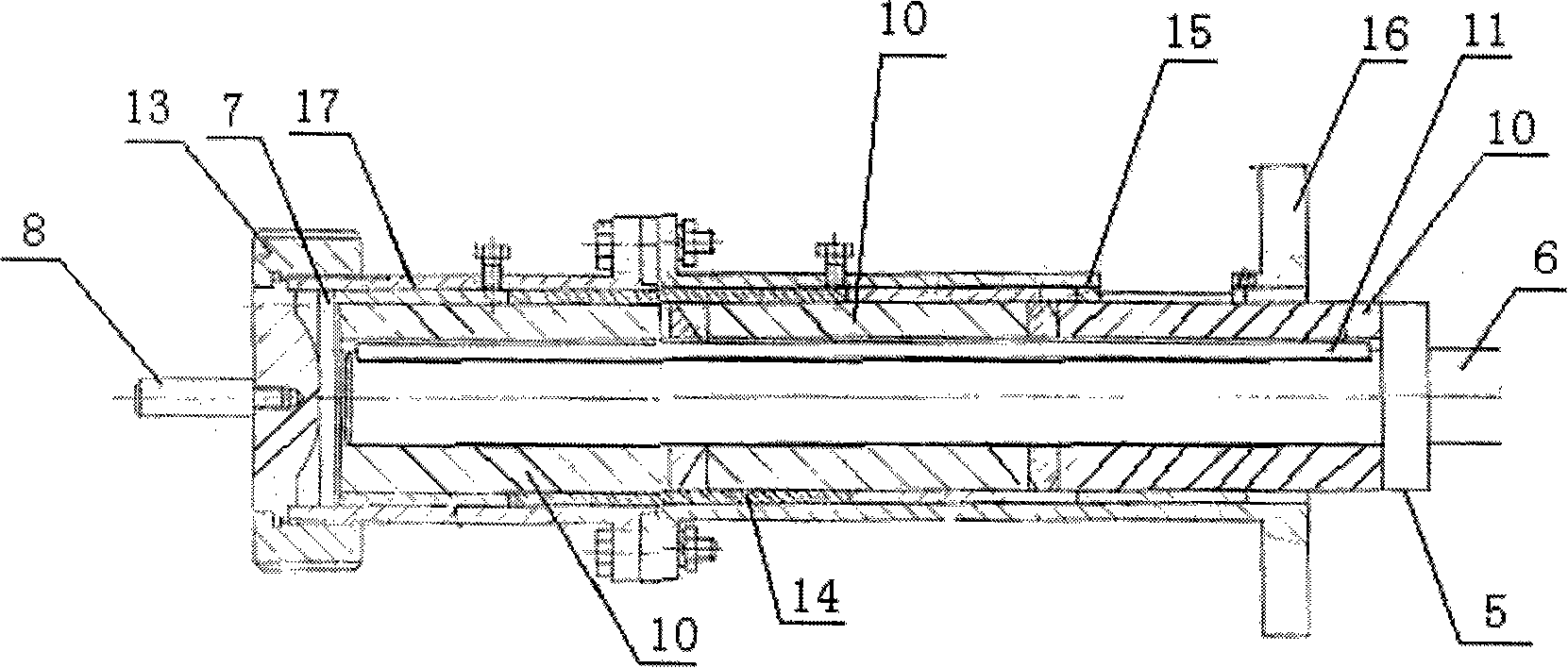

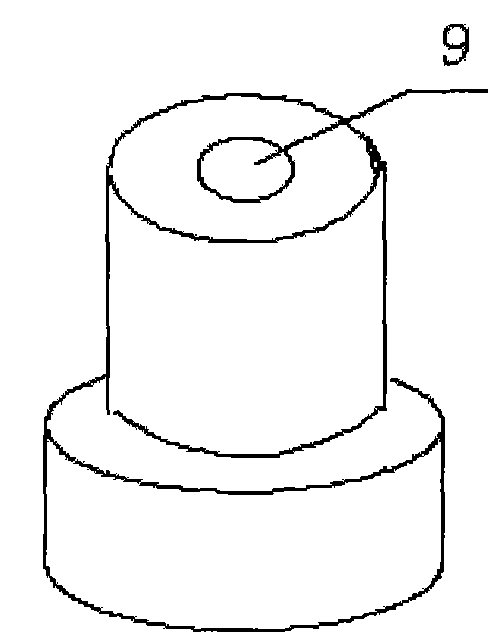

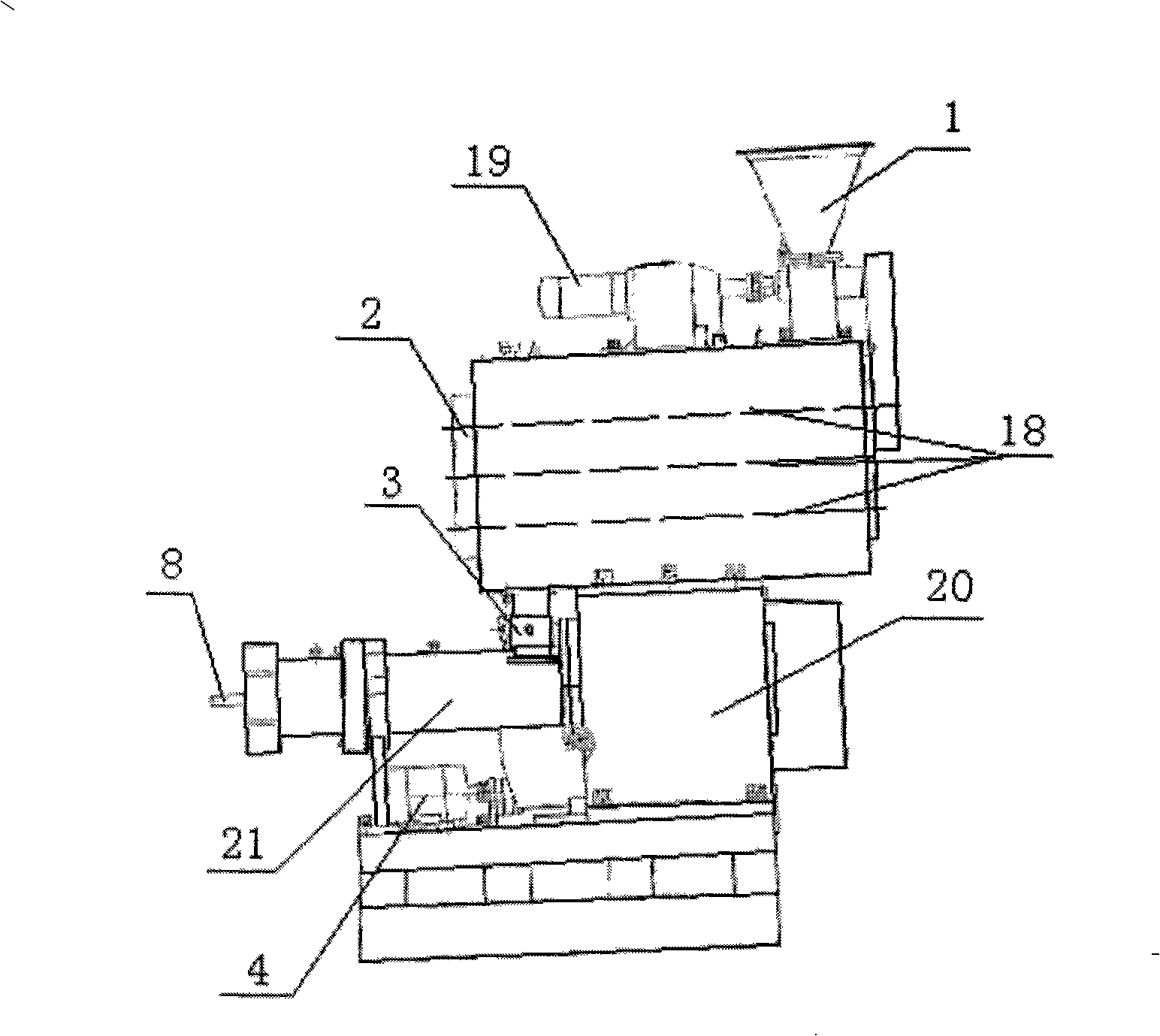

Tower-type graphite expanding microwave equipment

The invention discloses tower-type graphite expanding microwave equipment. Through adoption of a tower-type structure, by virtue of a feeding device on a tower body and the gravity, a graphite material is uniformly sent to a heating chamber for microwave heating expansion, so that a phenomenon of incomplete partial expansion due to nonuniform spreading of the graphite material can be reduced and the yield is increased; compared with the conventional expanding way, an expanding way provided by the invention has the advantages as follows: the tower-type graphite expanding microwave equipment issimple in structure and low in cost, the expanding way is easy to implement, and by the expanding way, the graphite expanding production efficiency can be greatly improved. The tower-type graphite expanding microwave equipment, comprises an overall equipment framework, the tower body, a cooling device and a control console, wherein the tower body is mounted inside the overall equipment framework;a smoke exhausting device, a heating chamber, a cooling buffer bin and a discharging device are sequentially arranged on the tower body from top to bottom; a feeding device is arranged beside the smoke exhausting device.

Owner:广州越能工业微波设备有限公司

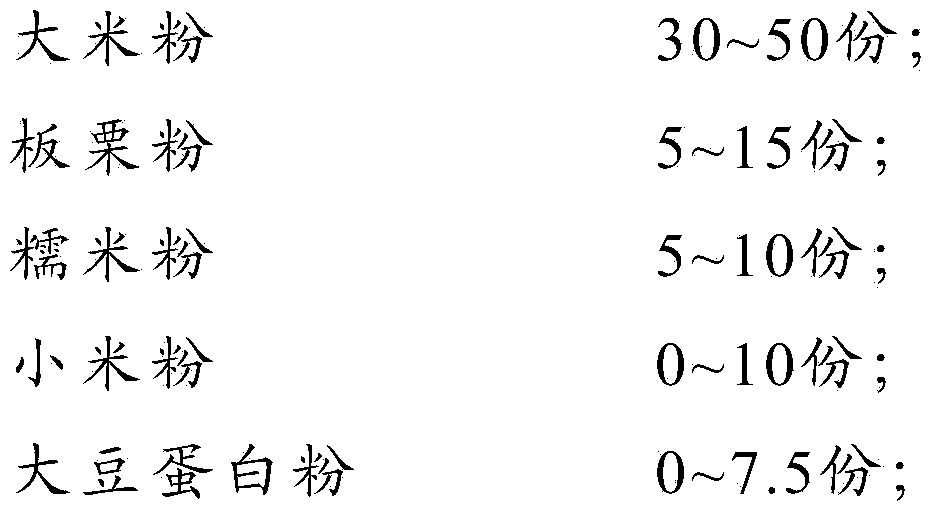

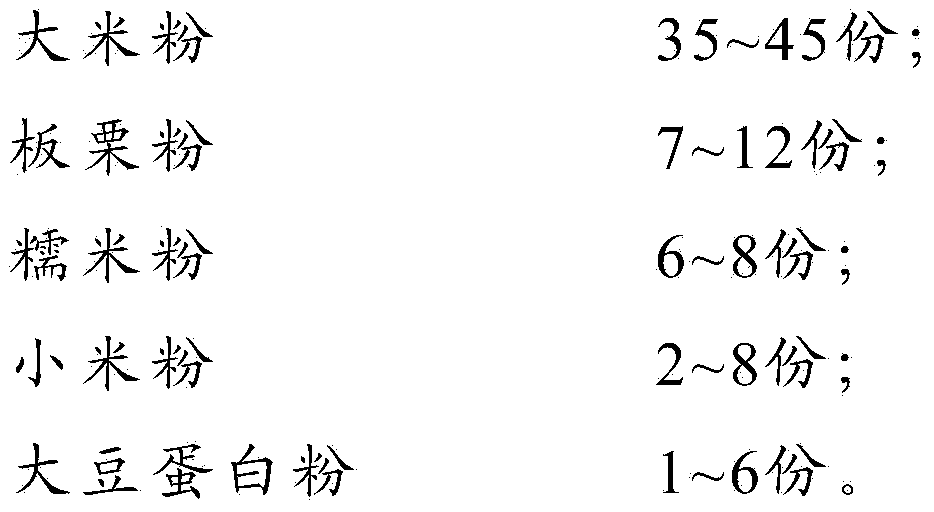

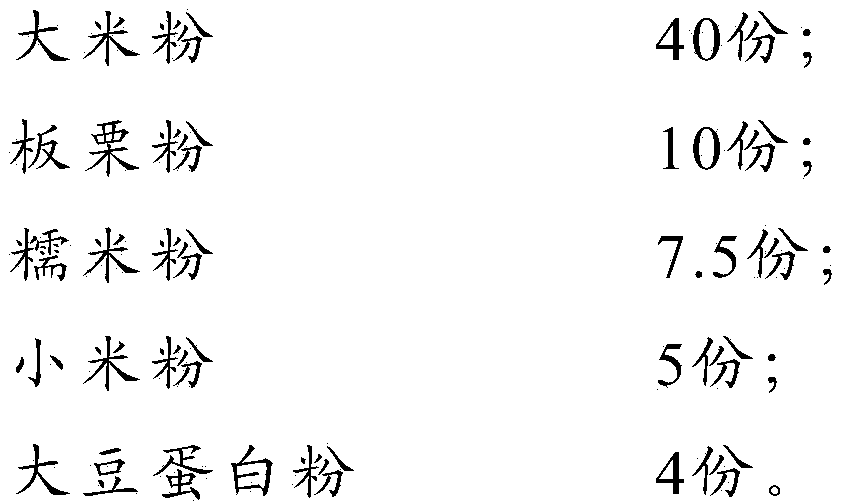

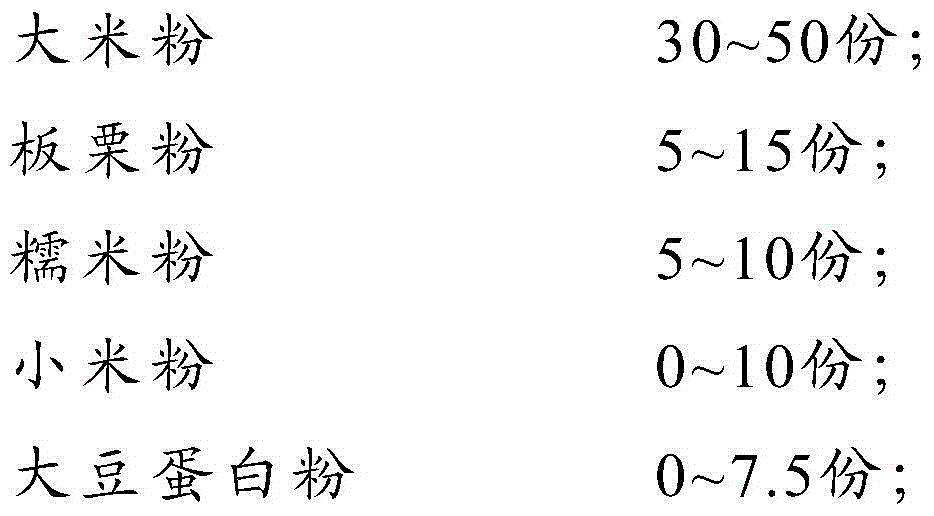

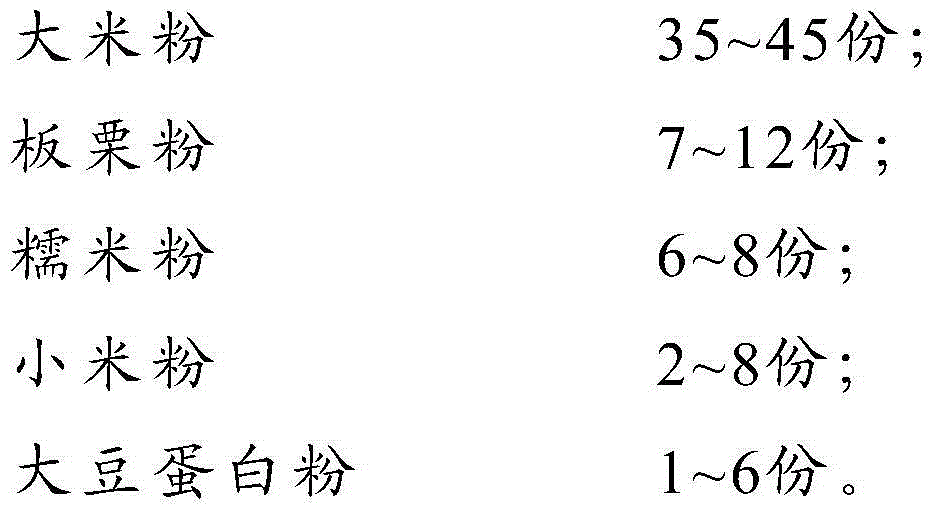

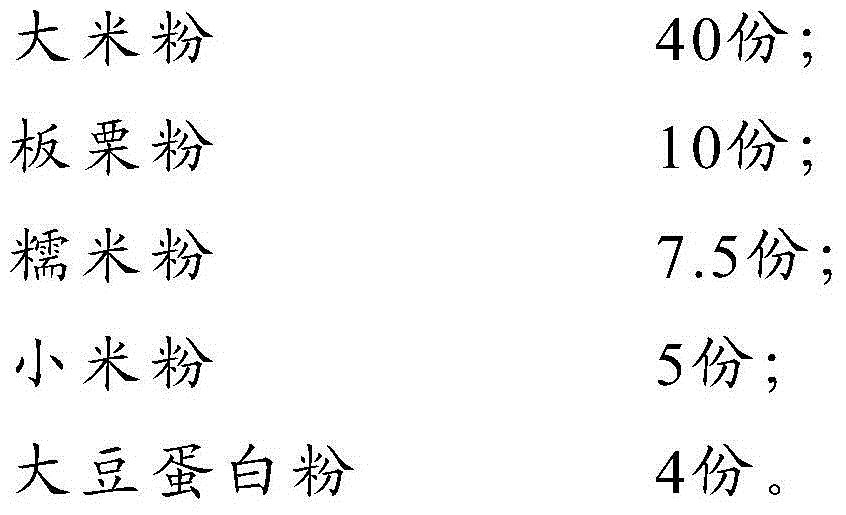

Microwave puffing Chinese chestnut food and manufacturing method thereof

ActiveCN103719943ANutritional balanceAppropriate tasteFood ingredient functionsFood preparationMicrowaveMillet flour

The invention discloses a microwave puffing Chinese chestnut food and a manufacturing method thereof. In the Chinese chestnut food, Chinese chestnut powder, rice flour, and glutinous rice flour are used as raw materials, and nutrition enrichment supplements such as millet flour or soybean protein powder and the like are selectively added; after microwave puffing, the Chinese chestnut food has balanced nutrition, crispy tastes and is easy to eat and digest; moreover, the chestnut food is unlikely to cause adverse feelings such as flatulence and the like. The manufacturing method of the microwave puffing food is simple, feasible, easy to operate and widely used.

Owner:BEIJING UNIV OF AGRI

Puffed coix seed and preparation method thereof

The invention discloses a puffed coix seed and a preparation method thereof. The preparation method of the puffed coix seed comprises the following steps: immersing coix seeds in a mixed water solution containing 0.5-1.5 percent of NaCl and 1.5-2.5 percent of glucose for a period of time to obtain coix seeds with a certain water content and some taste; then microwave puffing under the conditions that the microwave power is 450-600 w and the time is 3-5 minutes; and finally obtaining the puffed coix seeds with higher puffing rate and popping rate, lower charring rate and good sweetness and taste. As the preparation method of the puffed coix seed adopts a mode of immersing for seasoning before puffying, the coix seeds contain a certain amount of water and taste and are suitable for puffing, the coix seeds are puffed for a period of time under the appropriate microwave firepower, the puffing effect is good, and the product has a unique flavor.

Owner:SHANGHAI INST OF TECH

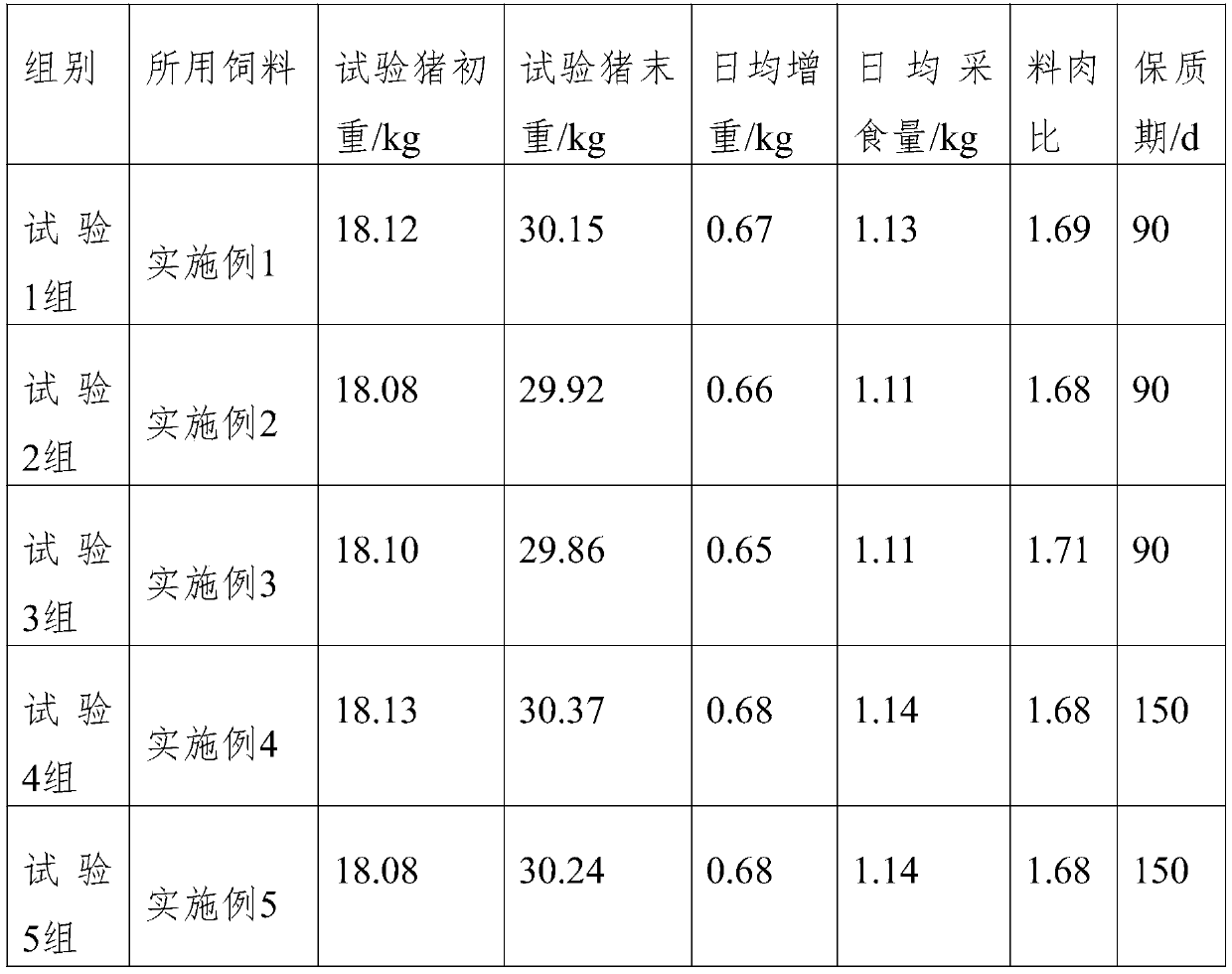

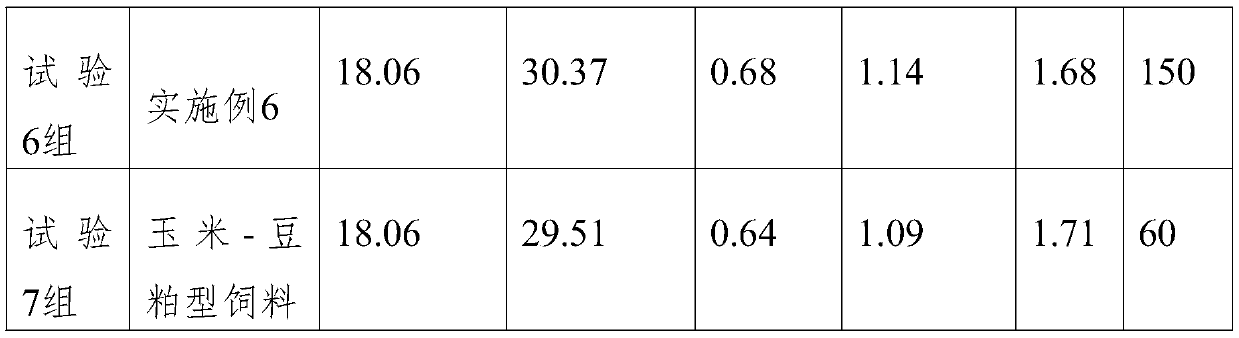

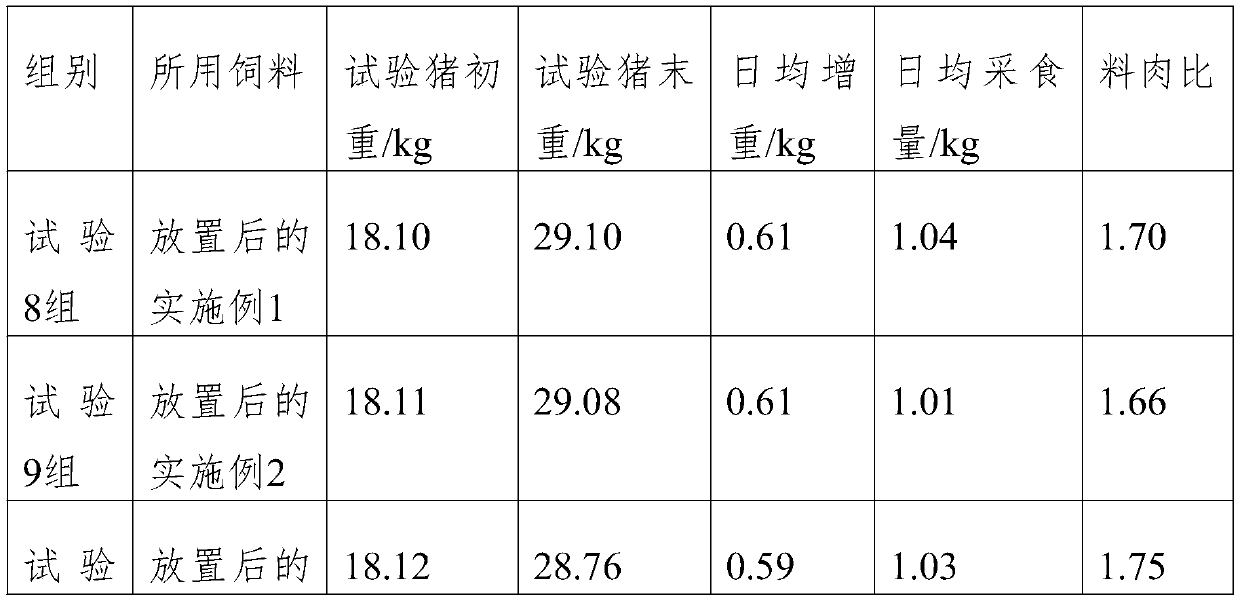

Novel fattened pig compound feed and preparation method thereof

ActiveCN103704484ALittle palatabilityReduce pollutionAnimal feeding stuffBiotechnologyAnimal science

The invention discloses a novel fattened pig compound feed and a preparation method thereof. The novel fattened pig compound feed is prepared from the following raw materials in percentage by weight: 35-50 percent of corns, 20-35 percent of puffed peas, 15-40 percent of wheat and 3-4 percent of a premix. According to the digestion physiological characteristic of a fattened pig, the peas, the corns and the wheat, which are high in biological utilization rate, are used as basic feed materials, and synthesized creatine monohydrate is creatively mixed with glucose, D-pinitol and other additives to replace conventional fish meal, so that under a condition of reducing the feeding cost, the lean rate is increased, the growth speed is increased, the digestion absorption rate is improved, and the resistance to pathogens is enhanced; nitrogen emission is alleviated, and the feeding environment is improved. Meanwhile, an advanced puffing technology is adopted, so that the puffing efficiency and the fat digestion rate as well as the palatability of the feed are improved. The novel fattened pig compound feed has the characteristics of high lean rate, stable quality, low cost, high fat digestion rate, high palatability, low excrement pollution and the like and has a high popularization value.

Owner:QUJING DAXING FEED

Preparation method of sandwiched crispy Chinese dates

InactiveCN105685867AOvercome the disadvantages of sufferingHigh dissolution rateFood dryingCooking & bakingFruit juice

The invention belongs to the technical field of food processing. A preparation method of sandwiched crispy Chinese dates comprises the following steps: taking dried Chinese dates, and washing to remove surface mud; removing kernels of the washed dried Chinese dates; filling stuffing into the Chinese dates without the kernels; spraying the Chinese dates filled with the stuffing with juice mist until fine and dense water beads are formed on the surfaces of the Chinese dates; storing the Chinese dates in a single layer into a freezer, and coldly soaking and quickly freezing the Chinese dates through cold air in the freezer, wherein the step of coldly soaking is to coldly soak in the air at 0 DEG C to 5 DEG C, and the temperature of quickly freezing is -10 DEG C to -15 DEG C; carrying out microwave expansion and dehydration: putting the raw material treated by the last step on a conveyor belt of a microwave expansion dryer and arraying in the single layer; adjusting the speed of the conveyor belt to be 1.2m / min to 1.5m / min, adjusting microwave power to be 50kw to 55kw and heating by microwaves for 12min to 15min; carrying out deep dehydration: dehydrating the Chinese dates subjected to the microwave expansion through an infrared baking oven, and baking and dehydrating at a baking temperature of 45 DEG C to 55 DEG C to obtain the sandwiched crispy Chinese dates with the moisture content of being lower than 12 percent.

Owner:SHANDONG RUZHI FOOD RES CO LTD

Production method of tobacco areca nuts

InactiveCN107440017AImprove puffing efficiencyTexture layering is obviousFood mechanical treatmentFood coatingArecolineFood flavor

The invention discloses a production method of tobacco areca nuts. The method mainly comprises the following steps of selecting fresh areca nuts, washing the selected fresh areca nuts, buffing the washed fresh areca nuts, soaking the buffed fresh areca nuts in calcium hydroxide, cooking the soaked areca nuts, smoking the cooked areca nuts, performing microwave puffing, performing fermentation, performing braising to generate fragrance, performing cutting to obtain slices and removing cores, performing packaging, performing microwave sterilization and the like. Through the adoption of the production method of tobacco areca nuts disclosed by the invention, the content of arecoline and the content of arecaidine in the tobacco areca nuts can be significantly reduced, so that the increased risk that eaters suffer from oral cancer can be reduced, and the tobacco areca nuts are safe to eat; and besides, the prepared tobacco areca nuts are high in puffing efficiency, fluffy, obvious in texture layering, soft in mouth feel, good in flexibility, good in mouth feel and stable in properties. The tobacco areca nuts not only reserve traditional characteristics of being fragrant, sweet and strong, but also have the characteristics of being delicately fragrant in fruity taste, fragrant rather than greasy, unique in mouth feel and flavor.

Owner:河南勃达微波电气自动化设备有限公司

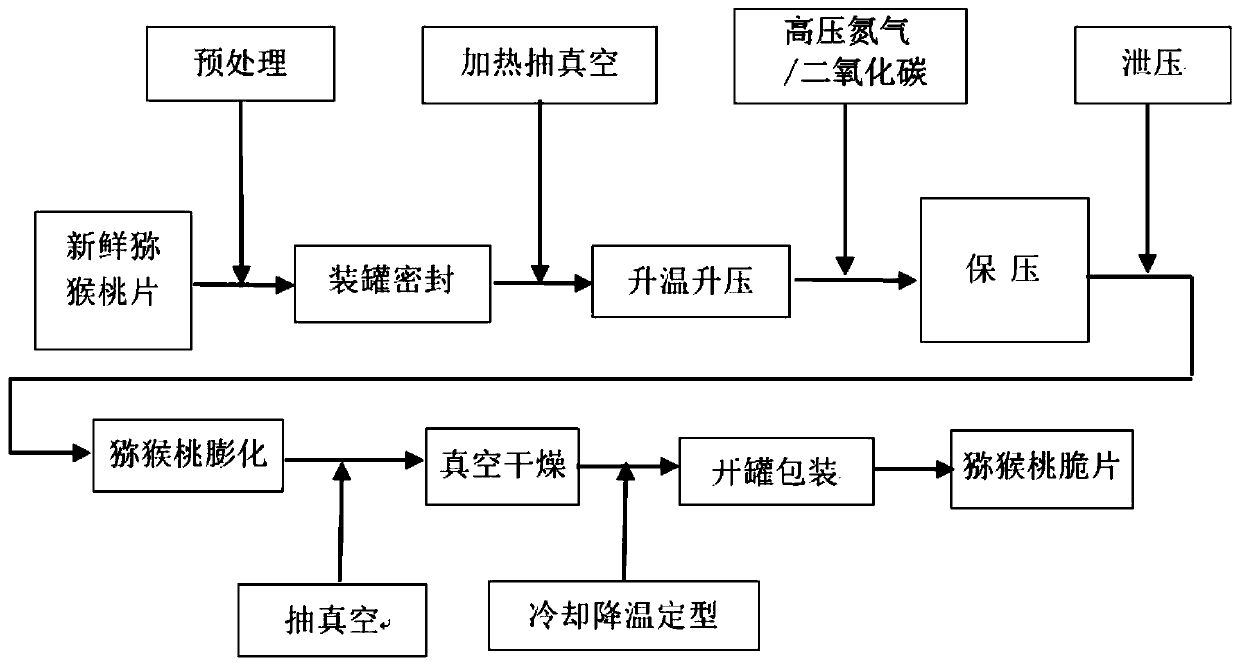

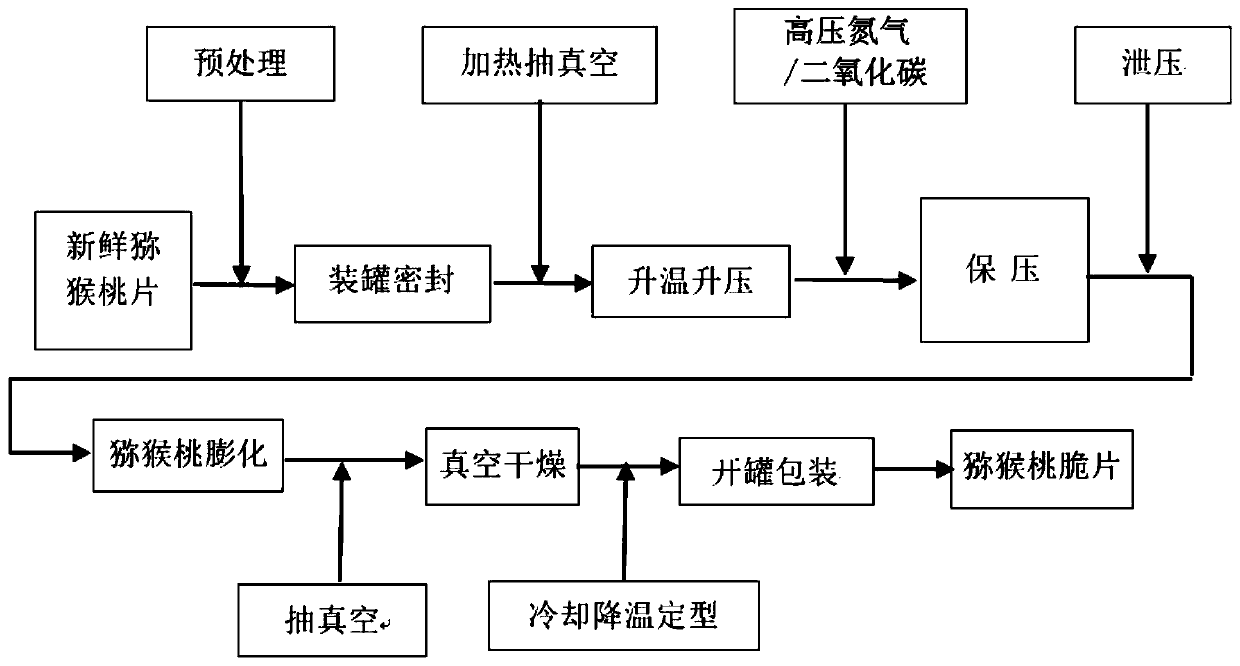

Puffing method for preparing kiwifruit crisp slices

InactiveCN109832586AEasy to vaporizePromote infiltrationFood shapingFruits/vegetable preservation by dehydrationFreeze thawingActinidia

The present invention discloses a puffing method for preparing kiwifruit crisp slices. Pre-dried kiwifruit slices after a freeze-thaw treatment are placed in a puffing tank for puffing, inert gas fills the entire puffing tank and slowly infiltrates through capillary holes inside the kiwi fruit slices, a highest pressure environment in the tank is kept for 10 min-20 min, so that internal and external pressures of the kiwi fruit slices are balanced; then the high pressure in the puffing tank is removed within 0.1 s, the pressure value is instantaneously reduced to atmospheric pressure, high-pressure gas inside the kiwi fruit slices is instantaneously vaporized to produce an outward expansion force, and blocking force of the capillary holes cooperates to break internal tissues of the kiwifruit slices to complete the puffing process. The kiwifruit crisp slices prepared by the method are crispy and delicious, free of any additives, green and healthy, and maintain original flavor, color, luster and nutrition of kiwifruits.

Owner:SHAANXI UNIV OF SCI & TECH

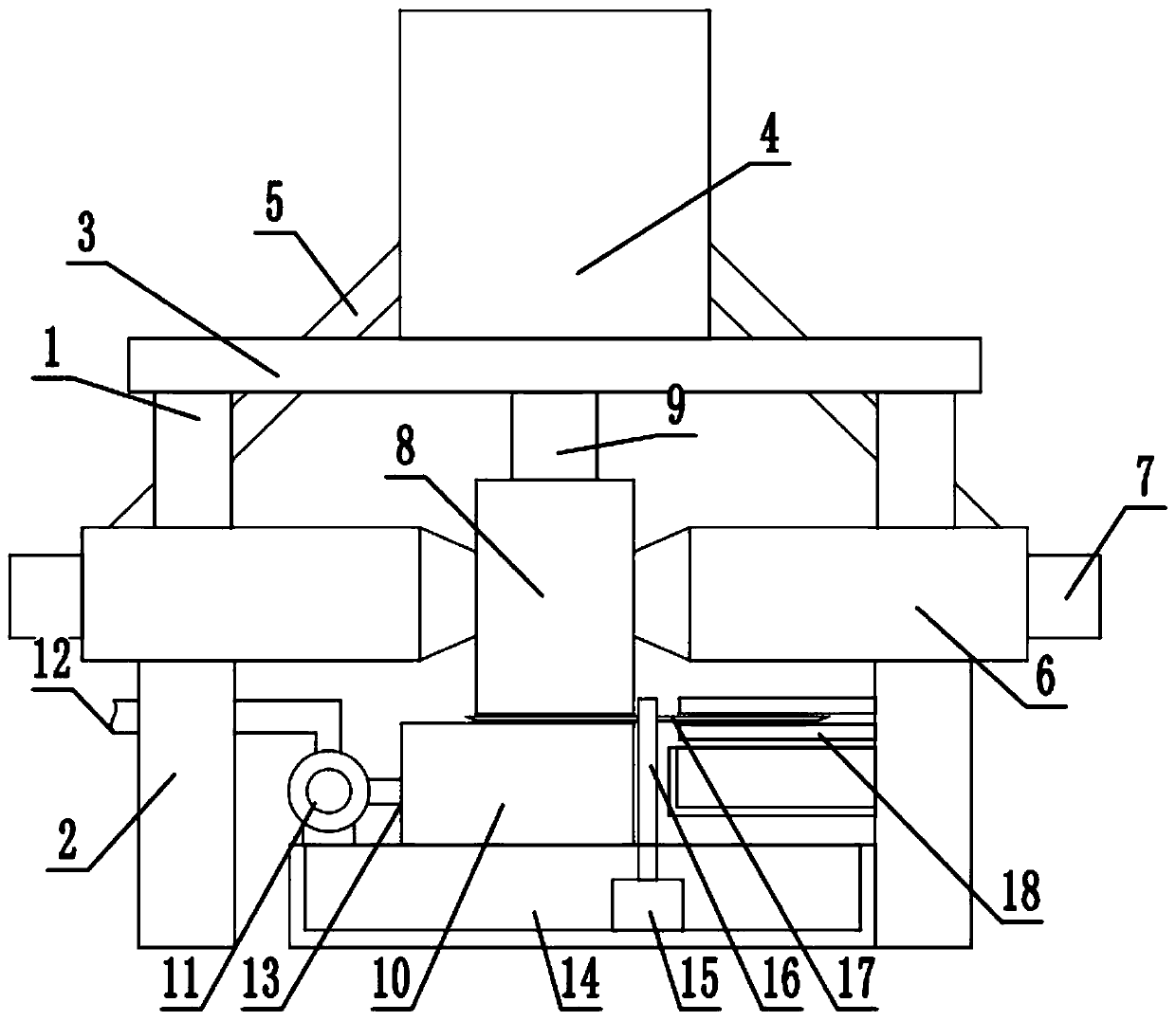

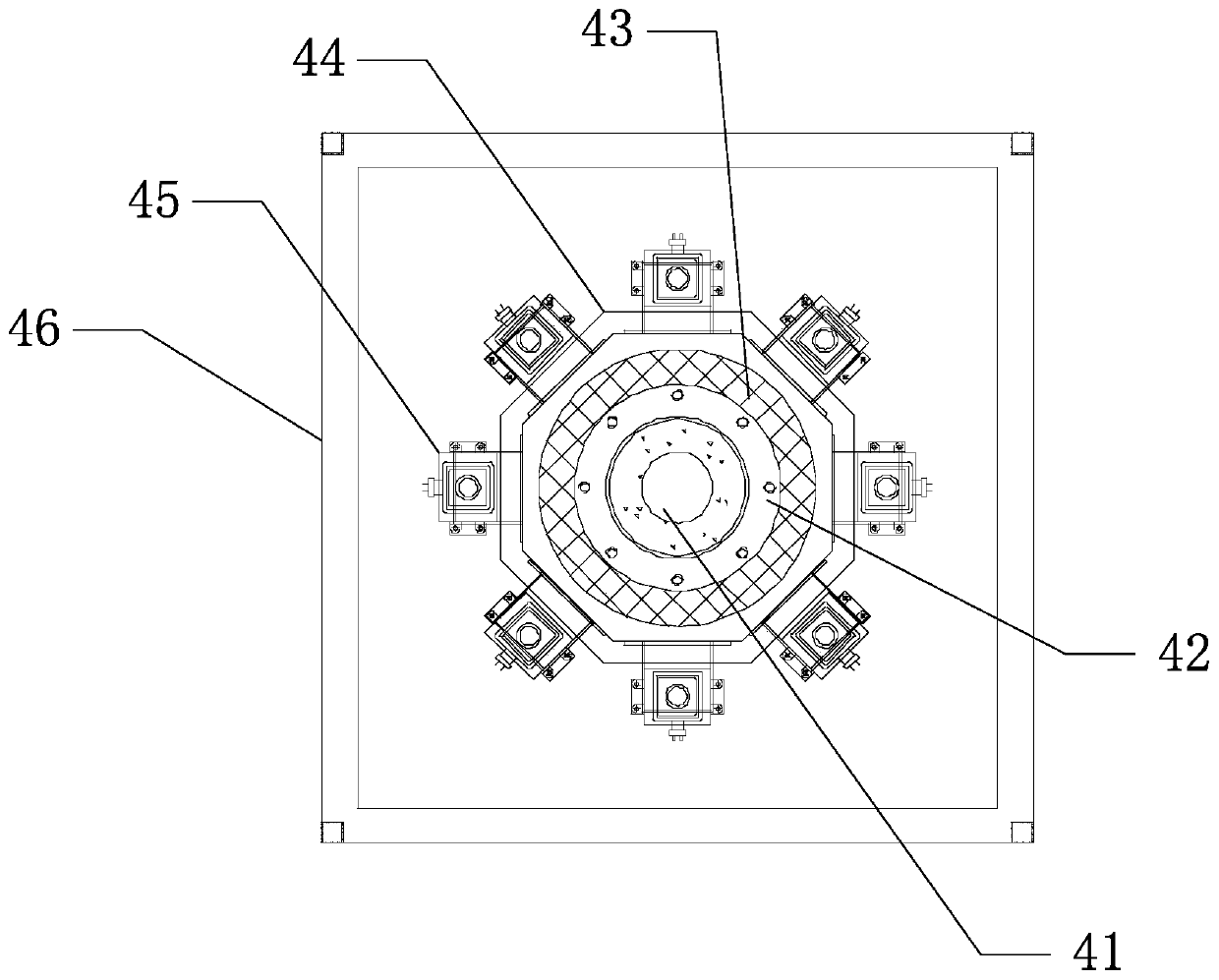

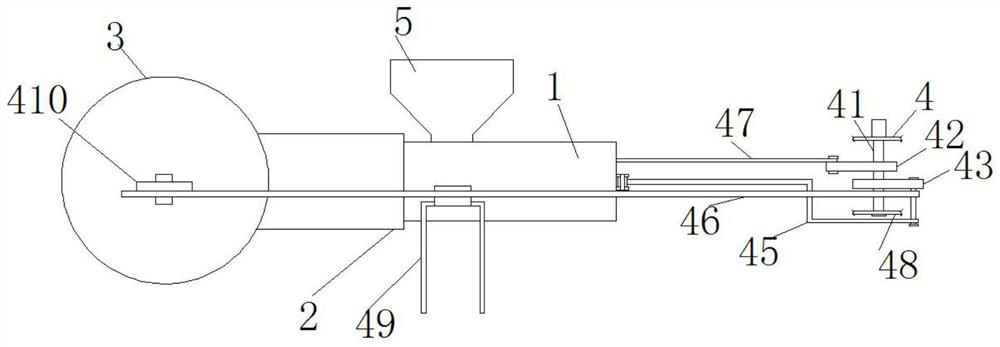

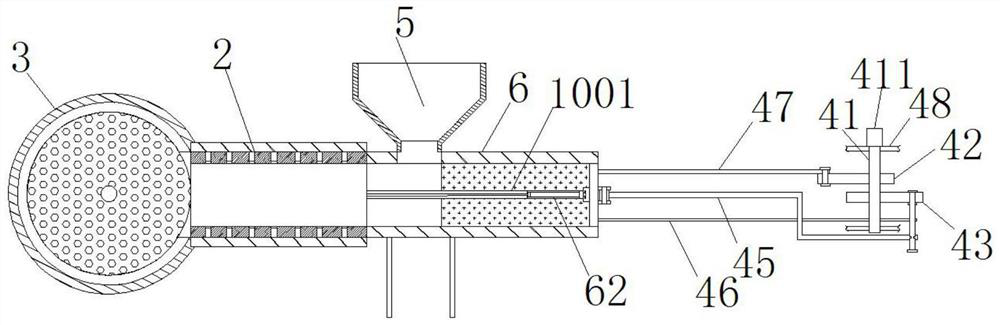

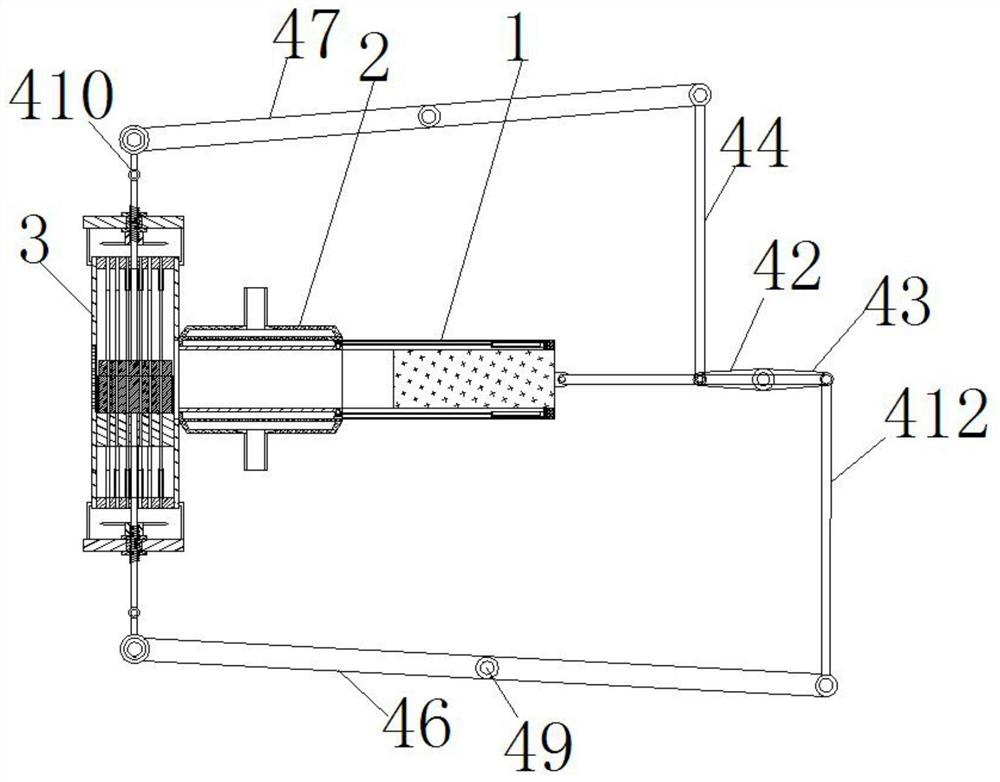

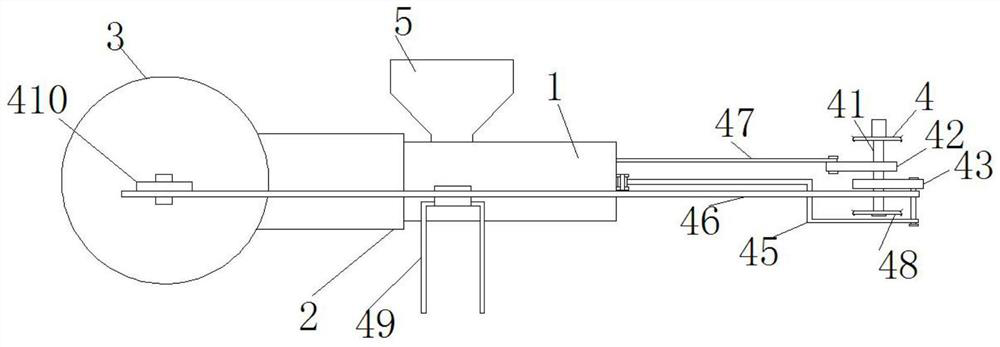

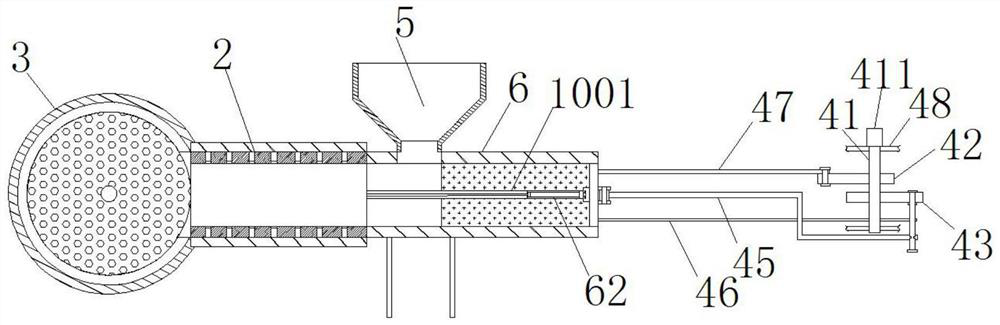

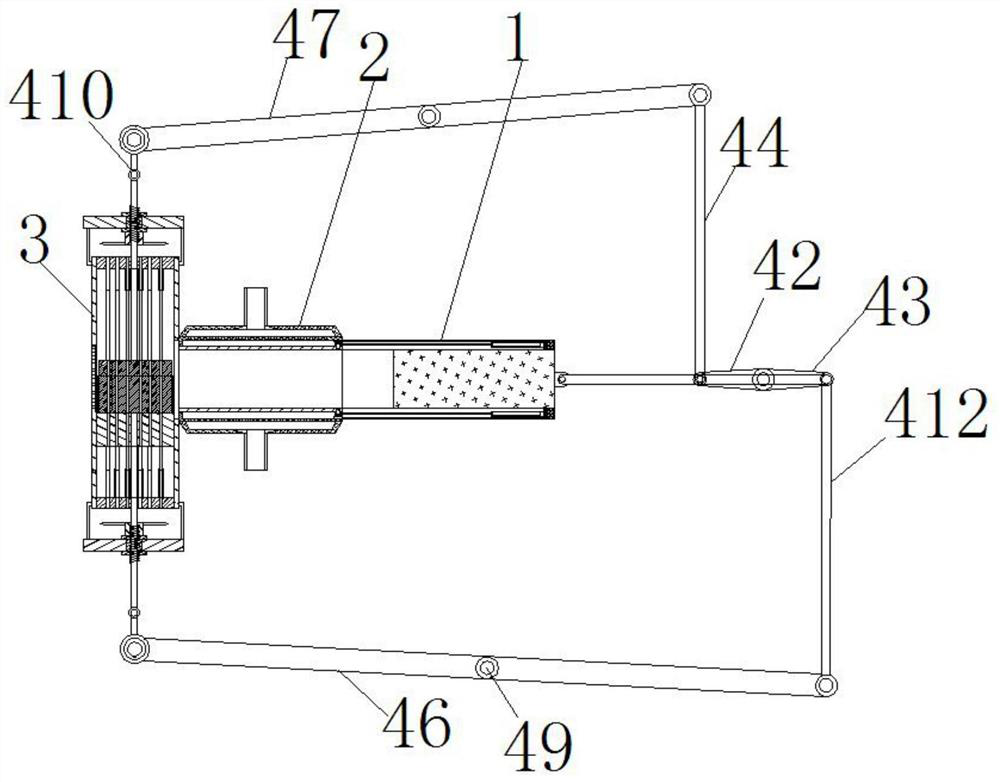

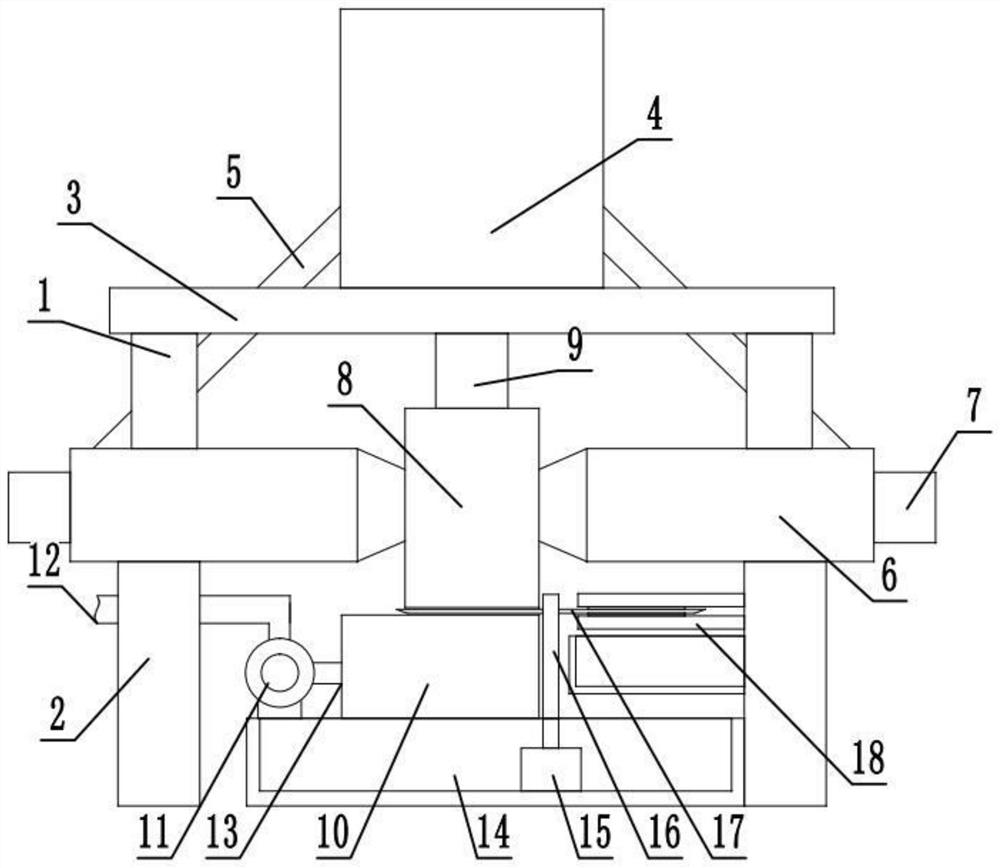

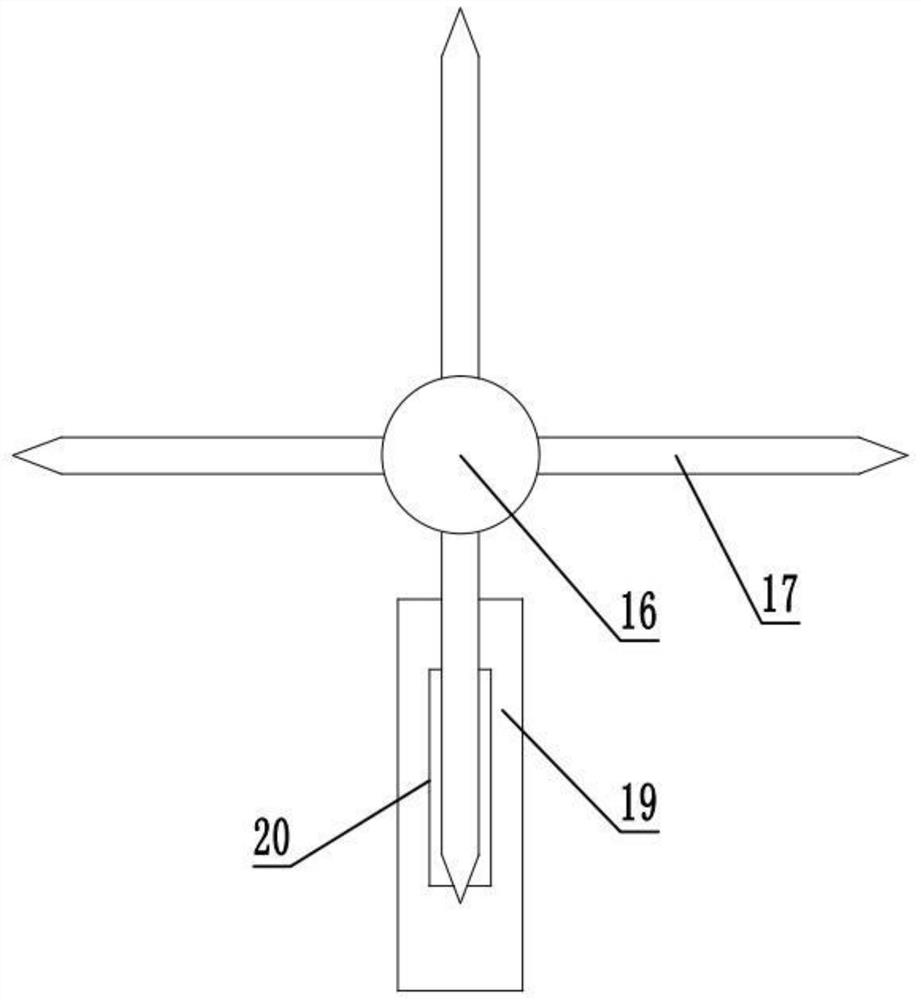

Bidirectional pressurizing feed puffing processing device for agricultural cultivation

ActiveCN111493345AHigh degree of automationRapid puffingFeeding-stuffGranulation by material expressionAgricultural scienceAgricultural engineering

The invention discloses a bidirectional pressurizing feed puffing processing device for agricultural cultivation. The device comprises a rack, the rack is provided with a plurality of supporting legsand a supporting table, a raw material box is arranged above the rack, an extrusion cylinder is arranged below the rack, pressurization conveying cylinders communicated with the extrusion cylinder arearranged in the centers of the two sides of the extrusion cylinder, and the pressurization conveying cylinders are embedded in the supporting legs and fixedly connected with the supporting legs. Whenthe device is used for processing, raw materials in the extrusion cylinder are pressurized through the two sides, the raw materials are extruded downwards through the extrusion cylinder, high-temperature heating is conducted on the raw materials, the feed can be rapidly puffed in a multi-directional pressurizing mode, the extruded feed is collected and cooled through the finished product box, andthe automation degree is high. Through the arrangement of a backflow prevention structure, the opening between fixed switch plates is opened intermittently, raw materials can be prevented from beingtransferred to the two sides, enough pressure is guaranteed, a certain pressure can be obtained in the raw material transferring process through the intermittently-closed opening, and the puffing efficiency is improved.

Owner:湖北省思乐牧业集团恩施市法希饲料有限公司

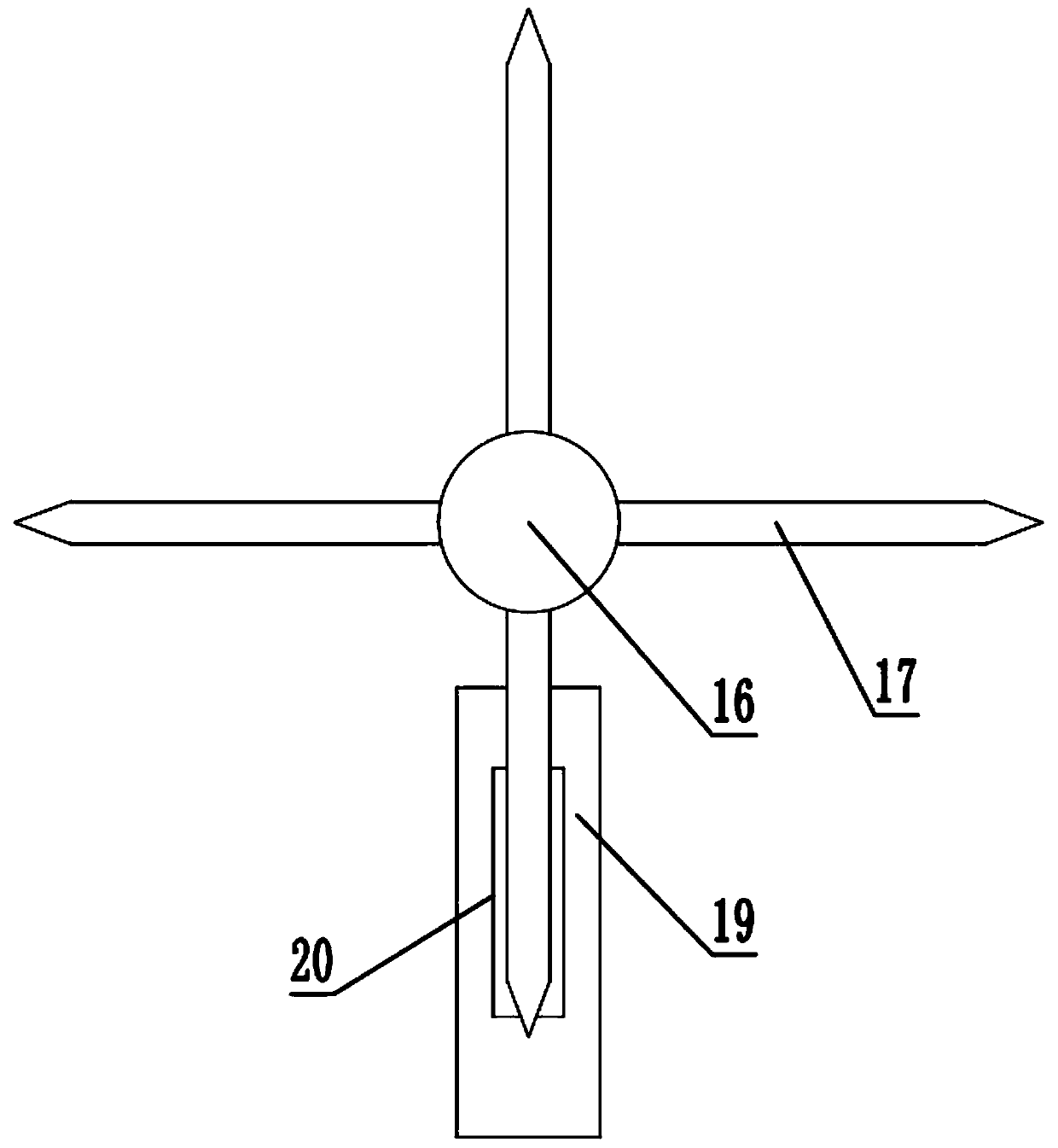

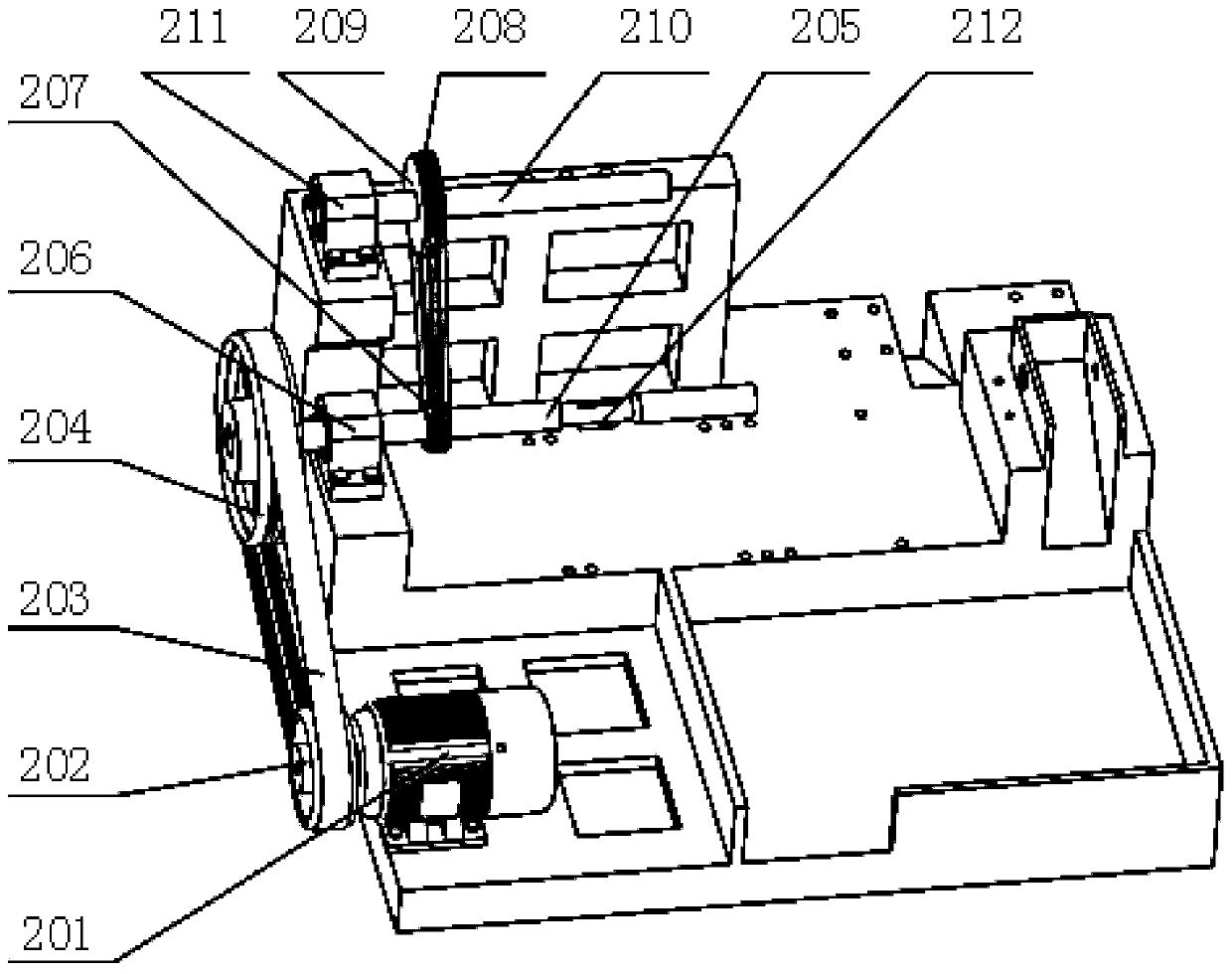

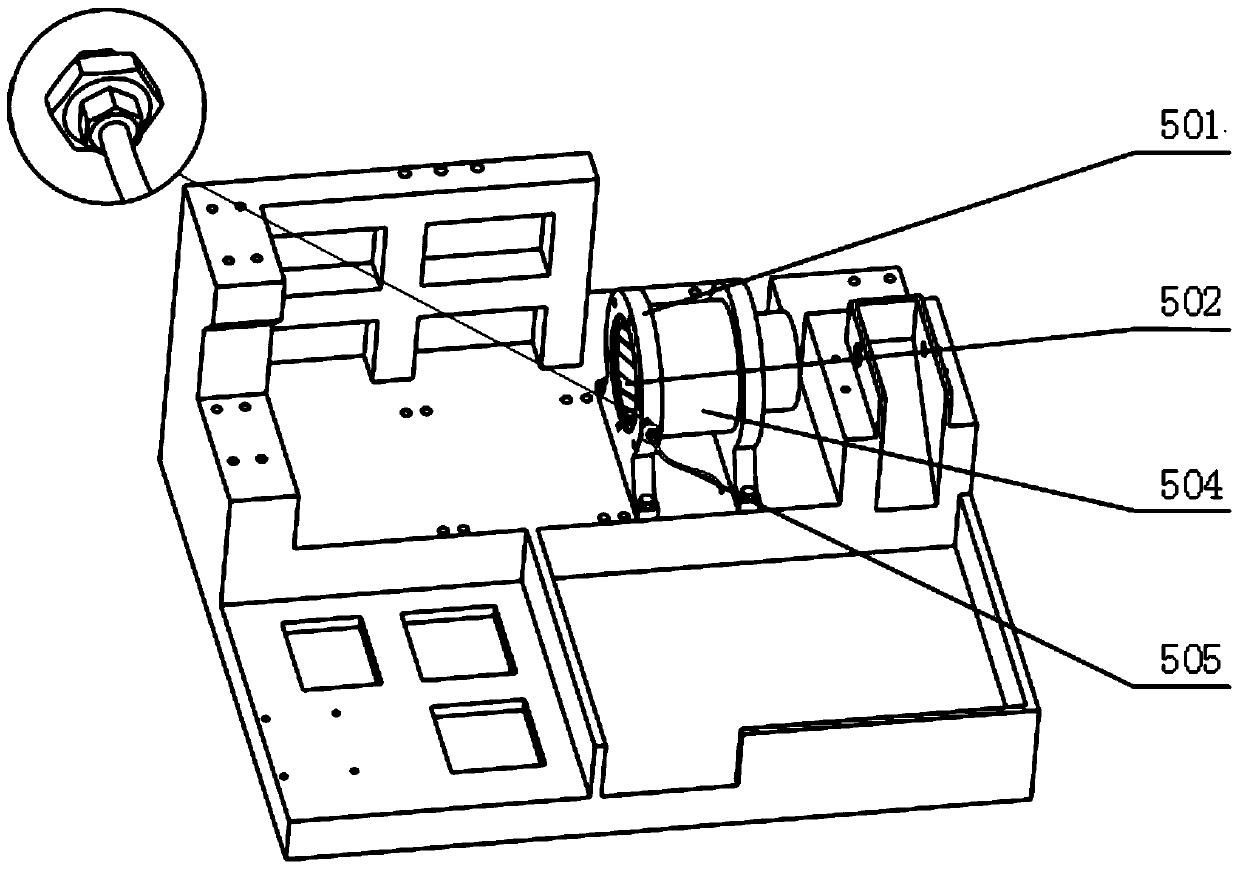

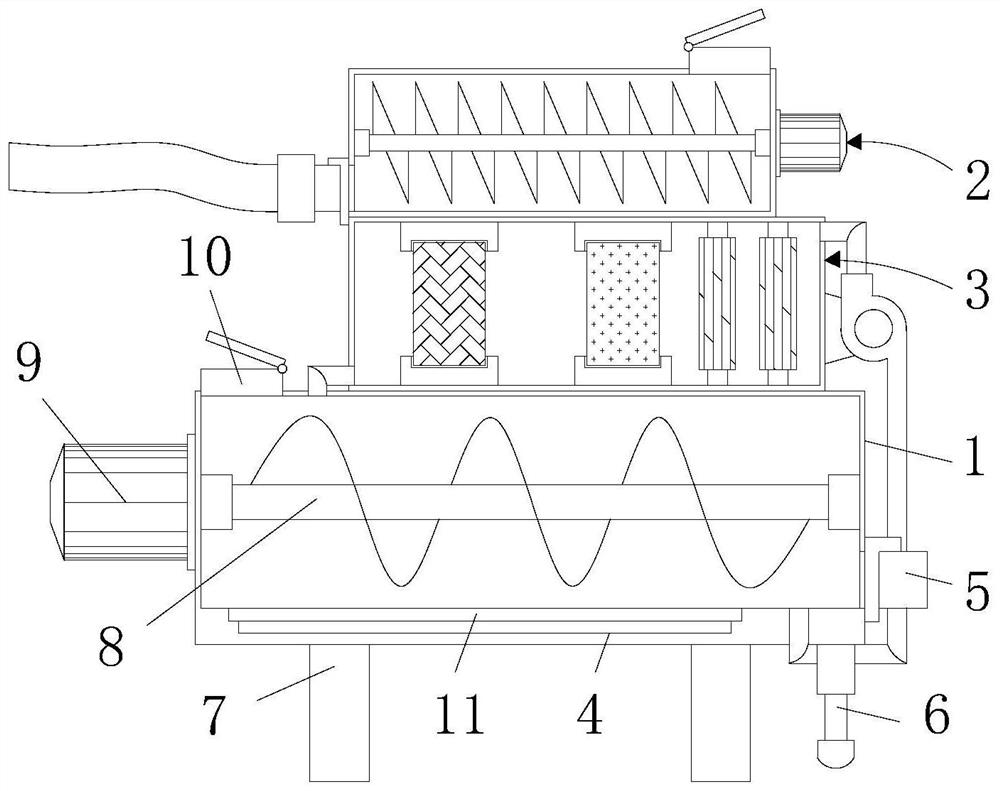

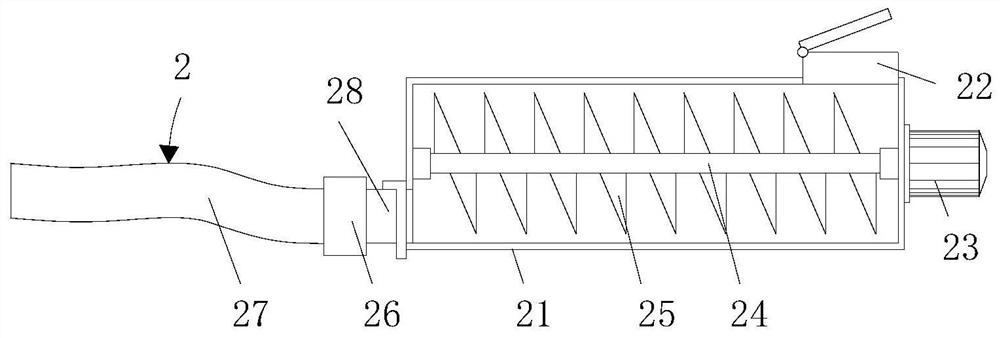

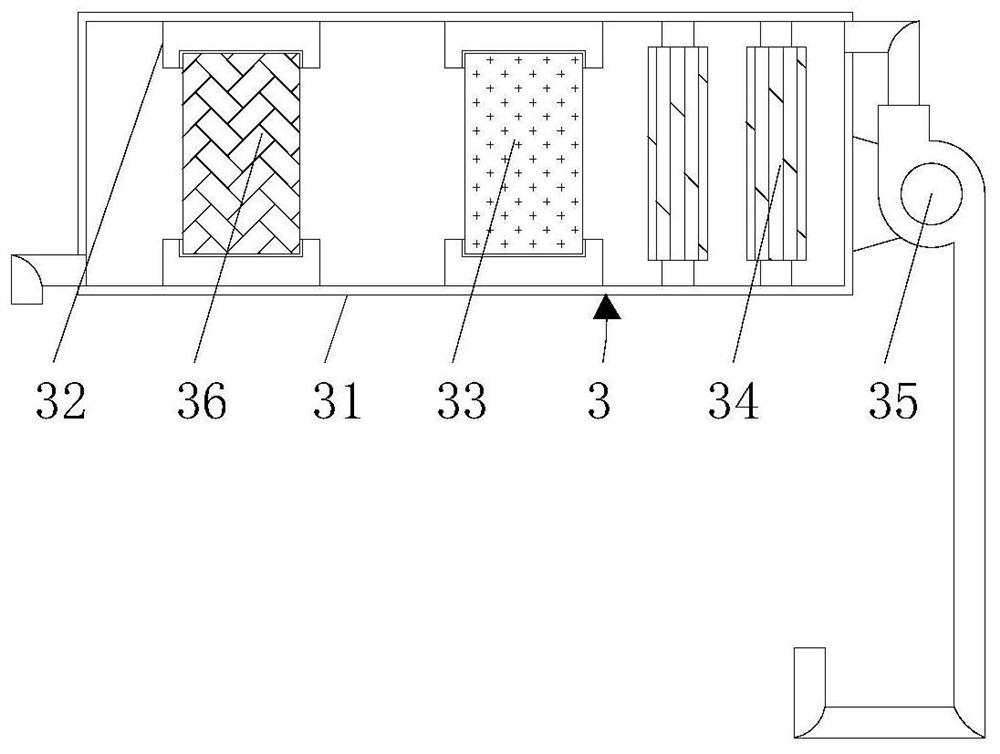

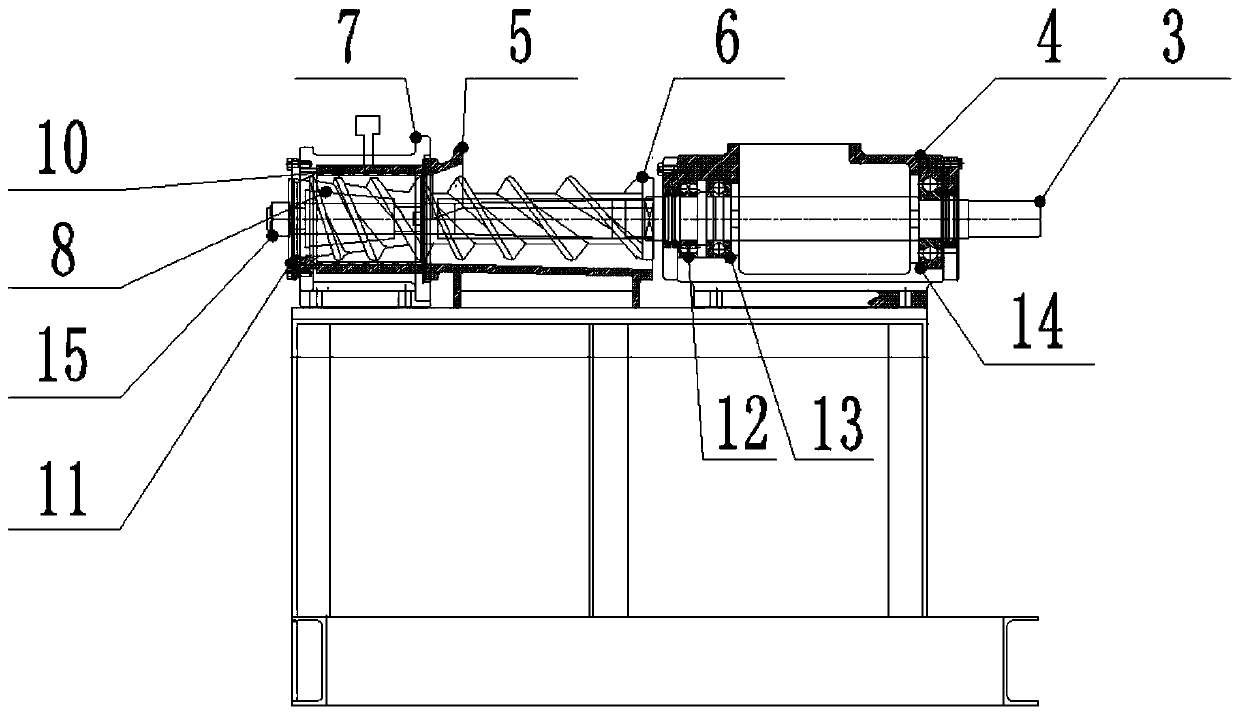

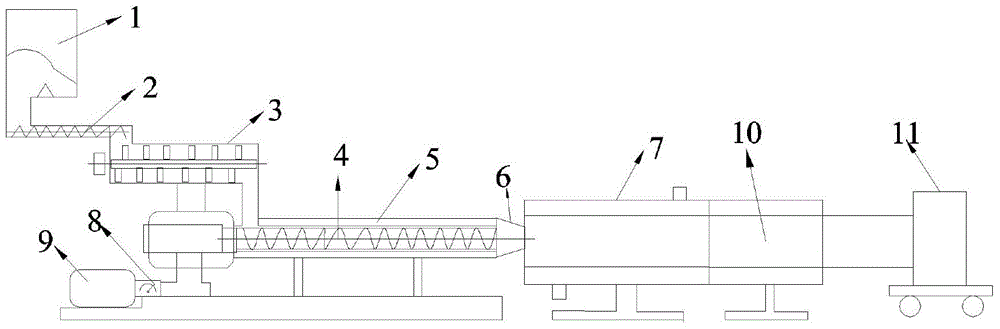

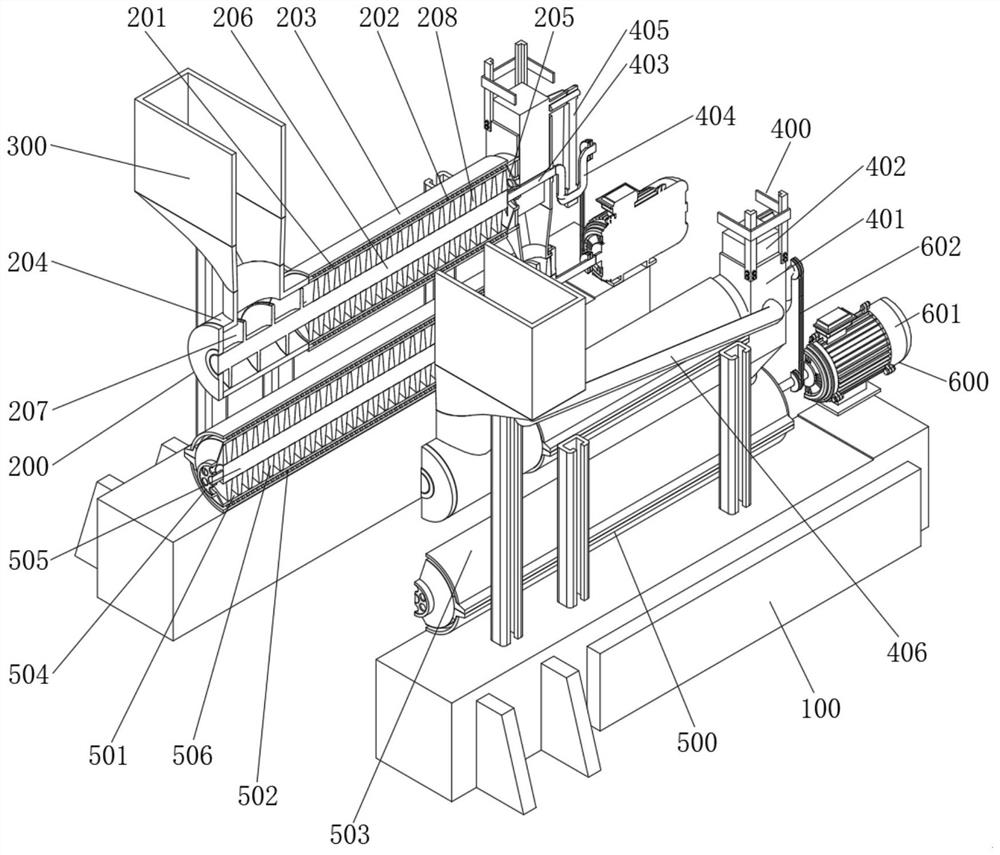

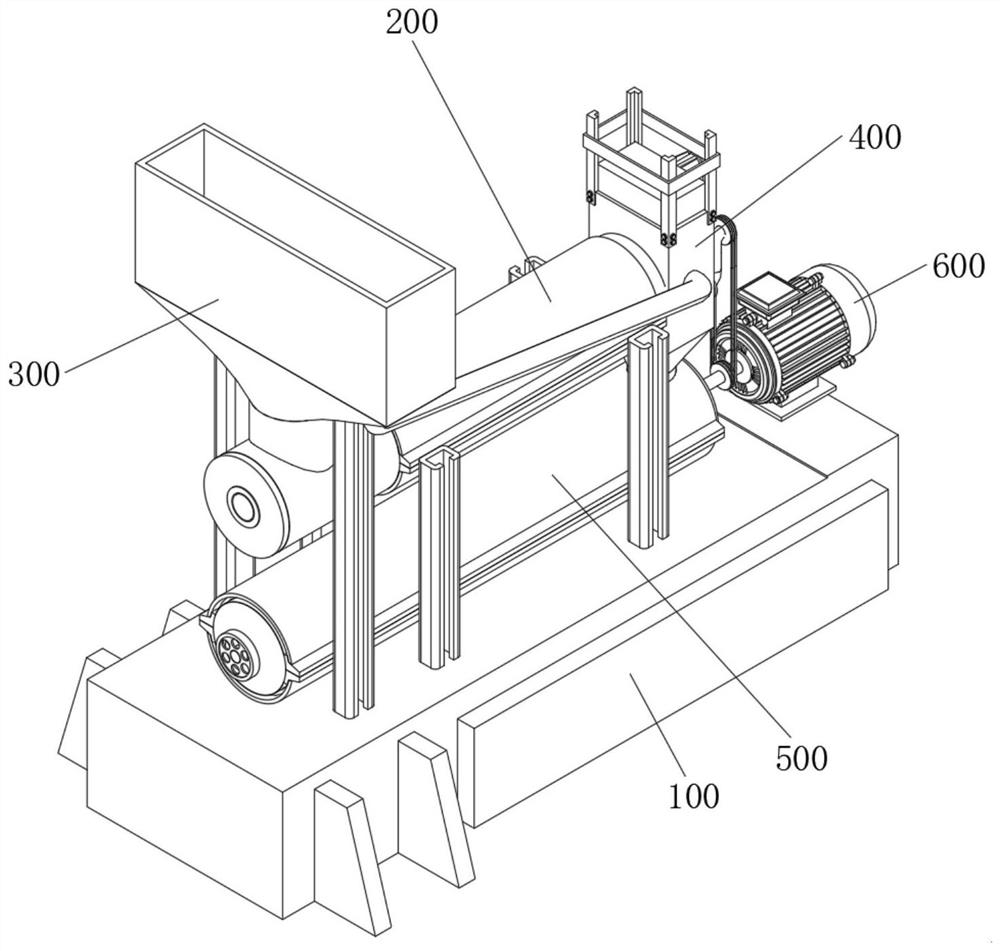

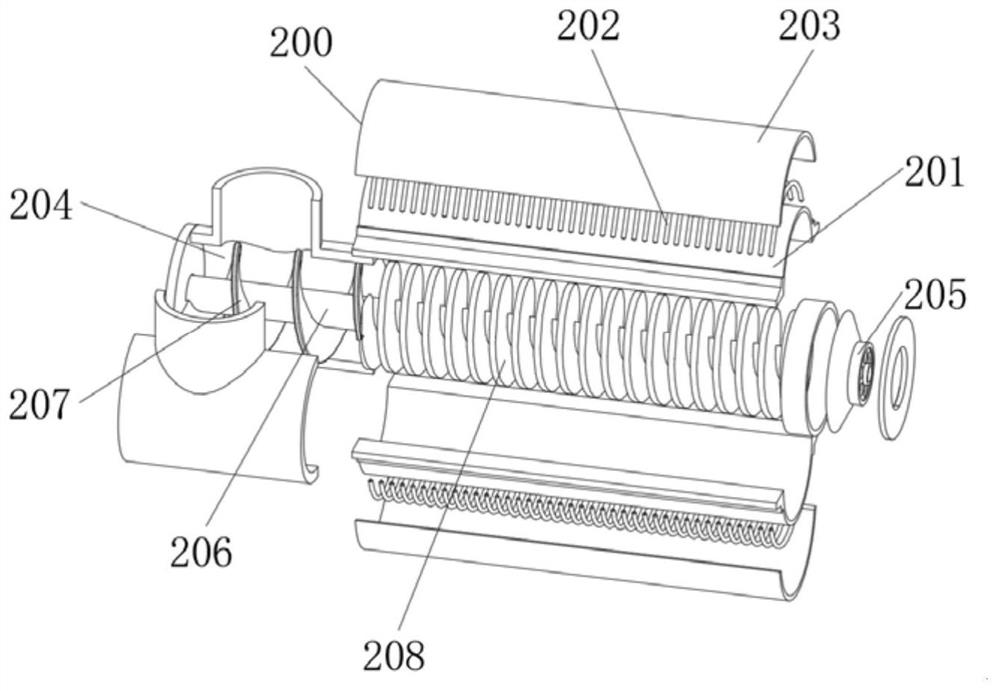

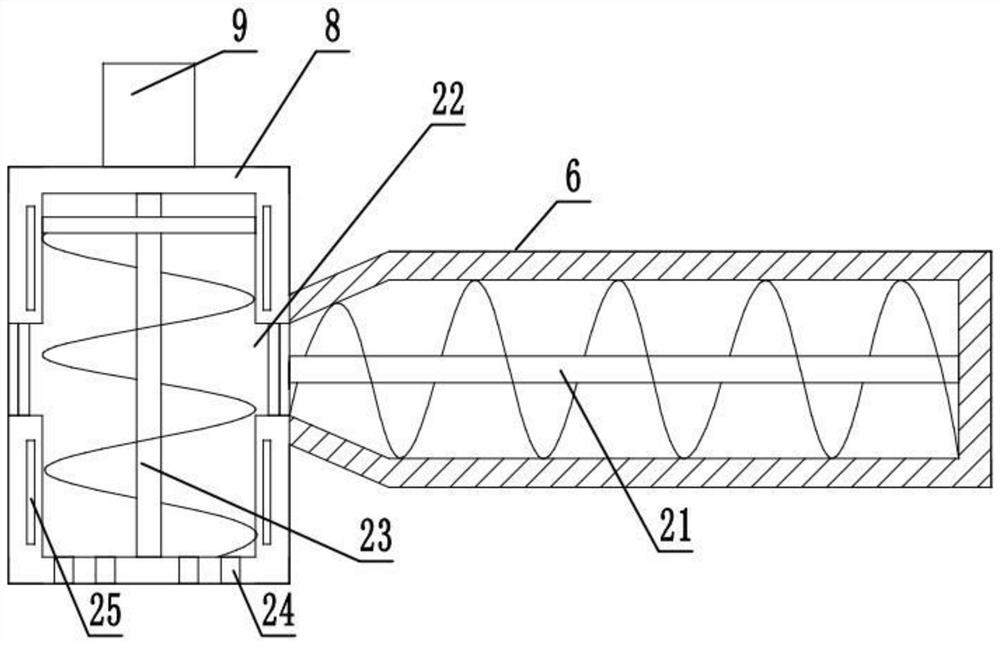

Secondary smashing extruder for straw and method

PendingCN109998139AReduce the probability of cloggingAvoid cloggingFeeding-stuffChinese charactersEngineering

The invention relates to a secondary smashing extruder for straw and a method, and belongs to the field of agricultural machines. A transmission system is fixedly installed on the left side of a rackthrough bolts; a material smashing and pushing system is fixedly installed at the position in the middle of a groove of the rack through bolts and located on the right side of the transmission system;a feeding system is fixedly installed on a support shaped like the Chinese character tian behind the rack through bolts and located above the material smashing and pushing system; a high-temperatureand high-pressure extrusion system is fixedly installed on the right side of the groove of the rack through bolts and located on the right side of the material smashing and pushing system; a discharging system is fixedly installed on the right side of the rack through bolts; a material collecting system is fixedly installed on the front right portion of the rack and located below the discharging system. The secondary smashing extruder has the advantages that the situation that excessive materials are fed at a time so as to block an inlet is avoided, and the using safety of the machine is improved; the smashing efficiency is easily improved, and the blocking rate of the machine is easily reduced; the temperature in a heating extrusion bin is ensured, and the extrusion efficiency is improved.

Owner:JILIN UNIV

Novel preparation technique of energy conservation material for buildings

InactiveCN103359993ASolve the problems caused by insufficient warm-upImprove warm-up effectThermal insulationFire resistance

The invention discloses a novel preparation technique of an energy conservation material for buildings. The energy conservation material for buildings is obtained by mixing expanded perlite, cement and a gelation additive, wherein the expanded perlite is prepared by using the technique comprising the following steps of: uniformly enabling the perlite ore sand to flow through a sand frying furnace using a feeding control device, preheating the perlite ore sand to 250-350 DEG C, inputting the preheated perlite ore sand to a gas furnace, heating to ensure that the perlite ore sand is rapidly expanded to obtain the expanded perlite, and controlling the outflow amount of the expanded perlite to convey partial expanded perlite to the sand frying furnace to form hot sand reflow heat supply, so that the heat energy of the partial expanded perlite can be used for uniformly and circularly preheating the perlite ore sand flowing in the sand frying furnace to cause all the perlite ore sand to reach the preheating temperature to be expanded to form the expanded perlite. The energy conservation material for buildings prepared by using the novel preparation technique disclosed by the invention not only has the characteristics of light weight, environmental-friendliness, and efficient thermal insulation, but also is environment-friendly, capable of realizing A-grade fire resistance, convenient to construct, unlikely to absorb water, expand, crack and fall off, high in durability, and long in service life.

Owner:江西佰科建筑节能材料有限公司

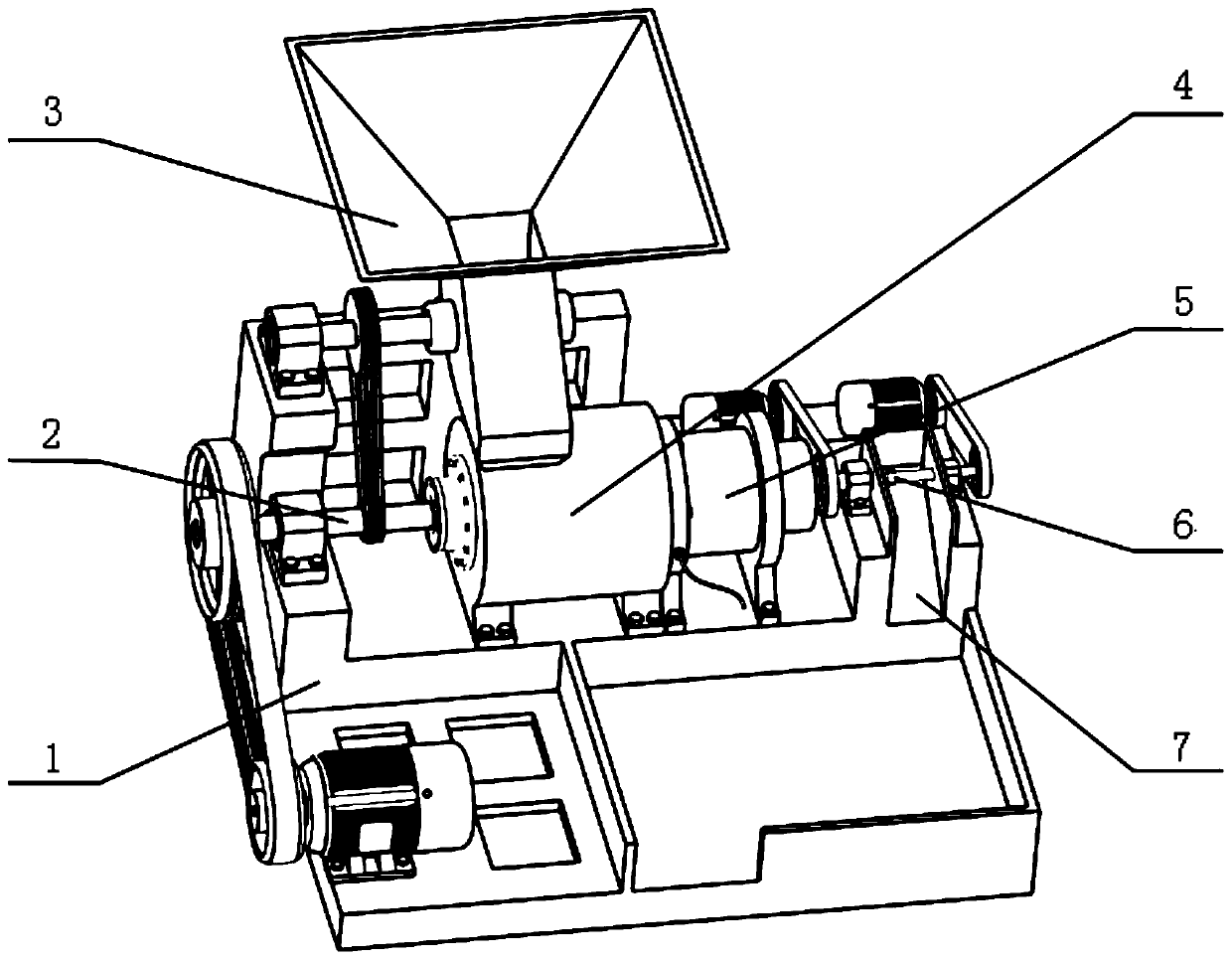

Biological feed extruder

InactiveCN107874311AImprove puffing efficiencyGood puffing effectFeeding-stuffFood shapingElectric energyEngineering

The invention relates to a biological feed extruder which comprises a base, an extruder body, an extruding nozzle, a rotary shaft, an auger blade, a charging pipeline I, a first motor, a charging pipeline II, a push plate, a ball nut pair, a second motor, a lead screw and a charging hole, wherein the extruding nozzle is formed in the left end of the extruder body; the charging pipeline I is arranged on the right side of the extruder body on the upper end surface of the base; the right end of the rotary shaft is fixedly connected to the output end of the first motor; the charging hole is formedin the left end of the charging pipeline II; the push plate is slidably connected in the charging pipeline II; the ball nut pair is fixedly arranged on the top end in the charging pipeline II; the lead screw is assembled in the ball nut pair; the lower end of the lead screw is in contact with the push plate; and the top end of the lead screw is fixedly connected to the output end of the second motor. According to the design, the biological feed is compressed by means of electric energy and then is fed into the extruder body to be extruded, and meanwhile, the feed needs not to be charged manually, so that the extruding efficiency is improved and the extruding effect is enhanced.

Owner:朱宗华

Method for preparing chicken feed

ActiveCN104054909APromote digestion and utilizationRich sourcesFood processingAnimal feeding stuffAnimal scienceProtein materials

The invention provides a method for preparing a chicken feed. The method comprises the following steps: firstly, adding mushrooms roots to the feed for the first time, reutilizing the waste mushrooms roots, meanwhile, matching with pigskin and a silkworm chrysalis material, so as to reduce the addition of the conventional protein in the feed. The feed cost is reduced, the puffed pigskin not only can be used as one of the protein materials in the feed by pigskin puffing in the feed, but also the volume is increased, and the space of the stomach is occupied, so that the effect of controlling the food consumption of the chicken can be achieved. Loss of a nutrient substance in the pigskin is reduced on the basis of simplifying the operation process by control of the puffing process of the pigskin in the feed, and the quality of the feed prepared by the method disclosed by the invention is ensured.

Owner:SICHUAN GUOFENG ZHONGKE BIOTECH

Food puffing device having heat energy recycling function

InactiveCN111869914AReach the purpose of recyclingImprove recycling ratesDispersed particle filtrationFood shapingActivated carbon filtrationWater vapor

The invention discloses a food puffing device having a heat energy recycling function. The food puffing device comprises a box body, wherein a heating plate is embedded at the left end of the bottom of an inner cavity of the box body, and a first motor of which an output shaft is fixedly connected with a spiral auger is fixedly mounted at the middle end of the left side of the box body. A heat energy recovery mechanism is arranged, so that a glass fiber filtering layer and an activated carbon filtering layer can perform two-stage physical filtering treatment on hot air entering a filtering box, then a draught fan and an ultraviolet lamp tube are turned on through an external controller, and ultraviolet sterilization treatment is performed on the hot air in the filtering box through the ultraviolet lamp tube; the fan conveys filtered and sterilized hot air back to the bottom of the box body through a pipeline, so that the purpose of recycling heat energy is achieved, besides, water vapor generated in the raw material puffing process can be filtered and adsorbed, the food puffing efficiency is also improved when the heat energy recycling rate is increased, and the food puffing deviceconforms to the benefits of enterprises.

Owner:杭州迹童精密机械有限公司

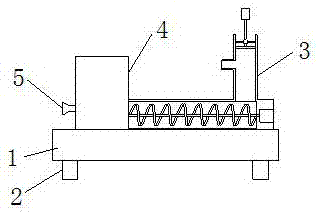

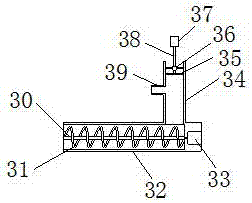

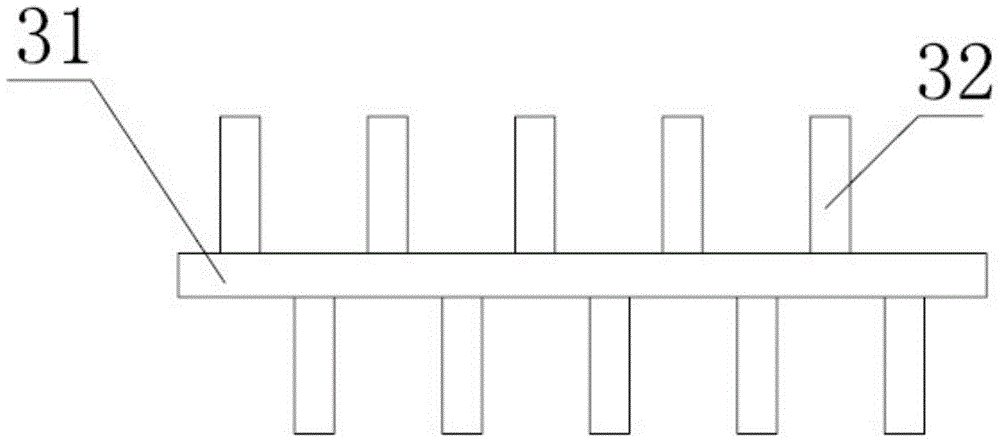

Straw puffing machine

PendingCN110122673AReduce processing costsIncrease profitFeeding-stuffWorking-up animal fodderHelical lineMechanical energy

The invention relates to a straw puffing machine. A disintegrating guide rod is a double-helix guide rod, the lead of the disintegrating guide rod is gradually reduced from a feed inlet to a dischargeoutlet, and the bottom diameter of the disintegrating guide rod is gradually increased from the feed inlet to the discharge outlet. The outer contour of the disintegrating guide rod is of a cylinder.The bifilar-helix design of the disintegrating guide rod makes the equipment convey materials stably, mechanical energy is converted into heat energy, and heat generated by friction is rapid and uniform. Compared with conventional puffing machines, the straw puffing machine has the advantages that compression of the radial force is decreased, the noise is reduced, the service life of the equipment is prolonged, the materials are discharged smoothly, the yield is increased, and the quality of end products is improved. The disintegrating guide rod of the straw puffing machine pushes the materials toward the discharge outlet along with the gradually shallow helical line, and the materials rub and squeeze a spiral sleeve to be broken. High temperature and high pressure are generated during operation, water molecules are rapidly expanded, and the materials are instantaneously sprayed, disintegrated and puffed by a disintegration ring. Compared with the conventional puffing machines, the straw puffing machine has the advantage that the yield is increased by 30% on the basis of the same power.

Owner:内蒙古坤珍天禧农牧科技有限责任公司

A tower type microwave graphite expansion equipment

The invention discloses tower-type graphite expanding microwave equipment. Through adoption of a tower-type structure, by virtue of a feeding device on a tower body and the gravity, a graphite material is uniformly sent to a heating chamber for microwave heating expansion, so that a phenomenon of incomplete partial expansion due to nonuniform spreading of the graphite material can be reduced and the yield is increased; compared with the conventional expanding way, an expanding way provided by the invention has the advantages as follows: the tower-type graphite expanding microwave equipment issimple in structure and low in cost, the expanding way is easy to implement, and by the expanding way, the graphite expanding production efficiency can be greatly improved. The tower-type graphite expanding microwave equipment, comprises an overall equipment framework, the tower body, a cooling device and a control console, wherein the tower body is mounted inside the overall equipment framework;a smoke exhausting device, a heating chamber, a cooling buffer bin and a discharging device are sequentially arranged on the tower body from top to bottom; a feeding device is arranged beside the smoke exhausting device.

Owner:广州越能工业微波设备有限公司

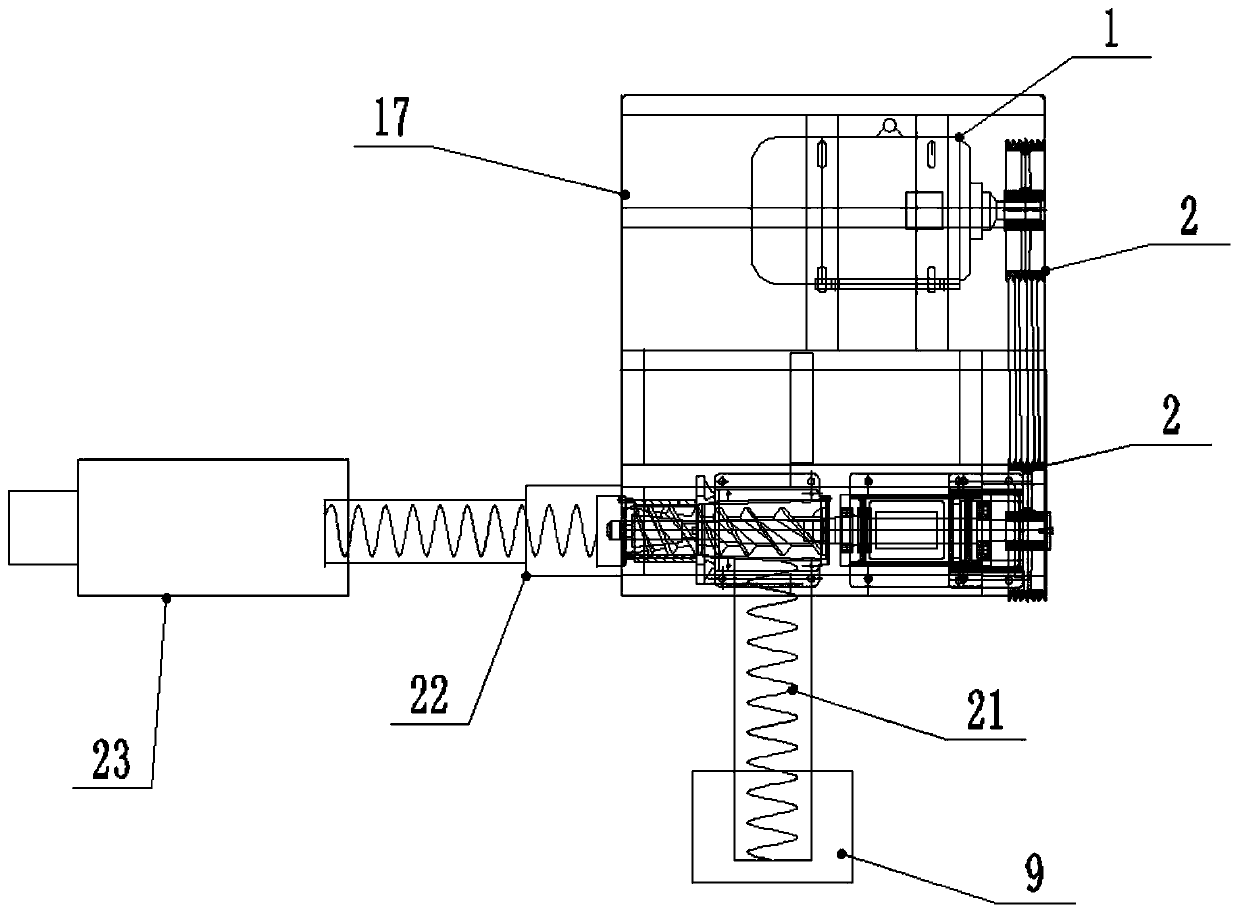

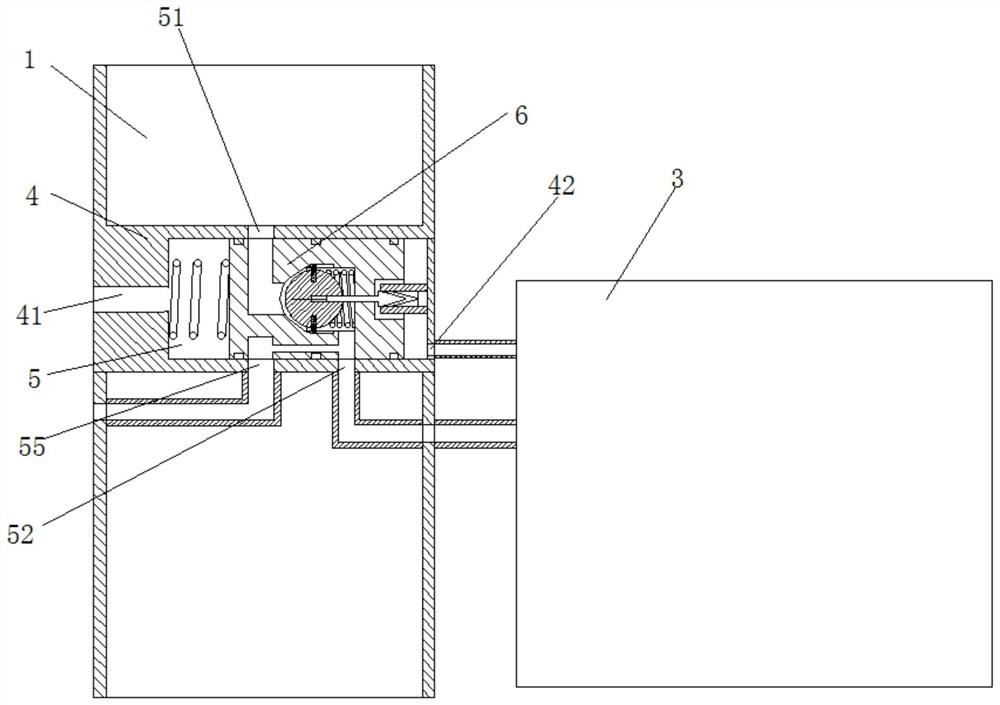

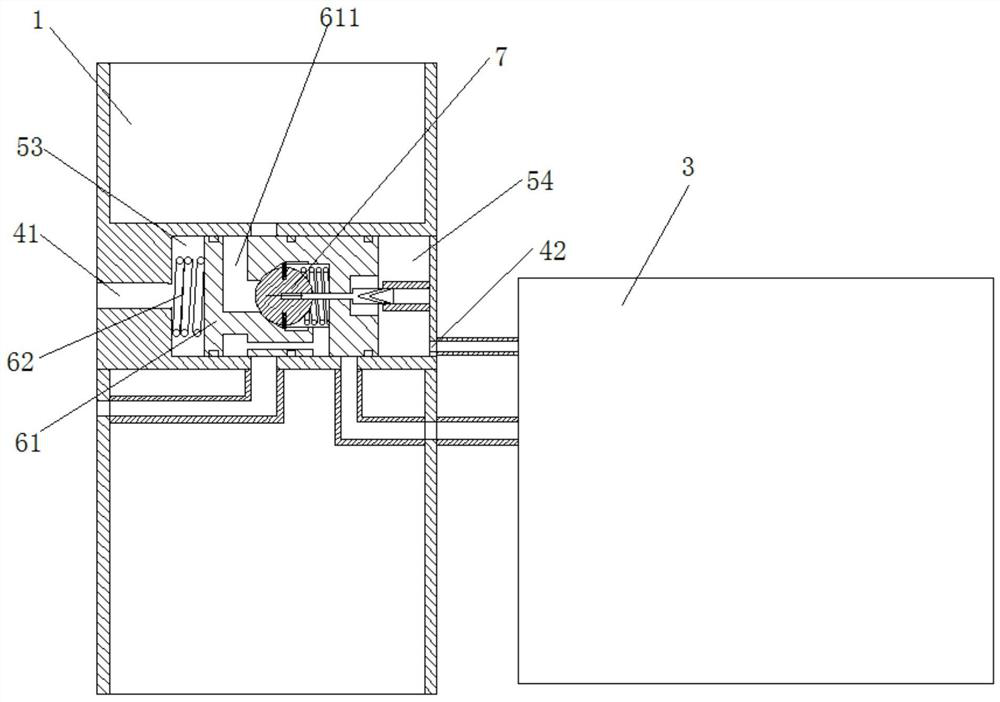

Puffing self-locking device for ice cream machine

The invention discloses a puffing self-locking device for an ice cream machine. The device comprises a feeding channel, the feeding channel is used for communicating a material storage box and a material barrel, a baffle block is arranged in the feeding channel, an adjusting cavity is arranged in the baffle block, the adjusting cavity is provided with a feeding hole communicated with the material storage box and a discharging hole communicated with the material barrel, an adjusting mechanism is arranged in the adjusting cavity, and the feeding hole and the discharging hole are selectively communicated through the adjusting mechanism. When air pressure during ice cream making in the material barrel reaches a critical value, the adjusting mechanism starts to work, so that the feeding hole and the discharging hole are not communicated, the discharging hole is sealed in advance before ice cream in the material barrel is expanded to block the discharging hole, and meanwhile, the situation that gas in the material barrel is extruded out to reduce the gas in the material barrel is prevented, and therefore, the sealing performance of the material barrel is ensured, and the puffing efficiency of the ice cream is improved; and by additionally arranging the material storage box and the feeding channel, the hardness of the ice cream can be controlled, so that ice cream with different tastes can be made, and the use experience of a user is improved.

Owner:ZHONGSHAN DONLIM WEILI ELECTRICAL APPLIANCES CO LTD

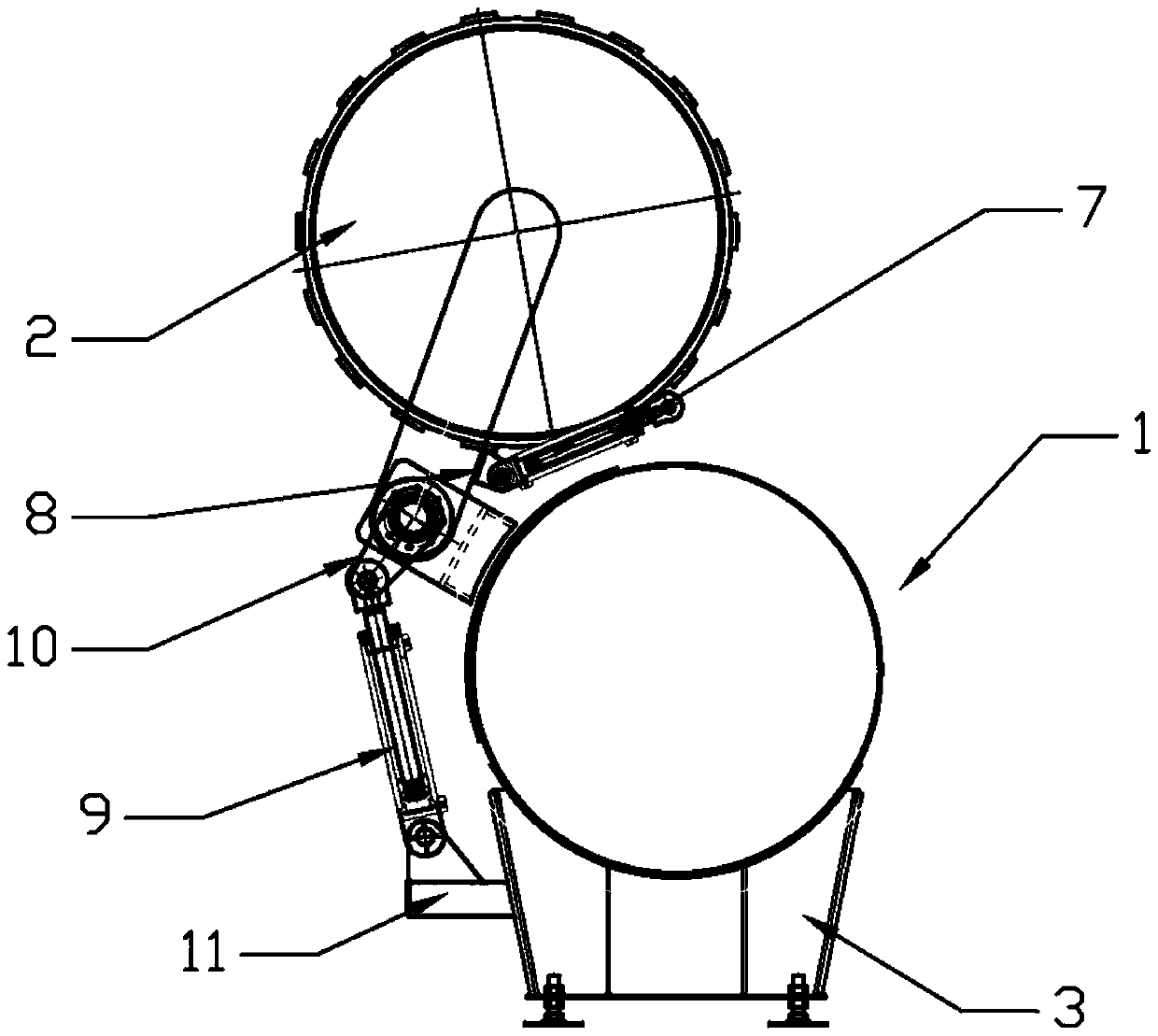

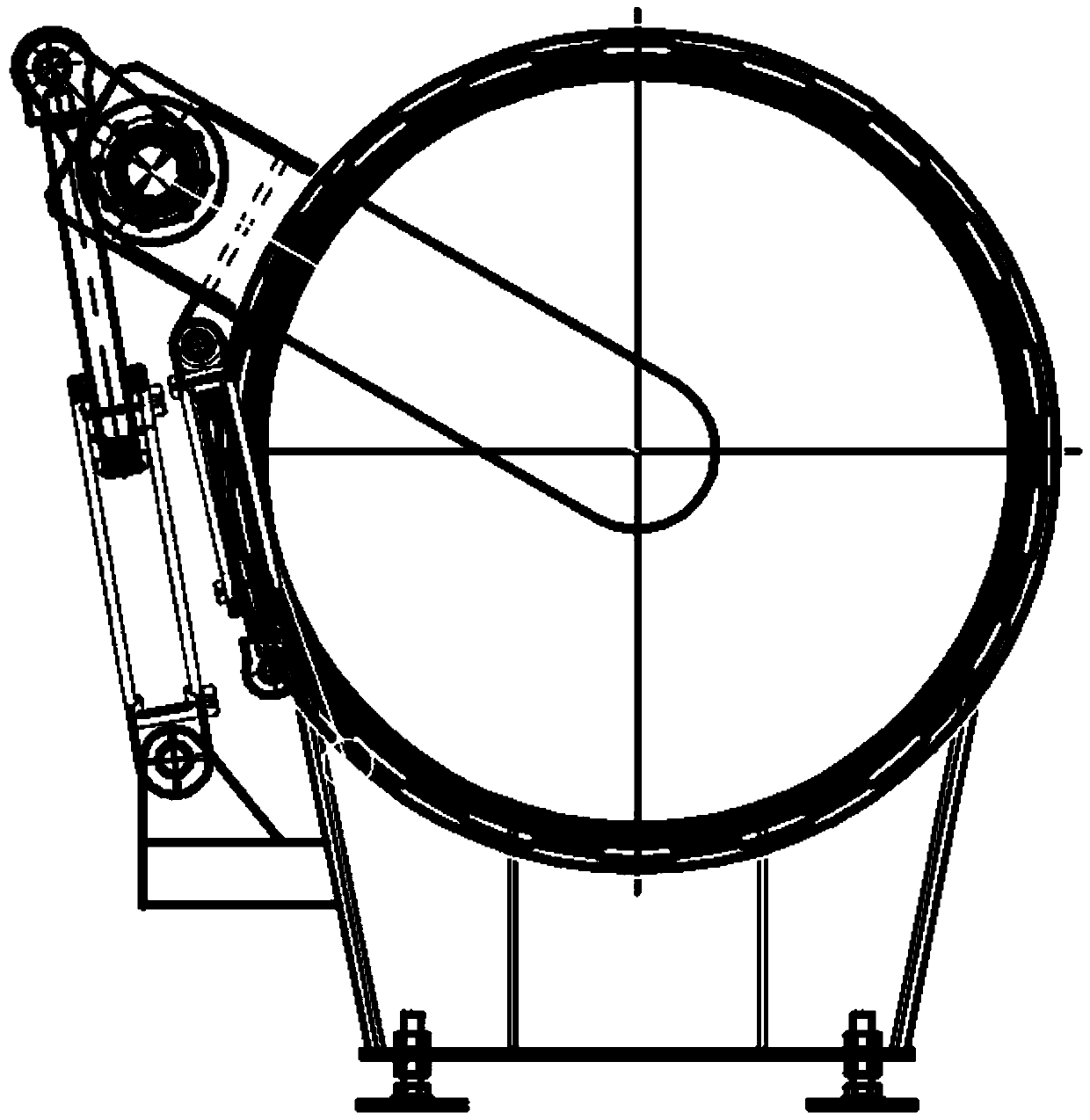

Rapid opening device for puffing equipment

InactiveCN109826526AWill not cause churnGreat tastePower-operated mechanismFood shapingAutomatic controlEngineering

The invention discloses a rapid opening device for puffing equipment. The rapid opening device comprises a puffing tank body, wherein one end of the puffing tank body is provided with an inlet / outlet, the inlet / outlet is provided with a movable cover body, the puffing tank body is arranged on a supporting base, the center of the cover body is provided with a connecting arm, the upper portion ofone side of the puffing tank body is provided with a support arm frame, the support arm frame is provided with a rotating shaft in the direction in accordance with the length direction of the puffingtank body, the upper end of the connecting arm is fixedly in fastening connection with one end of the rotating shaft, one side of the connecting arm is provided with a rotating connecting block, the rotating connecting block is hinged with a rotating oil cylinder, the other end of the rotating oil cylinder is hinged to the edge of one side of the cover body, and the middle of the rotating shaft isprovided with a rocker arm connecting block. The rapid opening device for the puffing equipment has the advantages that the defects in the prior art are overcome, the structure is reasonable, the manpower is saved by hydraulically opening the inlet / outlet, automatic control is achieved, and space is saved by opening the inlet / outlet upward.

Owner:山东嘉信工业装备有限公司

Method for preparing extruded animal feed from corn

InactiveCN108174973AImprove puffing efficiencyAnimal feeding stuffWorking-up animal fodderAcetic acidAdditive ingredient

The invention discloses a method for preparing extruded animal feed from corn. The method specifically comprises steps as follows: airing: corn is aired and dried; threshing: the aired corn is threshed through a thresher, and dried corn granules are obtained; crushing: large corn granules are crushed into small granules of 8-10 meshes by a crusher, and the granules are transferred to a storage house for storage, timed sampling is performed on water content of the corn granules during storage, the water content of the corn granules is maintained at 14%-18%, and if the water content is higher than the value, the stored corn granules are taken out and aired. A biological extruding agent is adopted, acetic acid in white vinegar or fruit vinegar and calcium carbonate ingredients in animal bonemeal are used to produce carbon dioxide, at the moment, soybean meal is matched for coating the corn granules, so that carbon dioxide gradually permeates into the dried corn granules, the extruding efficiency is improved in the later extrusion process, meanwhile, no heavy metal addition ingredients are used in the whole process, and the whole process is safer.

Owner:颍上县骏驰新能源有限公司

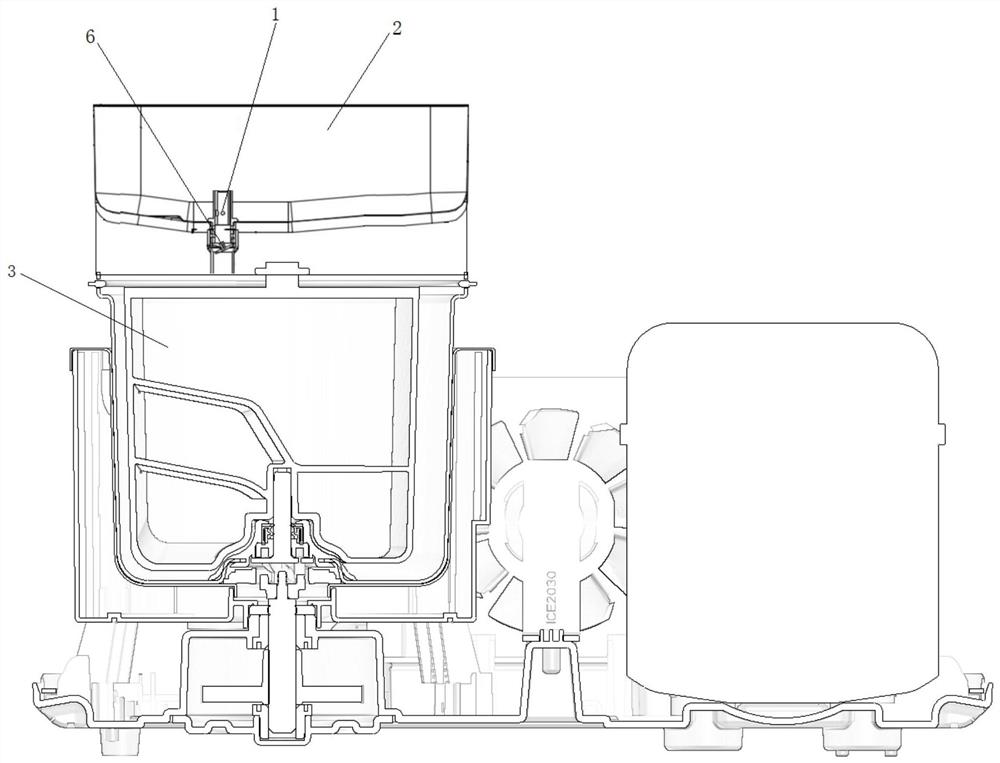

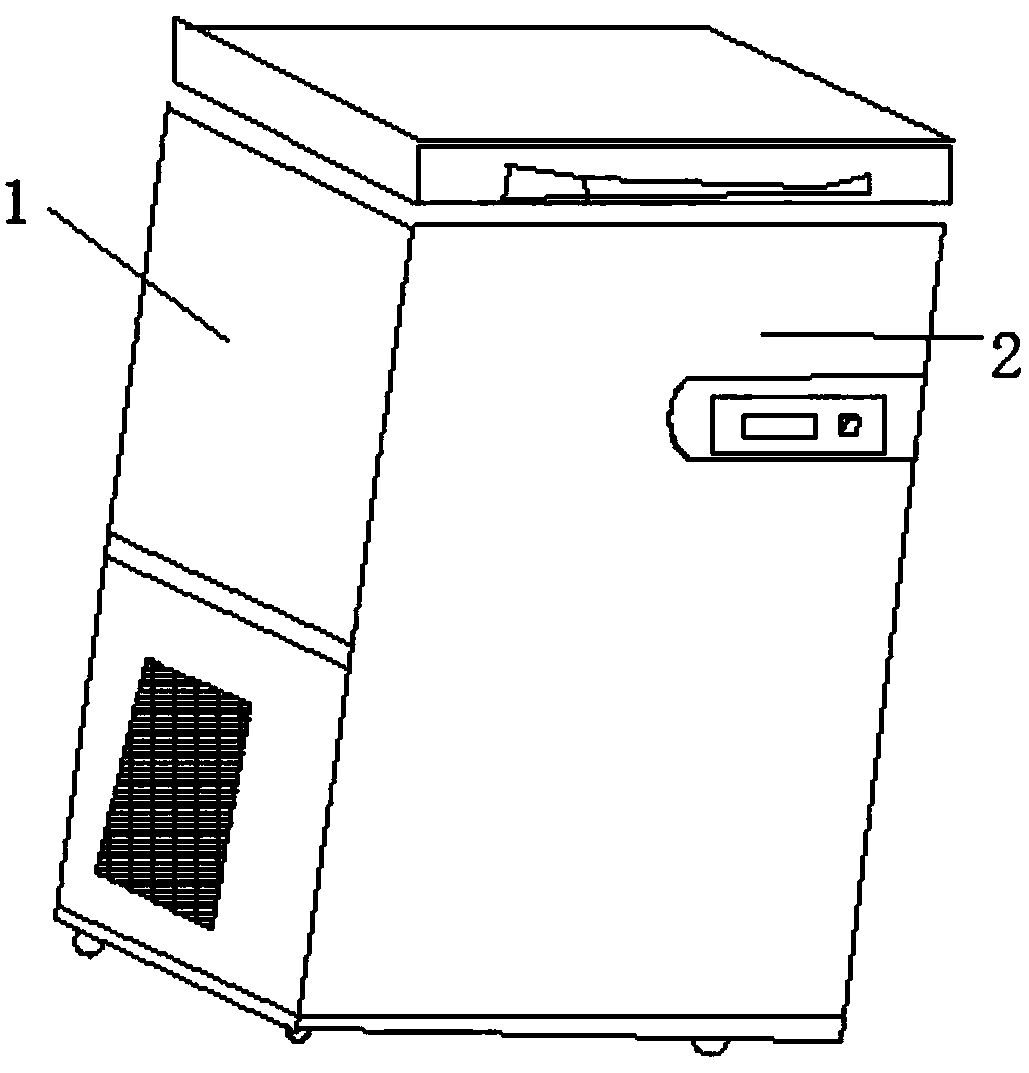

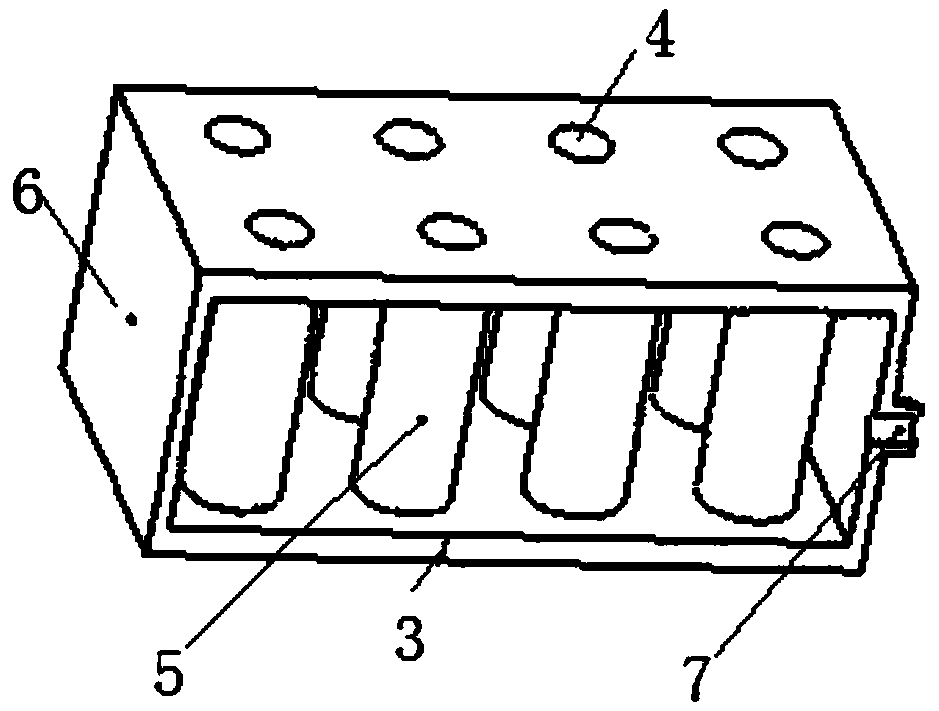

Test tube freezer

PendingCN108212260ASimple structureStable heat transferCryostatsTest tube stands/holdersEvaporationEngineering

The invention discloses a test tube freezer which comprises an outer body and a refrigeration system located in the outer body, wherein an evaporator is mounted in the outer body; at least one test tube hole is formed in a top plate of the evaporator; the test tube holes are tightly connected with test tube racks; the test tube racks are located in the evaporator; a liquid refrigerant inlet is formed at one end of the evaporator; a gas refrigerant outlet is formed at the other end of the evaporator; and the refrigerant inlet and the refrigerant outlet are connected with the refrigeration system. The effective evaporation capacity of the novel evaporator of the test tube freezer is large; the gasification efficiency of a liquid refrigerant is high; the refrigeration capacity power is large;the heat exchange area between test tubes and the refrigerant is large; the evaporator directly provides test tube refrigeration capacity; a refrigeration capacity transfer path of the refrigerant isshortened; and the refrigeration efficiency of the test tubes is improved.

Owner:ZHEJIANG HELI REFRIGERATION EQUIP

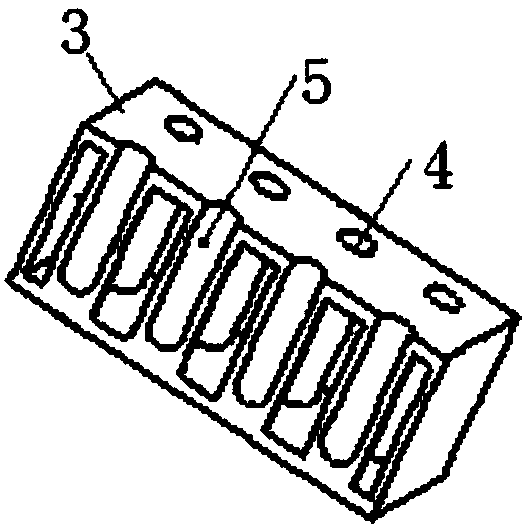

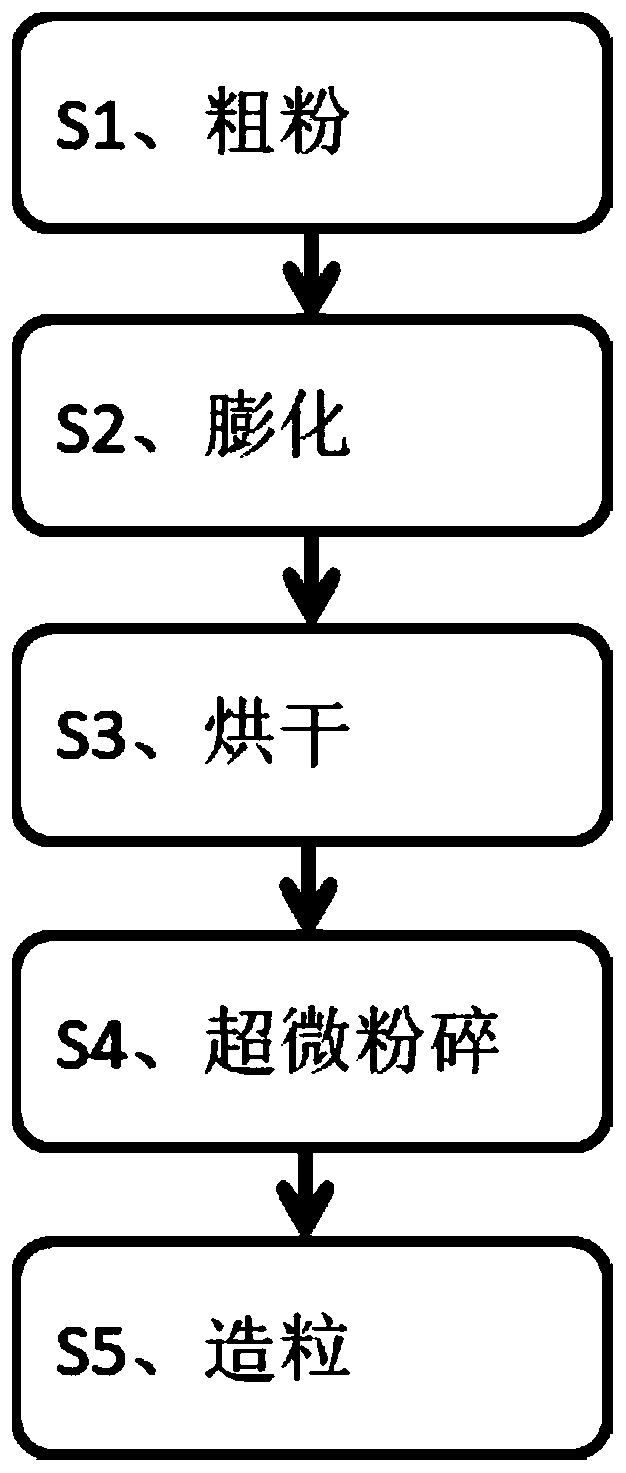

Manufacturing process and manufacturing device of myotonin granules

The invention discloses a manufacturing process of myotonin granules, wherein the process comprises the following steps: S1, coarse powder obtaining: crushing myotonin grains into powder; S2, puffing:gelatinizing starch of the myotonin powder produced by the step S1; S3, drying: drying puffed myotonin produced by the step S2; S4, ultrafine crushing: crushing the myotonin powder after being driedin the step S3 into ultrafine particles; and S5, granulation: granulating the ultrafine particles produced by the step S4. The problems that myotonin products of the prior art either has time-consuming and complex processing technology before eating or needs constant stirring due to easy agglomeration and caking during brewing are solved. A used manufacturing device has the advantages of high processing efficiency, energy saving and easy automation production.

Owner:贵州薏道科技有限公司

An integrated process of puffing and forming of low-temperature foam glass insulation material

Owner:宁波荣山新型材料有限公司

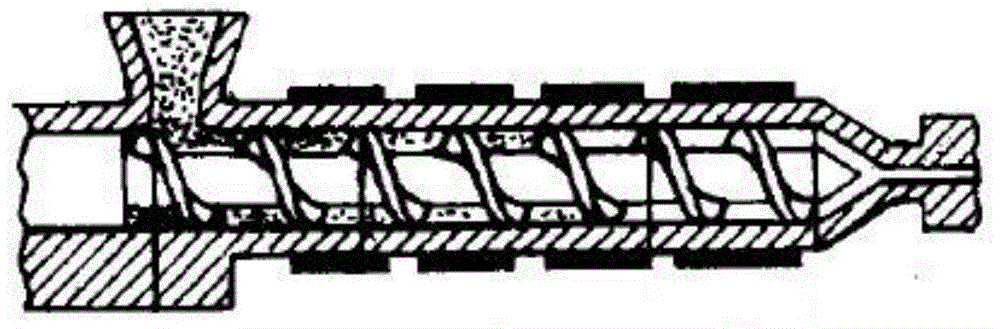

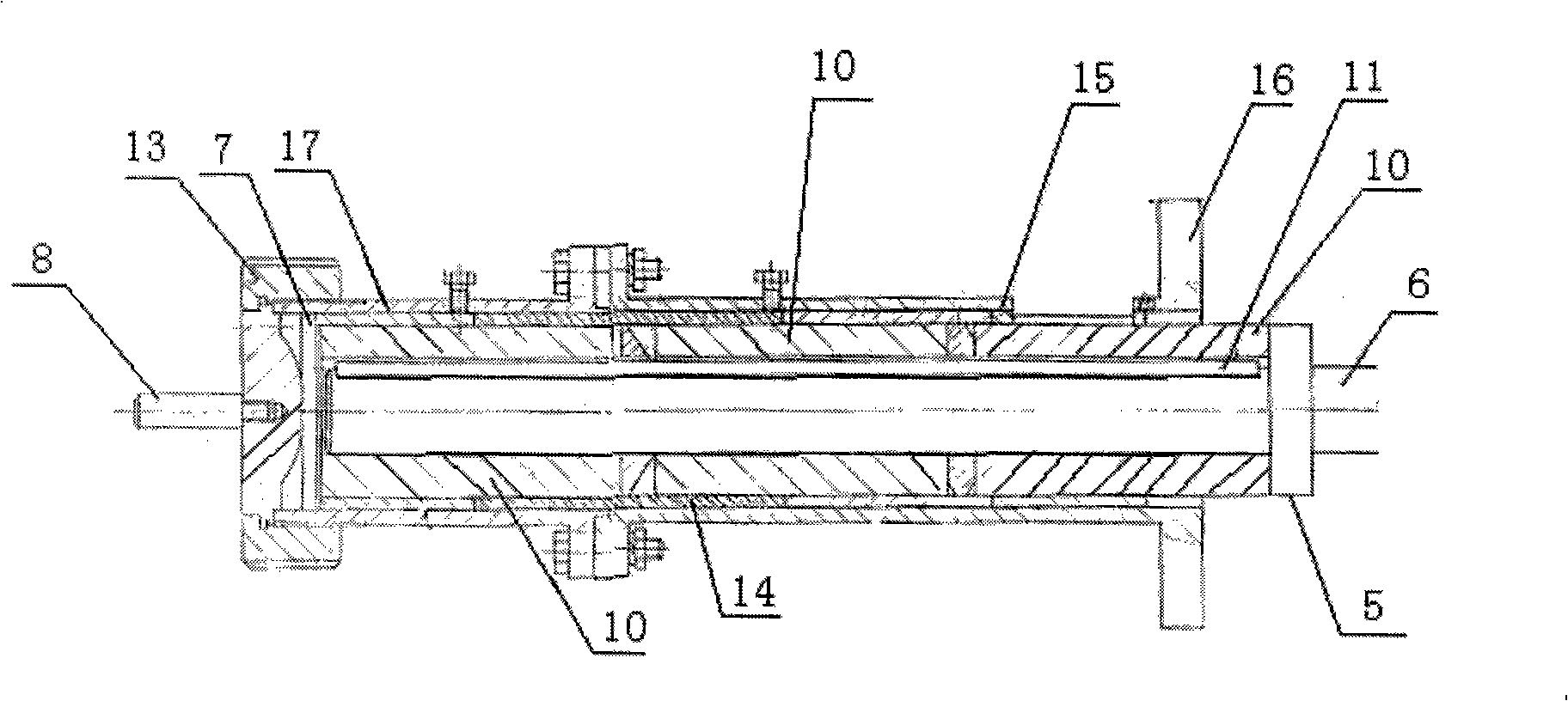

Blood powder protein puffing machine

InactiveCN101326957BMove fastThe problem of not breaking the balanceAnimal feeding stuffWastewaterSewage

The invention discloses a blood meal protein bulking machine which comprises a power part, a feed hopper, a feed opening and a bulking part; a power shaft is connected with a material pushing pressurizer and drives an animal material pushing pressurizer to move; the material pushing pressurizer is connected with the power shaft in a three-point way; the rotating speed of the power shaft is 580 to700 r / min; the tail end of the material pushing pressurizer is provided with a grinding plate; the grinding plate is provided with a plurality of grinding holes; the diameter of each grinding hole is2.2mm to 3.2mm; the other side of the grinding plate is provided with a bulking head; one end of the bulking head which contacts with the grinding plate is a semicircle R; the thread pitch of the material pushing pressurizer is two-end thread; the front end on the inner side of an outer tube is provided with an internal thread bush, and the rear end is provided with a light bush; the internal thread bush, the light bush and a bulking outer cover realize the three-joint pushing of the material pushing pressurizer. The blood meal protein bulking machine of the invention has high bulking rate, the product bulking degree is 1 to 23, the production process does not produce wastewater, and the production output is high.

Owner:李国明

feed pellet machine

ActiveCN112385871BControl opening and closing functionImprove puffing efficiencyFeeding-stuffEngineeringMechanical engineering

The invention discloses a feed granulator, which comprises a lower material cylinder, an extruding cylinder is installed at one end of the lower material cylinder, moving grooves are arranged on both sides of the inner cavity of the lower material cylinder, and an extruding cylinder is installed at one end of the expanding cylinder. Pressing cylinder, the inner cavity of the lower material cylinder is movably equipped with a piston rod, fixed seats are installed on both sides of the piston rod, and the fixed seats slide in the inner cavity of the moving groove, and a telescopic mechanism is installed at one end of the fixed seat, specifically related to feed production area. The invention not only completes the function of feeding the material to the inner cavity of the puffing cylinder by setting the piston rod, but also cooperates with the telescopic mechanism to realize the rolling function of the inner cylinder of the puffing cylinder. When the inner cylinder rolls Not only can it drive the raw materials in the inner cavity to perform tumbling and stirring operations, thereby improving the puffing efficiency, but also realizes the opening and closing function of the entrance and exit of the control high-temperature steam entering the inner cavity when the inner cylinder rotates.

Owner:沈阳美佳营养科技有限公司

Blood powder protein puffing machine

InactiveCN101326957AMove fastThe problem of not breaking the balanceAnimal feeding stuffWastewaterEngineering

The invention discloses a blood meal protein bulking machine which comprises a power part, a feed hopper, a feed opening and a bulking part; a power shaft is connected with a material pushing pressurizer and drives an animal material pushing pressurizer to move; the material pushing pressurizer is connected with the power shaft in a three-point way; the rotating speed of the power shaft is 580 to 700 r / min; the tail end of the material pushing pressurizer is provided with a grinding plate; the grinding plate is provided with a plurality of grinding holes; the diameter of each grinding hole is 2.2mm to 3.2mm; the other side of the grinding plate is provided with a bulking head; one end of the bulking head which contacts with the grinding plate is a semicircle R; the thread pitch of the material pushing pressurizer is two-end thread; the front end on the inner side of an outer tube is provided with an internal thread bush, and the rear end is provided with a light bush; the internal thread bush, the light bush and a bulking outer cover realize the three-joint pushing of the material pushing pressurizer. The blood meal protein bulking machine of the invention has high bulking rate, the product bulking degree is 1 to 23, the production process does not produce wastewater, and the production output is high.

Owner:李国明

Feed granulator

ActiveCN112385871AControl opening and closing functionImprove puffing efficiencyFeeding-stuffEngineeringMechanical engineering

The invention discloses a feed granulator. The feed granulator comprises a feeding cylinder, wherein a puffing cylinder is installed at one end of the feeding cylinder, moving grooves are formed in two sides of an inner cavity of the feeding cylinder, an extrusion cylinder is installed at one end of the puffing cylinder, a piston column is movably installed in the inner cavity of the feeding cylinder, fixing bases are installed on two sides of the piston column, and the fixing bases are located in inner cavities of the moving grooves in a slide manner, and a telescopic mechanism is installed at one end of each fixing base. The invention specifically related to the field of feed production. According to the feed granulator, by arranging the piston column, the function of feeding materials into an inner cavity of the puffing cylinder is achieved when the piston column moves forwards, the piston column is further matched with the telescopic mechanisms to achieve the rolling function of aninner cylinder of the puffing cylinder, when the inner cylinder of the puffing cylinder is rolled, the raw materials in the inner cavity of the puffing cylinder can be driven to roll and stir to promote puffing efficiency, and when the inner cylinder of the puffing cylinder is rotated, the function of controlling opening and closing of an inlet and an outlet of high-temperature steam entering theinner cavity of the puffing cylinder is achieved.

Owner:沈阳美佳营养科技有限公司

Puffed pea type suckling pig feed

InactiveCN110463839AImprove use valueExtended shelf lifeFood processingAnimal feeding stuffAnimal scienceThreonine

The invention relates to the technical field of the livestock feed, in particular to a puffed pea type suckling pig feed and a preparing method thereof. The puffed pea type suckling pig feed is prepared from corn, bean pump, puffed peas, puffed soybeans, fish meal, calcium hydrophosphate, rock flour, lysine, methionine, threonine, tryptophan and premix. By means of the obtained puffed pea type suckling pig feed, the daily feed intake and daily gain of suckling pigs are both remarkably increased, the feed cost can be as low as about 50 RMB per tonnage, and the price-to-meat ratio is reduced byabout 0.16 RMB per kilogram; after the peas are processed through a special puffing process, the storage period of the peas can be sufficiently prolonged, the retrogradation of starch is effectively prevented, the quality of the obtained puffed peas cannot be affected even after the peas are stored for a long time, the puffed peas can be stored for a long time, and the feed prepared from the peascan also be stored for a long time.

Owner:贵阳新希望农业科技有限公司

Novel fattened pig compound feed and preparation method thereof

The invention discloses a novel fattened pig compound feed and a preparation method thereof. The novel fattened pig compound feed is prepared from the following raw materials in percentage by weight: 35-50 percent of corns, 20-35 percent of puffed peas, 15-40 percent of wheat and 3-4 percent of a premix. According to the digestion physiological characteristic of a fattened pig, the peas, the corns and the wheat, which are high in biological utilization rate, are used as basic feed materials, and synthesized creatine monohydrate is creatively mixed with glucose, D-pinitol and other additives to replace conventional fish meal, so that under a condition of reducing the feeding cost, the lean rate is increased, the growth speed is increased, the digestion absorption rate is improved, and the resistance to pathogens is enhanced; nitrogen emission is alleviated, and the feeding environment is improved. Meanwhile, an advanced puffing technology is adopted, so that the puffing efficiency and the fat digestion rate as well as the palatability of the feed are improved. The novel fattened pig compound feed has the characteristics of high lean rate, stable quality, low cost, high fat digestion rate, high palatability, low excrement pollution and the like and has a high popularization value.

Owner:QUJING DAXING FEED

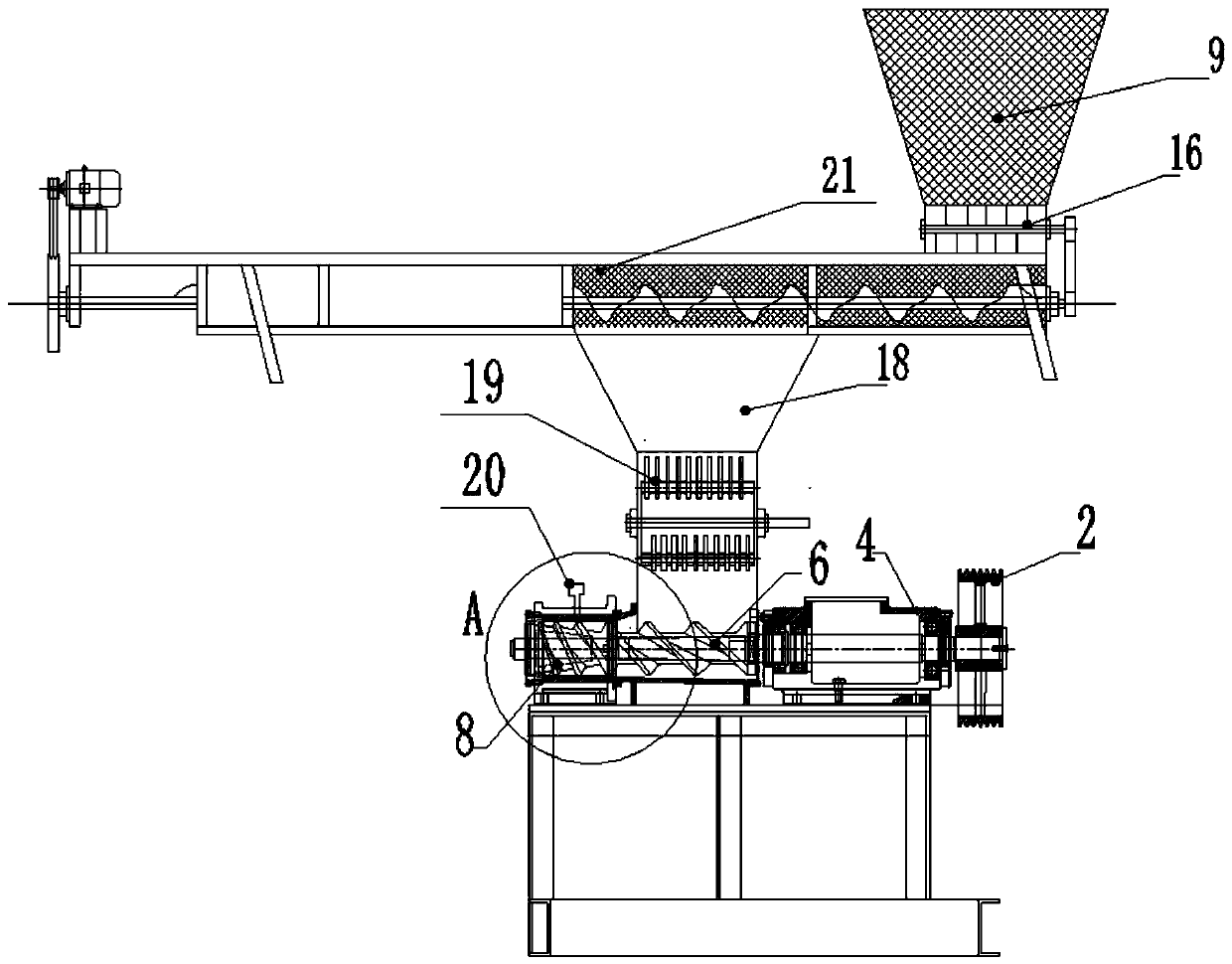

Feed processing bulking machine capable of improving material gelatinization degree and Ophiocealu sargus feed processing technology

InactiveCN113383977AHigh degree of gelatinizationImprove puffing efficiencyFeeding-stuffClimate change adaptationBiotechnologyAnimal science

The invention relates to the technical field of processing of Ophiocealu sargus feed, in particular to a feed processing bulking machine capable of improving the gelatinization degree of materials and a Ophiocealu sargus feed processing technology. The bulking machine comprises a base, the top of the base is fixedly provided with a section of bulking mechanism through a support, and the top of one end of the front face of the section of bulking mechanism is fixedly connected with a feeding hopper; one end of the back surface of the first-section bulking mechanism is connected with a second-section bulking mechanism through a switching mechanism, and a power mechanism is fixedly mounted at the top of one end of the back surface of the base. The first-section puffing mechanism and the second-section puffing mechanism are communicated with each other, cereal raw materials are subjected to puffing operation in advance by means of the first-section puffing mechanism, and then secondary gelatinization puffing is performed by means of the second-section puffing mechanism, so that the gelatinization degree of the cereal raw materials is effectively improved when the device is used for processing the Ophiocealu sargus feed, and the puffing efficiency of the Ophiocealu sargus feed during production and processing can be conveniently improved.

Owner:佛山市顺德区旺海饲料实业有限公司

A two-way pressurized feed puffing processing device for agricultural breeding

ActiveCN111493345BHigh degree of automationRapid puffingFeeding-stuffGranulation by material expressionAgricultural scienceAgricultural engineering

The invention discloses a two-way pressurized feed puffing processing device for agricultural breeding, which comprises a frame, the frame has a plurality of support legs and a support platform, a raw material box is arranged above the frame, and an extrusion There is a pressurized conveying cylinder connected to it at the central position on both sides of the extruding cylinder. The pressurized conveying cylinder is embedded on the support leg and fixedly connected with the support leg; The raw material inside the extrusion barrel is pressurized, and the raw material is extruded downward through the extrusion barrel to heat the raw material at high temperature. The multi-directional pressurization method can quickly expand the feed, and the extruded feed is collected and cooled through the finished product box , with a high degree of automation; through the setting of the anti-backflow structure, the opening between the fixed switch plates is intermittently opened, which can prevent the transfer of raw materials to both sides, ensure sufficient pressure, and enable the raw material transfer process through the intermittently closed openings. A certain pressure can be obtained in the middle, and the puffing efficiency can be improved.

Owner:湖北省思乐牧业集团恩施市法希饲料有限公司

Microwave puffing Chinese chestnut food and manufacturing method thereof

ActiveCN103719943BNutritional balanceAppropriate tasteFood ingredient functionsFood preparationMicrowaveMillet flour

The invention discloses a microwave puffing Chinese chestnut food and a manufacturing method thereof. In the Chinese chestnut food, Chinese chestnut powder, rice flour, and glutinous rice flour are used as raw materials, and nutrition enrichment supplements such as millet flour or soybean protein powder and the like are selectively added; after microwave puffing, the Chinese chestnut food has balanced nutrition, crispy tastes and is easy to eat and digest; moreover, the chestnut food is unlikely to cause adverse feelings such as flatulence and the like. The manufacturing method of the microwave puffing food is simple, feasible, easy to operate and widely used.

Owner:BEIJING UNIV OF AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com