An integrated process of puffing and forming of low-temperature foam glass insulation material

A technology of foam glass and thermal insulation materials, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low efficiency, large heat waste, discontinuous process, etc., and achieve strong process continuity, low production cost, The effect of high expansion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

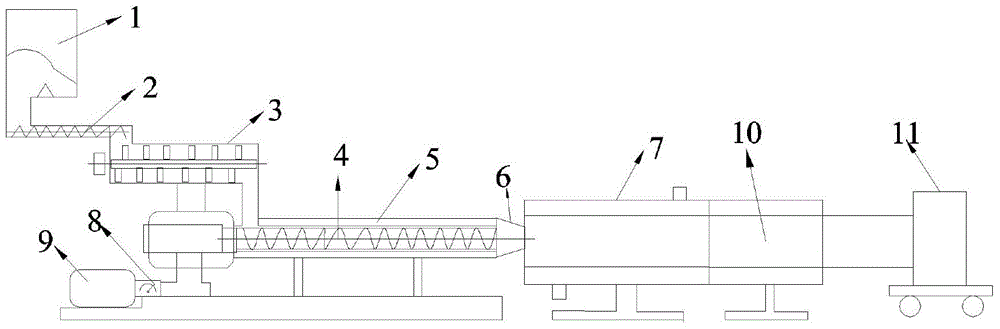

[0035] Now it is necessary to process square plate-shaped low-temperature foam glass insulation blocks. The specific steps are as follows:

[0036] (a) boron-containing raw material and water glass are used to prepare water-containing intermediate material by sol-gel method;

[0037] (b) Put the aqueous intermediate material into the silo 1, and the position of the aqueous intermediate material in the silo 1 is biased towards the side connected to the screw feeder 2;

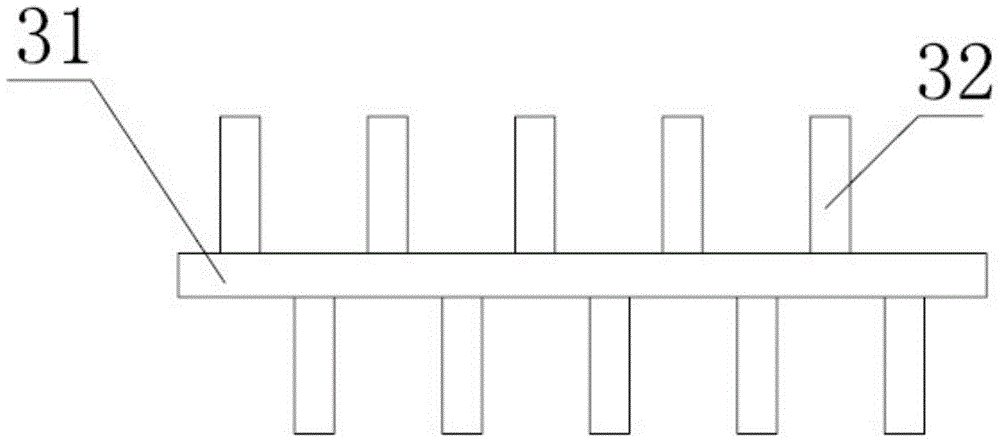

[0038] (c) The whole device starts to work, and the water-containing intermediate material enters the screw feeder 2 for preliminary stirring and then enters the mixer 3 to fully stir and mix with the additive;

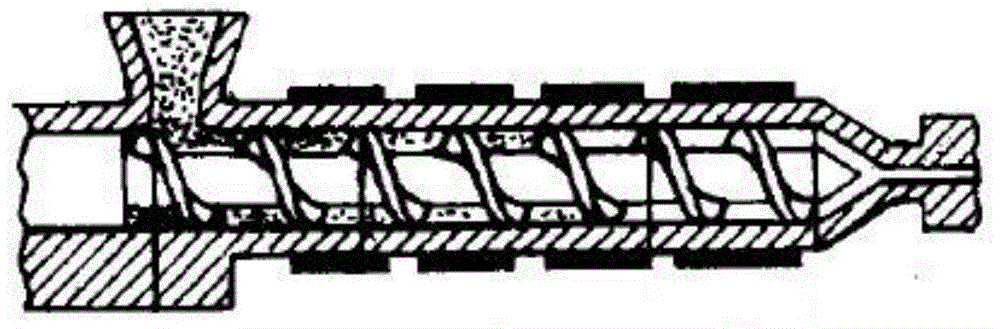

[0039] (d) The fully mixed water-containing intermediate material enters the extruder barrel and begins to melt and expand under the temperature of 200-400°C generated by the extrusion screw 4 and the high pressure of 3-8Mpa; the heat preservation and auxiliary heating sleeve 5 ensures temperature stabi...

Embodiment 2

[0045] Now it is necessary to process square plate-shaped low-temperature foam glass insulation blocks. The specific operation steps are the same as in Example 1, that is, in step e, the extrusion die 6 is replaced with a mold with a rectangular mold cavity. Uniform finished product, the finished product is 100mm×30mm×300mm low-temperature foam glass insulation block, the density is 170kg / m 3 , the thermal conductivity is about 0.042w / (m k), and the prepared low-temperature foam glass insulation block is directly constructed on the outer wall of 15 square meters. The construction process is simple and convenient, and the flatness is high after pasting, and the vertical surface strength is good. .

Embodiment 3

[0047] It is necessary to process the cylindrical low-temperature foam glass insulation block now, and the specific operation steps are the same as in Example 1, that is, in step e, the extruding die 6 is replaced with a circular mold with a molding cavity, and the cutting tool 11 cuts off a large or small Uniform finished product, the finished product is a 10mm low-temperature foam glass insulation block with a density of 190kg / m 3 , the thermal conductivity is about 0.050w / (m·k), it is filled into the pipe, and the heat preservation effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com