Straw puffing machine

An extruder and straw technology, applied in the field of agricultural machinery, can solve the problems of lack of bearing oil, easy breakage of the main shaft, power waste, etc., and achieve the effects of improving the service life of the equipment, improving product quality, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

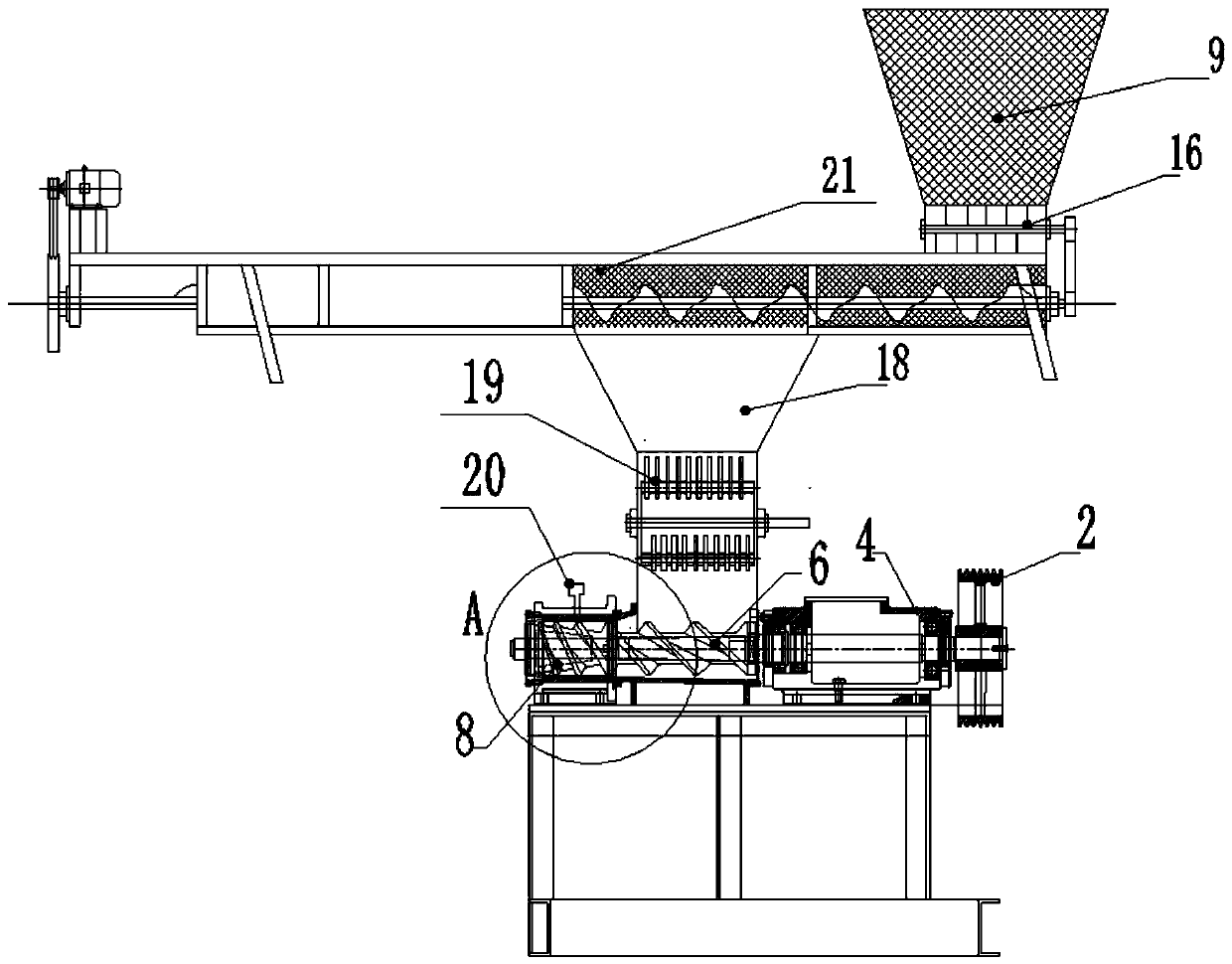

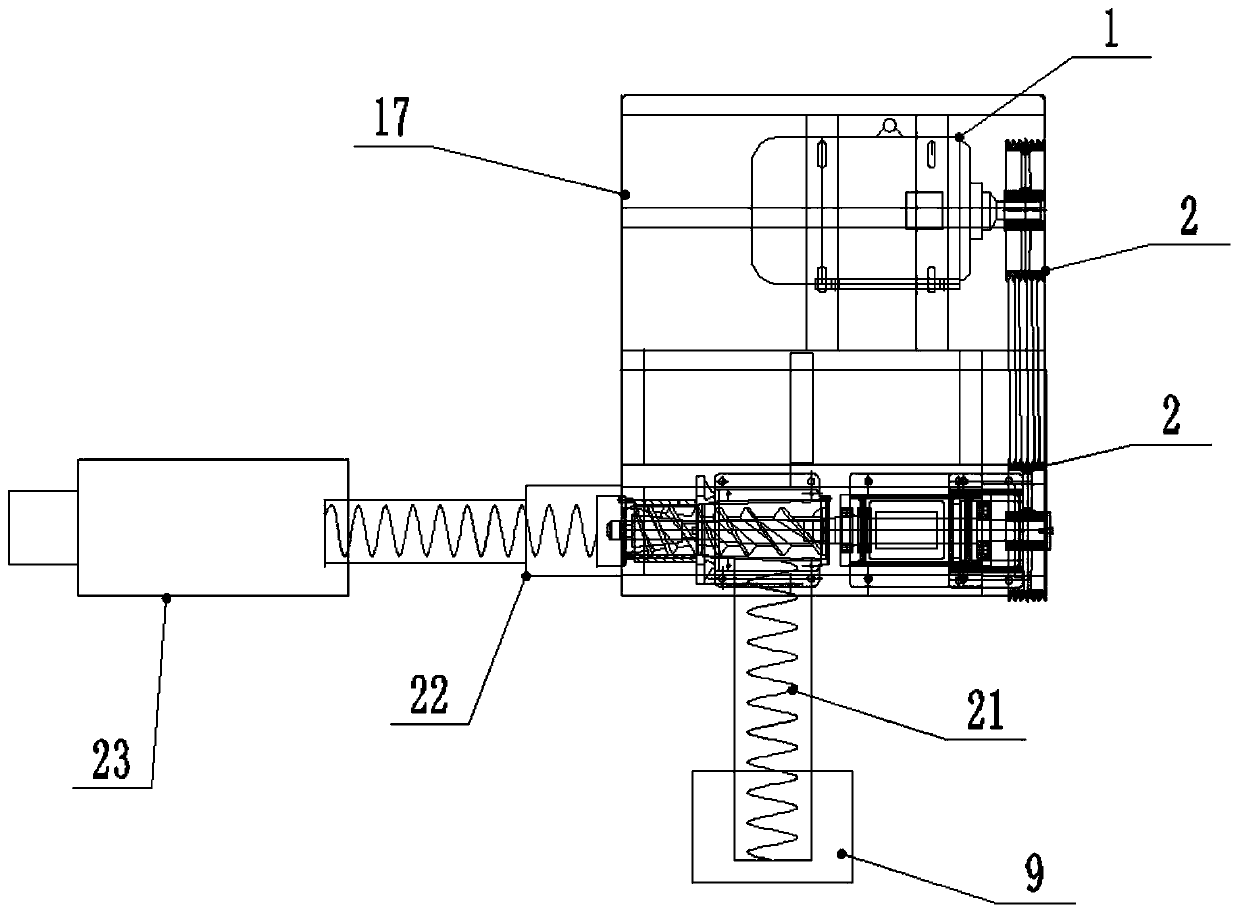

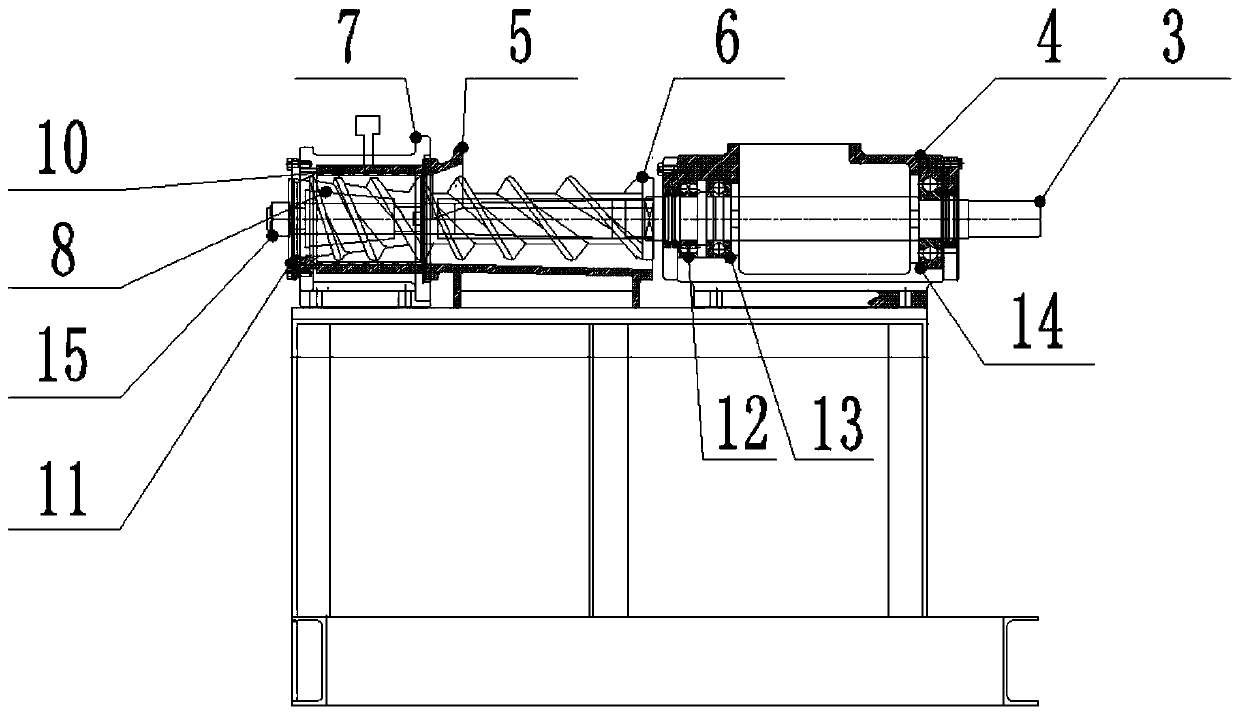

[0042] like Figure 1-Figure 5As shown, a straw puffing machine includes a feeding device, a power mechanism and an puffing device;

[0043] The expansion device comprises an expansion shell, a disintegration guide rod 8, a spiral barrel 10 and a disintegration ring 11. The top of one end of the expansion shell has a feed inlet, and the end of the other end has a discharge opening. The disintegration ring 11 is arranged at the outer edge of the discharge port and is fixedly connected with the shell of the extruder, and the spiral sleeve barrel 10 is sleeved in the other end of the expander shell and is connected with the shell of the extruder. The feed port is connected, and the disintegration guide rod 8 is sleeved in the spiral sleeve barrel 10 and the disin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com