Blood powder protein puffing machine

An extruder, protein technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of low extruding rate, low production yield, inappropriate extruding temperature and pressure ratio, etc., to improve the extruding efficiency and extruding rate. Improve and balance the effect of sterilization and amino acid not being destroyed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

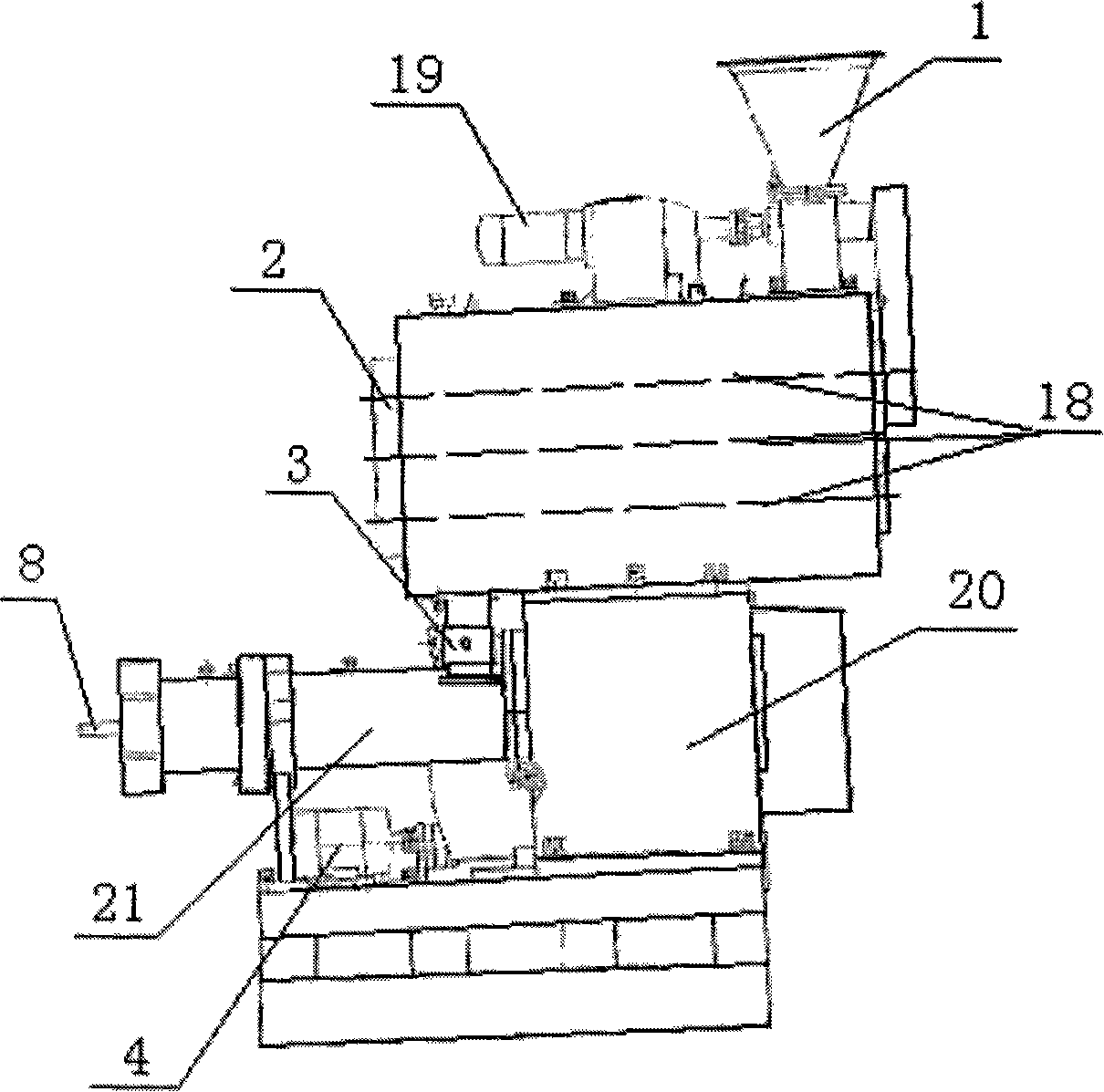

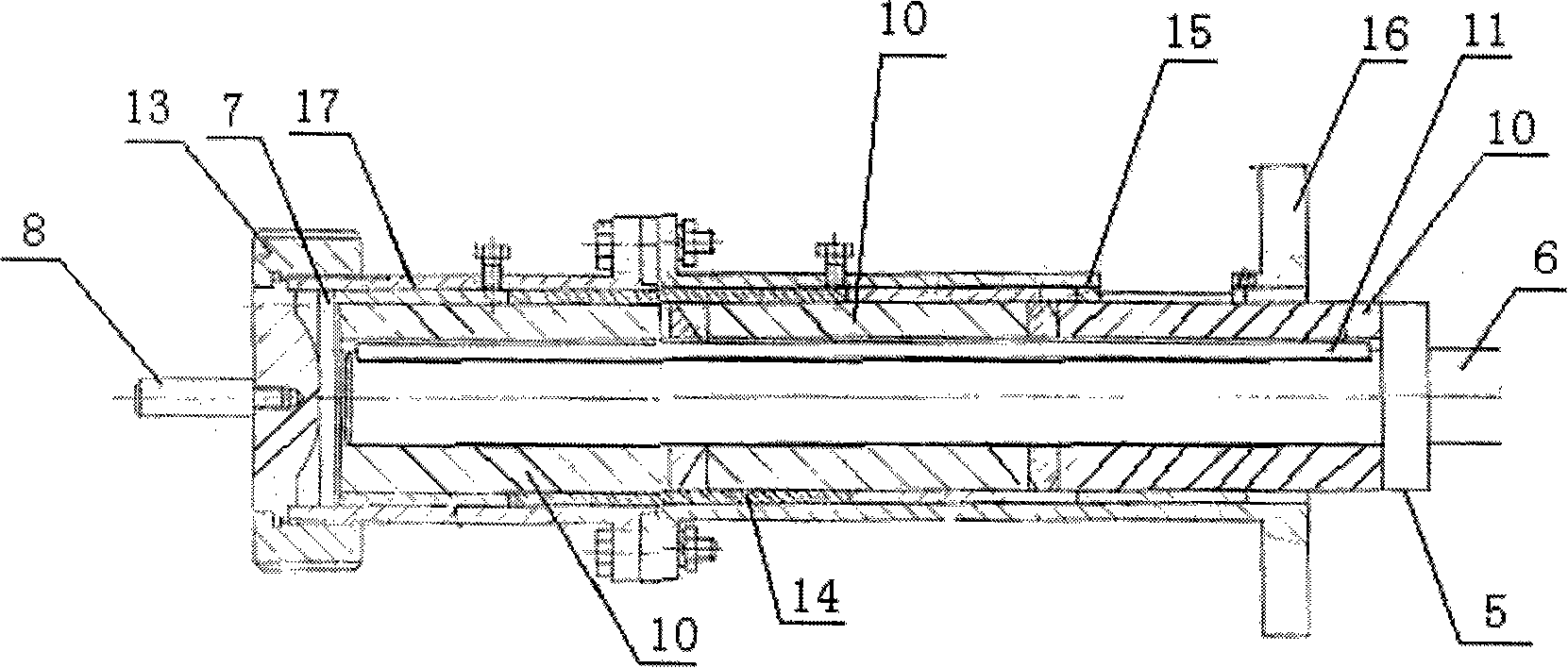

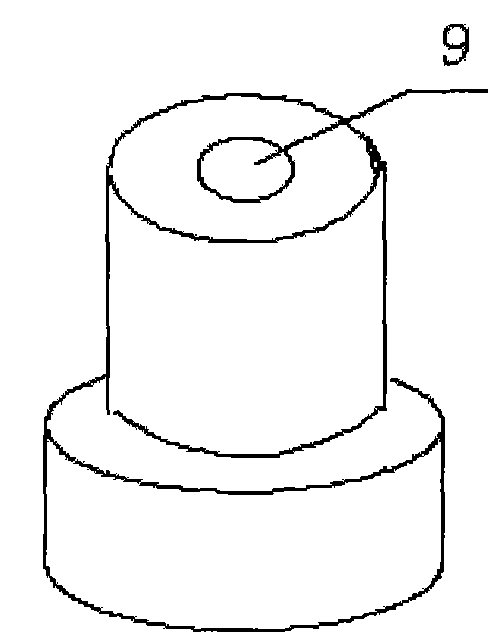

[0019] Such as Figure 1~4 As shown, the blood meal protein extruder in this embodiment includes a power part, a feed hopper 1, a conditioner 2, a feeding port 3 and an extruding part 21, wherein the power part includes a motor 4, a booster gear set and a gear box 20, The booster gear set is placed in the gear box 20 , and the puffing part 21 includes an outer tube 5 , a power shaft 6 , a grinding plate 7 , an puffing head 8 , puffing nozzles 9 and a material pusher 10 . The motor 4 is connected to the power shaft 6 through the booster gear set. The material pusher 10 and the power shaft 6 are provided with three flat grooves. The material pusher and the power shaft are connected with a flat buckle 11. The power shaft 6 Drive the material to push the presser 10 to rotate, wherein the rotating speed of the power shaft 6 is 580 rpm; the pitch of the material to push the presser 10 is both threads, and the end of the material to push the presser 10 is provided with a grinding pla...

Embodiment 2

[0022] Blood powder protein extruder as described in embodiment 1, wherein the rotating speed of power shaft is 700 revs / min, and the diameter of grinding hole is 3.2mm.

Embodiment 3

[0024] Blood meal protein extruder as described in embodiment 1, wherein the rotating speed of power shaft is 630 revs / min, and the diameter of grinding hole is 2.8mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com