Puffing method for preparing kiwifruit crisp slices

A technology of kiwifruit crisps and kiwifruit slices, which is applied in the field of puffing for the preparation of kiwifruit crisps, can solve the problems of rough product structure, loss, high heat, etc., solve the problem of poor technical economy, low equipment requirements, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

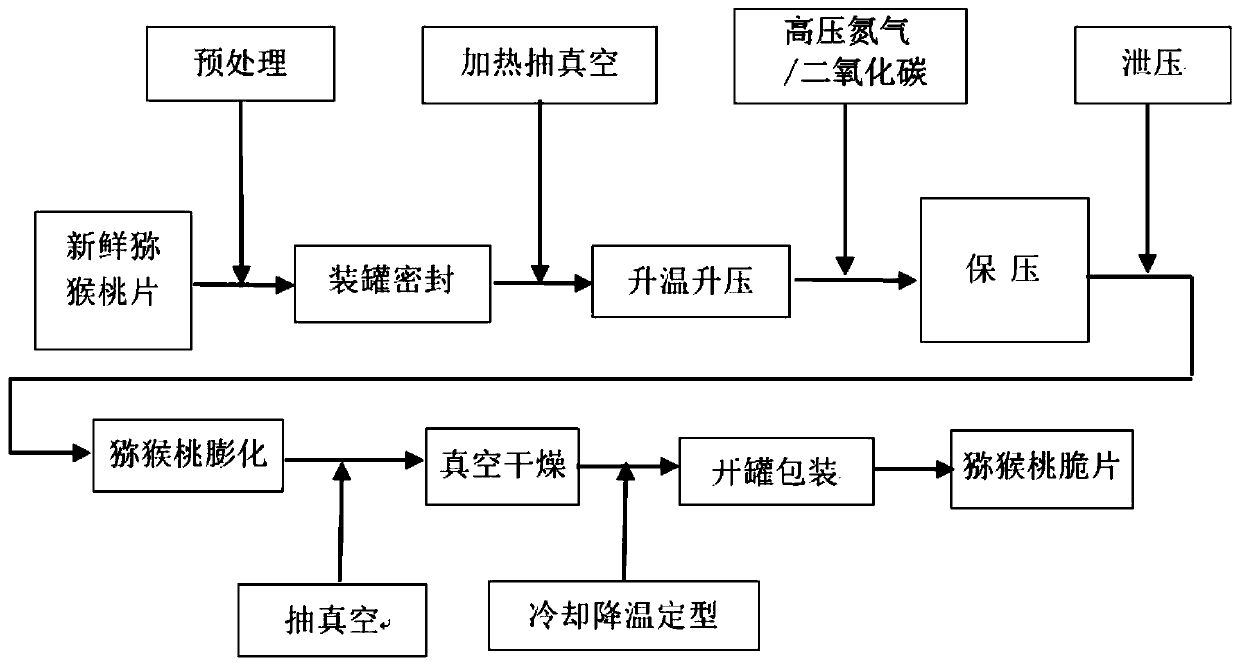

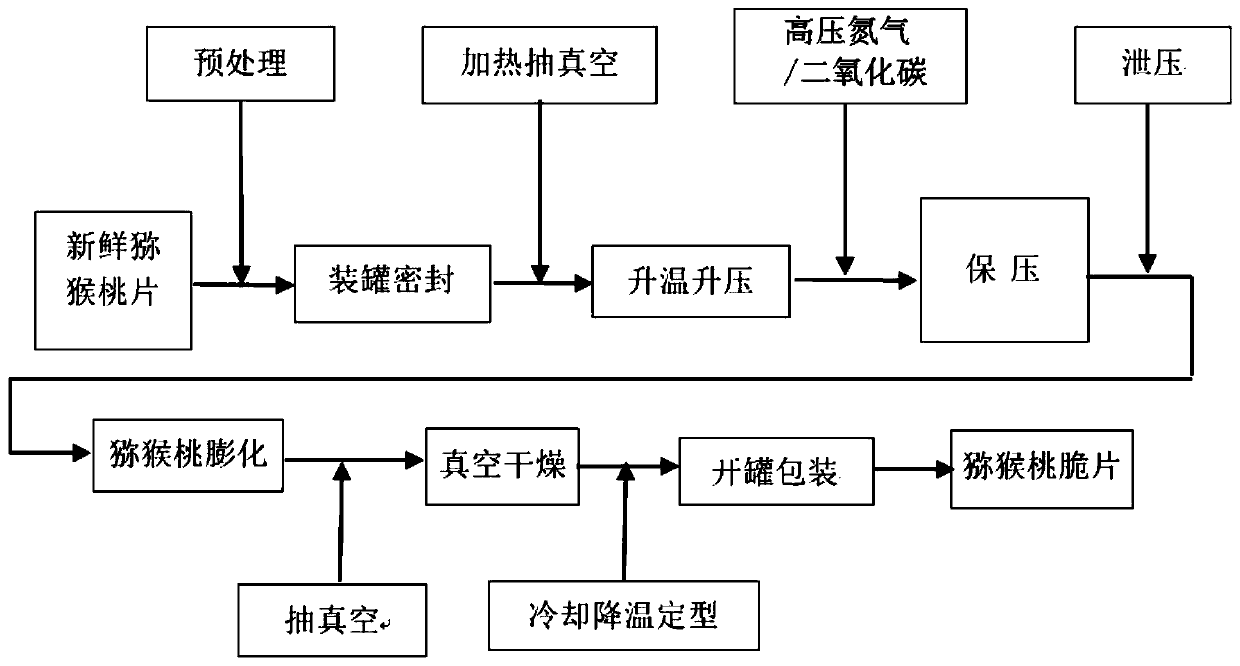

[0027] refer to figure 1 , a kind of puffing method for preparing kiwi crisps, comprising the following steps:

[0028] Step 1. Peel seven or eight mature fresh kiwifruit, freeze at -4°C for 16 hours, cut into kiwifruit slices of about 6mm after thawing, and then pre-dry the kiwifruit slices with hot air at 70°C until the moisture content is 20 %, the temperature of the kiwi slices was higher than its softening point at this time;

[0029] Step 2. Put the pretreated kiwi slices into the sealed expansion tank, put hot water into the jacket of the equipment to slowly heat the expansion tank and materials, and heat the expansion tank and materials to 70°C;

[0030] Step 3. Use a vacuum pump to evacuate the expansion tank, then fill the tank with high-pressure carbon dioxide (expansion pressure difference 1.1MPa), and expand at a temperature of 70°C. The carbon dioxide gas fills the entire expansion tank and passes through the capillary pores. Slowly infiltrate into the tissue o...

Embodiment 2

[0035] The difference between this example and Example 1 is that the slice thickness in step 1 is 8mm, and the moisture content after pre-drying is 30%; the evacuation time is 135 minutes, and the evacuation time is after the material puffing is completed, and the material is vacuum-dried to moisture content The time required for the rate to reach the standard start and end, the inert gas used in step 3 is nitrogen, the puffing pressure difference in step 3 (the pressure difference before and after pressurization in the puffing tank) is 1.82MPa, and the puffing temperature is 70°C. In step 5, the puffed kiwi fruit slices are continued to be dried in a vacuum environment, and a small amount of nitrogen gas is fed into the puffing tank during vacuum drying to keep the vacuum degree at -0.075MPa.

Embodiment 3

[0037] A kind of puffing method for preparing kiwi fruit chips, comprising the following steps:

[0038] Step 1, fresh kiwifruit is peeled, cut into 6mm kiwifruit slices, then the kiwifruit slices are pre-dried with hot air at 70°C to a moisture content of (20 ± 0.2)%, at this time the temperature of the kiwifruit slices is higher than its softening point;

[0039] Step 2, heating the kiwifruit slices after pretreatment (hot air drying) to above 70°C, and putting the kiwifruit slices with a temperature higher than 70°C into a sealed puffing tank;

[0040] Step 3. Vacuum the inside of the expansion tank so that the absolute pressure in the expansion tank is less than 12KPa. Then slowly fill high-pressure CO into the expansion tank 2 gas, the expansion pressure difference is 1.03, the expansion temperature is 80°C, and the high pressure CO 2 The gas penetrates into the raw material through the capillary pores of the material, the inflation time is 9 minutes, the final inflatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com