Patents

Literature

31results about How to "Control softness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

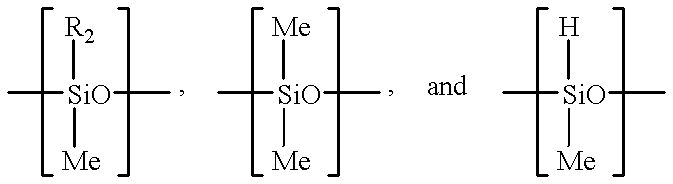

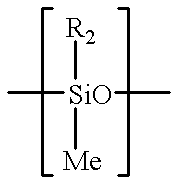

Grafted rubber-like silicone gel with enhanced oil compatibility and its synthetic process

InactiveUS6331604B1Improve compatibilityReduce capacityCosmetic preparationsToilet preparationsSilicone GelsVegetable oil

Fatty alcohol or aliphatic glycol-grafted rubber-like silicone gels with enhanced oil compatibility are synthesized by 1) reacting a fatty alcohol or a aliphatic glycol with methylhydrodimethylsiloxane copolymer in the presence of a platinum catalyst in a reaction medium of a silicone fluid or a cosmetic oil or a mixture thereof, and 2) further reacting the mixture with a vinyl-functional siloxane polymer. The resulting compounds may be used as gelling agents for hydrocarbon oils, vegetable oils and silicone oils. The efficient synthetic process approaches a 100% yield.

Owner:GRANT INDS

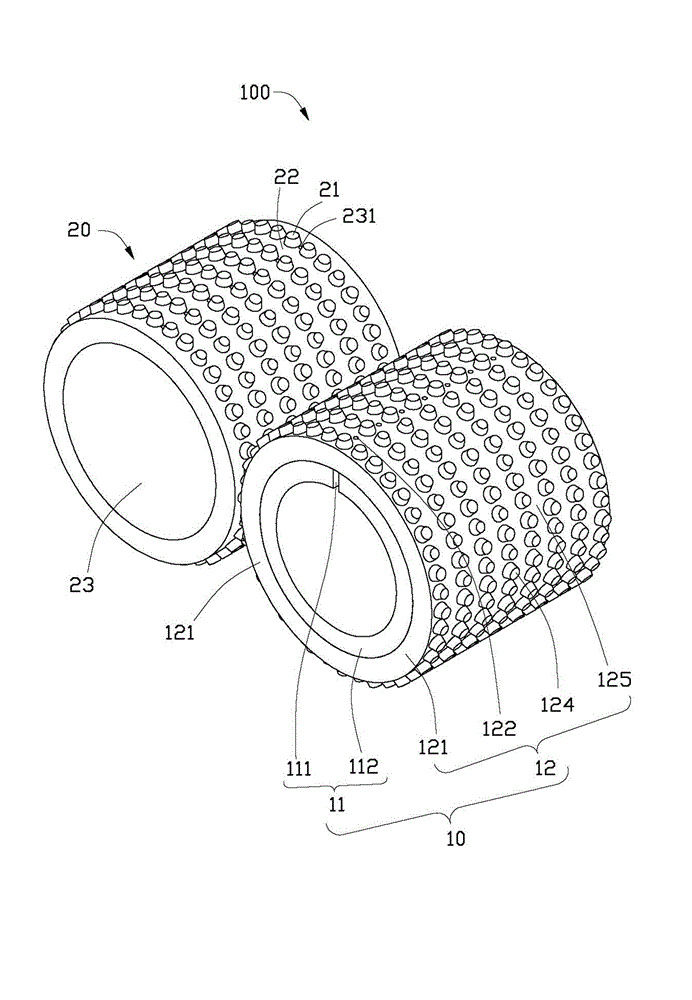

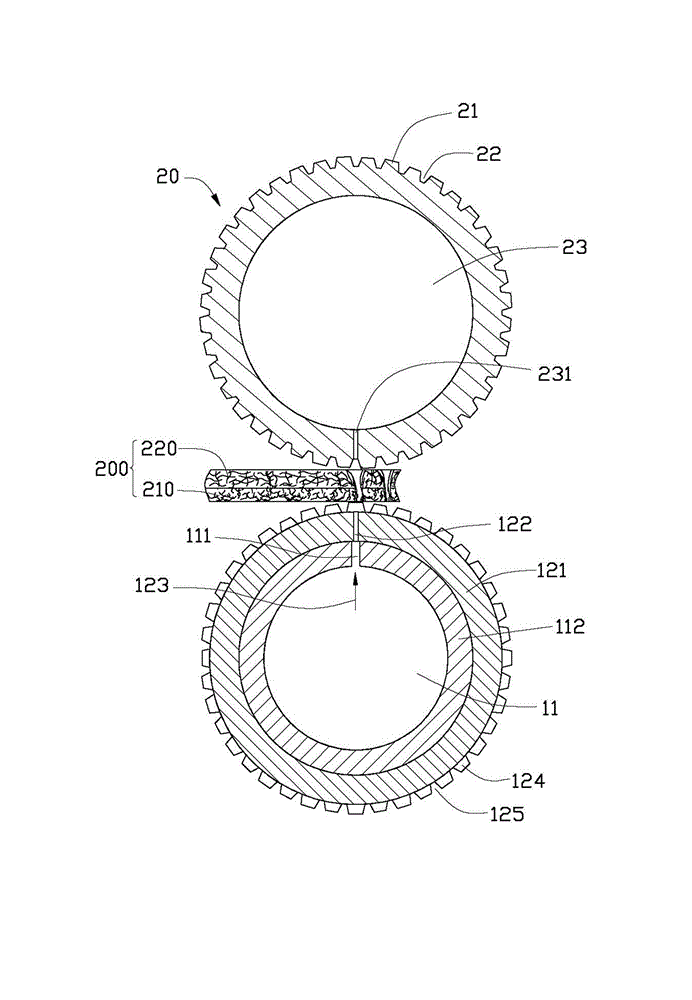

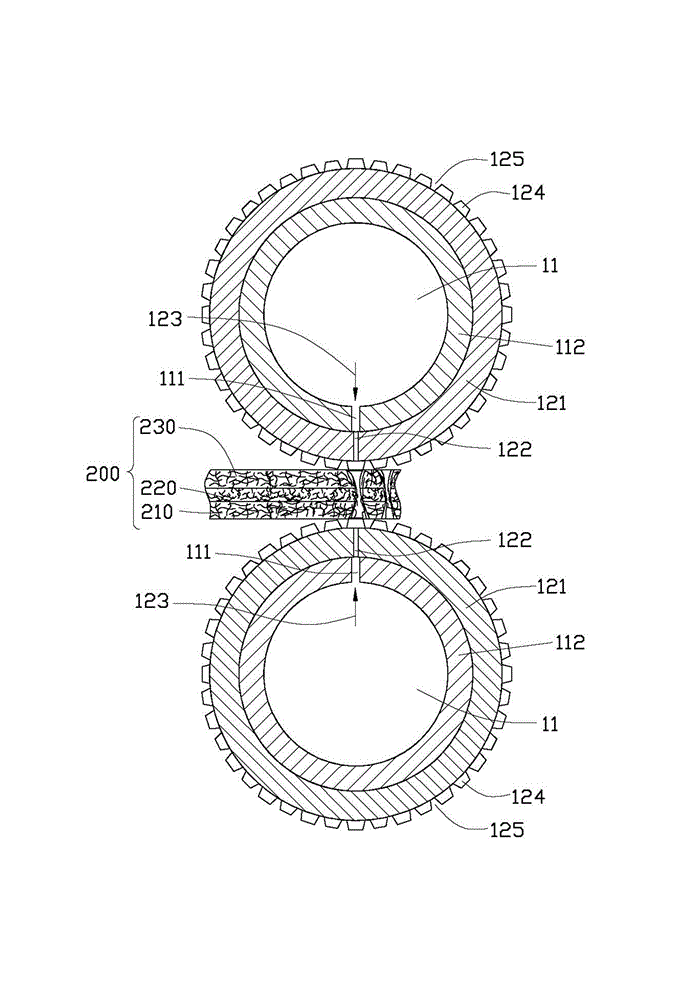

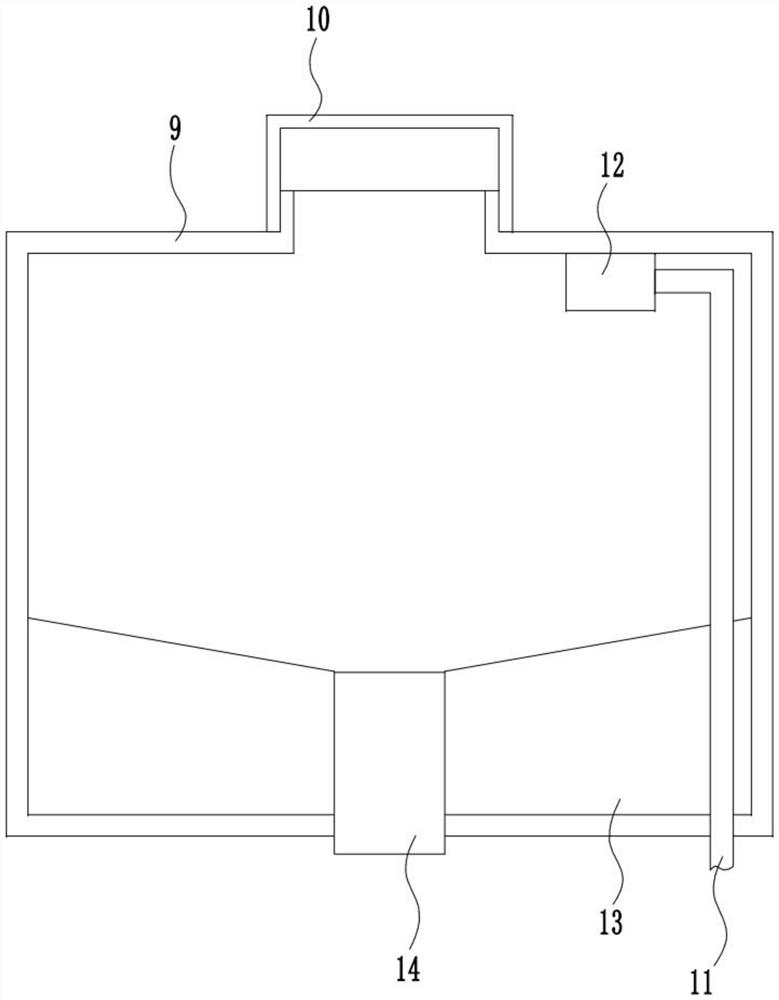

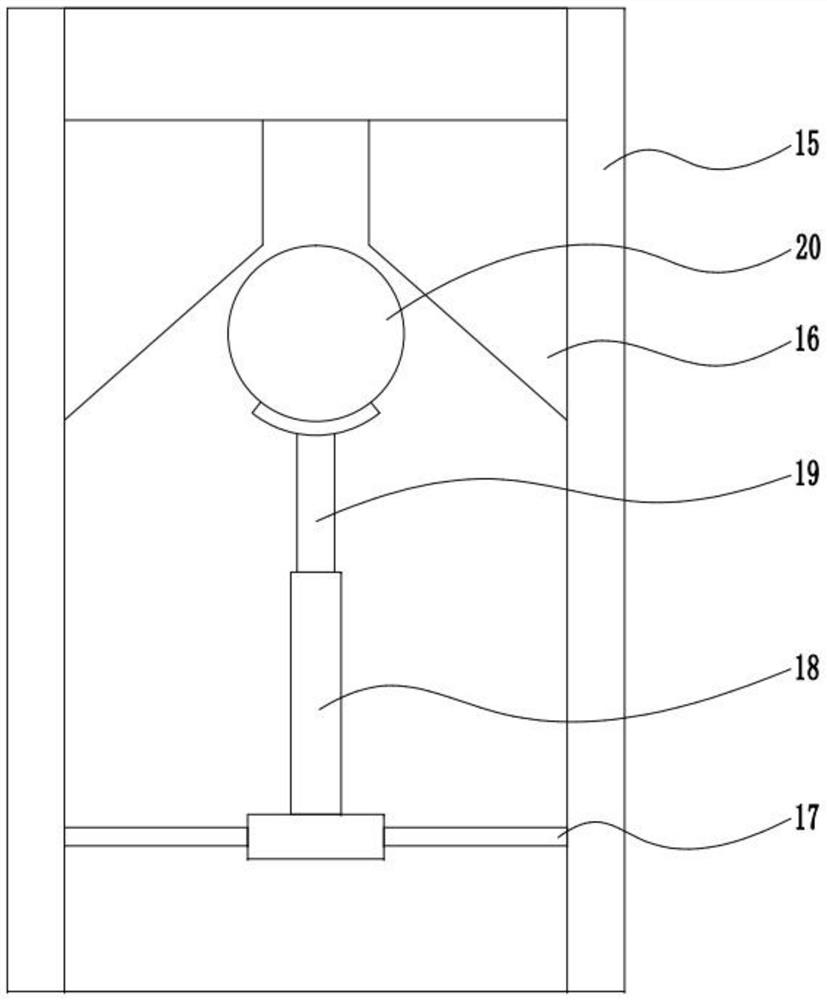

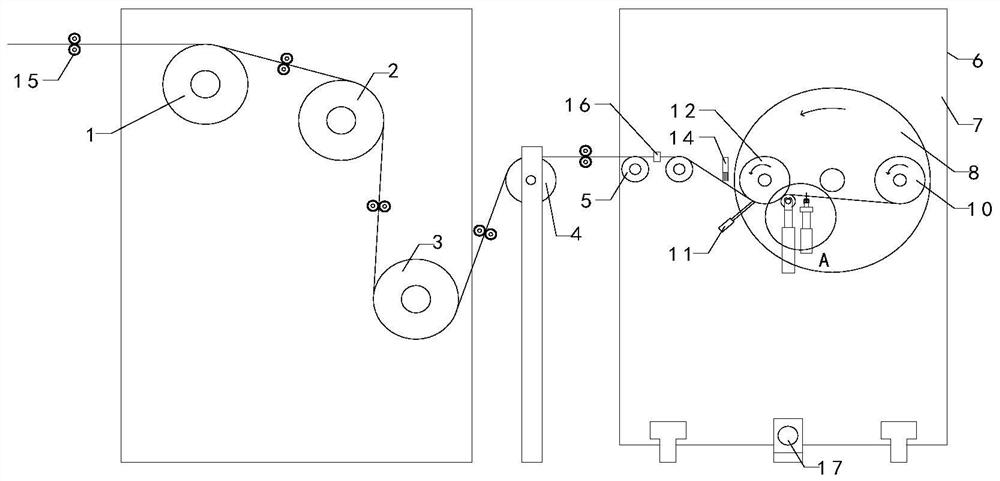

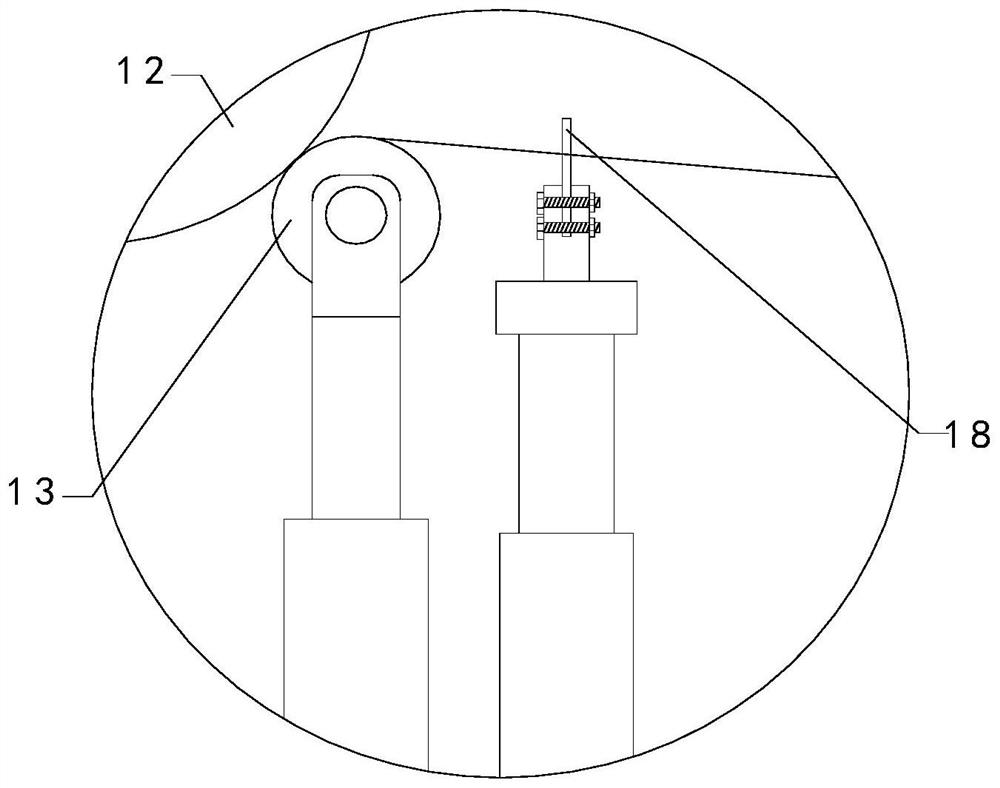

Embossing device and embossing process, composite non-woven fabric absorber, production device and process thereof

InactiveCN102747578AControl softnessControl fluff performancePattern makingNon-woven fabricsInjection portNonwoven fabric

The present invention relates to an embossing device, which comprises a first embossing roller and a second embossing roller, wherein the two embossing rollers are mutually cooperated, and the surface of at least one of the two embossing rollers is provided with embossing patterns. The first embossing roller further comprises a first hot air source and a first housing sleeved around the first hot air source, wherein the first hot air source has a first air outlet for outputting hot air gas to the outside. The first housing is provided with a first injection port corresponding to the first air outlet. When the first injection port rotates and reaches a position coinciding with the first air outlet, the hot air provided by the first hot air source is injected from the first ejection port to form at least a bunch of hot air jet. The present invention further relates to a process for carrying out embossing by using the embossing device, a composite non-woven fabric absorber production device comprising the embossing device, a composite non-woven fabric absorber production process and composite non-woven fabric absorber products.

Owner:GOLD HONG YE PAPER

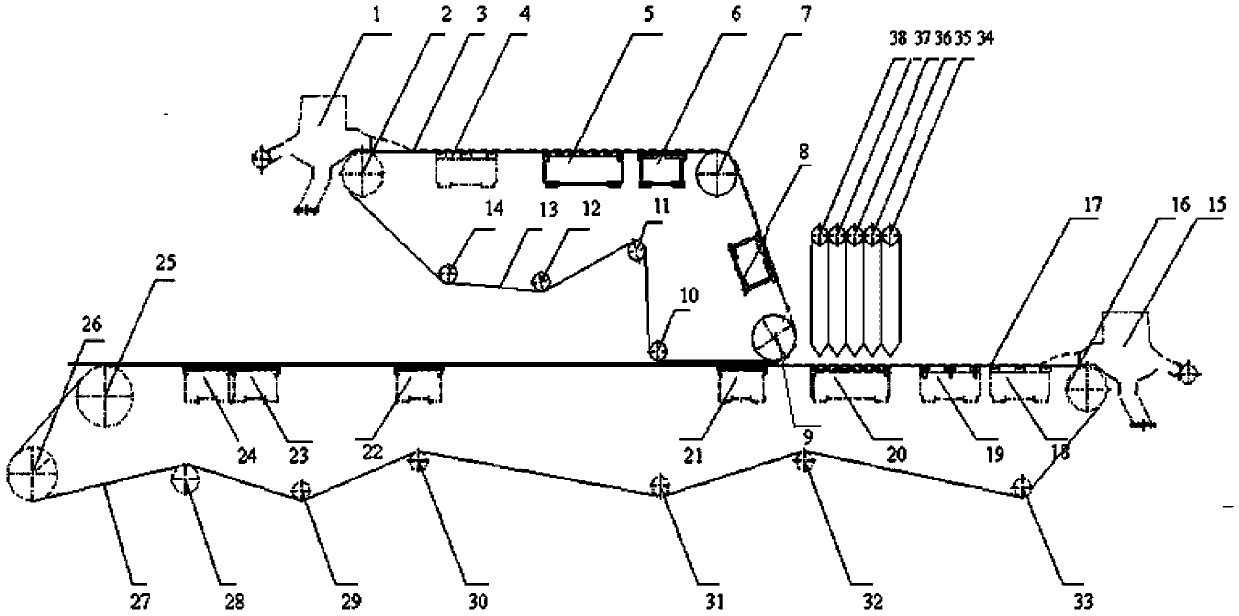

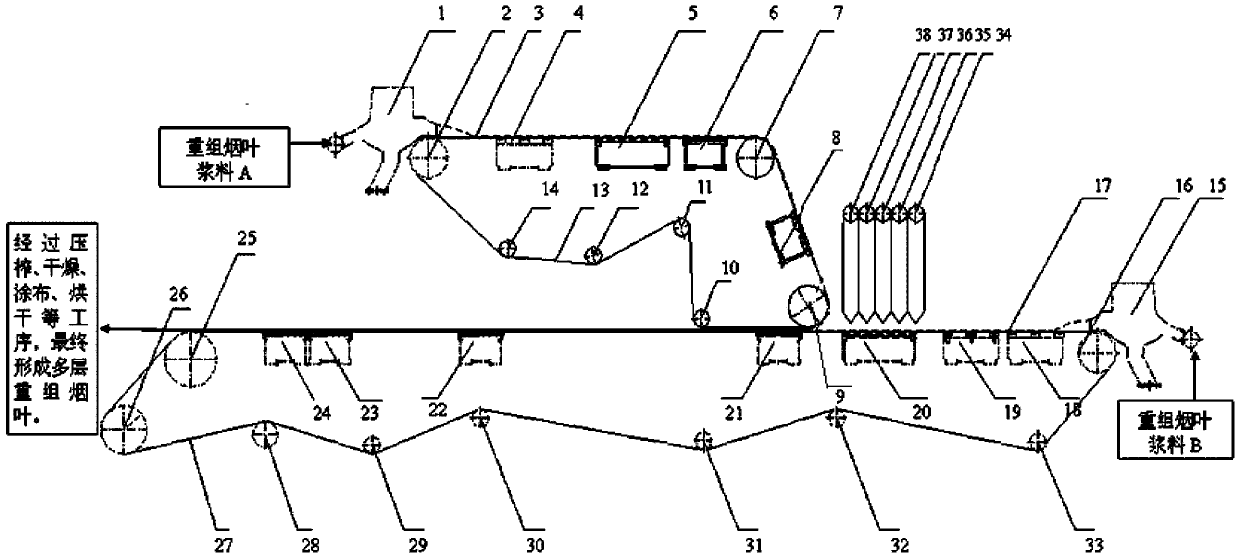

Method for manufacturing recombined tobacco leaves through paper-making mode

The invention relates to a method for manufacturing recombined tobacco leaves through a paper-making mode. The method is characterized in that two recombined tobacco leaf substrate net portion forming devices are adopted on a paper-making portion of a paper machine, namely, one is a bottom recombined tobacco leaf substrate net portion forming device, and the other is a top recombined tobacco leaf substrate net portion forming device, wherein the top recombined tobacco leaf substrate net portion forming device is located on the top layer of the paper-making portion, the bottom recombined tobacco leaf substrate net portion forming device is located on the bottom layer of the paper-making portion, and the two recombined tobacco leaf substrate net portion forming devices are arranged oppositely; a plurality of dusting devices with dusting powder quantity independently adjusted and controlled are arranged between the two recombined tobacco leaf substrate net portion forming devices, the dusting devices are successively arranged in the lengthwise direction of the paper-making portion on the bottom layer of a paper machine, the two recombined tobacco leaf substrate net portion forming devices convey recombined tobacco leaf pulp out in a flowing mode at the same time, the two recombined tobacco leaf substrate net portion forming devices are firstly independently formed in a flowing conveying mode to respectively form a wet substrate, and after the pulp flowing conveying substrates of the two recombined tobacco leaf substrate net portion forming devices are formed, the middle dusting devices are started. The method is scientific and reasonable, operation is convenient, and the bulk, the softness and the sensory quality of the recombined tobacco leaves through the paper-making mode can be adjusted according to requirements.

Owner:HUBEI CHINA TOBACCO IND +1

Elastomer gel water-in-water colorful system paint

The invention discloses an elastomer gel water-in-water colorful system paint which is formed by mixing a dispersed phase with a continuous phase, and the elastomer gel water-in-water colorful system painting is characterized in that: the dispersed phase consists of protective glue solution and elastic paint, the protective glue solution contains cation protective glue and is quaternary ammonium salt polysaccharide polymer with low grafting degree; the continuous phase contains gels which is anion polysaccharide cellulose ether; the weight ratio of the dispersed phase and the continuous phase is 1:1-2. When the cation protective glue in the dispersed phase meets the gels in the continuous phase, the cations and the anions can be bonded mutually; and simultaneously, the long-chain quaternary ammonium salt can form complex with acidic polysaccharide, chemical crosslinking occurs among active groups, so that the hardness of the paint can be adjusted, the stability is good, and the proportion of color grains can reach 40-50 percent.

Owner:安徽嘉年华漆业有限公司

Light non-toxic plasticine and preparation process thereof

InactiveCN100999603AStrong adaptability to temperature differenceColorfulToysWater basedPreservative

The present invention relates to one kind of children's toy plasticine and its preparation process. The light non-toxic toy plasticine consists of polystyrene acrylonitile through high temperature foaming treatment 3-10 wt%, polyvinyl alcohol 10-30 wt%, borax 0.01-0.05 wt%, glycerin 1-8 %, water base preservative 0.01-0.15 wt% and water for the rest. The present invention has the advantages of light weight, bright color, good hand feeling, etc. and may be used as children's toy, in making model, sculpture draft, etc.

Owner:浙江银太郎动漫文化股份有限公司

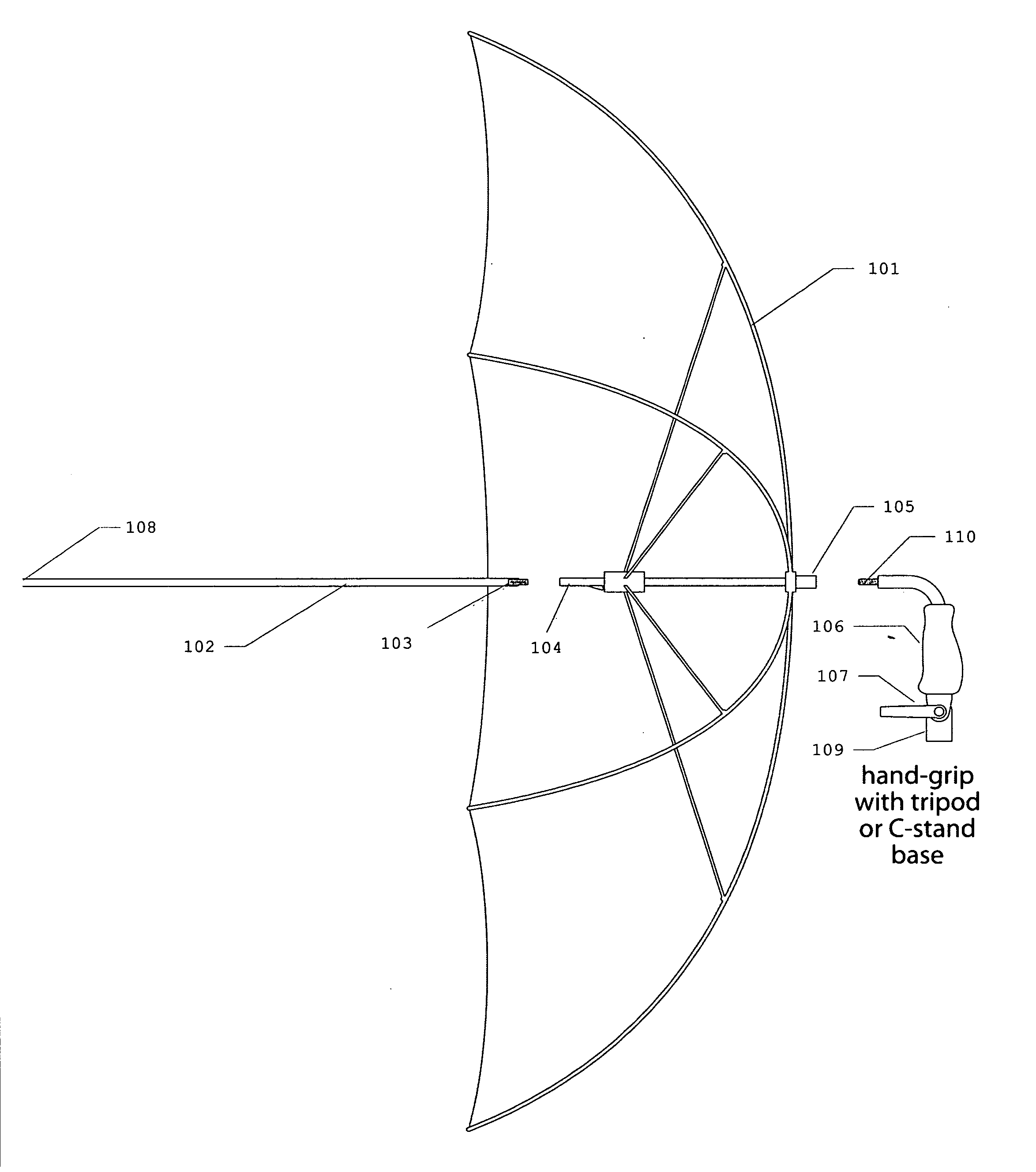

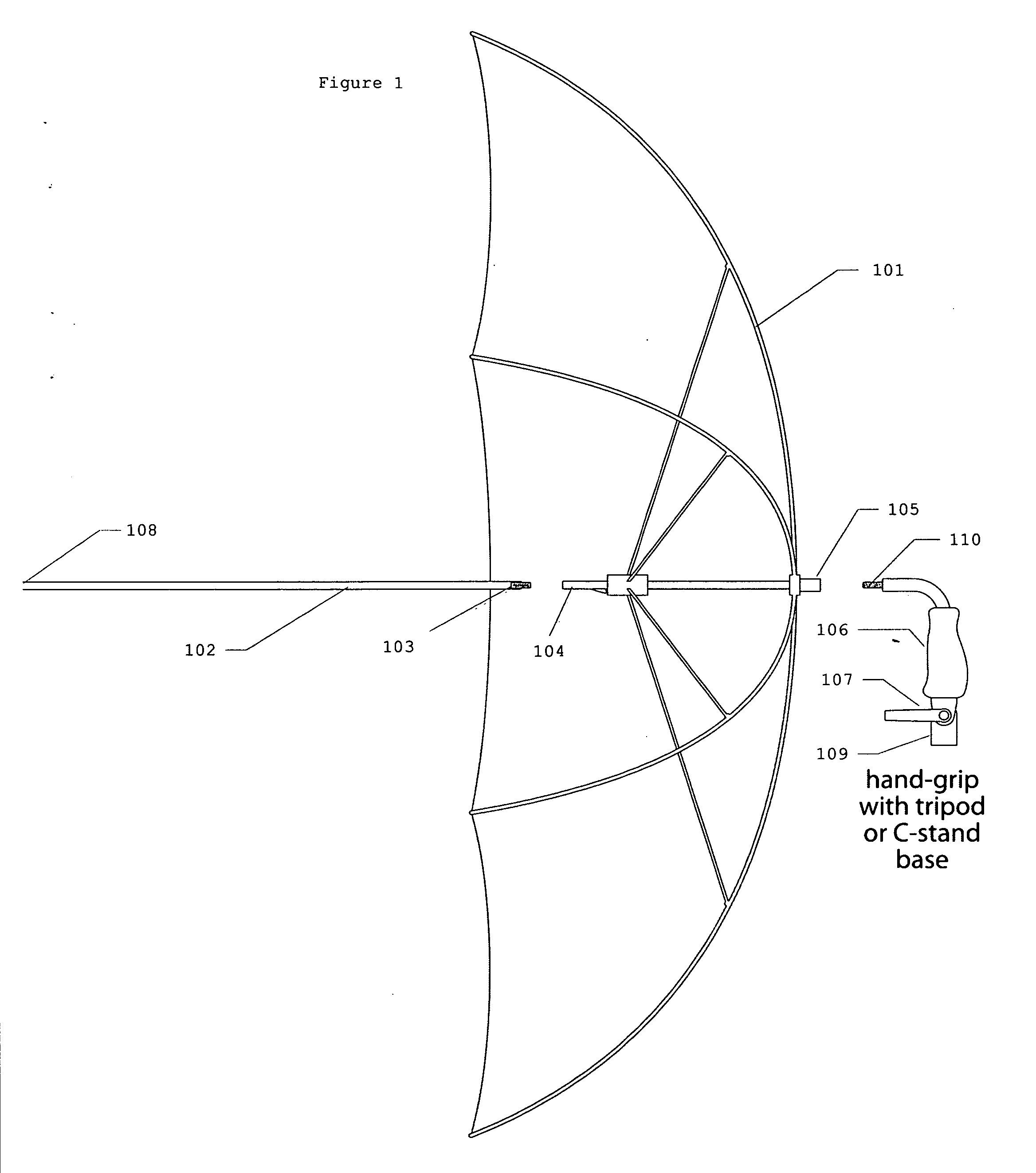

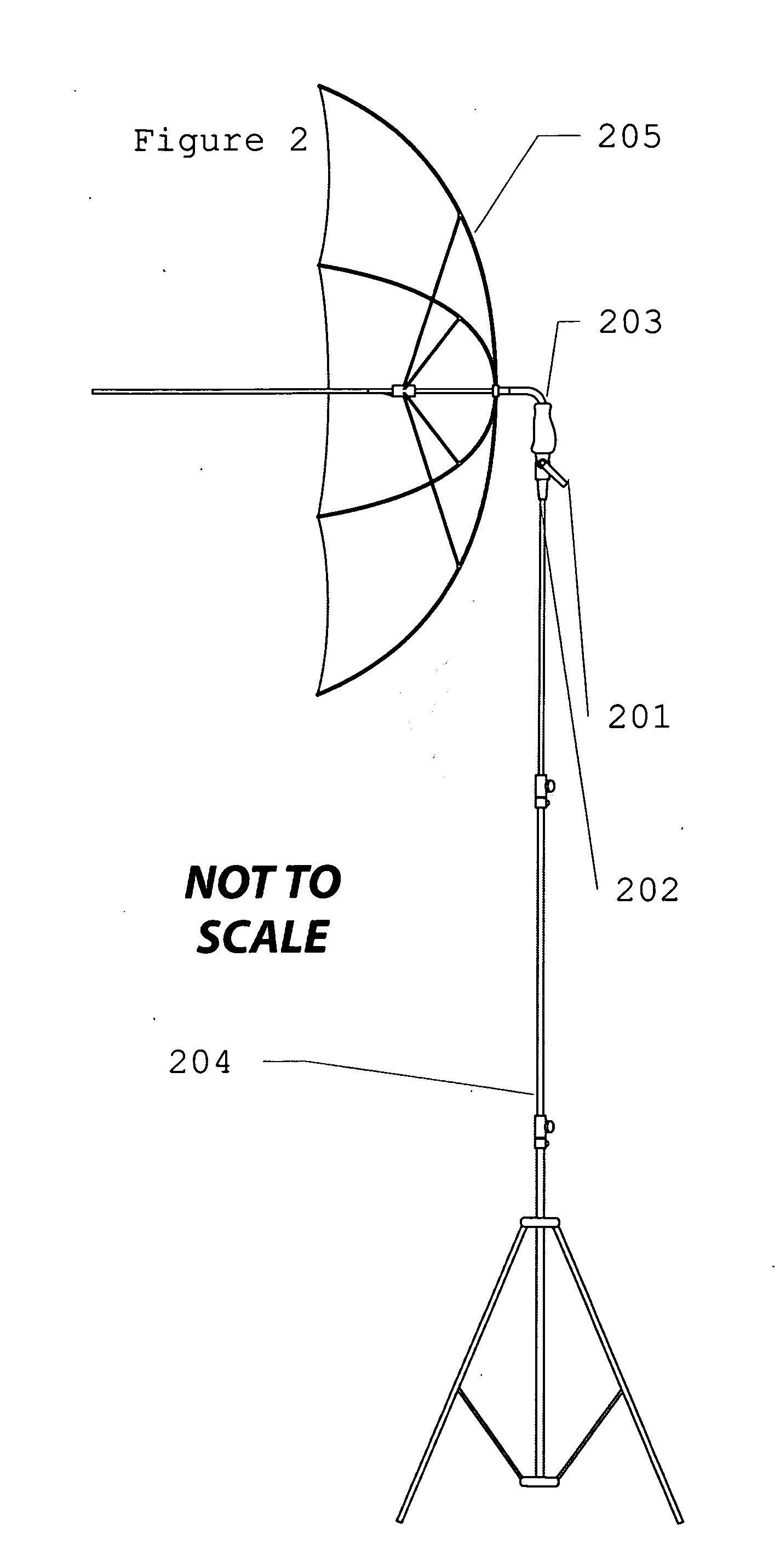

Apparatus to provide a multi-purpose reflective umbrella and lighting enhancement device for the purposes of providing illumination during still, motion, and video photography.

InactiveUS20130120960A1Extensive portabilityMaximum flexibilityLighting support devicesLight fasteningsComputer graphics (images)Effect light

Owner:HAROONI HOOSHMAND

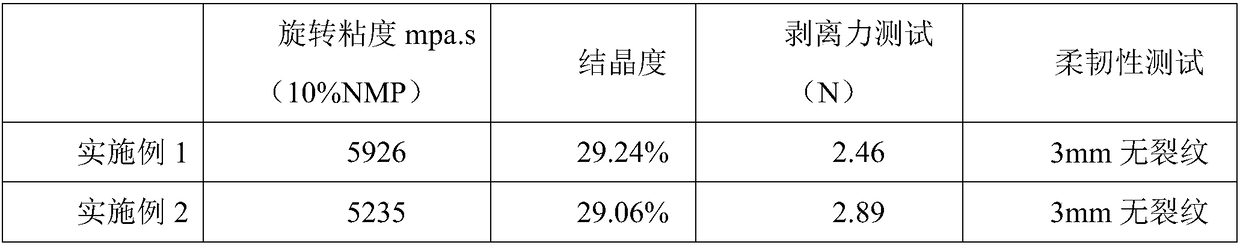

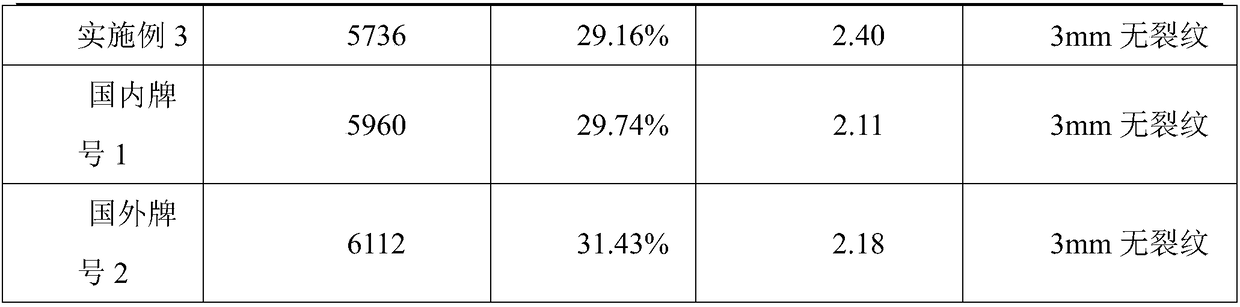

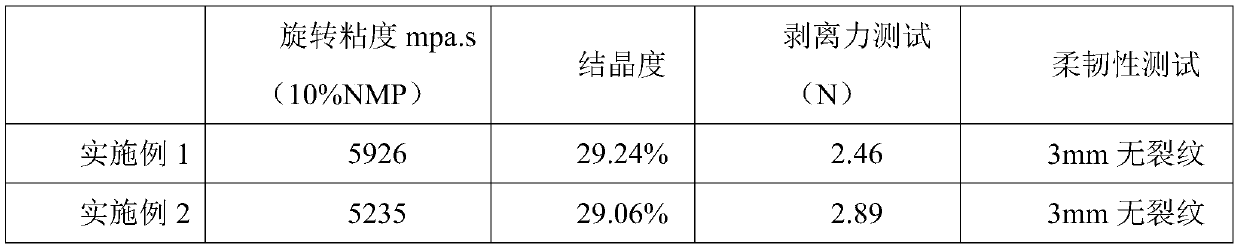

Preparation method of polyvinylidene fluoride modified composite conductive adhesive

The invention relates to a preparation method of a polyvinylidene fluoride modified composite conductive adhesive. The method includes the following steps: (1), adding a polyvinylidene fluoride dispersion emulsion to a reaction kettle, purging nitrogen to remove oxygen, stirring, adding a fluorine-containing monomer, heating, and adding an initiator and a molecular weight regulator; (2), keeping the polymerization temperature and stirring speed unchanged during the reaction, and after completing the reaction, cooling and discharging to obtain a composite material; and (3), adding deionized water, hydrochloric acid, a conductive polymer monomer and the composite material prepared in the step (2) to a reaction tank, performing ultrasonic dispersion, weighing the initiator, dissolving the initiator in the deionized water, adding the mixture to a reaction solution subjected to ultrasonic dispersion, stirring, separating, washing and drying. According to the scheme of the invention, polyvinylidene fluoride is modified by performing graft copolymerization on the fluorine-containing monomer, the crystallinity of PVDF can be reduced, and the stickiness and flexibility of polyvinylidene fluoride can be improved; and by adding the conductive polymer monomer, the conductivity of the composite adhesive can be improved, and the resistance can be reduced.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

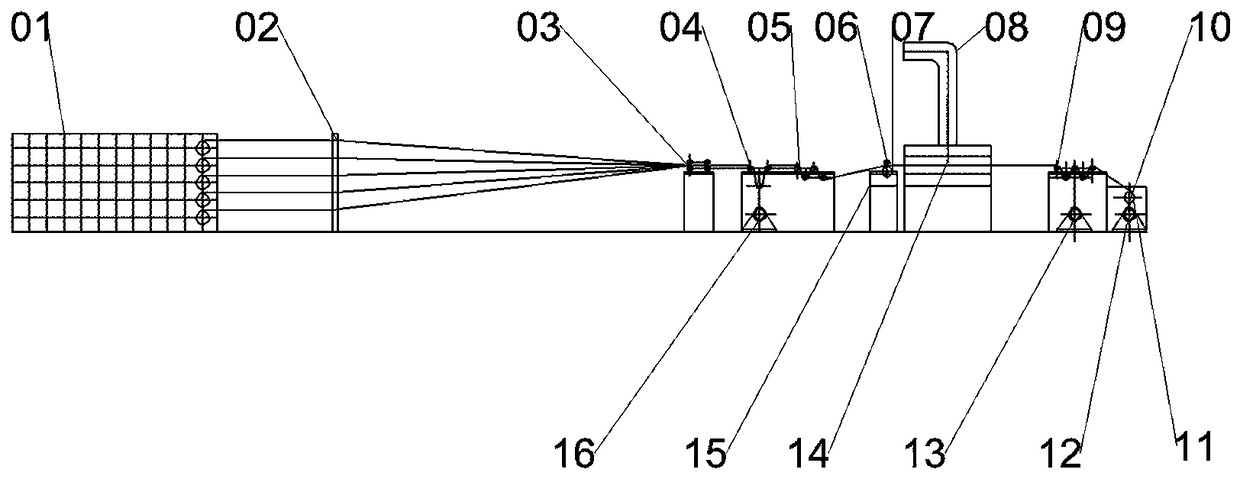

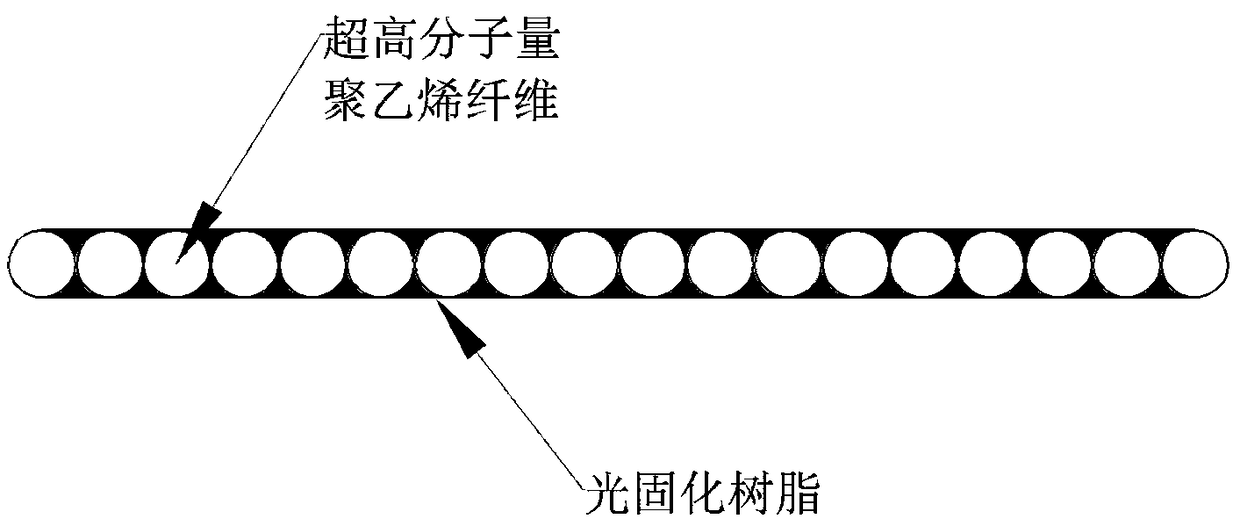

Ultrahigh molecular weight polyethylene UD non-woven fabric and photocuring preparation method

PendingCN108559116AIncrease productivityControl thicknessChemical industryTextiles and paperFiberCross-link

The invention discloses ultrahigh molecular weight polyethylene UD non-woven fabric and a photocuring preparation method. The method comprises the following steps: introducing ultrahigh molecular weight polyethylene fibers from a pay-out stand to a branching rack, introducing a fiber placement roller through carry over pinch rolls, introducing a gumming roller, fully impregnating fibers in light-cured resin, extruding the fibers fully impregnated in the light-cured resin through an extrusion roller to form single-layer impregnated fibers, entering a photocuring box and letting resin rapidly becured under the radiation of ultraviolet light, introducing into a wind-up roll through rear carry over pinch rolls to form the ultrahigh molecular weight polyethylene UD non-woven fabric. The produced UD non-woven fabric is coated with the light-cured resin, and under the radiation of a light source, the resin is rapidly cross-linked and cured so as to form the high-viscosity UD non-woven fabric. Meanwhile, resin among the fibers is rapidly cured under the light radiation to form a tightly combined integral body. Tensile strength and elastic modulus can be increased, sunken depth of a flak jacket is reduced, and nonpenetrative damage caused by impact is decreased. Then, the bulletproof property is enhanced.

Owner:湖北鼎中新材料有限公司

Wear-resisting and high-rigidity polycarbonate lens

The invention discloses a wear-resisting and high-rigidity polycarbonate lens. The wear-resisting and high-rigidity polycarbonate lens comprises a polycarbonate substrate and a coating which covers the surface of the polycarbonate substrate, wherein the coating is prepared from the following raw materials: a silicon resin pre-polymer, polyurethane, epoxy resin, hydroxyethyl methylacrylate, polyester polyol, aluminum acetylacetonate, dibutyltin dilaurate, tetrabutylammonium hydroxide, methylhexahydrophthalic anhydride, 2-methylimidazole, bicyclic amidine, a solvent, a silane coupling agent andan auxiliary agent. The wear-resisting and high-rigidity polycarbonate lens provided by the invention has good wear resistance, high surface rigidity, excellent heat-resisting performance and long service life.

Owner:望江县天长光学仪器有限公司

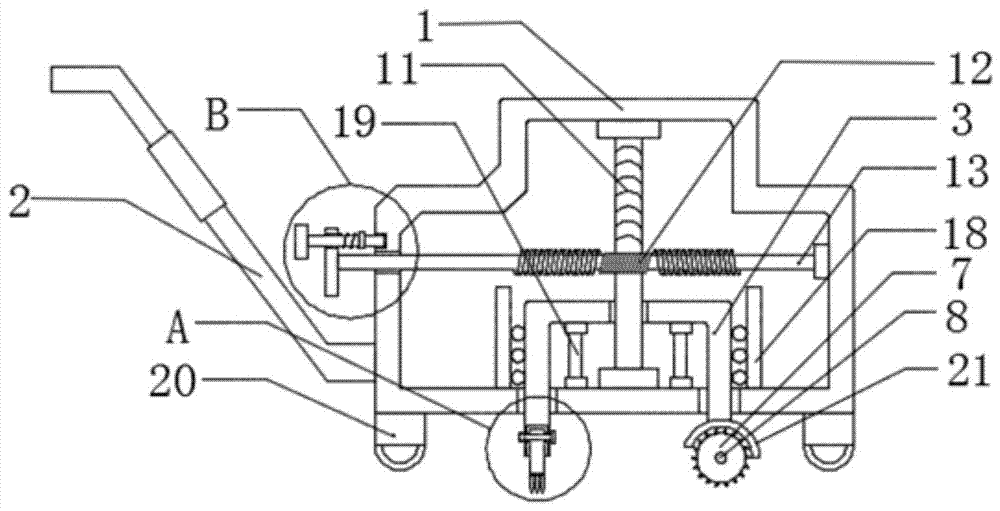

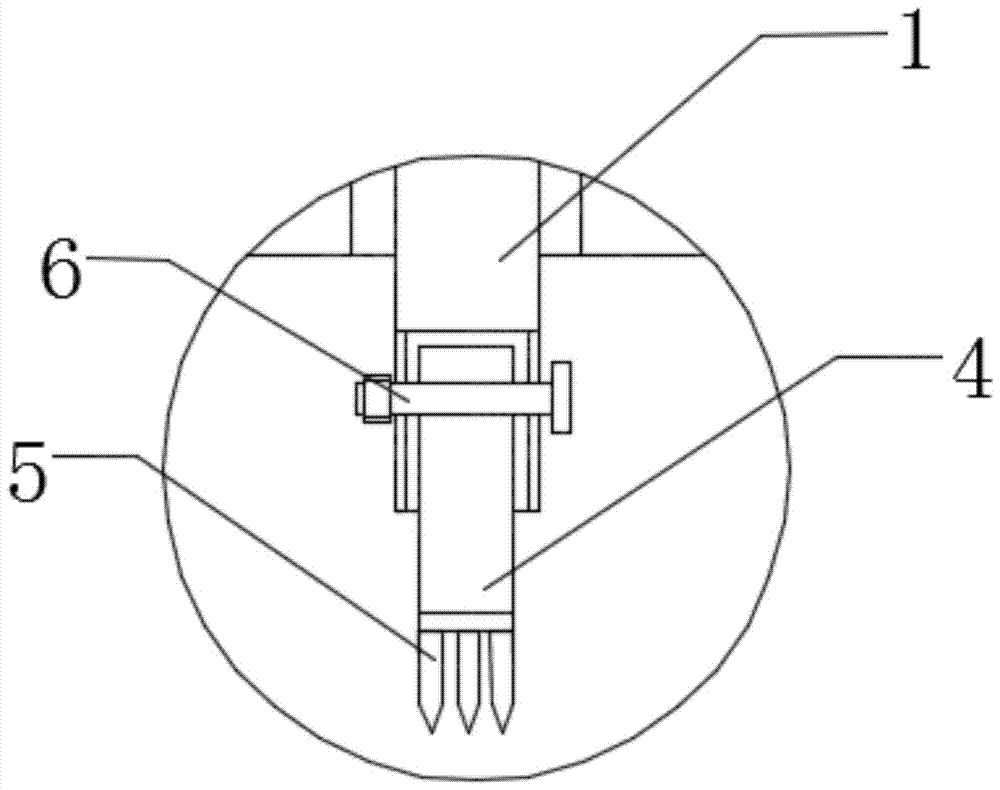

Trench smoother used for planting traditional Chinese medicinal material

InactiveCN107873155AImprove flexibility and applicabilityReduce labor intensitySpadesPloughsHandrailEngineering

The invention discloses a trench smoother used for planting traditional Chinese medicinal materials. The smoother comprises a housing. One side of the housing is fixedly connected with a handrail. Thehousing is internally provided with a reverse U-shaped joining frame. The bottom of the housing is provided with a through opening corresponding to an end of the reverse U-shaped joining frame. The reverse U-shaped joining frame is slidably connected with an inner side wall of the through opening. One end of the reverse U-shaped joining frame is provided with a smoothing plate. The bottom of thesmoothing plate is fixedly connected with a pointed cone. An end of the reverse U-shaped joining frame is provided with a clamping groove corresponding to the smoothing plate. One side of the smoothing plate, far away from the pointed cone, is fixedly connected with the clamping groove through a lock screw. One end of the reverse U-shaped joining frame, far away from the smoothing plate, is fixedly connected with a mounting cover. The mounting cover is rotatably connected with rollers through a rotating shaft. The trench smoother can perform clod breaking and smoothing on soil in an earth ditch through the rollers and the smoothing plate according to land softness, flatness, and depth degree, so as to reduce labor intensity of workers, and improve working efficiency.

Owner:嵩县禾源生态农业有限公司

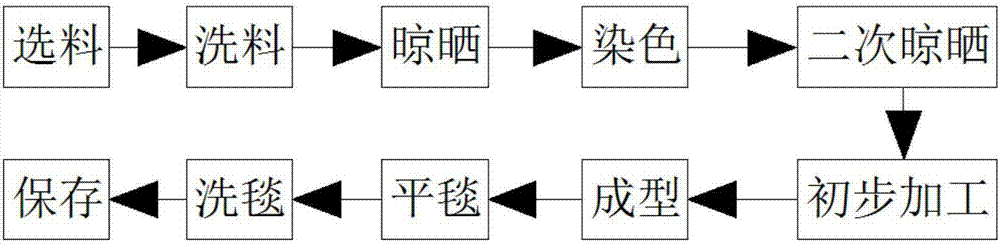

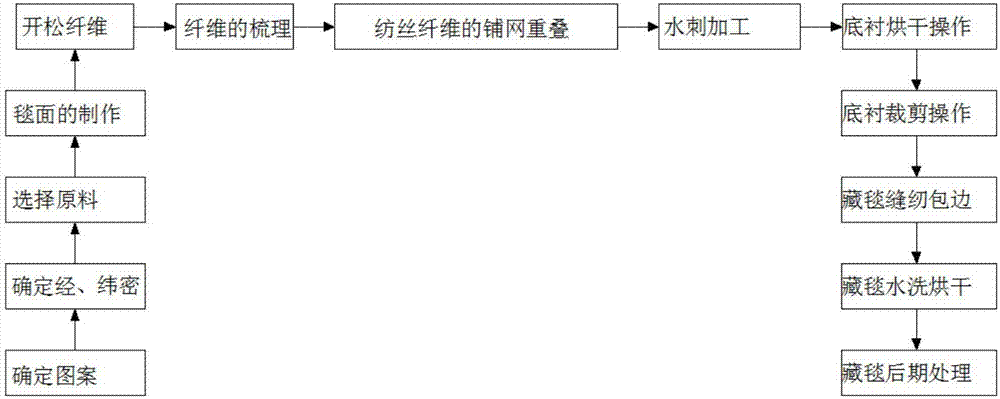

Environment-friendly peculiar smell removing Tibetan carpet manufacturing process

InactiveCN107400989AControl softnessImprove efficiencyDyeing processNon-woven fabricsProcess engineeringWater temperature

The invention discloses an environment-friendly peculiar smell removing Tibetan carpet manufacturing process. The environment-friendly peculiar smell removing Tibetan carpet manufacturing process comprises the following steps that 1, materials are selected, Tibetan wool is selected, wherein wool having the same color and luster is selected, and if a yak hair and wool mixed Tibetan carpet is needed, yak hair fluff is selected, yak hair is required to be identical in color and luster, and impurities in the raw materials are removed; 2, the materials are cleaned, the selected materials are separately put in corresponding material cleaning devices according to categories, wherein the water temperature of the material cleaning devices does not exceed 45 DEG C and is no lower than 30 DEG C, the cleaning time does not exceed 40 seconds each time, repeated cleaning is performed for five times till surface dust on the raw materials are comprehensively removed, and the original colors in the raw materials are exposed. The environment-friendly peculiar smell removing Tibetan carpet manufacturing process replaces a traditional spinning process through direct raw material compression forming, the material cost is reduced, and the defects existing in materials serving as carpet bottom liners in a traditional technology are overcome.

Owner:青海富腾生态科技有限公司

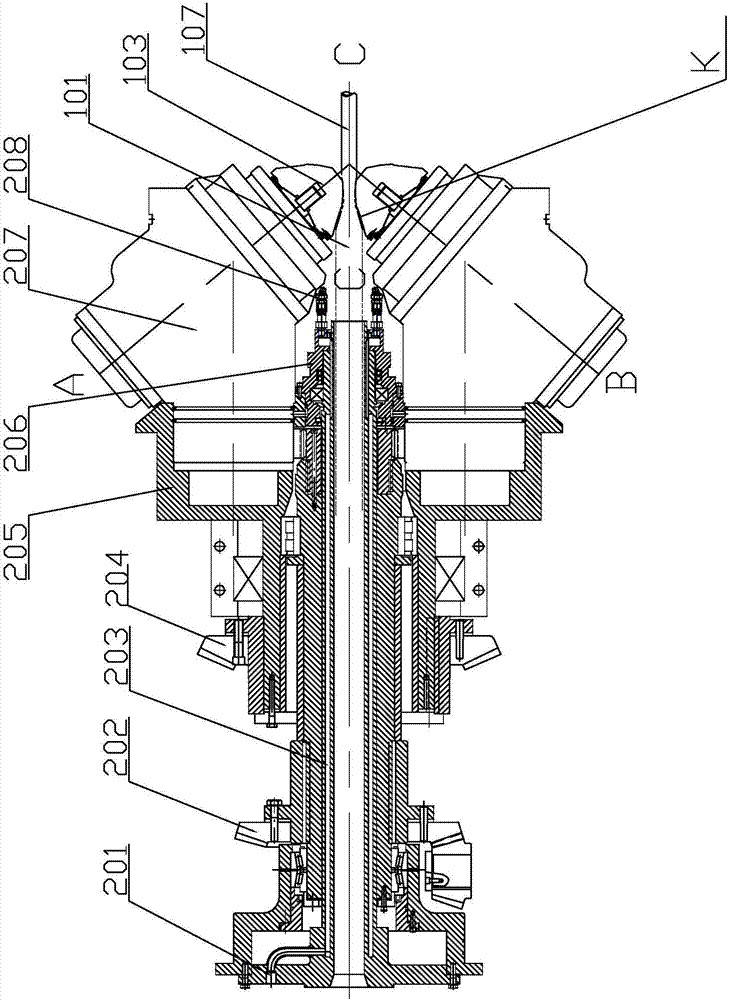

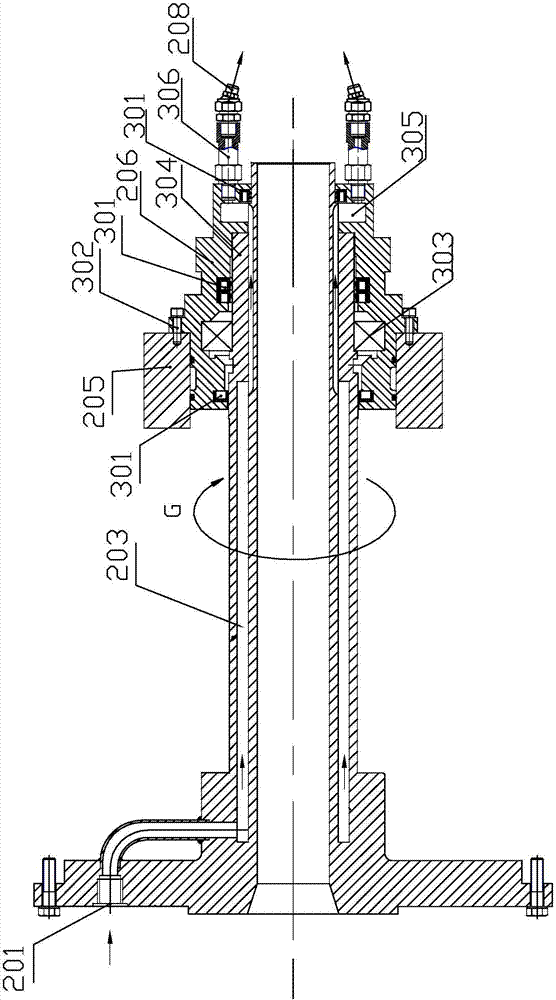

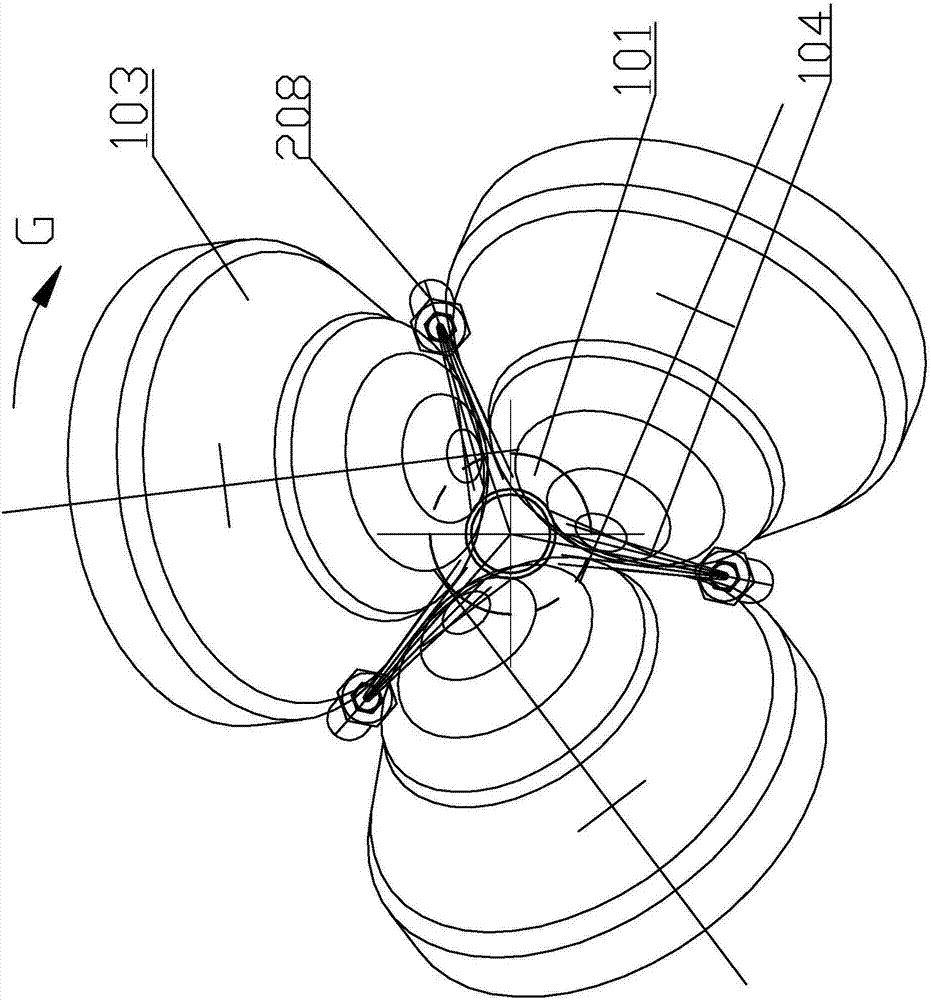

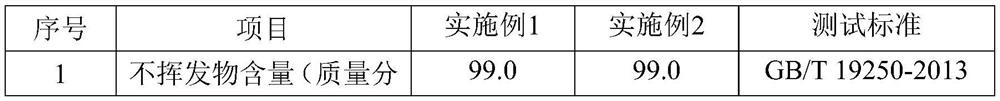

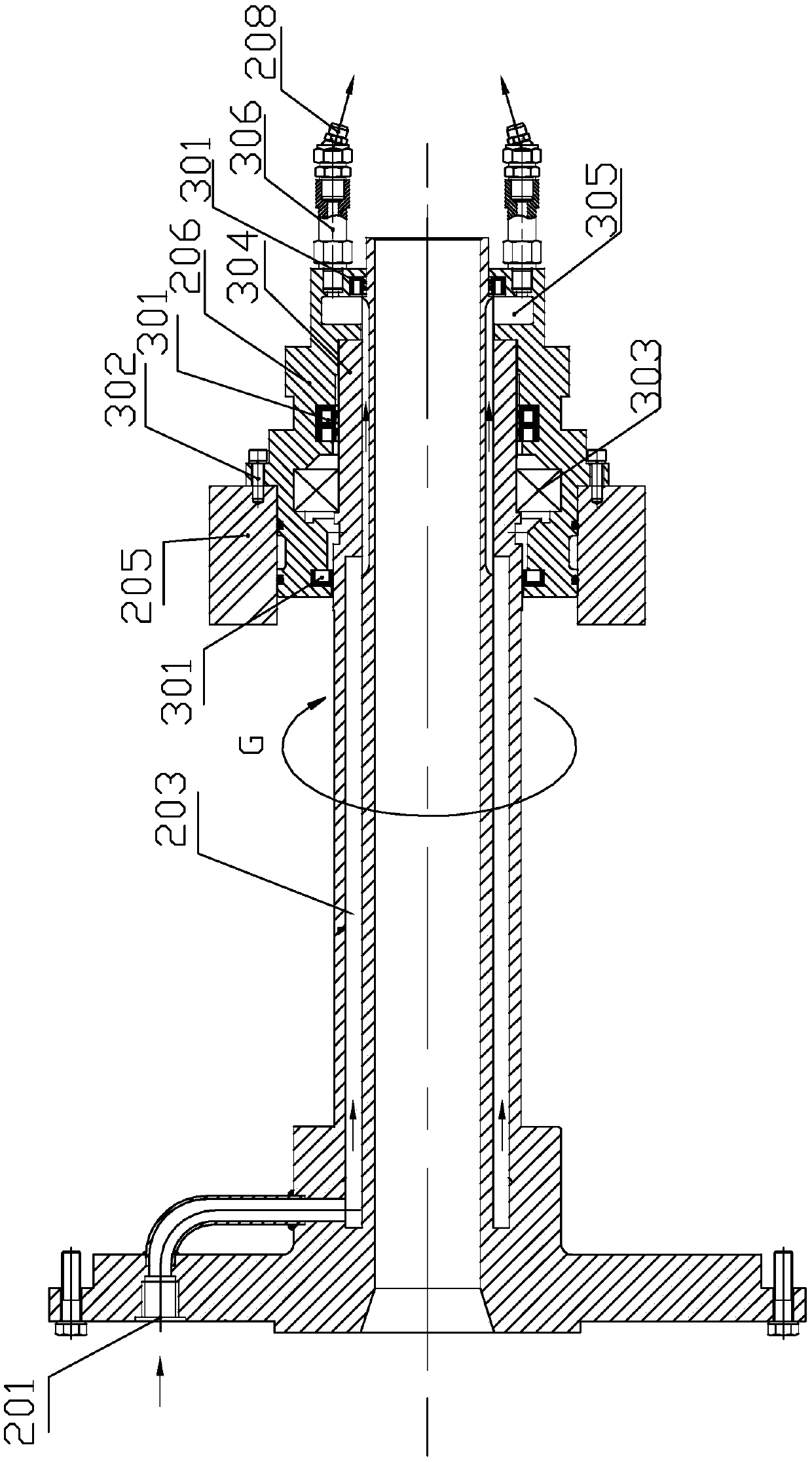

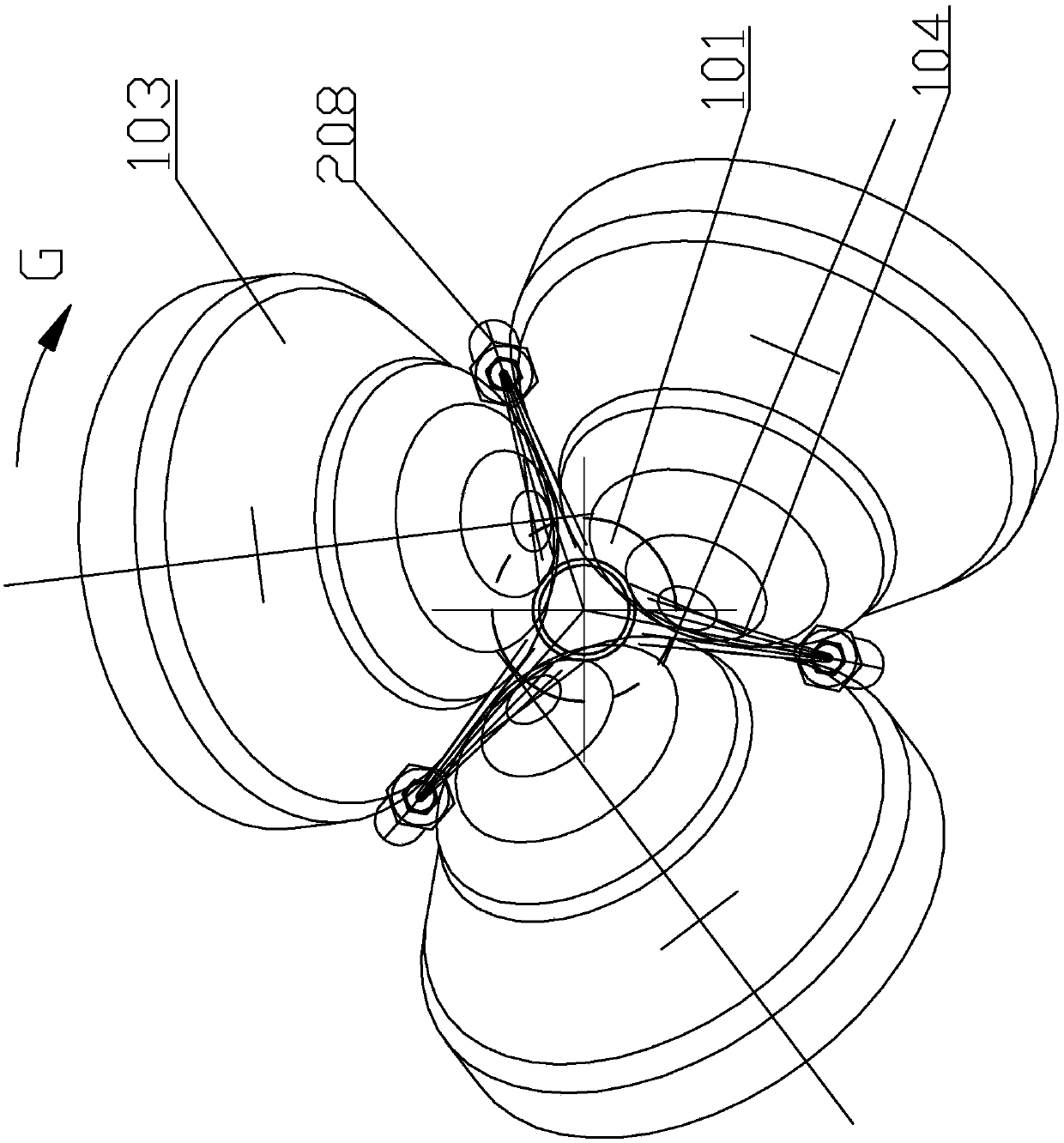

Cooling method of planetary rolling mill

ActiveCN107052053AIncrease productionImprove cooling efficiencyRollsMetal rolling arrangementsStrip millCooling effect

The invention relates to a cooling method of a planetary rolling mill, and the cooling method is used for cooing the planetary rolling mill. The cooling method of the planetary rolling mill adopts the technical scheme of comprising cooling water nozzles (208), rollers (103), a revolved body (205), a rolling center line (C-C) and a rolling deformation zone (K); and the technical scheme is characterized in that when the rolling mill works, the cooling water nozzles (208) and the revolved body (205) rotate synchronously around the rolling center line (C-C), the cooling water nozzles (208) spray cooling water to the rolling deformation zone (K), and / or the cooling water nozzles (208) spray the cooling water to the rollers (103). After the technical scheme is adopted, the cooling effect of the deformation zone and the rollers of the planetary rolling mill can be remarkably improved, and the production efficiency of the planetary rolling mill can be improved.

Owner:JIANGSU XINGRONG HI TECH

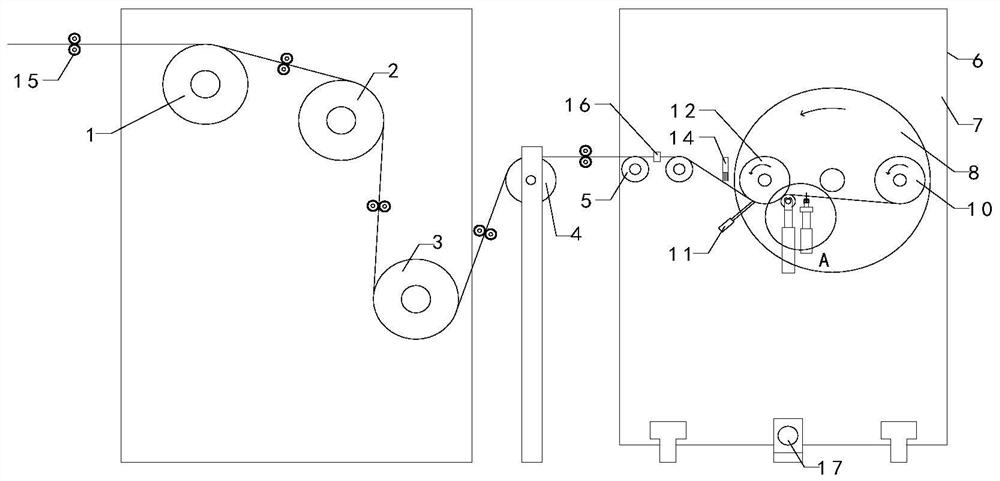

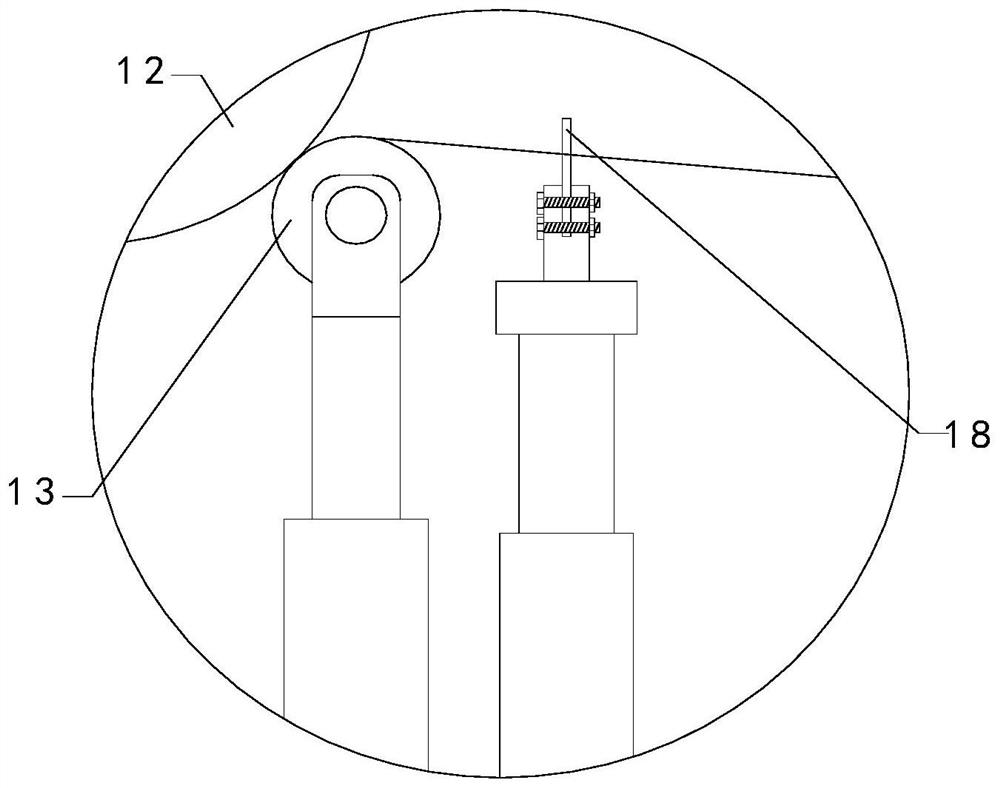

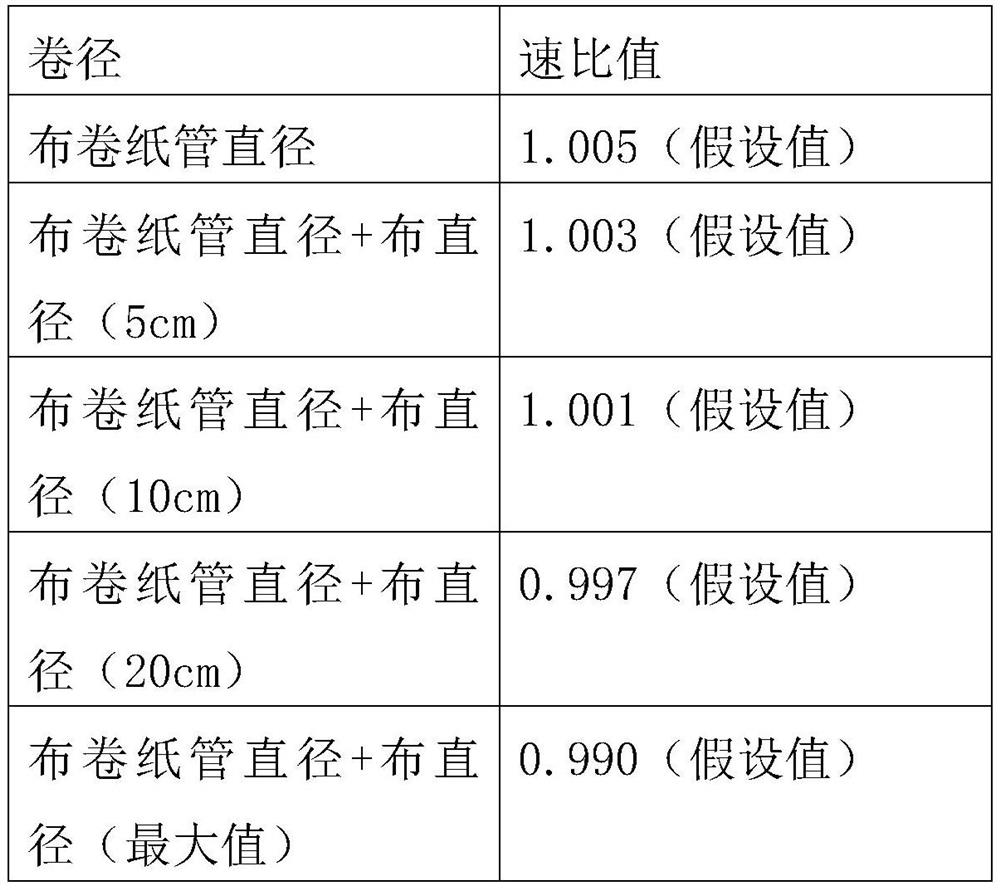

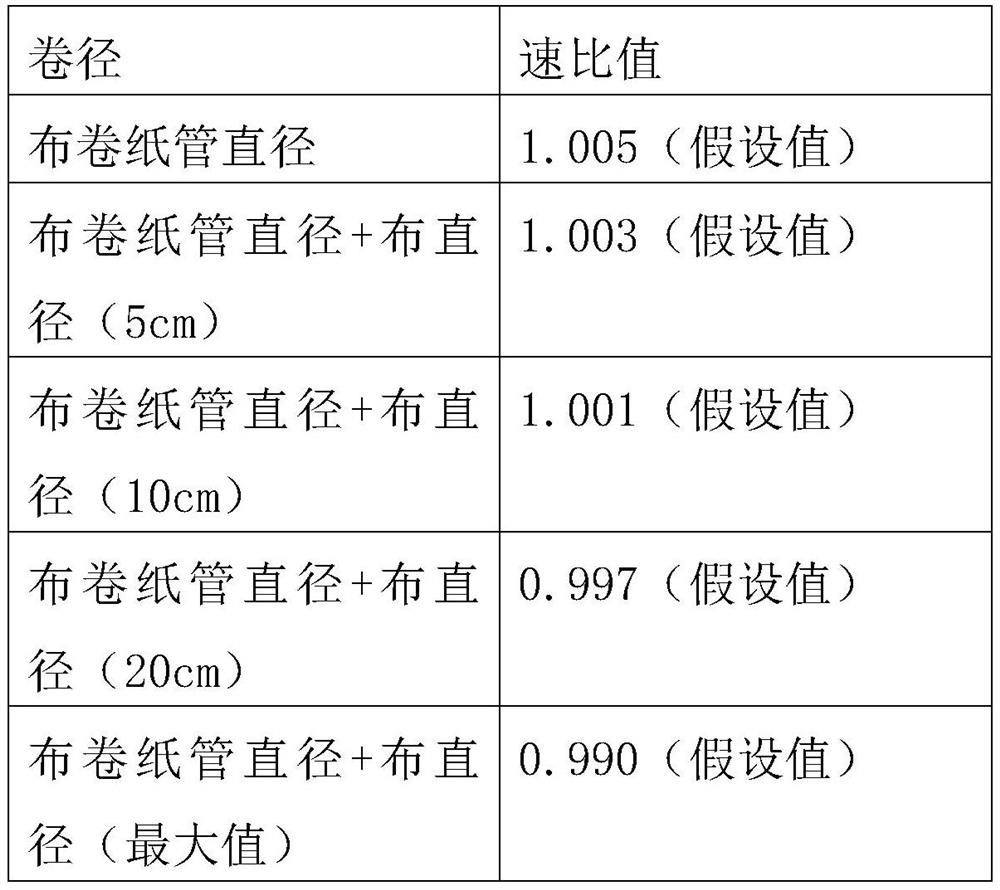

Cloth roll guide transmission method of loom

The invention relates to the technical field of loom cloth roll winding, in particular to a cloth roll guiding transmission method of a loom. The cloth roll guiding transmission method of the loom prevents cloth rolls from deviating, replacing the cloth rolls is conveniently carried out, adjusting the hardness of the cloth rolls can be carried out, and the quality of the cloth rolls is improved. The method comprises the following steps that S1, woven cloth passes through a first driving roller, a second driving roller and a third driving roller and then moves to a fourth driving roller; S2, the woven cloth passes through the fourth driving roller, then passes through two sets of driven rollers with the same model and then moves to a winding machine; S3, the winding machine comprises two sets of supports, the two sets of supports are rotationally provided with winding discs; S4, real-time diameter detection is carried out on a cloth roll paper tube on a first group of pneumatic chuck and the cloth rolls on the cloth roll paper tube by infrared roll diameter testers on the two groups of supports; S5, the cloth roll paper tube is clamped on a second set of pneumatic chuck; S6, contactrollers on the two sets of supports rise; and S7, after roll changing is completed, the hardness of the cloth on the cloth roll paper tube is adjusted.

Owner:苏州欧尼迪纺织科技有限公司

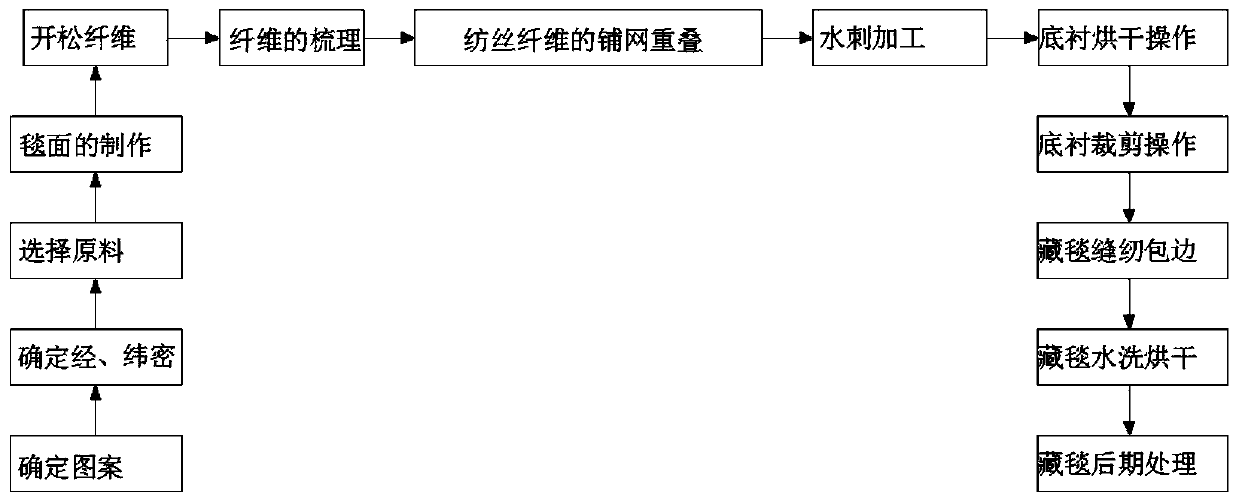

Production process of high-gram-weight non-woven Tibetan carpet

ActiveCN107400966AImprove the quality effectPromote environmental protectionWork-feeding meansSevering textilesGramEngineering

The invention discloses a production process of a high-gram-weight non-woven Tibetan carpet. The production process comprises the following steps that patterns required by the Tibetan carpet are determined, then design and colors and patterns of the Tibetan carpet are designed by using a computer, the warp density and weft density of the Tibetan carpet are determined, the warp density is 300-600, the weft density is 1000-2000, chinlon, polypropylene fiber, dacron, wool and viscose are selected as raw material yarns, corresponding colors are selected according to the color of the required Tibetan carpet, a yarn count parameter is 1000-4000 d, 5000-8000 yarns are spooled, formed and installed on a creel, the ends of various colors of yarns on the creel are led out and are connected to a loom, and an upper-half-portion carpet surface of the Tibetan carpet is woven by using a digital management control loom. The production process of the high-gram-weight non-woven Tibetan carpet can ensure the properties of high quality, high environmental friendliness and high safety of the Tibetan carpet and adopts a high-elasticity, crude-fiber, pre-needled and non-woven fabric as a bottom liner of the carpet, the hardness of the carpet is effectively controlled, the material using efficiency is improved, and the material cost is reduced.

Owner:俊富生态修复科技(青海)有限公司

Light non-toxic plasticine and preparation process thereof

InactiveCN100447195CStrong adaptability to temperature differenceColorfulToysWater basedPreservative

The present invention relates to one kind of children's toy plasticine and its preparation process. The light non-toxic toy plasticine consists of polystyrene acrylonitile through high temperature foaming treatment 3-10 wt%, polyvinyl alcohol 10-30 wt%, borax 0.01-0.05 wt%, glycerin 1-8 %, water base preservative 0.01-0.15 wt% and water for the rest. The present invention has the advantages of light weight, bright color, good hand feeling, etc. and may be used as children's toy, in making model, sculpture draft, etc.

Owner:浙江银太郎动漫文化股份有限公司

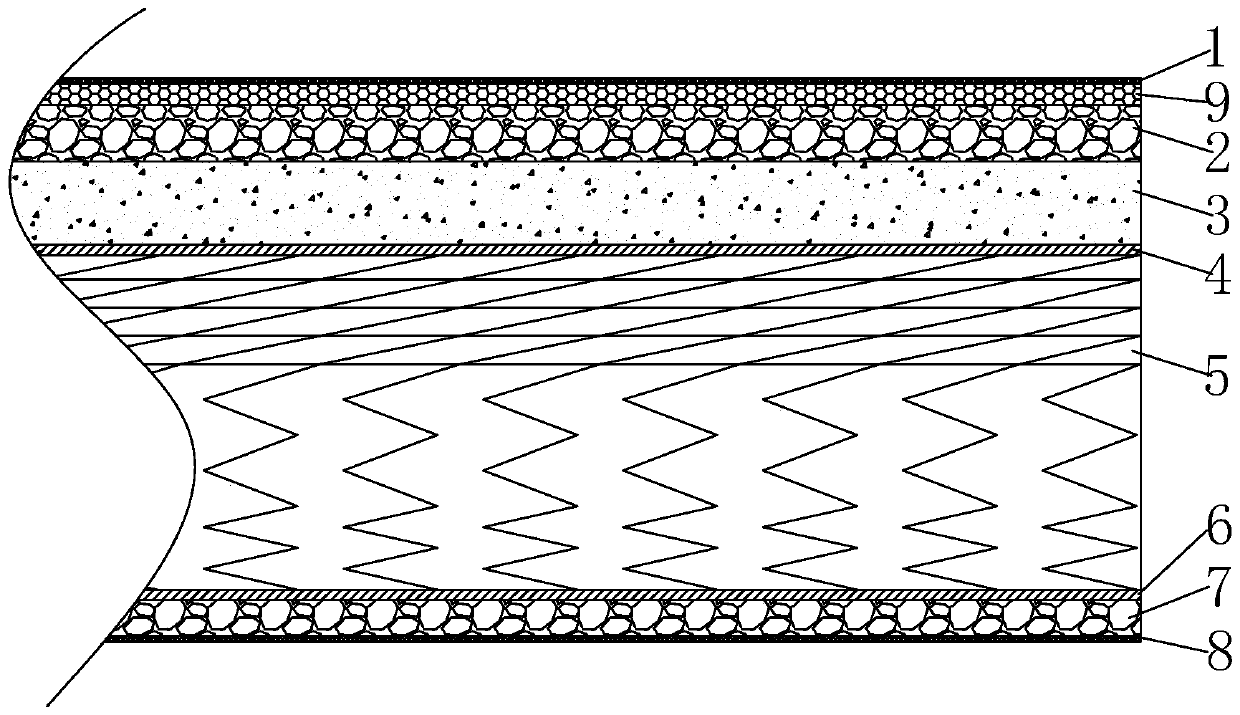

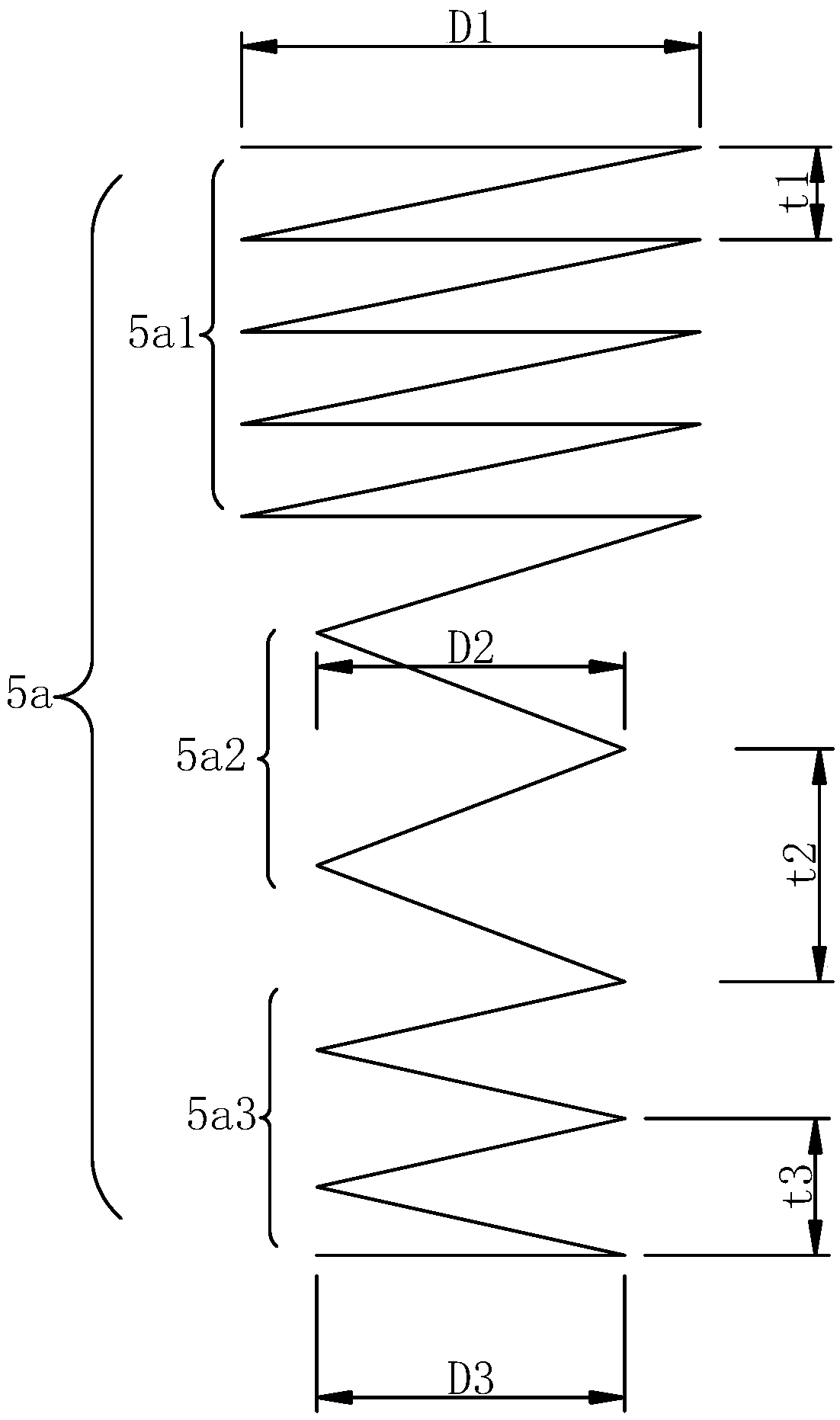

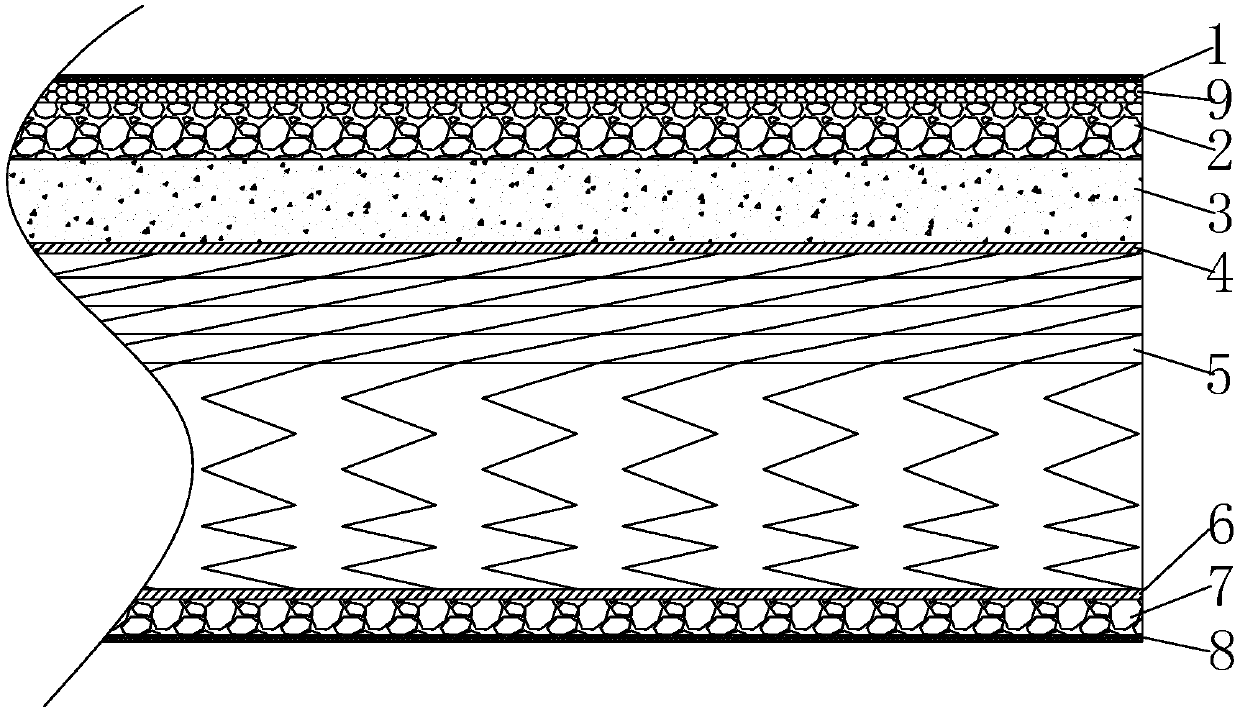

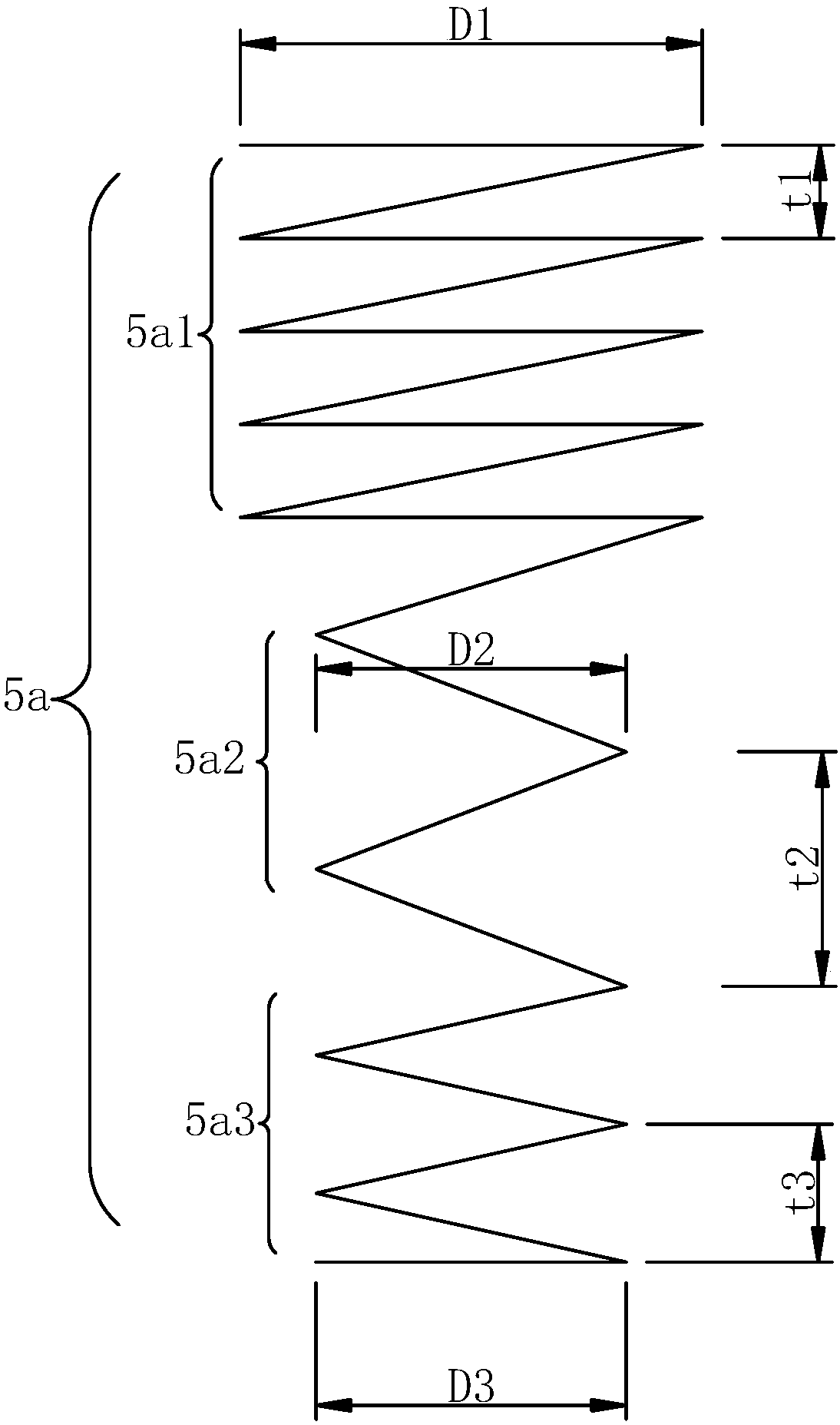

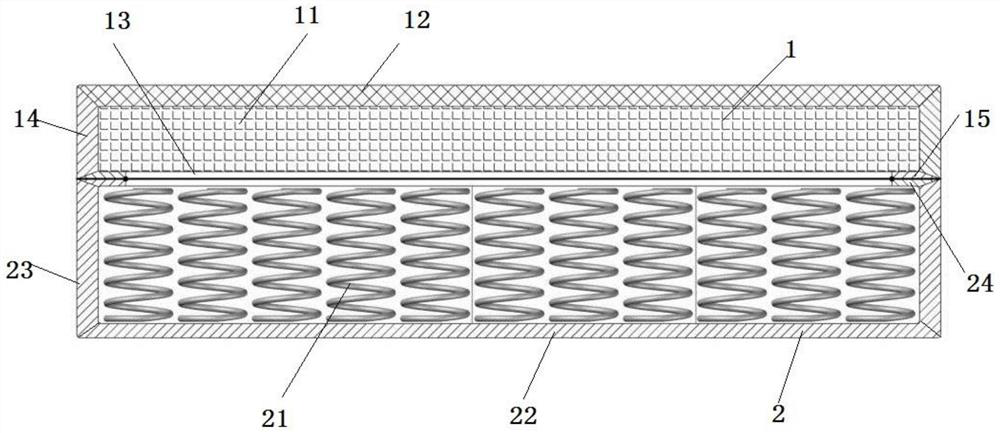

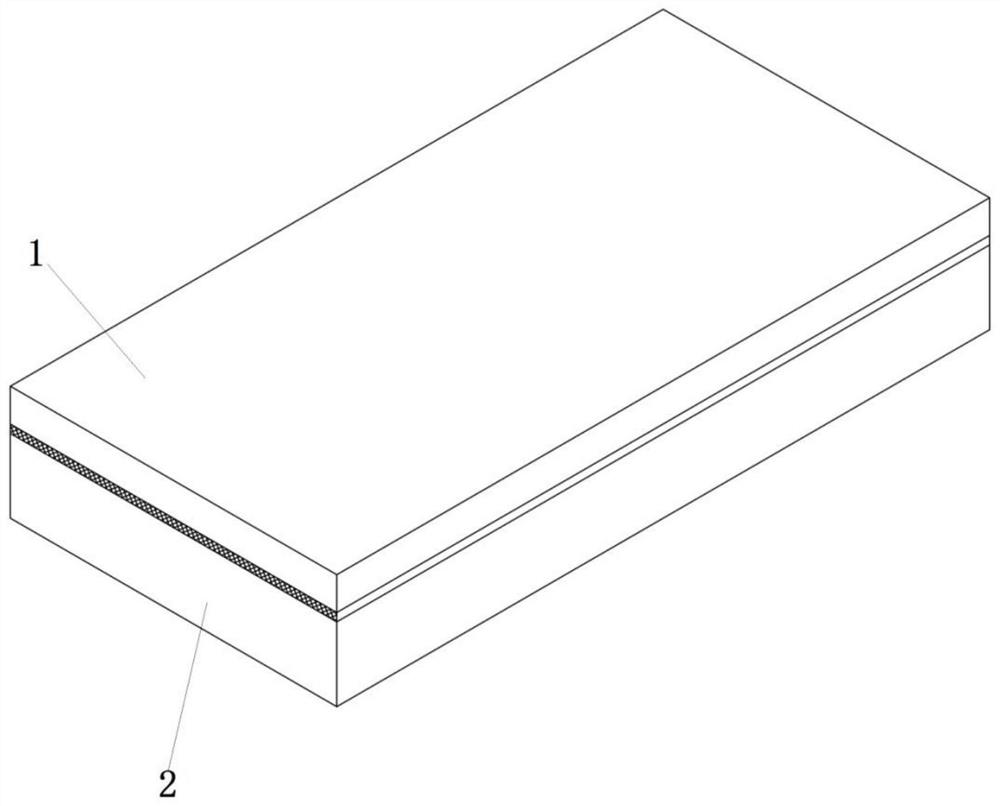

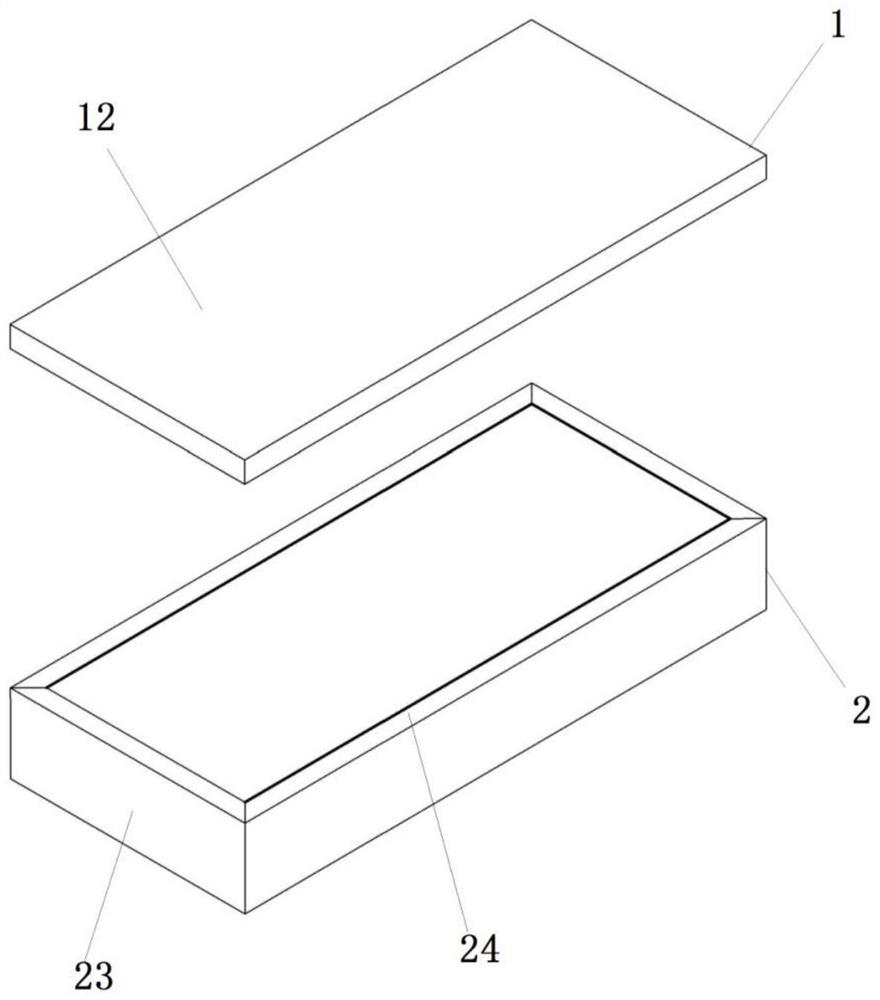

Mattress with soft top and hard middle

The invention discloses a mattress with a soft top and a hard middle. The mattress comprises an upper knitted fabric layer, an upper high-resilience sponge layer, a gel memory cotton layer, an upper environment-friendly felt layer, an independent cloth bag spring layer, a lower environment-friendly felt layer, a lower high-resilience sponge layer and a lower knitted fabric layer, which are overlapped together from top to bottom, wherein each spring in the independent cloth bag spring layer comprises an upper spring region, a middle spring region and a lower spring region in sequence from top to bottom; the pitch diameter of the spring in the upper spring region is D1, and the pitch of the upper spring region is t1; the pitch diameter of the spring in the middle spring region is D2, and the pitch of the middle spring region is t2; the pitch diameter of the spring in the lower spring region is D3, and the pitch of the lower spring region is t3; the D2 is equal to the D3 and the D3 is smaller than D1; the t3 is more than the t1 and less than the t2; and a latex layer is arranged between the upper knitted fabric layer and the upper high-resilience sponge layer. The technical scheme of the invention is applicable to the mattresses.

Owner:WUHAN GUOTAI LONGXIANG HOME CO LTD

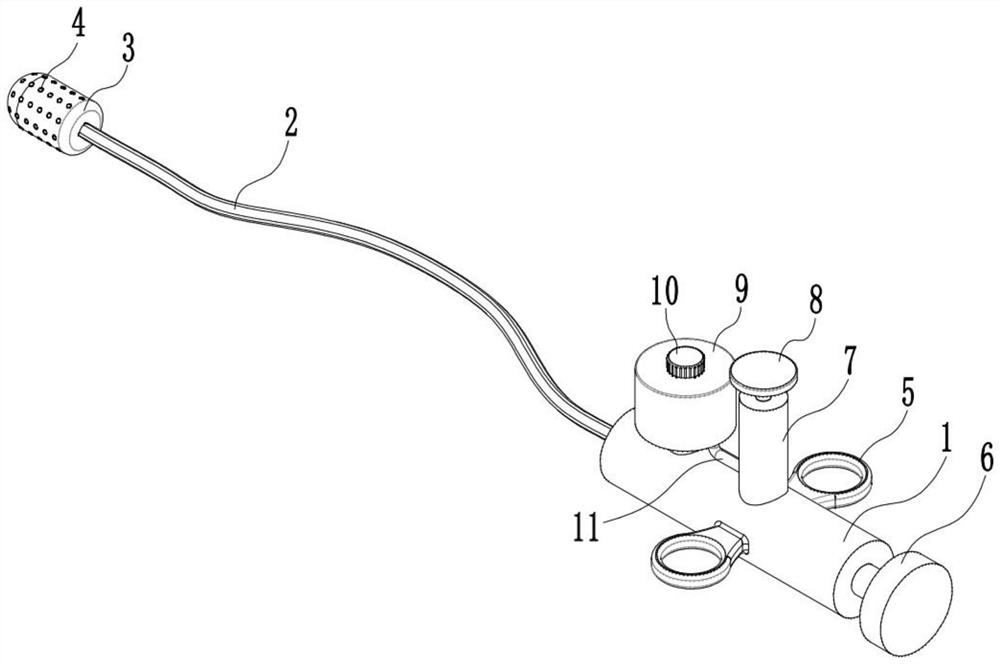

Esophagus applicator for digestive system department

PendingCN114367010AControl softnessGood application aidMedical devicesPharmacy medicineEsophago-esophageal

The invention discloses an esophagus applicator for the digestive system department, and relates to the technical field related to medical instruments, the esophagus applicator comprises a handheld tube, the front end of the handheld tube is fixedly connected with an insertion tube, the end, away from the handheld tube, of the insertion tube is fixedly connected with an applying head, the applying head is provided with a plurality of outflow holes, and the handheld tube is provided with a medicine storage assembly, a pressurizing mechanism and an inflating assembly; the medicine storage assembly comprises a medicine storage barrel fixedly arranged on the handheld pipe, the top end of the medicine storage barrel is in threaded connection with a sealing cover, the bottom end in the medicine storage barrel is fixedly connected with a gathering base, and the center of the gathering base is fixedly connected with a medicine placing assembly; by arranging the medicine storage assembly, needed medicine can be stored, by arranging the pressurizing mechanism, the medicine can be continuously output, conveying and stopping of the medicine can be controlled, by arranging the inflating assembly, the softness degree of the inserting pipe can be controlled, adjustment can be conveniently conducted according to use requirements, and the practicability is high. The esophagus applicator is good in medicine applying assistance for the esophagus of the digestive system department, easy to operate and high in functionality.

Owner:开封市陇海医院

A loom roll guide transmission method

Owner:苏州欧尼迪纺织科技有限公司

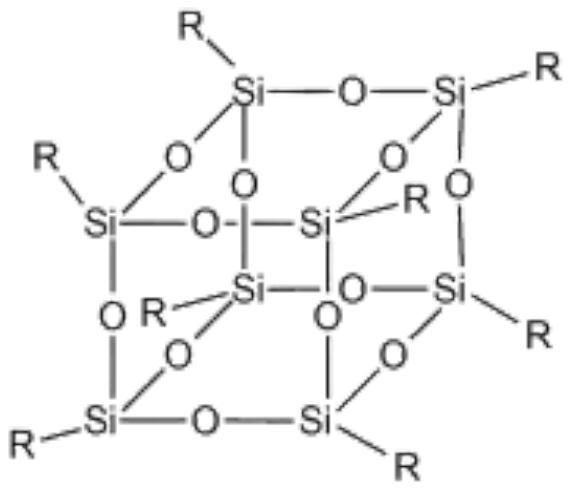

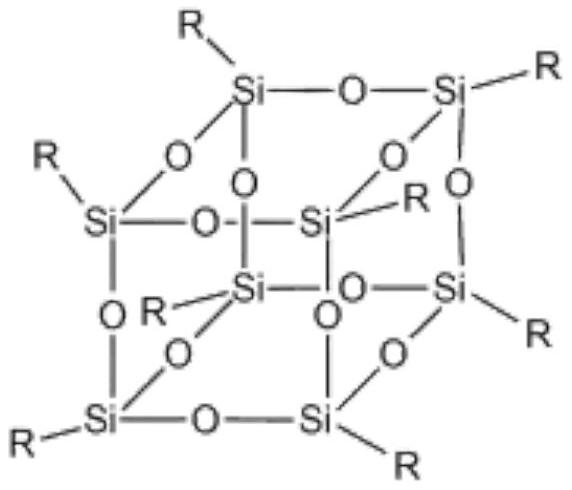

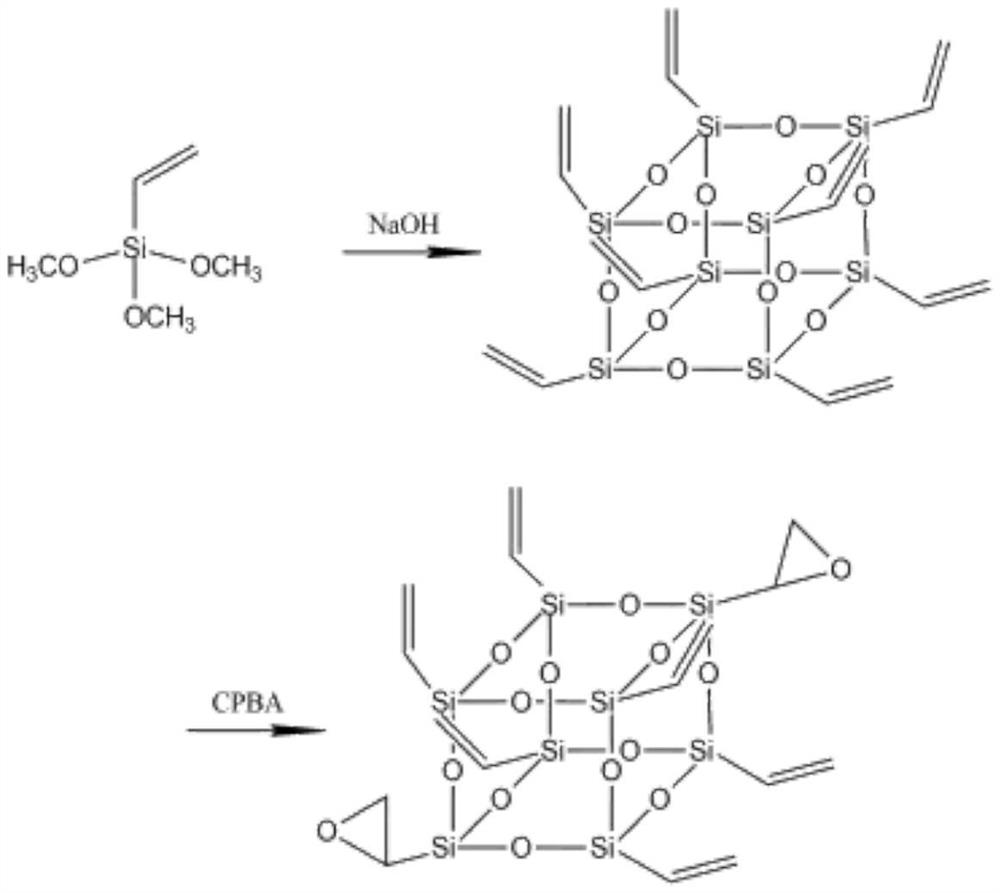

Organic silicon pressure-sensitive adhesive without pause marks and with high anchoring property, preparation method and application thereof

PendingCN113956837AImprove cohesive strengthControl softnessMacromolecular adhesive additivesPressure sensitive film/foil adhesivesSilicone resinOrganosilicon

The invention discloses an organic silicon pressure-sensitive adhesive without pause marks and with high anchoring property. The formula of the organic silicon pressure-sensitive adhesive comprises an epoxy ethyl vinyl polyhedral oligomeric silsesquioxane (POSS) functional additive, vinyl silicone rubber with different vinyl contents, hydroxyl raw rubber, hydroxyl MQ silicon resin, vinyl MQ silicon resin, an inhibitor and a solvent. The POSS additive with customized functional groups is added, so that the pressure-sensitive adhesive film has good stripping force, meanwhile, pause marks do not appear when a protective film is stripped, good anchoring performance can be formed on a base material, the adhesive force is good, degumming is not prone to occurring, and meanwhile bubbles can be rapidly removed in the attaching process. The prepared organic silicon pressure-sensitive adhesive can meet the harsh requirements in the related fields of high-end process protection, fingerprint-resistant glass protection films, waste discharge films and the like.

Owner:WANHUA CHEM GRP CO LTD

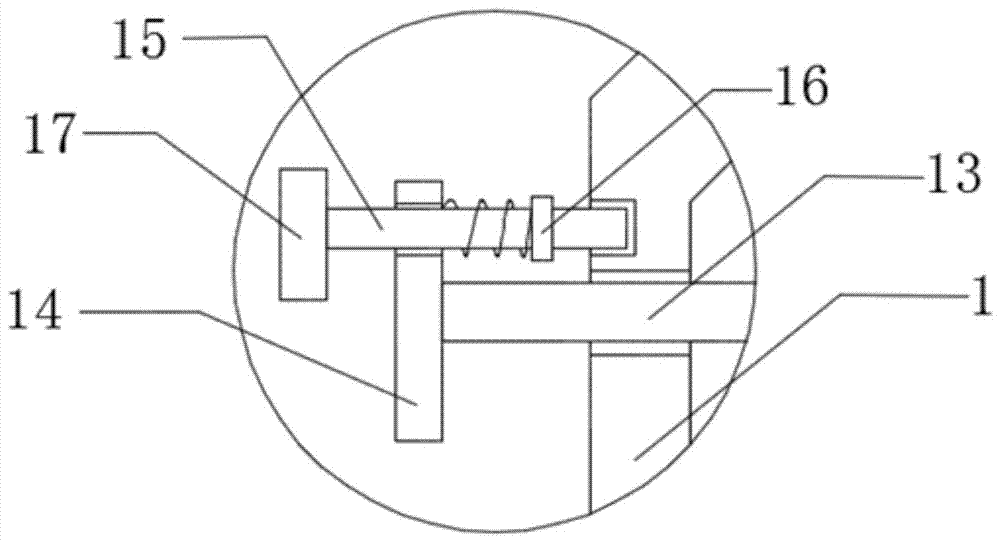

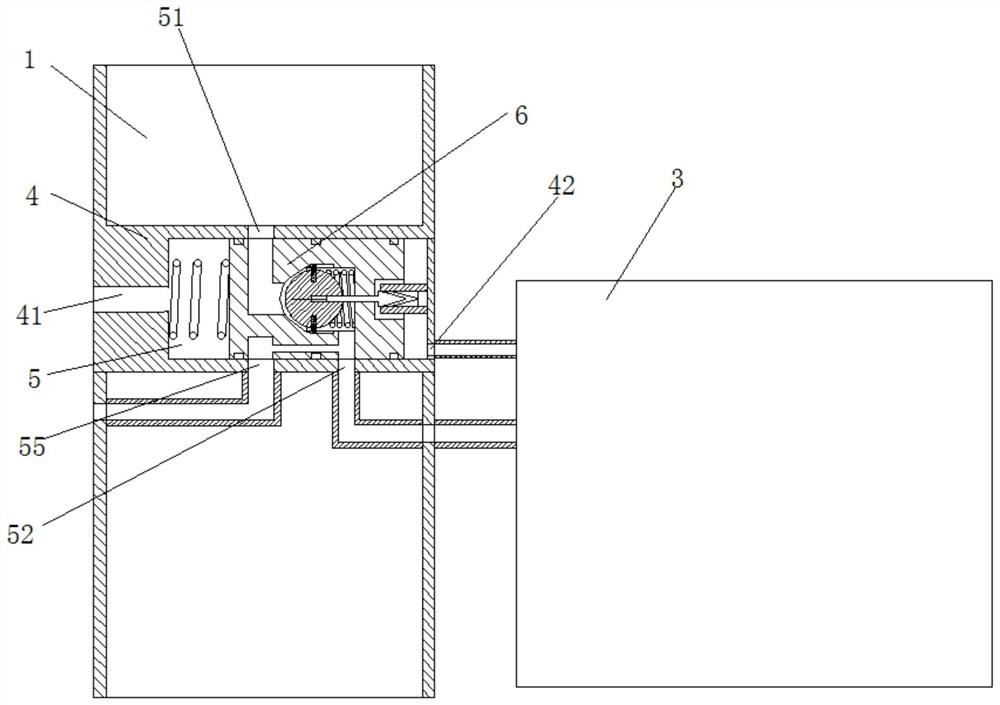

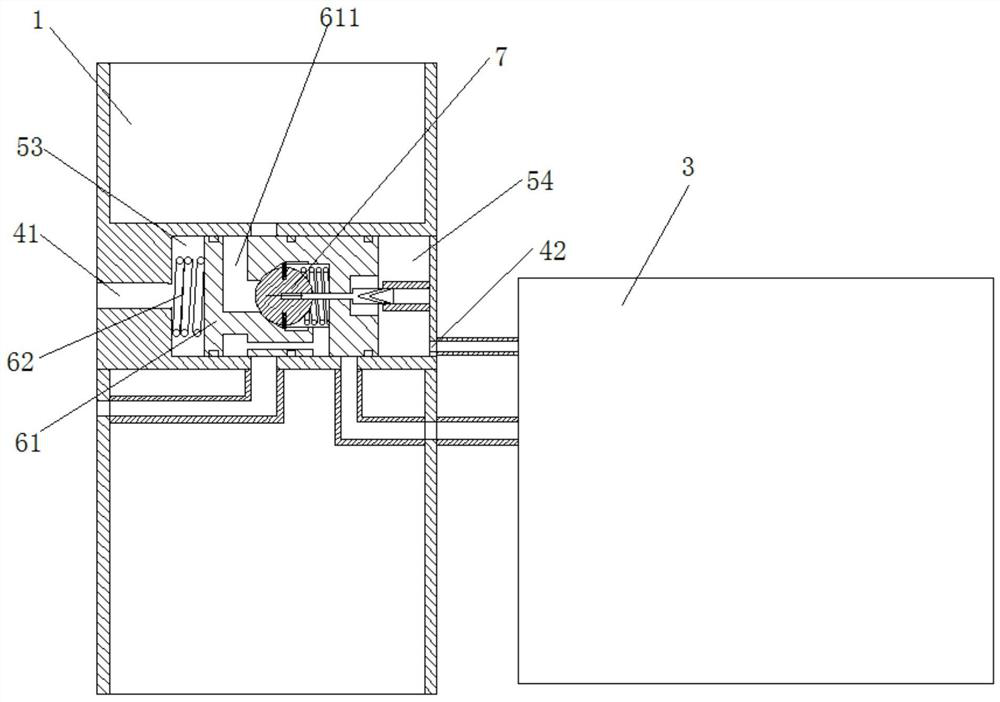

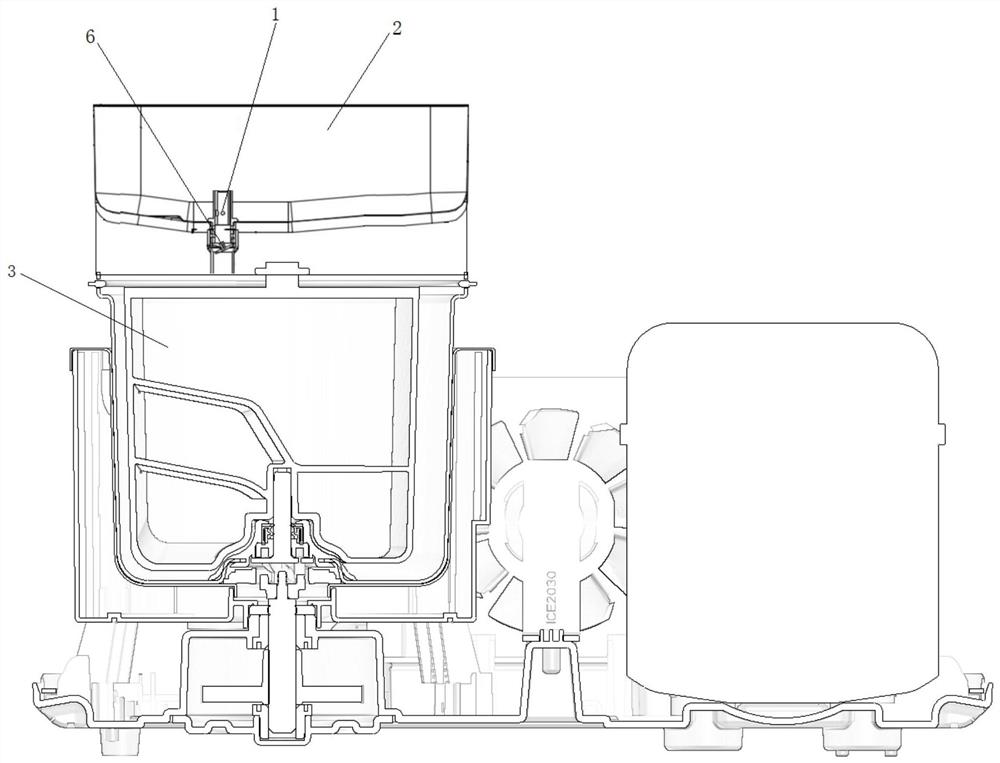

Puffing self-locking device for ice cream machine

The invention discloses a puffing self-locking device for an ice cream machine. The device comprises a feeding channel, the feeding channel is used for communicating a material storage box and a material barrel, a baffle block is arranged in the feeding channel, an adjusting cavity is arranged in the baffle block, the adjusting cavity is provided with a feeding hole communicated with the material storage box and a discharging hole communicated with the material barrel, an adjusting mechanism is arranged in the adjusting cavity, and the feeding hole and the discharging hole are selectively communicated through the adjusting mechanism. When air pressure during ice cream making in the material barrel reaches a critical value, the adjusting mechanism starts to work, so that the feeding hole and the discharging hole are not communicated, the discharging hole is sealed in advance before ice cream in the material barrel is expanded to block the discharging hole, and meanwhile, the situation that gas in the material barrel is extruded out to reduce the gas in the material barrel is prevented, and therefore, the sealing performance of the material barrel is ensured, and the puffing efficiency of the ice cream is improved; and by additionally arranging the material storage box and the feeding channel, the hardness of the ice cream can be controlled, so that ice cream with different tastes can be made, and the use experience of a user is improved.

Owner:ZHONGSHAN DONLIM WEILI ELECTRICAL APPLIANCES CO LTD

Preparation method of polyvinylidene fluoride modified composite conductive adhesive

The invention relates to a preparation method of a polyvinylidene fluoride modified composite conductive adhesive. The method includes the following steps: (1), adding a polyvinylidene fluoride dispersion emulsion to a reaction kettle, purging nitrogen to remove oxygen, stirring, adding a fluorine-containing monomer, heating, and adding an initiator and a molecular weight regulator; (2), keeping the polymerization temperature and stirring speed unchanged during the reaction, and after completing the reaction, cooling and discharging to obtain a composite material; and (3), adding deionized water, hydrochloric acid, a conductive polymer monomer and the composite material prepared in the step (2) to a reaction tank, performing ultrasonic dispersion, weighing the initiator, dissolving the initiator in the deionized water, adding the mixture to a reaction solution subjected to ultrasonic dispersion, stirring, separating, washing and drying. According to the scheme of the invention, polyvinylidene fluoride is modified by performing graft copolymerization on the fluorine-containing monomer, the crystallinity of PVDF can be reduced, and the stickiness and flexibility of polyvinylidene fluoride can be improved; and by adding the conductive polymer monomer, the conductivity of the composite adhesive can be improved, and the resistance can be reduced.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

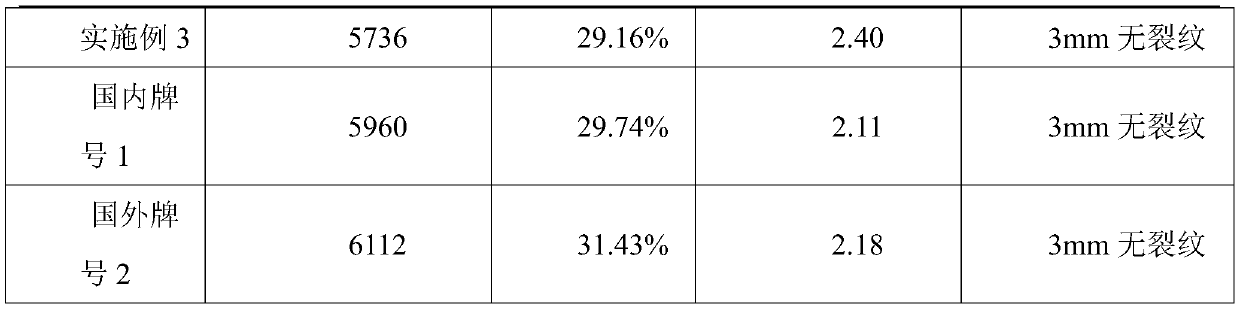

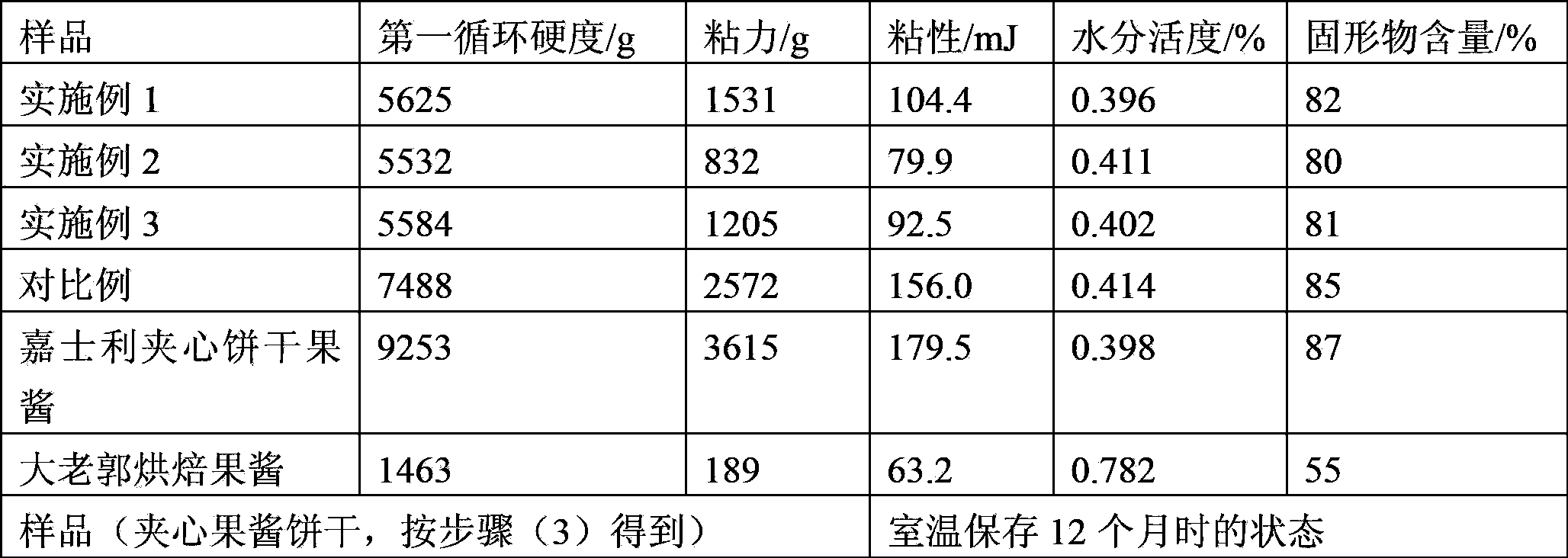

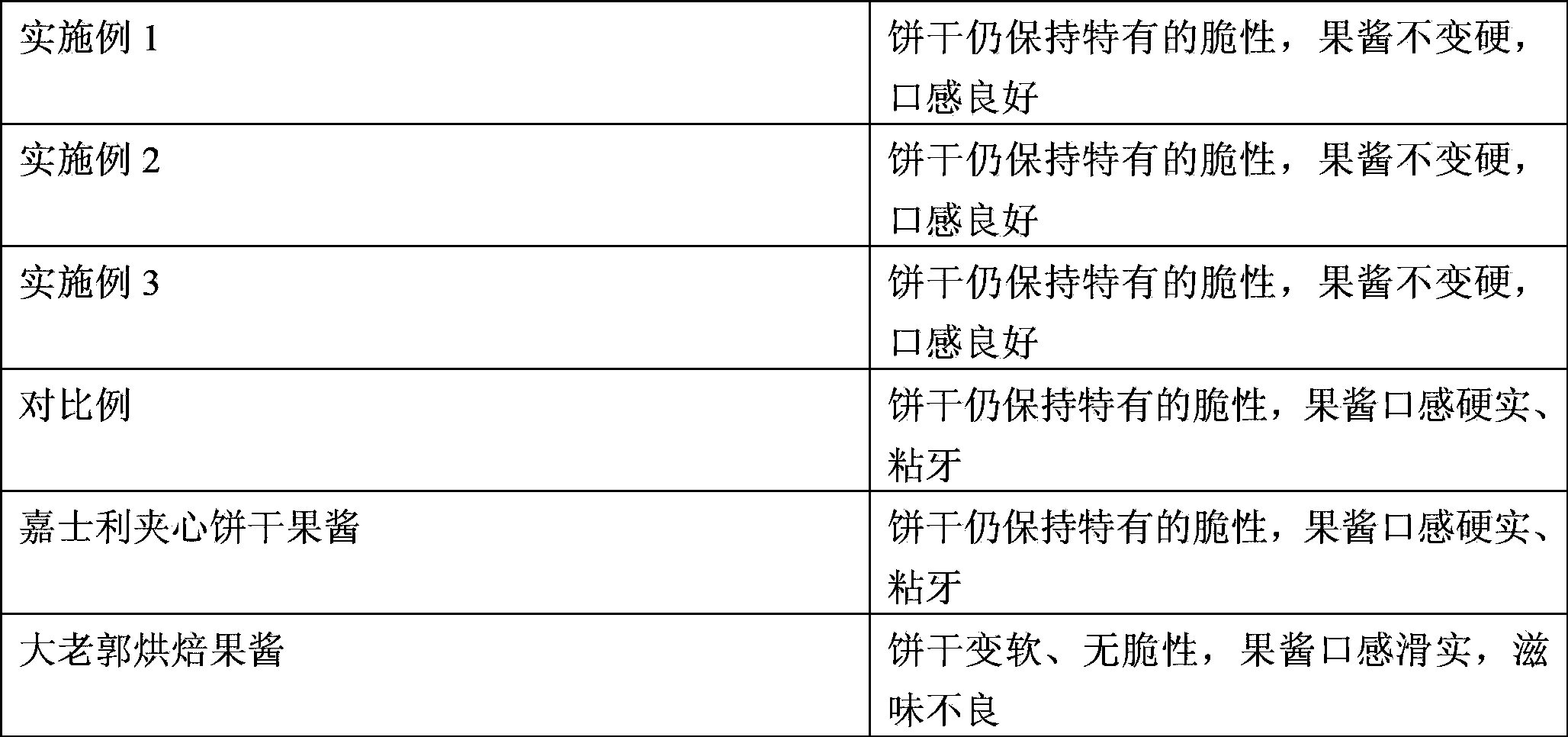

Dried fruit jam of sanwiched cake for industrial production and preparation method and applications thereof

ActiveCN103005244BDelicate and smooth tasteHigh degree of meltingBakery product preservationFood preparationGlycerolSlurry

The invention discloses a dried fruit jam of a layer cake for industrial production and a preparation method and applications thereof. The jam comprises the following components: 20-35% of granulated sugar, 30-40% of high fructose corn syrup, 10-20% of d-sorbitol solution, 5-10% of modified starch, 2-8% of edible glycerol, 0.5-0.7% of composite colloid, 0.6-0.8% of composite chelate salt, 0.1-0.3% of citric acid and 2-5% of dried fruit. According to the dried fruit jam, the modified starch, the composite colloid, the composite chelate salt are evenly mixed, water is added and then the mixture is stirred for dissolving until no obvious particle exists to obtain slurry; the high fructose corn syrup, the d-sorbitol solution and the granulated sugar are stirred and mixed, the slurry is added and the mixture is stirred while being heated; the mixture is heated and pasted to volatilize water until the content of solid content is 80-82%; the edible glycerol is added and the mixture is evenly mixed and cooled to 85-95 DEG C; and the dried fruit and the citric acid solution are added and the mixture is evenly stirred to obtain the jam. According to the dried fruit jam, the water activity of the jam is below 0.45, the mouthfeel is smooth and fine. The jam does not stick to teeth and the melting degree in mouth is high. The gel-state jam has a low heating temperature and can conveniently industrially prepare layer cakes.

Owner:广州合诚实业有限公司

A mattress with upper soft and medium firmness

The invention discloses a mattress with a soft top and a hard middle. The mattress comprises an upper knitted fabric layer, an upper high-resilience sponge layer, a gel memory cotton layer, an upper environment-friendly felt layer, an independent cloth bag spring layer, a lower environment-friendly felt layer, a lower high-resilience sponge layer and a lower knitted fabric layer, which are overlapped together from top to bottom, wherein each spring in the independent cloth bag spring layer comprises an upper spring region, a middle spring region and a lower spring region in sequence from top to bottom; the pitch diameter of the spring in the upper spring region is D1, and the pitch of the upper spring region is t1; the pitch diameter of the spring in the middle spring region is D2, and the pitch of the middle spring region is t2; the pitch diameter of the spring in the lower spring region is D3, and the pitch of the lower spring region is t3; the D2 is equal to the D3 and the D3 is smaller than D1; the t3 is more than the t1 and less than the t2; and a latex layer is arranged between the upper knitted fabric layer and the upper high-resilience sponge layer. The technical scheme of the invention is applicable to the mattresses.

Owner:WUHAN GUOTAI LONGXIANG HOME CO LTD

Preparation, application and mattress of a kind of bamboo spring

ActiveCN113616032BMeet quantitative supportImprove interfacial pressure distributionStuffed mattressesSpring mattressesPolymer scienceEngineering

The invention provides a method for preparing a bamboo spring, which comprises the following steps: obtaining bamboo silk, and classifying the bamboo silk into six grades per 5GPa according to the elastic modulus; The primary raw materials of bamboo silk in 5 and 6 are chemically and impregnated in turn: the modified bamboo silk is divided into silk, coiled, and preliminarily cured at the same time as coiling; Curing treatment, and then drying treatment; (4) After polishing treatment, the bamboo springs of the same specification are divided into several density grades according to the quality difference from small to large, and finally bamboo spring bodies of different specifications and different quality grades are obtained. The present invention also provides the application of the above bamboo spring and the bamboo spring mattress. The bamboo spring prepared by the invention has the advantages of ventilation and moisture dissipation, antibacterial and antibacterial, green, low-carbon and environmental protection, and at the same time, the bamboo spring mattress can meet the quantitative support requirements of people of different body shapes and weights.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Method for regulating and controlling hardness of extruded textured protein

PendingCN114365793AControl softnessMeet individual needsProteins working-up by texturisingVegetable proteins working-upProtein foodFood products

The invention relates to a method for regulating and controlling the hardness of extruded textured protein, and belongs to the field of food manufacturing. According to the regulation and control method, the adjustable hardness range of the extruded textured protein is 1302 + / -180.0 [g] to 2136 + / -129.6 [g]; the difference value between the average value of the maximum hardness and the average value of the minimum hardness is 834 [g]; the average value of the maximum hardness and the minimum hardness is 1719 [g]; the percentage (P) of (the difference between the maximum hardness and the minimum hardness) in (the average value of the maximum hardness and the minimum hardness) is 48.5%. According to the method for regulating and controlling the hardness of the extruded textured protein, a novel scheme for simply and quickly regulating and controlling the hardness of the extruded textured protein is provided. By applying the scheme, the hardness of the extruded textured protein can be quantitatively regulated and controlled in a wide range, so that extruded textured protein foods with different hardness can be conveniently produced, and the individual requirements of consumers on the hardness can be met.

Owner:麦岐(深圳)生物科技有限公司

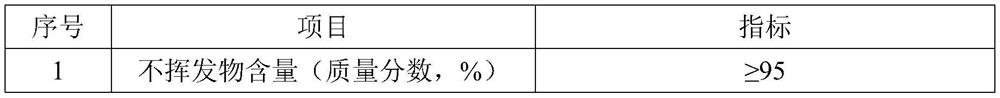

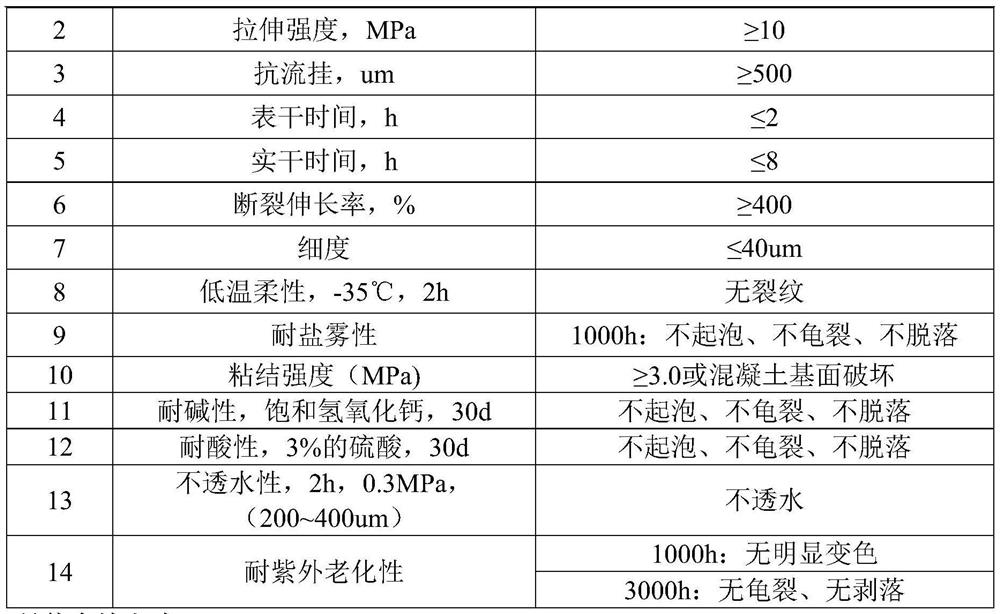

Anti-sagging quick-drying two-component polyurethane waterproof paint as well as preparation method and application thereof

InactiveCN112457761ALow viscosityGood anti-sag performanceProtective foundationRoof covering insulationsPolymer sciencePtru catalyst

The invention discloses an anti-sagging quick-drying two-component polyurethane waterproof paint, which comprises a component A and a component B. The weight ratio of the component A to the componentB is (1: 1)-(1: 2), and the component A is mainly prepared from polytetrahydrofuran ether glycol, aliphatic isocyanate, a plasticizer, a chain extender and a catalyst A; and the component B is mainlyprepared from ethylene diamine polyether, polyaspartate polyurea resin, a plasticizer, carbon black, a catalyst B, an inorganic filler, a thixotropic agent and other assistants. The preparation methodcomprises the following steps: carrying out vacuum dehydration on polytetrahydrofuran ether glycol, cooling, and adding other components to prepare the component A; uniformly dispersing ethylene diamine polyether and polyaspartic acid ester polyurea resin, adding other components, and grinding to obtain the component B; the waterproof paint is an aliphatic polyurethane waterproof paint, a concrete protective layer is not needed in waterproof layer construction, the waterproof paint can be directly exposed, meanwhile, a concrete protective layer is not needed, the sagging resistance value of the waterproof paint is 500 [mu]m or above, surface drying and hard drying are fast, and the product maintenance period is shortened.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

A cooling method for a planetary pipe mill

ActiveCN107052053BIncrease productionImprove cooling efficiencyRollsMetal rolling arrangementsStrip millCooling effect

The invention relates to a cooling method of a planetary rolling mill, and the cooling method is used for cooing the planetary rolling mill. The cooling method of the planetary rolling mill adopts the technical scheme of comprising cooling water nozzles (208), rollers (103), a revolved body (205), a rolling center line (C-C) and a rolling deformation zone (K); and the technical scheme is characterized in that when the rolling mill works, the cooling water nozzles (208) and the revolved body (205) rotate synchronously around the rolling center line (C-C), the cooling water nozzles (208) spray cooling water to the rolling deformation zone (K), and / or the cooling water nozzles (208) spray the cooling water to the rollers (103). After the technical scheme is adopted, the cooling effect of the deformation zone and the rollers of the planetary rolling mill can be remarkably improved, and the production efficiency of the planetary rolling mill can be improved.

Owner:JIANGSU XINGRONG HI TECH

Production process of a high-weight non-woven Tibetan blanket

ActiveCN107400966BImprove the quality effectPromote environmental protectionWork-feeding meansSevering textilesCrude fibreProcess engineering

The invention discloses a production process of a high-gram-weight non-woven Tibetan carpet. The production process comprises the following steps that patterns required by the Tibetan carpet are determined, then design and colors and patterns of the Tibetan carpet are designed by using a computer, the warp density and weft density of the Tibetan carpet are determined, the warp density is 300-600, the weft density is 1000-2000, chinlon, polypropylene fiber, dacron, wool and viscose are selected as raw material yarns, corresponding colors are selected according to the color of the required Tibetan carpet, a yarn count parameter is 1000-4000 d, 5000-8000 yarns are spooled, formed and installed on a creel, the ends of various colors of yarns on the creel are led out and are connected to a loom, and an upper-half-portion carpet surface of the Tibetan carpet is woven by using a digital management control loom. The production process of the high-gram-weight non-woven Tibetan carpet can ensure the properties of high quality, high environmental friendliness and high safety of the Tibetan carpet and adopts a high-elasticity, crude-fiber, pre-needled and non-woven fabric as a bottom liner of the carpet, the hardness of the carpet is effectively controlled, the material using efficiency is improved, and the material cost is reduced.

Owner:俊富生态修复科技(青海)有限公司

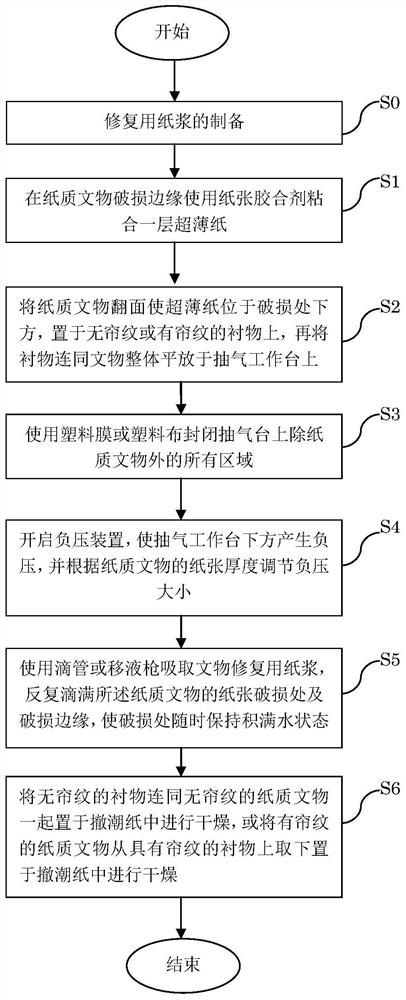

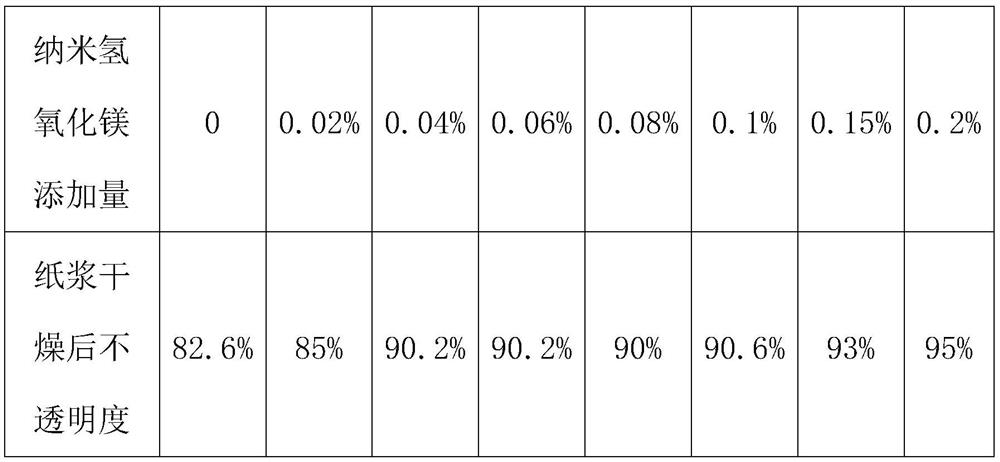

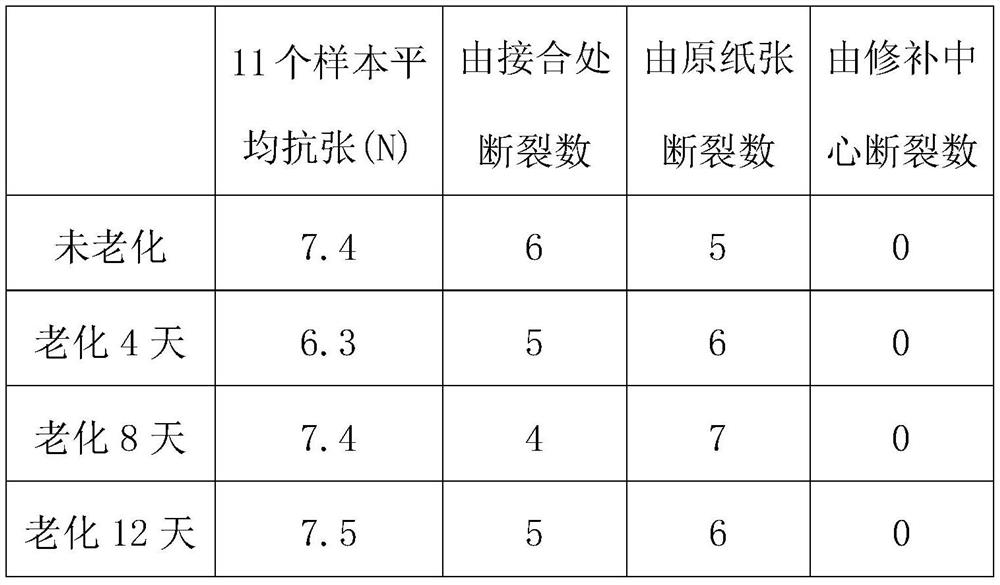

Pulp composite repair method and repair pulp

ActiveCN110424185BGood suspensionGood dispersionOld paper after-treatmentInorganic compound additionSuspending AgentsMechanical engineering

The invention provides a pulp repair method for fragile water-resistant paper cultural relics and the repairing pulp, belonging to the field of cultural relic restoration and protection. The restoration pulp provided by the invention comprises the following components: inorganic matter powder, not more than 0.9%; suspending agent, not more than 0.6%; original pulp, the rest. The pulp repair method for fragile water-resistant paper cultural relics provided by the present invention comprises the steps of: S1, adhering a layer of thin paper on the damaged edge of the paper cultural relics; S2, turning the thin paper over so that the thin paper is placed on the lining under the damaged part, Place the whole on the suction table; S3, close all areas on the suction table except paper cultural relics; S4, turn on the negative pressure device to generate negative pressure under the suction table; S5, absorb the pulp for cultural relics restoration, and repeatedly drip the paper Damaged parts and damaged edges of quality cultural relics; S6, dry. Because the invention adopts a new restoration technique and new paper pulp, the risk of handwriting and pigments being smudged by water can be reduced, the pulp fibers in the repaired place are more evenly distributed, and the restored cultural relics have higher mechanical strength.

Owner:FUDAN UNIV

Elastomer gel water-in-water colorful system paint

ActiveCN102220060BSoft and hard adjustableControl softnessMulticolor effect coatingsElastomerCellulose

The invention discloses an elastomer gel water-in-water colorful system paint which is formed by mixing a dispersed phase with a continuous phase, and the elastomer gel water-in-water colorful system painting is characterized in that: the dispersed phase consists of protective glue solution and elastic paint, the protective glue solution contains cation protective glue and is quaternary ammonium salt polysaccharide polymer with low grafting degree; the continuous phase contains gels which is anion polysaccharide cellulose ether; the weight ratio of the dispersed phase and the continuous phase is 1:1-2. When the cation protective glue in the dispersed phase meets the gels in the continuous phase, the cations and the anions can be bonded mutually; and simultaneously, the long-chain quaternary ammonium salt can form complex with acidic polysaccharide, chemical crosslinking occurs among active groups, so that the hardness of the paint can be adjusted, the stability is good, and the proportion of color grains can reach 40-50 percent.

Owner:安徽嘉年华漆业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com